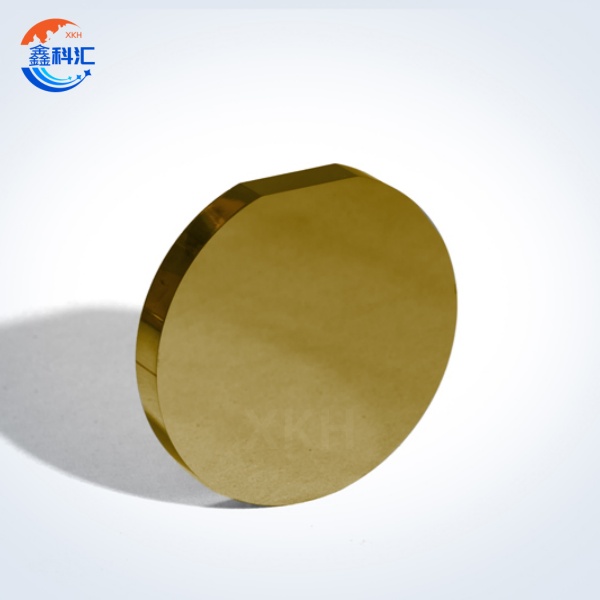

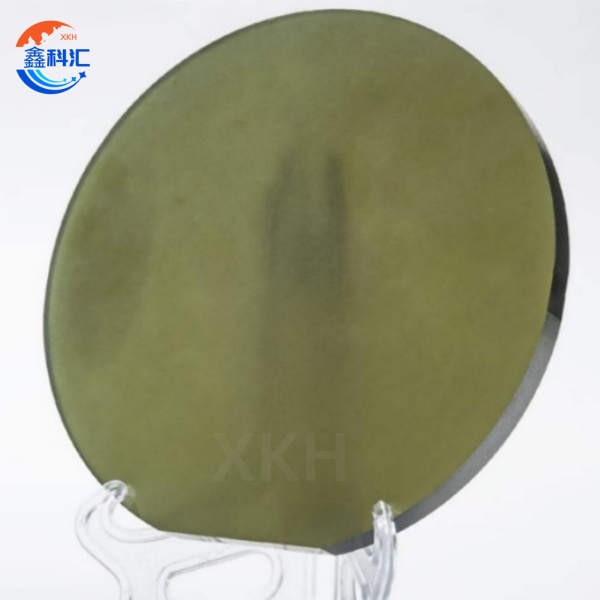

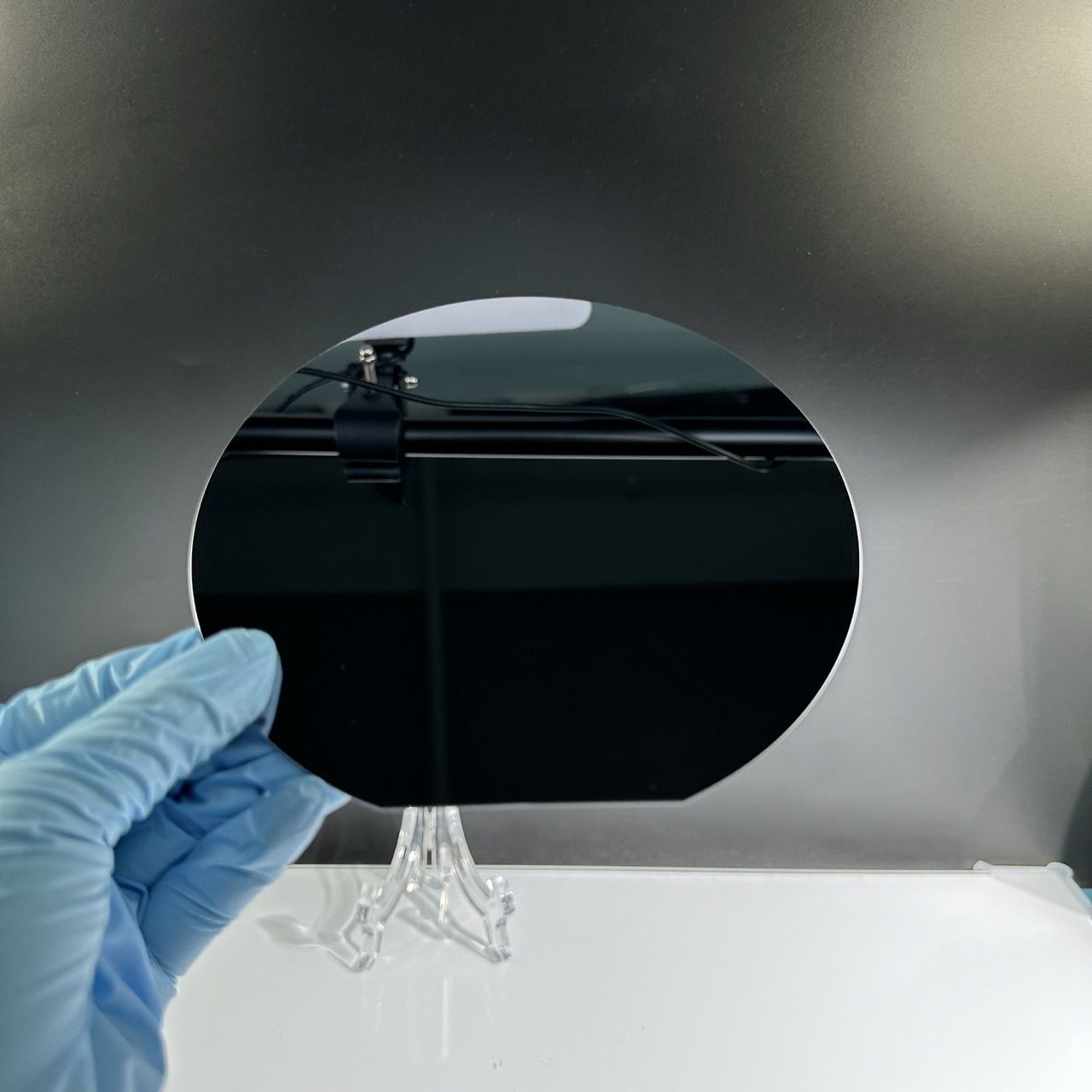

12 Inch SiC substrate Diameter 300mm Botenya 750μm 4H-N Mofuta o ka etsoa

Litekanyetso tsa tekheniki

| Tlhaloso ea 12 inch Silicon Carbide (SiC) Substrate | |||||

| Kereiti | Tlhahiso ea ZeroMPD Kereiti(Z Kereiti) | Tlhahiso e Tloaelehileng Kereiti(P Grade) | Sehlopha sa Dummy (D Kereiti) | ||

| Diameter | 3 0 0 limilimithara ~ 1305mm | ||||

| Botenya | 4H-N | 750μm±15 μm | 750μm±25 μm | ||

| 4H-SI | 750μm±15 μm | 750μm±25 μm | |||

| Wafer Orientation | Off axis : 4.0° ho leba <1120 >±0.5° bakeng sa 4H-N, On axis : <0001>±0.5° bakeng sa 4H-SI | ||||

| Boima ba Micropipe | 4H-N | ≤0.4cm-2 | ≤4cm-2 | ≤25cm-2 | |

| 4H-SI | ≤5cm-2 | ≤10cm-2 | ≤25cm-2 | ||

| Ho hanyetsa | 4H-N | 0.015~0.024 Ω·cm | 0.015~0.028 Ω·cm | ||

| 4H-SI | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |||

| Maemo a Motheo a Flat | {10-10} ±5.0° | ||||

| Bolelele ba Phatlalatso ba Pele | 4H-N | N/A | |||

