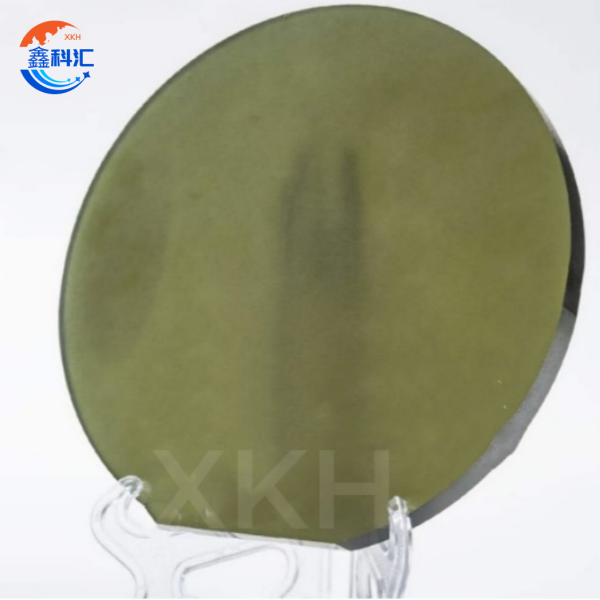

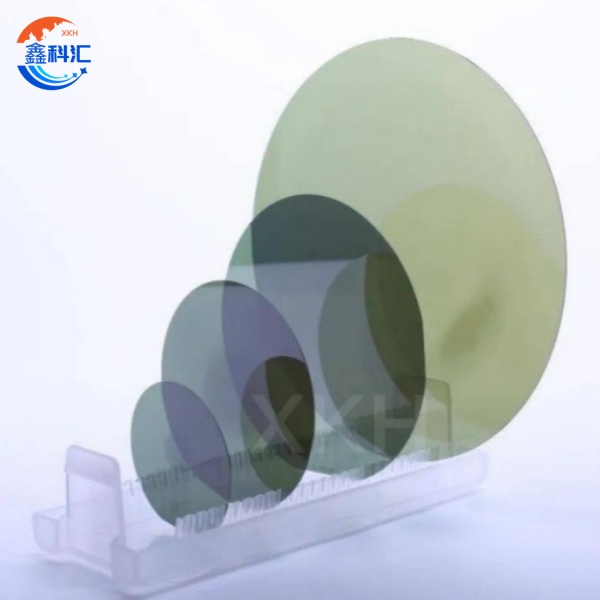

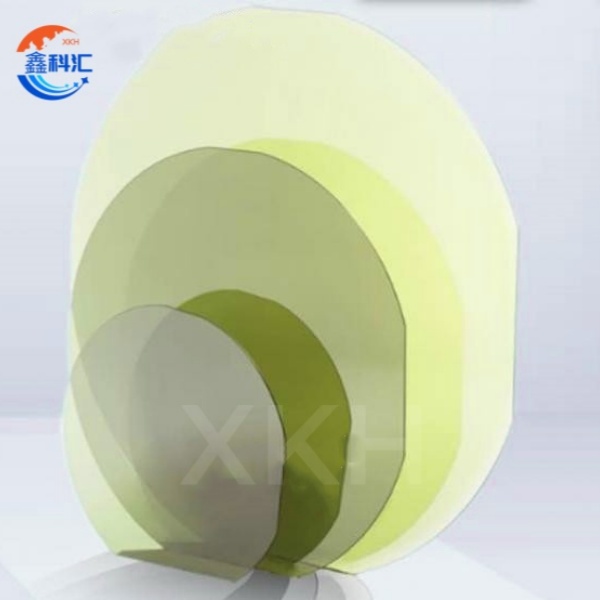

12 inch SIC substrate silicon carbide prime grade diameter 300mm boholo bo boholo 4H-N E loketse bakeng sa mocheso o phahameng oa lisebelisoa tsa mocheso

Litšobotsi tsa sehlahisoa

1. Mocheso o phahameng oa mocheso: mocheso oa mocheso oa silicon carbide o feta makhetlo a 3 ho feta a silicon, e leng se loketseng ho senya mocheso oa sesebelisoa sa matla a phahameng.

2. Matla a matla a tšimo ea ho senya: Matla a tšimo ea ho senya ke makhetlo a 10 a silicon, a loketseng likopo tse phahameng tsa khatello.

3.Wide bandgap: Letlapa ke 3.26eV (4H-SiC), e loketseng mocheso o phahameng le lisebelisoa tse phahameng tsa maqhubu.

