12 inch SiC Substrate N Mofuta Oa Boholo bo Holimo Likopo tsa RF tse sebetsang

Litekanyetso tsa tekheniki

| Tlhaloso ea 12 inch Silicon Carbide (SiC) Substrate | |||||

| Kereiti | Tlhahiso ea ZeroMPD Kereiti(Z Kereiti) | Tlhahiso e Tloaelehileng Kereiti(P Grade) | Sehlopha sa Dummy (D Kereiti) | ||

| Diameter | 3 0 0 limilimithara ~ 1305mm | ||||

| Botenya | 4H-N | 750μm±15 μm | 750μm±25 μm | ||

| 4H-SI | 750μm±15 μm | 750μm±25 μm | |||

| Wafer Orientation | Off axis : 4.0° ho leba <1120 >±0.5° bakeng sa 4H-N, On axis : <0001>±0.5° bakeng sa 4H-SI | ||||

| Boima ba Micropipe | 4H-N | ≤0.4cm-2 | ≤4cm-2 | ≤25cm-2 | |

| 4H-SI | ≤5cm-2 | ≤10cm-2 | ≤25cm-2 | ||

| Ho hanyetsa | 4H-N | 0.015~0.024 Ω·cm | 0.015~0.028 Ω·cm | ||

| 4H-SI | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |||

| Maemo a Motheo a Flat | {10-10} ±5.0° | ||||

| Bolelele ba Phatlalatso ba Pele | 4H-N | N/A | |||

| 4H-SI | Notch | ||||

| Kenyelletso ea Edge | 3 limilimithara | ||||

| LTV/TTV/Bow /Warp | ≤5μm/≤15μm/≤35 μm/≤55 μm | ≤5μm/≤15μm/≤35 □ μm/≤55 □ μm | |||

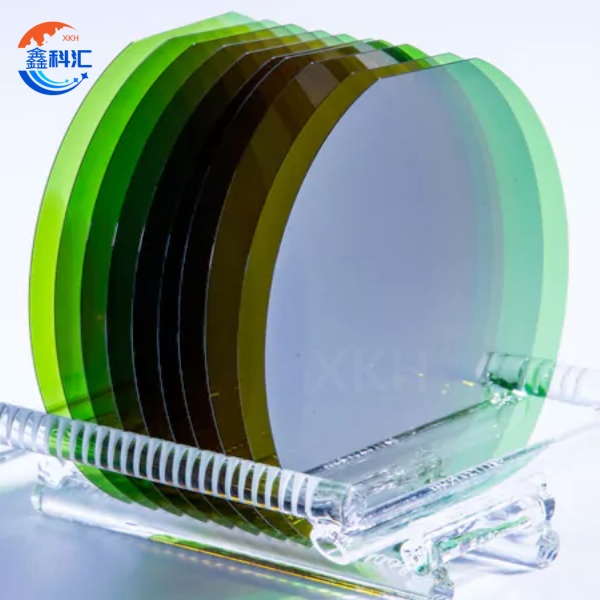

| Boqhobane | Polish Ra≤1 nm | ||||

| CMP Ra≤0.2 nm | Ra≤0.5 nm | ||||

| Edge Cracks By High Intensity Leseli Hex Plates By High Intensity Light Libaka tsa Polytype Ka Leseli le Matla a Phahameng Likakaretso tsa Carbon tse bonoang Silicon Surface Scratches By High Intensity Light | Ha ho letho Kakaretso ≤0.05% Ha ho letho Kakaretso ≤0.05% Ha ho letho | Bolelele bo akaretsang ≤ 20 mm, bolelele bo le bong≤2 mm Kakaretso ≤0.1% Kakaretso≤3% Kakaretso ≤3% Bolelele ba kakaretso≤1× bophara ba wafer | |||

| Edge Chips Ka Leseli le Matla a Phahameng | Ha ho e lumelletsoeng ≥0.2mm bophara le botebo | 7 e lumelletsoe, ≤1 mm ka 'ngoe | |||

| (TSD) Ho kheloha ha screw | ≤500 cm-2 | N/A | |||

| (BPD) Ho kheloha ha sefofane sa motheo | ≤1000 cm-2 | N/A | |||

| Tšilafalo ea Sefahleho sa Silicon Ka Leseli le Matla a Phahameng | Ha ho letho | ||||