| 4H-SI | Notch | ||||

| Kenyelletso ea Edge | 3 limilimithara | ||||

| LTV/TTV/Bow /Warp | ≤5μm/≤15μm/≤35 μm/≤55 μm | ≤5μm/≤15μm/≤35 □ μm/≤55 □ μm | |||

| Boqhobane | Polish Ra≤1 nm | ||||

| CMP Ra≤0.2 nm | Ra≤0.5 nm | ||||

| Edge Cracks By High Intensity Leseli Hex Plates By High Intensity Light Libaka tsa Polytype Ka Leseli le Matla a Phahameng Likakaretso tsa Carbon tse bonoang Silicon Surface Scratches By High Intensity Light | Ha ho letho Kakaretso ≤0.05% Ha ho letho Kakaretso ≤0.05% Ha ho letho | Bolelele bo akaretsang ≤ 20 mm, bolelele bo le bong≤2 mm Kakaretso ≤0.1% Kakaretso≤3% Kakaretso ≤3% Bolelele ba kakaretso≤1× bophara ba wafer | |||

| Edge Chips Ka Leseli le Matla a Phahameng | Ha ho e lumelletsoeng ≥0.2mm bophara le botebo | 7 e lumelletsoe, ≤1 mm ka 'ngoe | |||

| (TSD) Ho kheloha ha screw | ≤500 cm-2 | N/A | |||

| (BPD) Ho kheloha ha sefofane sa motheo | ≤1000 cm-2 | N/A | |||

| Tšilafalo ea Sefahleho sa Silicon Ka Leseli le Matla a Phahameng | Ha ho letho | ||||

