12inch Fully Automatic Precision Dicing Saw Equipment Wafer Dedicated Cutting System bakeng sa Si/SiC & HBM (Al)

Litekanyetso tsa tekheniki

| Paramethara | Tlhaloso |

| Boholo ba Mosebetsi | Φ8", Φ12" |

| Spindle | Dual-axis 1.2/1.8/2.4/3.0, Max 60000 rpm |

| Boholo ba Blade | 2"~3" |

| Y1 / Y2 Axis

| Keketseho ea mohato o le mong: 0.0001 mm |

| Ho nepahala ha boemo: <0.002 mm | |

| Sebaka sa ho itšeha: 310 mm | |

| X Axis | Lebelo la ho fepa: 0.1–600 mm/s |

| Z1 / Z2 Axis

| Keketseho ea mohato o le mong: 0.0001 mm |

| Ho nepahala ha boemo: ≤ 0.001 mm | |

| θ Axis | Ho nepahala ha boemo: ±15" |

| Ho Hloekisa Seteishene

| Lebelo la ho potoloha: 100-3000 rpm |

| Mokhoa oa ho hloekisa: Hlatsoa ka bohona le ho omisa | |

| Voltage e sebetsang | 3-mohato 380V 50Hz |

| Litekanyo (W×D×H) | 1550×1255×1880 limilimithara |

| Boima ba 'mele | 2100 lik'hilograma |

Molao-motheo oa ho Sebetsa

Thepa e sebetsa ka mokhoa o nepahetseng ka ho fetisisa ka theknoloji e latelang:

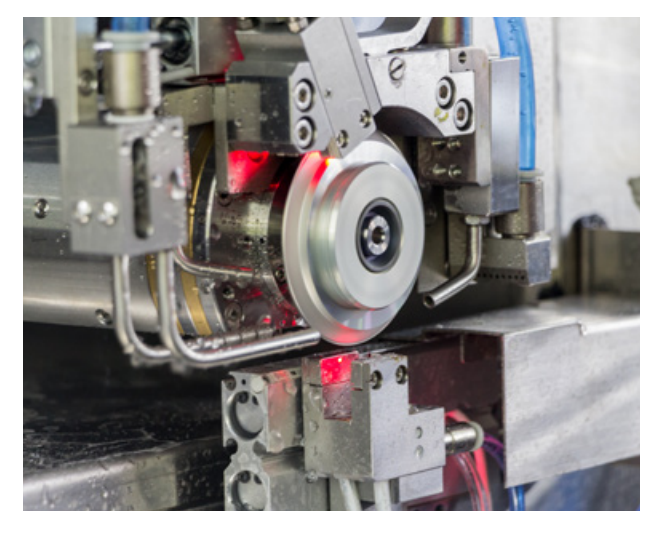

1.High-Rigidity Spindle System: Lebelo la ho potoloha ho fihlela ho 60,000 RPM, e nang le likhahla tsa daemane kapa lihlooho tsa ho itšeha laser ho ikamahanya le thepa e fapaneng ea thepa.

2.Multi-Axis Motion Control: X / Y / Z-axis positioning e nepahetseng ea ± 1μm, e kopantsoe le litekanyo tse phahameng tsa grating ho netefatsa litsela tsa ho itšeha tse se nang ho kheloha.

3.Intelligent Visual Alignment: CCD e nang le qeto e phahameng (5 megapixels) e lemoha ka bo eona literata tse sehang 'me e lefella lintho tse sothehileng kapa tse fosahetseng.