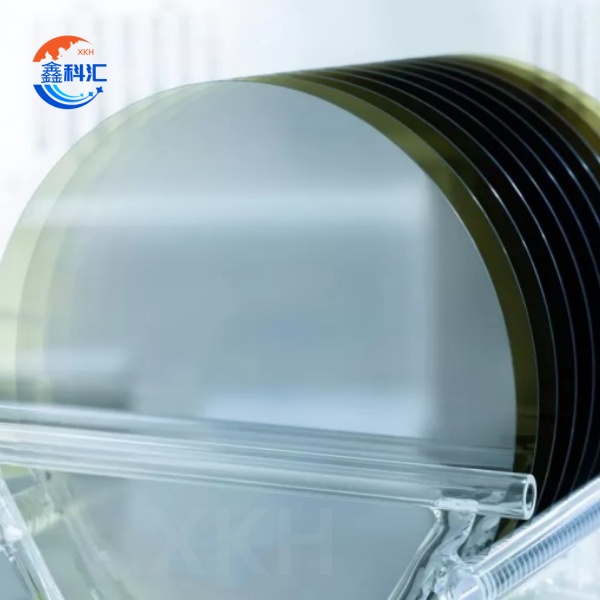

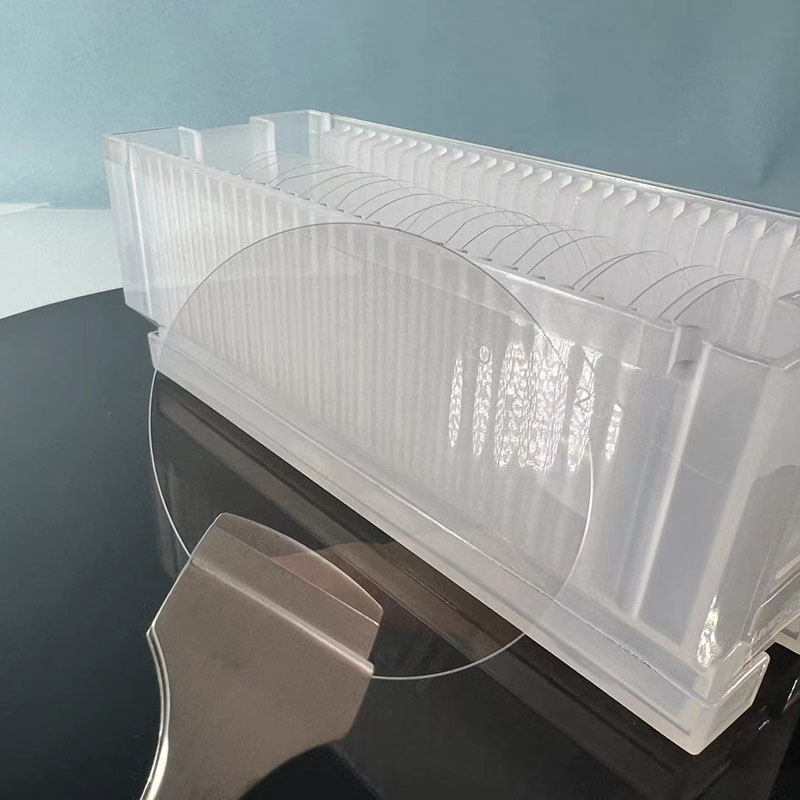

| Sephutheloana | Multi-wafer Cassette Kapa Single Wafer Container | ||||

| Lintlha: | |||||

| 1 Meeli e nang le mefokolo e sebetsa sebakeng sohle sa wafer ntle le sebaka se ka thoko. 2Mengoako e lokela ho hlahlojoa ho Si face feela. 3 Lintlha tsa dislocation li tsoa ho li-wafers tse kentsoeng tsa KOH feela. | |||||

Likarolo tsa Bohlokoa

1. Molemo o moholo oa boholo ba boholo: The substrate ea SiC ea 12-inch (12-inch silicon carbide substrate) e fana ka sebaka se seholoanyane se nang le sekoahelo se le seng, se nolofalletsang hore li-chips tse ngata li hlahisoe ka sephaphatha, kahoo ho fokotsa litšenyehelo tsa tlhahiso le ho eketsa chai.