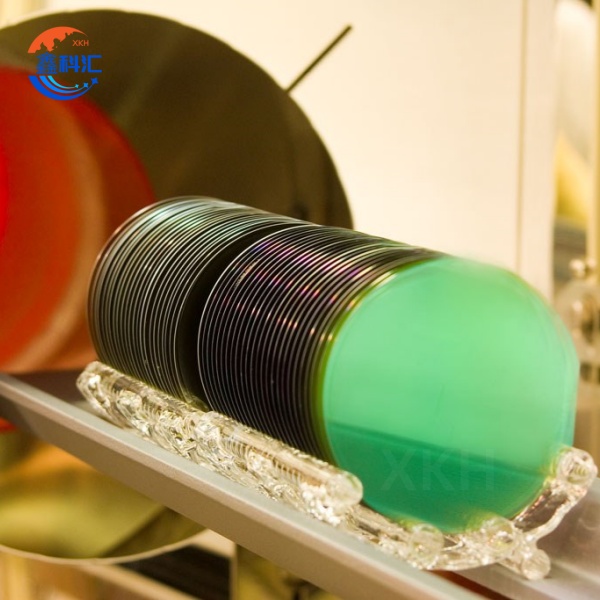

| Sephutheloana | Multi-wafer Cassette Kapa Single Wafer Container | ||||

| Lintlha: | |||||

| 1 Meeli e nang le mefokolo e sebetsa sebakeng sohle sa wafer ntle le sebaka se ka thoko. 2Mengoako e lokela ho hlahlojoa ho Si face feela. 3 Lintlha tsa dislocation li tsoa ho li-wafers tse kentsoeng tsa KOH feela. | |||||

Likarolo tsa Bohlokoa

1.Bokhoni ba Tlhahiso le Melemo ea Litšenyehelo: Tlhahiso e boima ea 12-inch SiC substrate (12-inch silicon carbide substrate) e tšoaea nako e ncha ea tlhahiso ea semiconductor. Palo ea li-chips tse fumanoang ho tloha sephakeng se le seng e fihla makhetlo a 2,25 ho feta li-substrates tse 8-inch, e leng se etsang hore ka ho toba ho be le katleho ea tlhahiso. Maikutlo a bareki a bonts'a hore ho amohela li-substrates tse 12-inch ho fokolitse litšenyehelo tsa tlhahiso ea module ea matla ka 28%, ho theha monyetla oa tlholisano 'marakeng oo ho tsekoang ka matla.

2.Tlhaloso e Tsoileng Matsoho ea 'Mele: Karolo ea 12-inch SiC substrate e rua melemo eohle ea thepa ea silicon carbide - conductivity ea eona ea mocheso ke makhetlo a 3 a silicon, ha matla a eona a ho senyeha a fihla makhetlo a 10 a silicon. Litšobotsi tsena li nolofalletsa lisebelisoa tse thehiloeng ho li-substrates tse 12-inch hore li sebetse ka mokhoa o tsitsitseng libakeng tse phahameng tsa mocheso tse fetang 200 ° C, e leng se etsang hore li tšoanelehe ka ho khetheha bakeng sa likopo tse hlokahalang tse kang likoloi tsa motlakase.

3.Surface Treatment Technology: Re thehile mokhoa o mocha oa ho hloekisa lik'hemik'hale (CMP) ka ho khetheha bakeng sa li-substrates tsa SiC tsa 12-inch, ho finyella boemo bo holimo ba atomic (Ra <0.15nm). Katleho ena e rarolla phephetso ea lefats'e ka bophara ea kalafo e kholo ea silicon carbide wafer surface, e tlosa litšitiso bakeng sa kholo ea boleng bo holimo ea epitaxial.