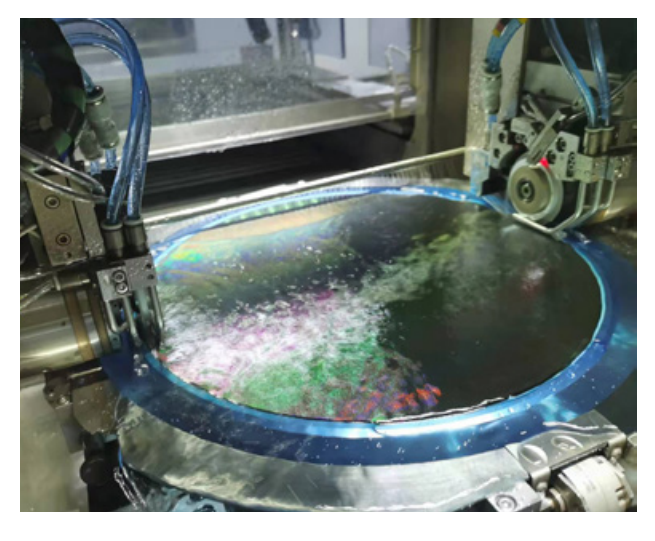

4.Ho Folisa le ho Tlosa Lerōle: Mokhoa o kopantsoeng oa ho futhumatsa metsi a hloekileng le ho tlosa lerōle la vacuum ho fokotsa tšusumetso ea mocheso le tšilafalo ea likaroloana.

Mekhoa ea ho itšeha

1.Blade Dicing: E loketse lisebelisoa tsa setso tsa semiconductor tse kang Si le GaAs, ka bophara ba kerf ea 50-100μm.

