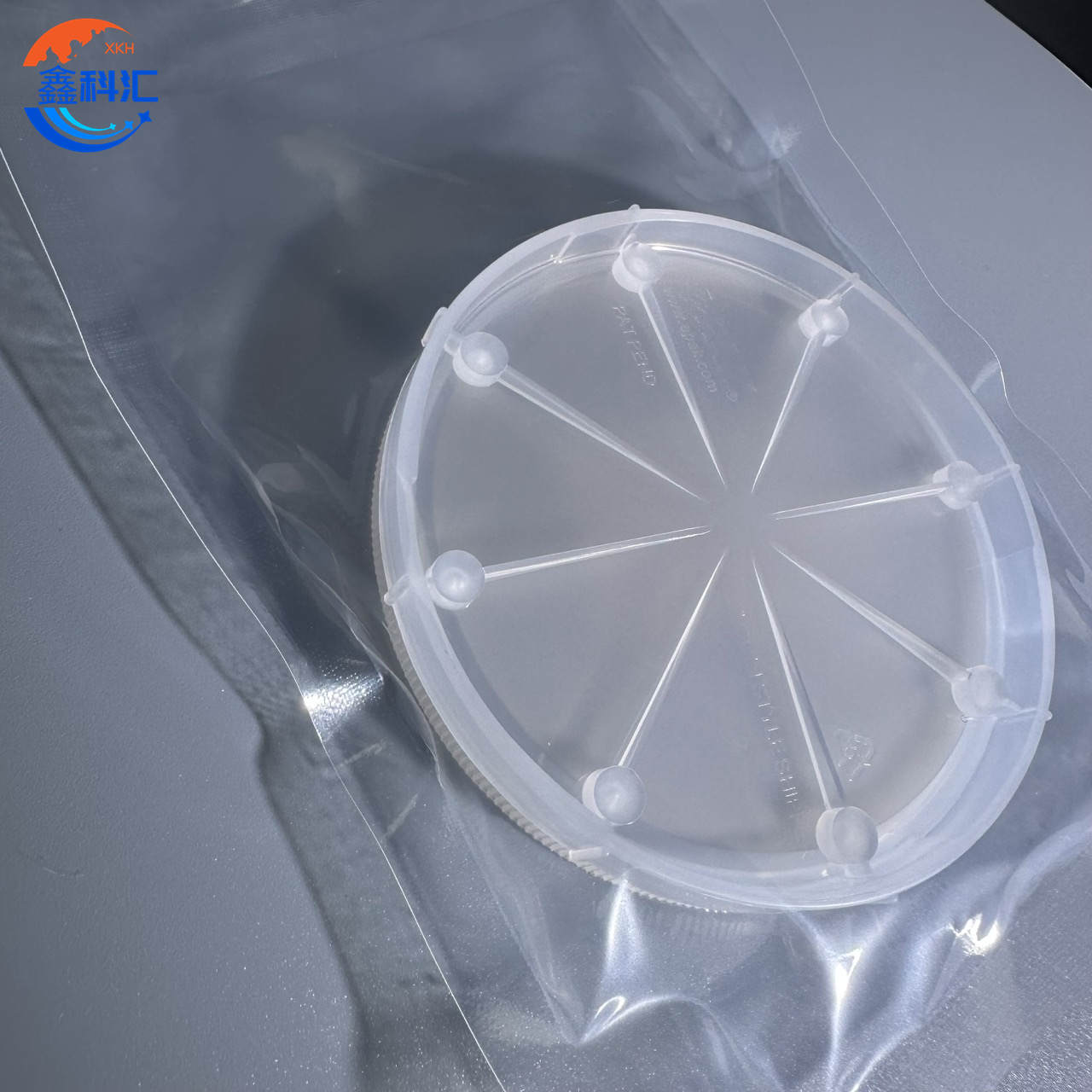

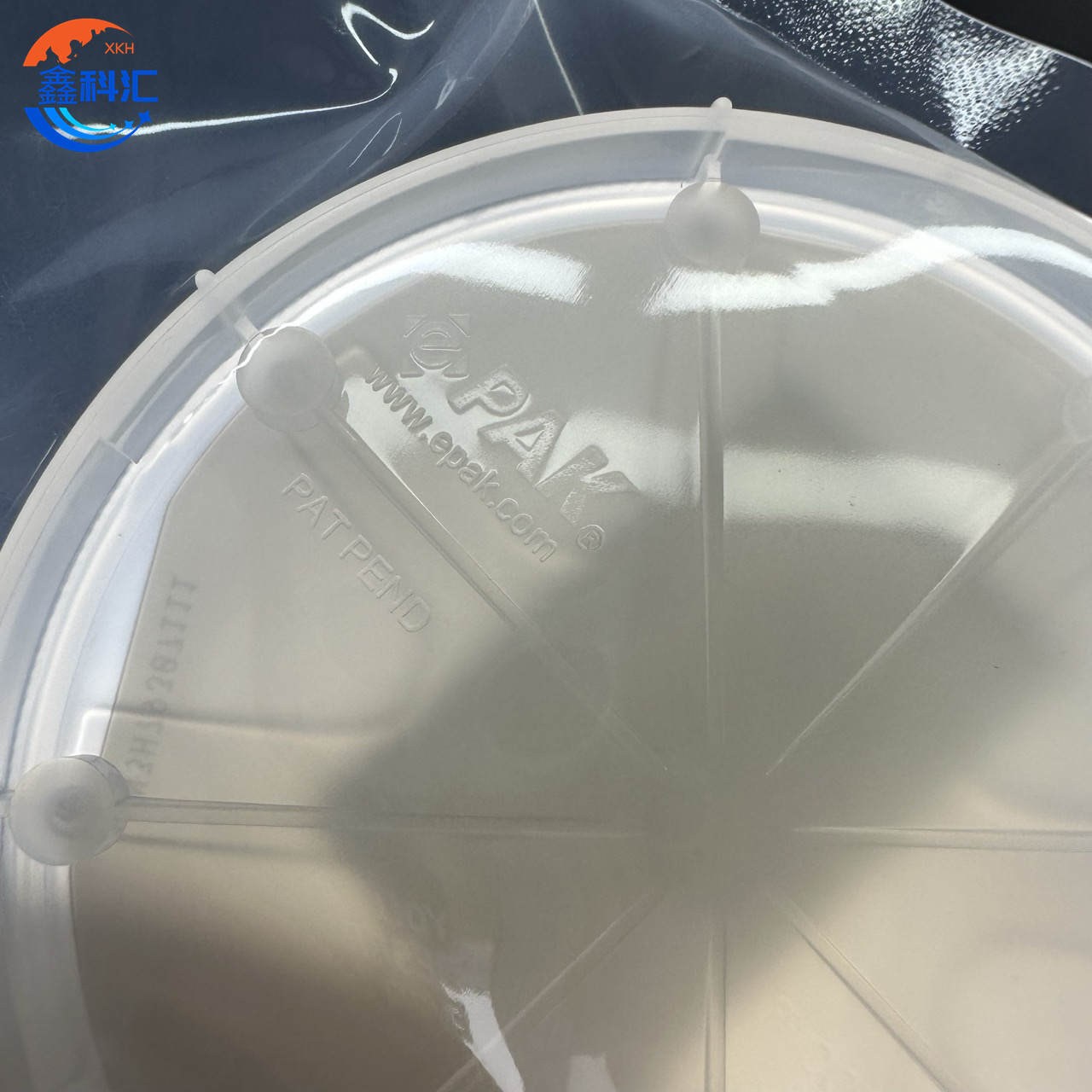

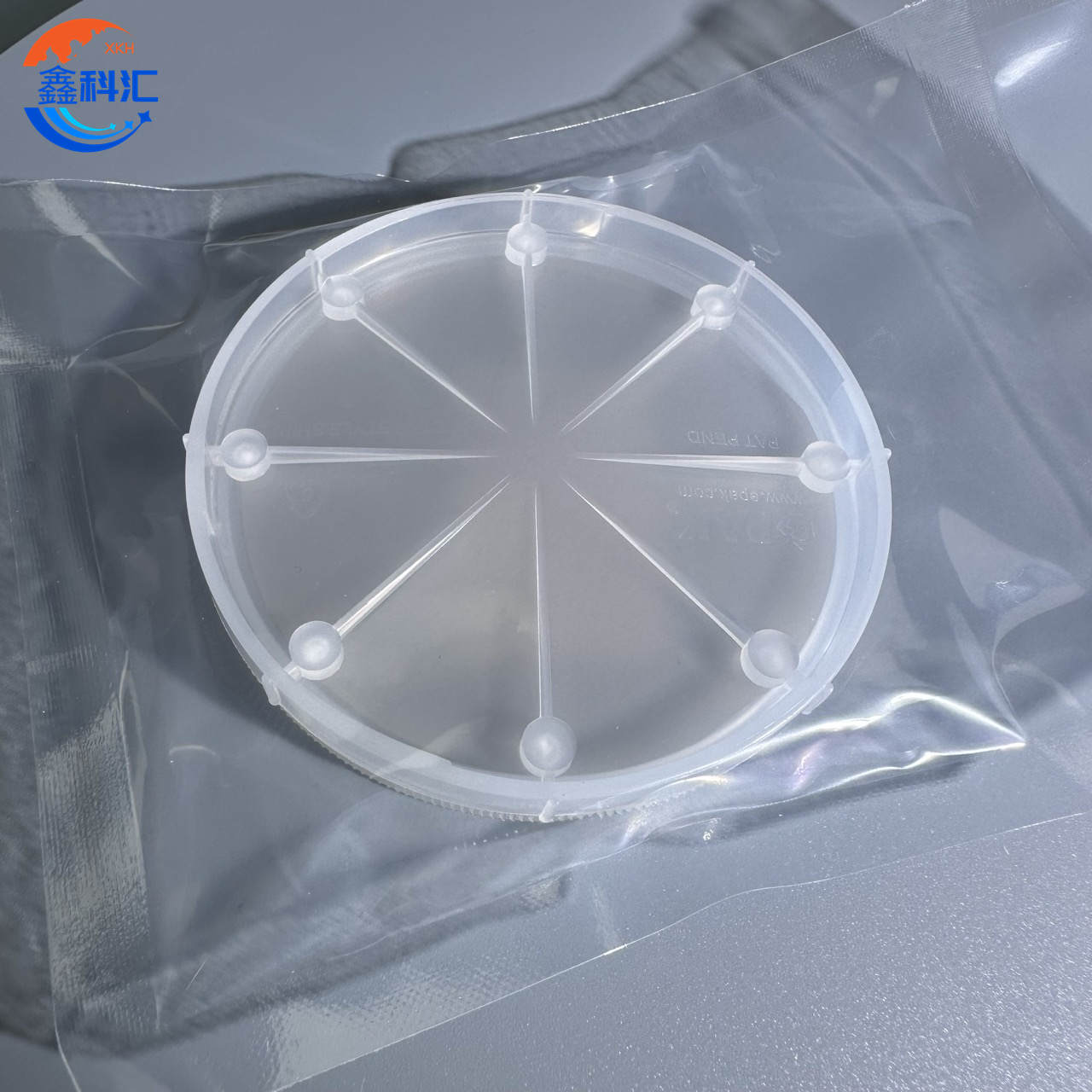

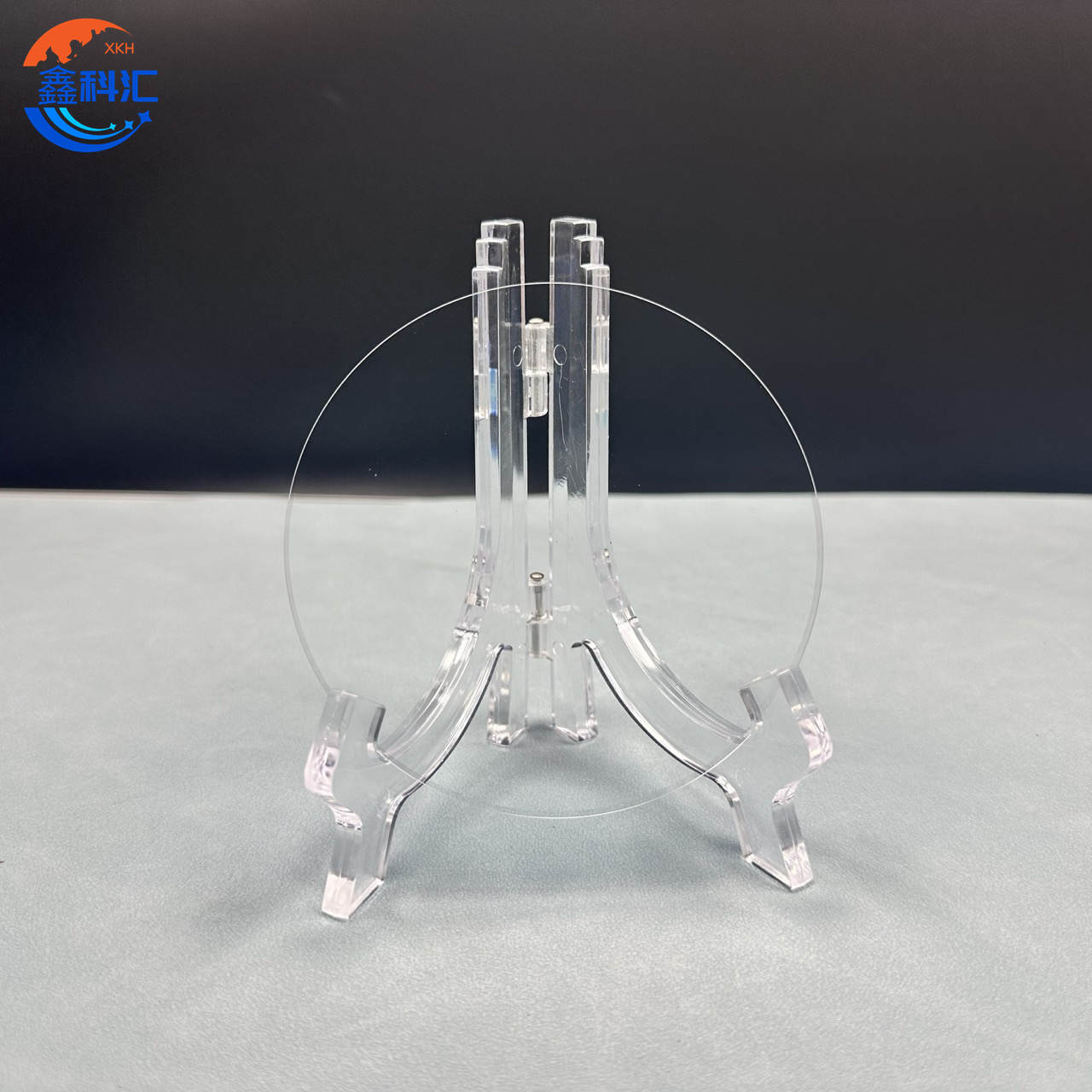

3inch High purity Semi-Insulating (HPSI) SiC wafer 350um Dummy grade grade

Kopo

Li-wafers tsa HPSI SiC li bohlokoa ho nolofatseng lisebelisoa tsa motlakase tsa moloko o latelang, tse sebelisoang mefuteng e fapaneng ea ts'ebetso e phahameng:

Sistimi ea Phetoho ea Matla: Li-wafers tsa SiC li sebetsa e le lisebelisoa tsa mantlha bakeng sa lisebelisoa tsa motlakase tse joalo ka li-MOSFET tsa matla, diode, le li-IGBT, tse bohlokoa bakeng sa phetolo ea matla e sebetsang lipotolohong tsa motlakase. Likarolo tsena li fumaneha lisebelisoa tsa motlakase tse sebetsang hantle haholo, li-drive tsa makoloi le li-inverters tsa indasteri.

