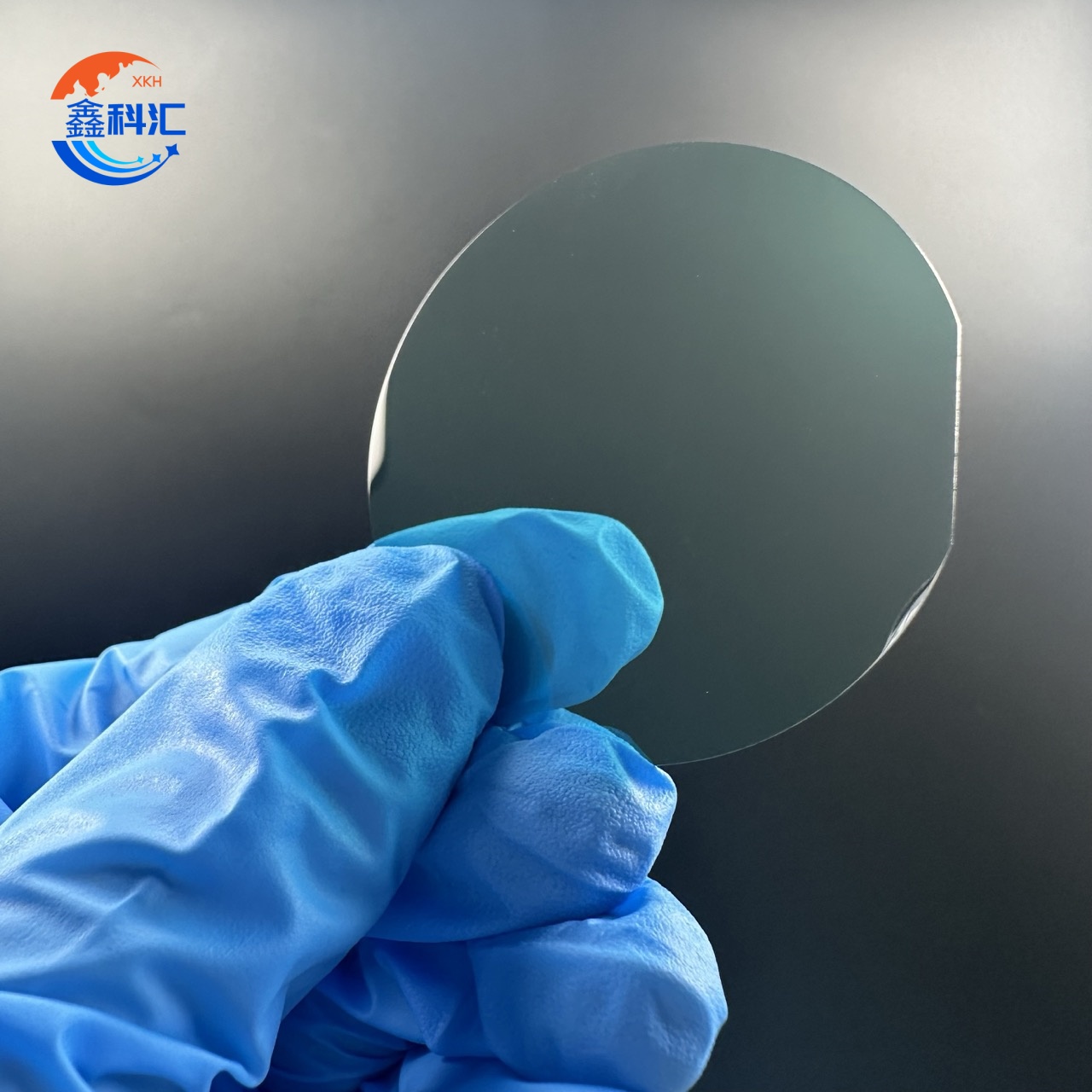

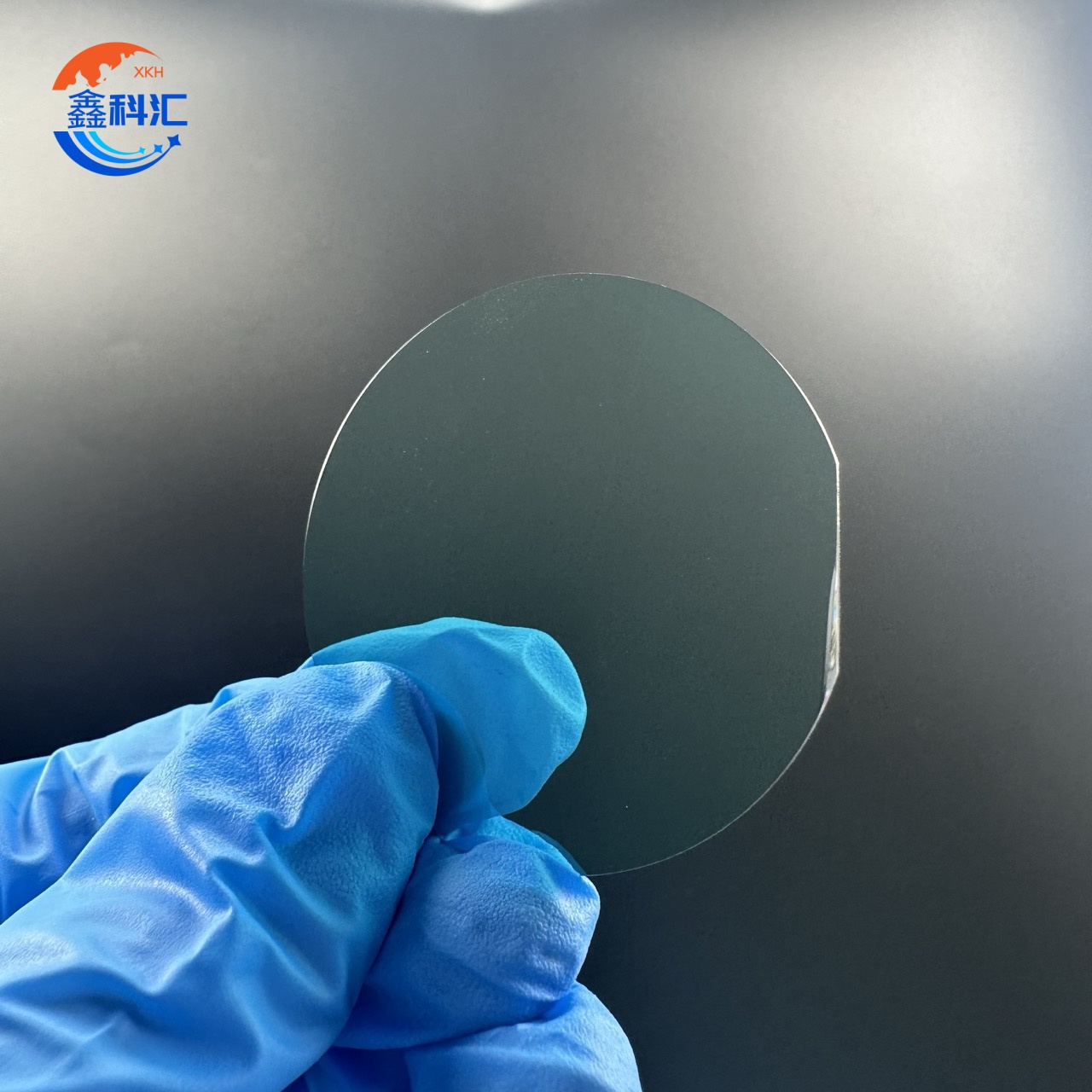

2inch silicon carbide substrate 6H-N habeli mahlakoreng a bentšitsoeng bophara ba 50.8mm sehlopha sa lipatlisiso tsa sehlopha sa tlhahiso.

Tse latelang ke litšobotsi tsa 2inch silicon carbide wafer:

1. Ho hanyetsa mahlaseli ho molemo: Li-wafers tsa SIC li na le matla a matla a ho hanyetsa mahlaseli, a etsang hore li tšoanelehe ho sebelisoa libakeng tsa mahlaseli. Mehlala e kenyelletsa lifofa-sebakeng le lisebelisoa tsa nyutlelie.