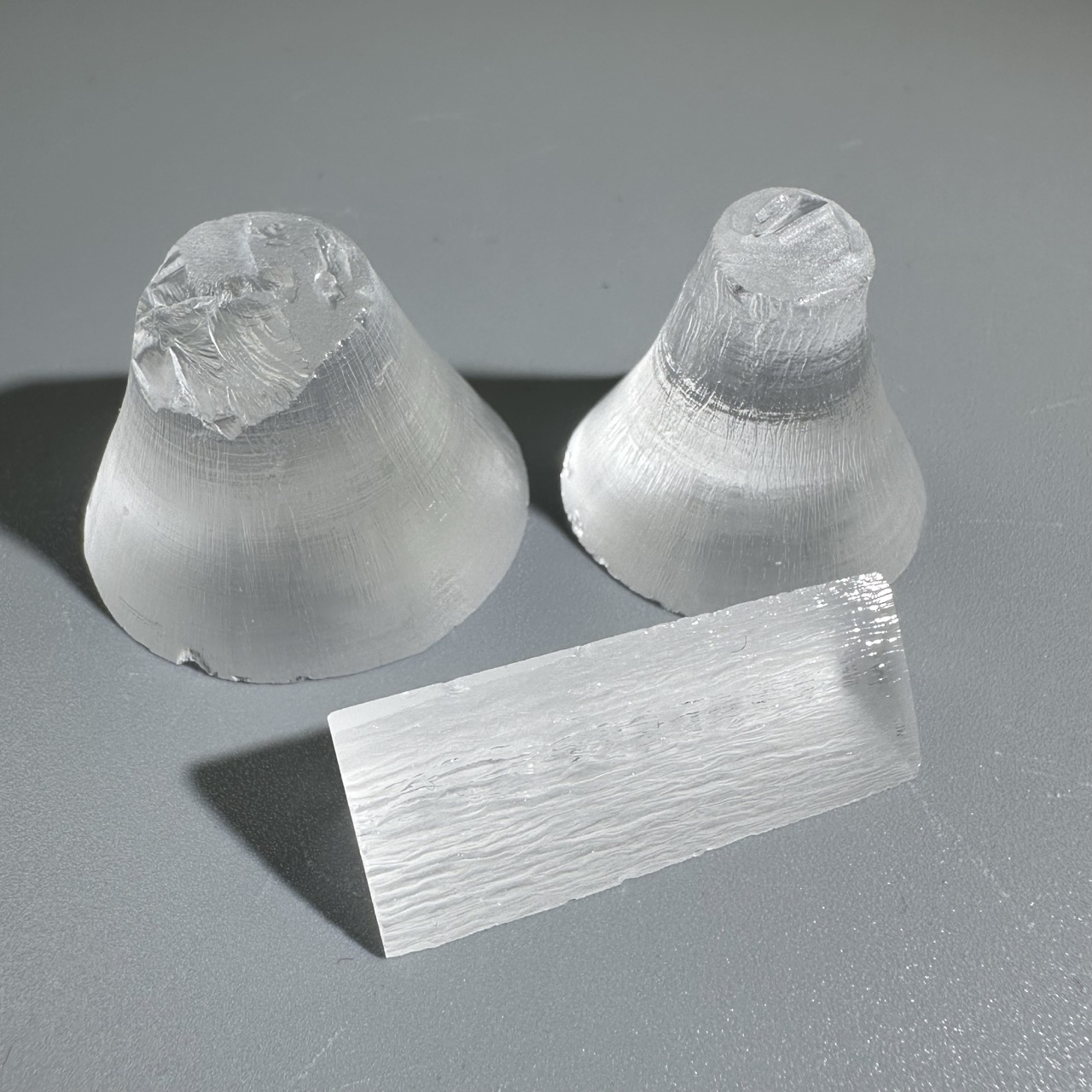

2.Stealth Laser Dicing: E sebelisoa bakeng sa li-wafers tse tšesaane haholo (<100μm) kapa lisebelisoa tse senyehang (mohlala, LT/LN), tse nolofalletsang karohano e se nang khatello ea maikutlo.

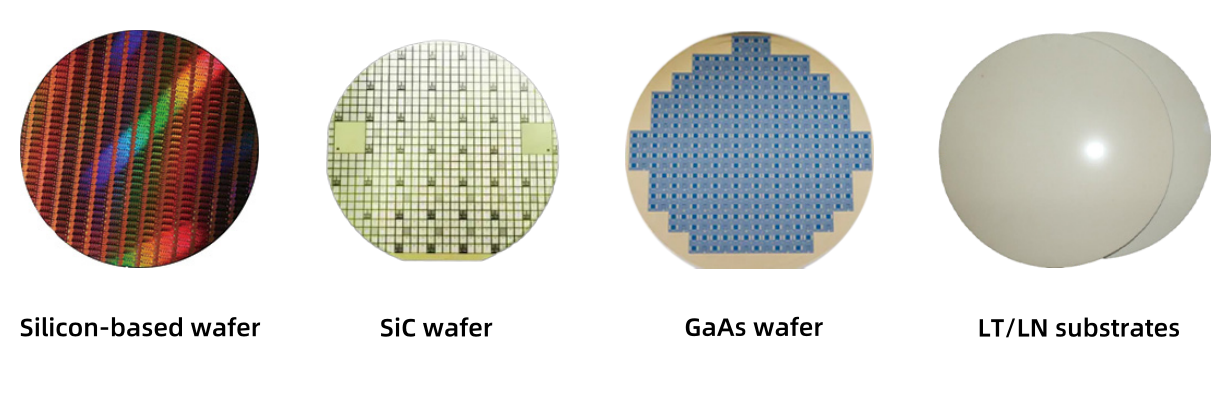

Lisebelisoa tse Tloaelehileng

| Boitsebiso bo Tšoanang | Sebaka sa Kopo | Litlhoko tsa ho sebetsa |

| Silicon (Si) | Li-IC, li-sensor tsa MEMS | Ho itšeha ka mokhoa o phahameng, ho phunya <10μm |

| Silicon Carbide (SiC) | Lisebelisoa tsa motlakase (MOSFET/diode) | Ts'enyehelo e tlase, ts'ebetso ea taolo ea mocheso |

| Gallium Arsenide (GaAs) | Lisebelisoa tsa RF, lisebelisoa tsa optoelectronic | Thibelo ea micro-crack, taolo ea bohloeki |

| Lisebelisoa tsa LT/LN | Li-filters tsa SAW, li-modulator tsa optical | Ho itšeha ho se nang khatello ea maikutlo, ho boloka thepa ea piezoelectric |

| Lisebelisoa tsa Ceramic | Li-module tsa matla, liphutheloana tsa LED | High-hardness material processing, bohale flatness |

| Liforeimi tsa QFN/DFN | Pakete e tsoetseng pele | Multi-chip ka nako e le 'ngoe ho itšeha, ho ntlafatsa katleho |

| Lisebelisoa tsa WLCSP | Sephutheloana sa Wafer-level | Li-dicing tse se nang tšenyo ea li-wafers tse tšesaane haholo (50μm) |

Melemo

1. Ho hlahloba foreimi ea lik'hasete tsa lebelo le phahameng ka lialamo tsa thibelo ea ho thulana, boemo ba phetisetso e potlakileng, le bokhoni bo matla ba ho lokisa liphoso.