4. Boima bo phahameng: boima ba Mohs ke 9.2, ea bobeli feela ho daemane, ho hanyetsa ho apara ka mokhoa o babatsehang le matla a mochine.

5. Ho tsitsa ha lik'hemik'hale: ho hanyetsa ho bola ho matla, ts'ebetso e tsitsitseng mocheso o phahameng le tikoloho e thata.

6. Boholo bo boholo: substrate ea 12 inch (300mm), ntlafatsa katleho ea tlhahiso, fokotsa litšenyehelo tsa yuniti.

7.Low defect density: boleng bo phahameng ba theknoloji e le 'ngoe ea khōlo ea kristale ho etsa bonnete ba hore ho na le sekoli se tlaase le ho lumellana ho phahameng.

Tataiso ea kopo ea mantlha ea sehlahisoa

1. Lisebelisoa tsa elektroniki:

Mosfets: E sebelisoa likoloing tsa motlakase, likoloi tsa liindasteri le li-converter tsa motlakase.

Li-Diode: tse kang Schottky diodes (SBD), tse sebelisetsoang ho lokisa hantle le ho fetola lisebelisoa tsa motlakase.

2. Lisebelisoa tsa Rf:

Rf amplifier ea matla: e sebelisoang liteisheneng tsa 5G tsa puisano le likhokahano tsa satellite.

Lisebelisoa tsa Microwave: Li loketse lisebelisoa tsa puisano tsa radar le tse se nang mohala.

3. Likoloi tse ncha tsa matla:

Sistimi ea ho khanna motlakase: balaoli ba makoloi le li-inverter bakeng sa likoloi tsa motlakase.

Phatlalatso ea ho tjhaja: Mojule oa matla bakeng sa lisebelisoa tsa ho tjhaja kapele.

4. Lisebelisoa tsa indasteri:

High voltage inverter: bakeng sa taolo ea likoloi tsa indasteri le taolo ea matla.

Smart grid: Bakeng sa phetisetso ea HVDC le li-transformer tsa motlakase tsa motlakase.

5. Sepakapaka:

Mocheso o phahameng oa elektronike: o loketse maemo a mocheso a phahameng a lisebelisoa tsa sefofane.

6. Sebaka sa lipatlisiso:

Patlisiso e pharaletseng ea semiconductor ea bandgap: bakeng sa nts'etsopele ea lisebelisoa le lisebelisoa tse ncha tsa semiconductor.

The 12-inch silicon carbide substrate ke mofuta o phahameng oa ts'ebetso ea semiconductor ea thepa e nang le thepa e ntle joalo ka conductivity e phahameng ea mocheso, matla a maholo a ho senyeha ha tšimo le lekhalo le pharaletseng la lihlopha. E sebelisoa haholo ho lisebelisoa tsa elektronike tse matla, lisebelisoa tsa maqhubu a seea-le-moea, likoloi tse ncha tsa matla, taolo ea indasteri le sefofane, 'me ke thepa ea bohlokoa ho khothalletsa nts'etsopele ea moloko o latelang oa lisebelisoa tsa elektronike tse sebetsang hantle le tse phahameng.

Leha li-substrates tsa silicon carbide hajoale li na le lits'ebetso tse fokolang tse tobileng ho lisebelisoa tsa elektroniki tsa bareki joalo ka likhalase tsa AR, bokhoni ba tsona ba taolo e nepahetseng ea matla le lisebelisoa tsa elektroniki tse nyane li ka ts'ehetsa litharollo tsa phepelo ea motlakase tse bobebe, tse sebetsang hantle bakeng sa lisebelisoa tsa AR/VR tsa nako e tlang. Hajoale, nts'etsopele ea mantlha ea silicon carbide substrate e tsepamisitsoe libakeng tsa indasteri joalo ka likoloi tse ncha tsa matla, meaho ea puisano le boiketsetso ba indasteri, mme e khothaletsa indasteri ea semiconductor ho nts'etsapele ka tsela e sebetsang hantle le e tšepahalang.

XKH e ikemiselitse ho fana ka li-substrates tsa 12 "SIC tsa boleng bo holimo tse nang le ts'ehetso le lits'ebeletso tse felletseng, ho kenyelletsa:

1. Tlhahiso e ikhethileng: Ho ea ka litlhoko tsa bareki ho fana ka resistivity e fapaneng, mokhoa oa kristale le substrate ea phekolo ea holim'a metsi.

2. Ts'ebetso ea ts'ebetso: Fana ka bareki ka tšehetso ea tekheniki ea kholo ea epitaxial, tlhahiso ea lisebelisoa le mekhoa e meng ea ho ntlafatsa ts'ebetso ea sehlahisoa.