Ts'ebetso ea Tsamaiso ea 4.Thermal: Lits'ebetsong tse sebetsang, li-substrates tsa 12-inch SiC li bonts'a bokhoni bo tsotehang ba ho senya mocheso. Lintlha tsa liteko li bontša hore tlas'a matla a tšoanang a matla, lisebelisoa tse sebelisang li-substrates tse 12-inch li sebetsa mocheso oa 40-50 ° C ka tlaase ho lisebelisoa tse thehiloeng ka silicon, e leng ho lelefatsang bophelo ba tšebeletso ea thepa haholo.

Lisebelisoa tse ka Sehloohong

1.New Energy Vehicle Ecosystem: The 12-inch SiC substrate (12-inch silicon carbide substrate) e fetola meralo ea motlakase ea koloi ea motlakase. Ho tloha ho li-charger tsa onboard (OBC) ho ea ho li-inverter tse kholo le lits'ebetso tsa taolo ea betri, lintlafatso tse tlisitsoeng ke li-substrates tsa 12-inch li eketsa lebelo la likoloi ka 5-8%. Litlaleho tse tsoang ho moetsi oa likoloi ea ka sehloohong li bontša hore ho sebelisa li-substrates tsa rona tsa 12-inch ho fokotsa tahlehelo ea matla tsamaisong ea bona ea ho tjhaja ka potlako ka 62%.

2.Lekala la Matla a Tsosolositsoeng: Litsing tsa motlakase oa photovoltaic, li-inverters tse thehiloeng ho li-substrates tsa 12-inch SiC ha li fane feela ka lintlha tse nyenyane tsa mefuta empa hape li finyella katleho ea phetoho e fetang 99%. Haholo-holo maemong a fetisoang, ts'ebetso ena e phahameng e fetolela chelete ea selemo le selemo ea li-yuan tse makholo a likete tahlehelong ea motlakase bakeng sa basebetsi.

3.Industrial Automation: Li-converter tsa maqhubu tse sebelisang li-substrates tsa 12-inch li bontša ts'ebetso e babatsehang ho liroboto tsa indasteri, lisebelisoa tsa mochine oa CNC, le lisebelisoa tse ling. Litšobotsi tsa bona tsa ho fetoha ha maqhubu a phahameng li ntlafatsa lebelo la karabelo ea makoloi ka 30% ha li ntse li fokotsa tšitiso ea motlakase ho karolo ea boraro ea tharollo e tloaelehileng.

4.Consumer Electronics Innovation: Moloko o latelang oa theknoloji ea ho tjhaja li-smartphone ka potlako e se e qalile ho amohela li-substrate tsa 12-inch SiC. Ho hakanngoa hore lihlahisoa tse tjhajang ka potlako tse kaholimo ho 65W li tla fetohela ka botlalo ho litharollo tsa silicon carbide, ka li-substrates tse 12-inch tse hlahang e le khetho e nepahetseng ea ts'ebetso ea litšenyehelo.

XKH Litšebeletso tse Itokiselitsoeng bakeng sa 12-inch SiC Substrate

Ho fihlela litlhoko tse ikhethileng bakeng sa li-substrates tsa 12-inch SiC (12-inch silicon carbide substrates), XKH e fana ka tšehetso e felletseng ea litšebeletso:

1.Thickness Customization:

Re fana ka li-substrates tsa 12-inch ka litlhaloso tse fapaneng tsa botenya ho kenyelletsa le 725μm ho fihlela litlhoko tse fapaneng tsa kopo.

2. Ho tsepamisa maikutlo ho sebelisa lithethefatsi:

Tlhahiso ea rona e ts'ehetsa mefuta e mengata ea li-conductivity ho kenyelletsa le li-n-type le p-type substrates, tse nang le taolo e nepahetseng ea ho hanyetsa ka har'a mefuta ea 0.01-0.02Ω · cm.

3. Litšebeletso tsa Teko:

Ka lisebelisoa tse felletseng tsa tlhahlobo ea wafer-level, re fana ka litlaleho tse felletseng tsa tlhahlobo.

XKH e utloisisa hore moreki e mong le e mong o na le litlhoko tse ikhethang bakeng sa li-substrates tsa SiC tsa 12-inch. Ka hona re fana ka mekhoa ea tšebelisano-'moho ea khoebo e bonolo ho fana ka litharollo tsa tlholisano ka ho fetisisa, ebang ke tsa:

· R&D disampole

· Theko ea tlhahiso ea molumo

Litšebeletso tsa rona tse ikhethileng li netefatsa hore re ka fihlela litlhoko tsa hau tsa tekheniki le tlhahiso bakeng sa li-substrates tsa 12-inch SiC.