2. Optimized dual-spindle cutting mode, ho ntlafatsa bokhoni ba hoo e ka bang 80% ha ho bapisoa le litsamaiso tse nang le li-spindle tse le 'ngoe.

3. Li-screws tsa bolo tse kenngoeng ka mokhoa o nepahetseng, litataiso tsa mela, le sekala sa Y-axis grating se koetsoeng, se netefatsang botsitso ba nako e telele ba machining a phahameng ka ho fetesisa.

4. Ho kenya / ho laolla ka ho feletseng, boemo ba ho fetisa, ho khaola ho lumellana, le ho hlahloba kerf, ho fokotsa haholo mosebetsi oa opereishene (OP).

5.Sebopeho sa mokhoa oa ho kenya li-spindle, se nang le sebaka se fokolang sa 24mm, se nolofalletsang ho ikamahanya le maemo a pharaletseng bakeng sa mekhoa ea ho seha ha li-spindle tse peli.

Likaroloana

1.Boemo bo phahameng bo nepahetseng bo sa amaneng le batho.

2.Multi-wafer dual-blade sehiloeng holim'a terei e le 'ngoe.

3.Automatic calibration, kerf hlahloba, le mekhoa ea ho lemoha ho robeha ha lehare.

4.E tšehetsa mekhoa e fapaneng e nang le li-algorithms tsa ho ikamahanya le maemo.

5.Tlhahiso ea phoso ea ho itokisa le ho shebella maemo a mangata ka nako ea sebele.

6.Bokhoni ba ho hlahloba ka lekhetlo la pele ka mor'a ho qaptjoa ha pele.

7.Customizable fektheri automation modules le mesebetsi e meng ea boikhethelo.

Litšebeletso tsa Thepa

Re fana ka ts'ehetso e felletseng ho tloha ho khetho ea lisebelisoa ho isa tlhokomelong ea nako e telele:

(1) Ntlafatso ea Customized

· Khothaletsa litharollo tsa ho itšeha ka lehare/laser tse ipapisitseng le thepa (mohlala, boima ba SiC, brittleness ea GaAs).

· Fana ka liteko tsa mahala tsa sampole ho netefatsa boleng ba ho itšeha (ho kenyeletsoa ho cheka, bophara ba kerf, bohloeki ba bokaholimo, jj.).

(2) Koetliso ea Theknoloji

· Koetliso ea Motheo: Ts'ebetso ea lisebelisoa, phetoho ea parameter, tlhokomelo ea kamehla.

· Lithuto tse tsoetseng pele: Ts'ebetso ea ts'ebetso ea lisebelisoa tse rarahaneng (mohlala, ho itšeha ntle le khatello ea li-substrates tsa LT).

(3) Tšehetso ea Ka mor'a-Thekiso

· 24/7 Karabo: Tlhahlobo ea hole kapa thuso ea sebaka sa marang-rang.

· Phepelo ea Likaroloana tsa Spare: Li-spindle, li-blades, le likaroloana tsa mahlo bakeng sa ho nchafatsoa ka potlako.

· Tlhokomelo e Thibelang: Ho lekanya khafetsa ho boloka ho nepahala le ho lelefatsa bophelo ba ts'ebeletso.

Melemo ea Rōna

✔ Phihlelo ea Indasteri: Ho sebeletsa 300+ lefatšeng ka bophara semiconductor le baetsi ba lisebelisoa tsa elektroniki.

✔ Theknoloji ea Cutting-Edge: Litataiso tse nepahetseng le lits'ebetso tsa servo li netefatsa botsitso bo etelletseng pele indastering.

✔ Global Service Network: Tšehetso e fumanehang Asia, Europe le Amerika Leboea bakeng sa tšehetso ea lehae.

Bakeng sa liteko kapa lipotso, ikopanye le rona!