2. Boima bo phahameng: Li-wafers tsa SIC li thata ho feta silicon, e leng ho matlafatsang ho tšoarella ha li-wafers nakong ea ts'ebetso.

3. Nako e ka tlaase ea dielectric: Li-wafers tsa dielectric tsa SIC li tlaase ho feta tsa silicon, tse thusang ho fokotsa matla a likokoana-hloko ka sesebelisoa le ho ntlafatsa ts'ebetso e phahameng ea maqhubu.

4. Lebelo le phahameng la ho hoholeha ha elektronike: Li-wafer tsa SIC li na le lebelo le holimo la ho hoholeha ha elektronike ho feta silicon, e fanang ka lisebelisoa tsa SIC monyetla oa ho sebelisa maqhubu a phahameng.

5. Matla a matla a phahameng: Ka litšobotsi tse ka holimo, lisebelisoa tsa SIC tsa wafer li ka finyella matla a phahameng a matla ka boholo bo fokolang.

2inch silicon carbide wafer e na le lits'ebetso tse 'maloa.

1. Lisebelisoa tsa elektronike tsa motlakase: Li-wafers tsa SiC li sebelisoa haholo lisebelisoa tsa elektronike tse matla tse kang li-converter tsa matla, li-inverters le li-switches tse nang le matla a phahameng ka lebaka la matla a tsona a ho senyeha ha matla le litšobotsi tse tlaase tsa tahlehelo ea matla.

2. Likoloi tsa motlakase: Li-wafers tsa silicon carbide li sebelisoa ka motlakase oa motlakase oa koloi ho ntlafatsa katleho le ho fokotsa boima ba 'mele, e leng se etsang hore ho be le ho tjhaja ka potlako le nako e telele ea ho khanna.

3. Matla a tsosolositsoeng: Li-wafers tsa silicon carbide li phetha karolo ea bohlokoa lits'ebetsong tsa matla a tsosolositsoeng tse kang li-inverters tsa letsatsi le tsamaiso ea matla a moea, ho ntlafatsa matla a ho fetola matla le ho tšepahala.

4.Aerospace le Tšireletso: Li-wafers tsa SiC li bohlokoa indastering ea lifofane le ea tšireletso bakeng sa mocheso o phahameng, matla a phahameng le lisebelisoa tse hanyetsanang le mahlaseli a kotsi, ho kenyelletsa le lisebelisoa tsa matla a lifofane le lisebelisoa tsa radar.

ZMSH e fana ka lits'ebeletso tsa ho iketsetsa lihlahisoa bakeng sa liphaephe tsa rona tsa silicon carbide. Li-wafers tsa rona li entsoe ka likarolo tse phahameng tsa silicon carbide tse tsoang Chaena ho netefatsa ho tšoarella le ho ts'epahala. Bareki ba ka khetha khethong ea rona ea boholo ba liphaephe le litlhaloso ho fihlela litlhoko tsa bona tse ikhethileng.

Li-wafer tsa rona tsa Silicon Carbide li tla ka mefuta le boholo bo fapaneng, mohlala ke Silicon Carbide.

Re fana ka mefuta e fapaneng ea liphekolo tsa holim'a metsi ho kenyelletsa le polishing e le 'ngoe/habeli ka mahlakoreng a mabeli a nang le mafika a holimo ≤1.2nm le flatness Lambda/10. Re boetse re fana ka likhetho tse phahameng / tse tlase tsa resistivity tse ka ikamahanyang le litlhoko tsa hau. EPD ea rona ea ≤1E10/cm2 e netefatsa hore li-wafers tsa rona li finyella litekanyetso tse phahameng ka ho fetisisa tsa indasteri.

Re amehile ka lintlha tse ling le tse ling tsa sephutheloana, ho hloekisa, anti-static , phekolo ea ho tšoha .Ho ea ka bongata le sebōpeho sa sehlahisoa, re tla nka mokhoa o fapaneng oa ho paka! Hoo e ka bang ka li-cassette tsa wafer tse le 'ngoe kapa lik'hasete tse 25pcs ka kamoreng ea ho hloekisa ea grade 100.