3. Teko le setifikeiti: Fana ka tlhahlobo e tiileng ea sekoli le setifikeiti sa boleng ho netefatsa hore substrate e kopana le maemo a indasteri.

Tšebelisano ea 4.R&d: Ka kopanelo hlahisa lisebelisoa tse ncha tsa silicon carbide le bareki ho khothaletsa boqapi ba theknoloji.

Chate ea data

| Tlhaloso ea Substrate ea 1 2 inch Silicon Carbide (SiC). | |||||

| Kereiti | Tlhahiso ea ZeroMPD Kereiti(Z Kereiti) | Tlhahiso e Tloaelehileng Kereiti(P Grade) | Sehlopha sa Dummy (D Kereiti) | ||

| Diameter | 3 0 0 limilimithara ~ 305mm | ||||

| Botenya | 4H-N | 750μm±15 μm | 750μm±25 μm | ||

| 4H-SI | 750μm±15 μm | 750μm±25 μm | |||

| Wafer Orientation | Off axis : 4.0° ho leba <1120 >±0.5° bakeng sa 4H-N, On axis : <0001>±0.5° bakeng sa 4H-SI | ||||

| Boima ba Micropipe | 4H-N | ≤0.4cm-2 | ≤4cm-2 | ≤25cm-2 | |

| 4H-SI | ≤5cm-2 | ≤10cm-2 | ≤25cm-2 | ||

| Ho hanyetsa | 4H-N | 0.015~0.024 Ω·cm | 0.015~0.028 Ω·cm | ||

| 4H-SI | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |||

| Maemo a Motheo a Flat | {10-10} ±5.0° | ||||

| Bolelele ba Phatlalatso ba Pele | 4H-N | N/A | |||

| 4H-SI | Notch | ||||

| Kenyelletso ea Edge | 3 limilimithara | ||||

| LTV/TTV/Bow /Warp | ≤5μm/≤15μm/≤35 μm/≤55 μm | ≤5μm/≤15μm/≤35 □ μm/≤55 □ μm | |||

| Boqhobane | Polish Ra≤1 nm | ||||

| CMP Ra≤0.2 nm | Ra≤0.5 nm | ||||

| Edge Cracks By High Intensity Leseli Hex Plates By High Intensity Light Libaka tsa Polytype Ka Leseli le Matla a Phahameng Likakaretso tsa Carbon tse bonoang Silicon Surface Scratches Ka Leseli le Matla a Phahameng | Ha ho letho Kakaretso ≤0.05% Ha ho letho Kakaretso ≤0.05% Ha ho letho | Bolelele bo akaretsang ≤ 20 mm, bolelele bo le bong≤2 mm Kakaretso ≤0.1% Kakaretso≤3% Kakaretso ≤3% Bolelele ba kakaretso≤1× bophara ba wafer | |||

| Edge Chips Ka Leseli le Matla a Phahameng | Ha ho e lumelletsoeng ≥0.2mm bophara le botebo | 7 e lumelletsoe, ≤1 mm ka 'ngoe | |||

| (TSD) Ho kheloha ha screw | ≤500 cm-2 | N/A | |||

| (BPD) Ho kheloha ha sefofane sa motheo | ≤1000 cm-2 | N/A | |||

| Tšilafalo ea Sefahleho sa Silicon Ka Leseli le Matla a Phahameng | Ha ho letho | ||||

| Sephutheloana | Multi-wafer Cassette Kapa Single Wafer Container | ||||

| Lintlha: | |||||

| 1 Meeli e nang le mefokolo e sebetsa sebakeng sohle sa wafer ntle le sebaka se ka thoko. 2Mengoako e lokela ho hlahlojoa ho Si face feela. 3 Lintlha tsa dislocation li tsoa ho li-wafers tse kentsoeng tsa KOH feela. | |||||

XKH e tla tsoelapele ho tsetela lipatlisiso le nts'etsopele ho ntšetsa pele katleho ea 12-inch silicon carbide substrates ka boholo bo boholo, bofokoli bo tlaase le ho tsitsa ho phahameng, ha XKH e hlahloba lits'ebetso tsa eona libakeng tse hlahang tse kang lisebelisoa tsa elektronike tsa bareki (tse kang li-module tsa matla bakeng sa lisebelisoa tsa AR / VR) le quantum computing. Ka ho fokotsa litšenyehelo le ho eketsa bokhoni, XKH e tla tlisa katleho ho indasteri ea semiconductor.

Setšoantšo se qaqileng