2. Lisebelisoa tse Phahameng ka ho Fetisisa: Ho hanyetsa mocheso o phahameng oa Silicon carbide le matla a masimo a ho senyeha ho etsa hore substrate ea 12-inch e be e loketseng bakeng sa lisebelisoa tse phahameng tsa motlakase le tse phahameng, tse kang li-inverters tsa EV le mekhoa ea ho tjhaja ka potlako.

3. Tšebelisano ea Ts'ebetso: Ho sa tsotellehe boima bo phahameng le mathata a ho sebetsana le SiC, substrate ea SiC ea 12-inch e finyella mefokolo e tlaase ea holim'a metsi ka mekhoa e metle ea ho itšeha le ho polishing, ho ntlafatsa lihlahisoa tsa lisebelisoa.

4. Tsamaiso e Phahameng ea Thermal: Ka conductivity e ntle ea mocheso ho feta lisebelisoa tse thehiloeng ka silicon, substrate ea 12-inch e sebetsana ka katleho le ho senya mocheso ka lisebelisoa tse matla a matla, ho eketsa nako ea bophelo ba thepa.

Lisebelisoa tse ka Sehloohong

1. Likoloi tsa Motlakase: The substrate ea 12-inch SiC (12-inch silicon carbide substrate) ke karolo ea mantlha ea mekhoa ea motlakase ea motlakase ea moloko o latelang, e leng ho nolofalletsang li-inverters tse phahameng tse ntlafatsang mefuta le ho fokotsa nako ea ho tjhaja.

2. 5G Base Stations: Li-substrates tsa SiC tse kholo li tšehetsa lisebelisoa tse phahameng tsa RF, tse finyellang litlhoko tsa liteishene tsa motheo tsa 5G bakeng sa matla a phahameng le tahlehelo e tlaase.

3.Industrial Power Supplies: Ka li-inverters tsa letsatsi le li-grids tse bohlale, substrate ea 12-inch e ka mamella maqhubu a phahameng ha e ntse e fokotsa tahlehelo ea matla.

4.Consumer Electronics: Licheja tse potlakileng tsa nako e tlang le lisebelisoa tsa motlakase tsa setsi sa data li ka sebelisa li-substrates tsa SiC tsa 12-inch ho fihlela boholo bo kopanetsoeng le katleho e phahameng.

Litšebeletso tsa XKH

Re ipapisitse le lits'ebeletso tse ikhethileng tsa 12-inch SiC substrates (12-inch silicon carbide substrates), ho kenyelletsa:

1. Dicing & polishing: Ts'ebetso ea substrate e senyehang e tlaase, e phahameng-flatness e lumellanang le litlhoko tsa bareki, ho netefatsa ts'ebetso e tsitsitseng ea lisebelisoa.

2. Tšehetso ea Khōlo ea Epitaxial: Litšebeletso tsa boleng bo phahameng ba epitaxial wafer ho potlakisa tlhahiso ea chip.

3. Small-Batch Prototyping: E ts'ehetsa netefatso ea R&D bakeng sa litsi tsa liphuputso le likhoebo, e khutsufatsa nako ea ntlafatso.

4. Technical Consulting: Litharollo tsa ho qetela ho tloha ho khetho ea thepa ho ea ho ts'ebetsong, ho thusa bareki ho hlōla mathata a ho sebetsana le SiC.

Ebang ke bakeng sa tlhahiso ea bongata kapa mokhoa o ikhethileng, lits'ebeletso tsa rona tsa 12-inch SiC li tsamaisana le litlhoko tsa projeke ea hau, li matlafatsa tsoelo-pele ea mahlale.