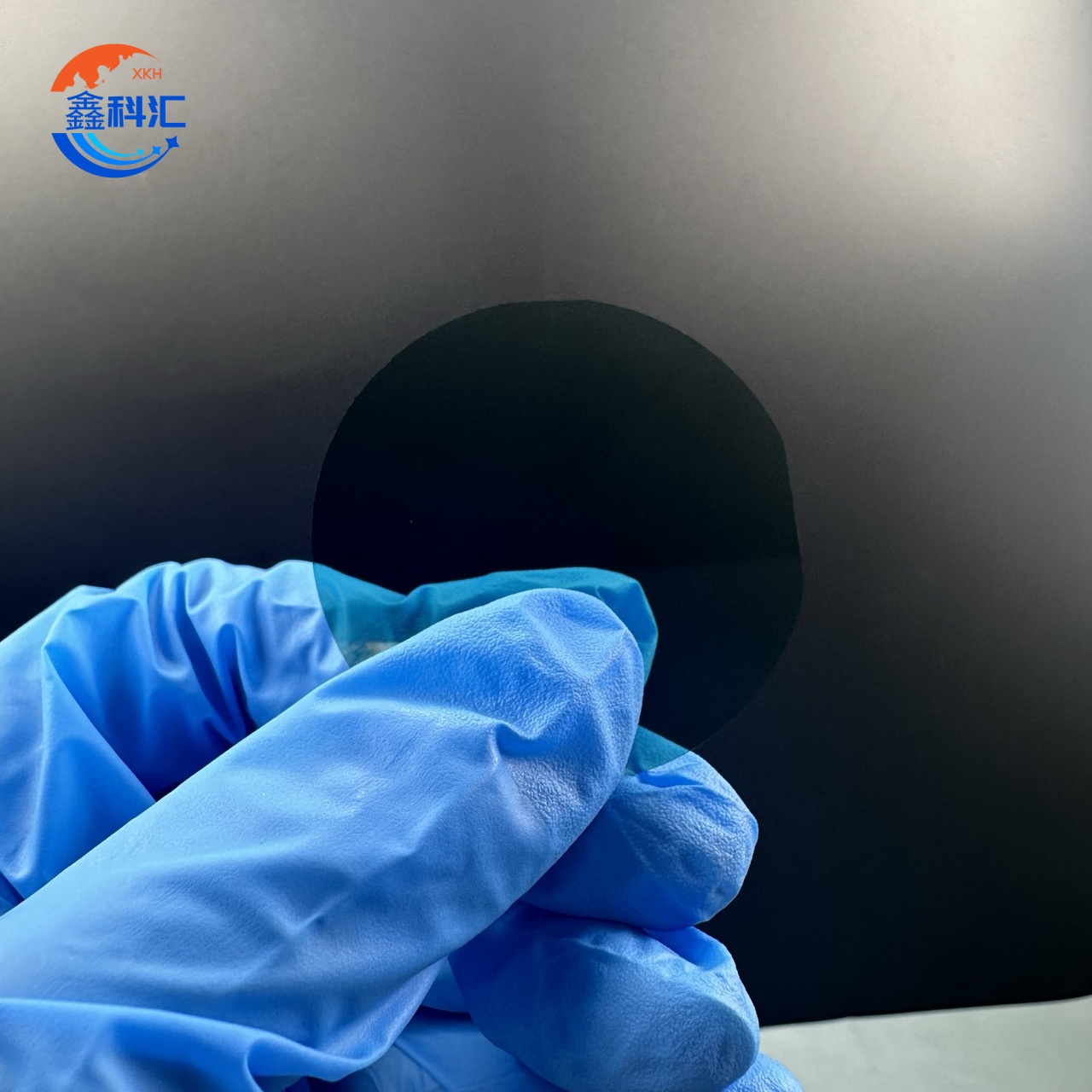

Setšoantšo se qaqileng