Likoloi tsa Motlakase (EVs):Tlhokahalo e ntseng e eketseha ea likoloi tsa motlakase e hloka hore ho sebelisoe lisebelisoa tsa elektroniki tse sebetsang hantle, 'me li-wafer tsa SiC li ka pele ho phetoho ena. Ho li-powertrains tsa EV, li-wafers tsena li fana ka ts'ebetso e phahameng le bokhoni ba ho chencha kapele, bo kenyang letsoho ho nako ea ho tjhaja kapele, sebaka se selelele, le ts'ebetso e ntlafalitsoeng ea koloi ka kakaretso.

Matla a Tsosolositsoeng:Litsamaisong tsa matla tse nchafalitsoeng joalo ka matla a letsatsi le a moea, li-wafers tsa SiC li sebelisoa ho li-inverters le li-converter tse nolofalletsang ho hapa le ho ajoa ha matla haholoanyane. The high conductivity thermal conductivity and superior breakdown voltage of SiC etsa bonnete ba hore litsamaiso tsena li sebetsa ka botšepehi, esita le tlas'a maemo a feteletseng a tikoloho.

Indasteri ea Boiketsetso le Liroboto:Lisebelisoa tsa motlakase tse sebetsang hantle haholo lits'ebetsong tsa liindasteri le liroboto li hloka lisebelisoa tse khonang ho fetoha kapele, ho sebetsana le meroalo e meholo ea matla, le ho sebetsa tlasa khatello e matla. Li-semiconductors tse thehiloeng ho SiC li fihlela litlhoko tsena ka ho fana ka ts'ebetso e phahameng le matla, esita le maemong a thata a ts'ebetso.

Mekhoa ea puisano ea mehala:Mehahong ea likhokahano tsa mehala, moo ho ts'eptjoang haholo le phetolo ea matla e sebetsang hantle, li-wafers tsa SiC li sebelisoa phepelong ea motlakase le li-converter tsa DC-DC. Lisebelisoa tsa SiC li thusa ho fokotsa tšebeliso ea matla le ho ntlafatsa ts'ebetso ea sistimi litsing tsa data le marang-rang a puisano.

Ka ho fana ka motheo o tiileng bakeng sa likopo tsa matla a phahameng, sephaphatha sa HPSI SiC se nolofalletsa nts'etsopele ea lisebelisoa tse bolokang matla, ho thusa liindasteri ho fetela ho litharollo tse tala, tse tsitsitseng haholoanyane.

Thepa

| operty | Kereiti ya Tlhahiso | Sehlopha sa Lipatlisiso | Sehlopha sa Dummy |

| Diameter | 75.0 limilimithara ± 0.5 limilimithara | 75.0 limilimithara ± 0.5 limilimithara | 75.0 limilimithara ± 0.5 limilimithara |

| Botenya | 350 µm ± 25 µm | 350 µm ± 25 µm | 350 µm ± 25 µm |

| Wafer Orientation | Ka lehlakoreng le leng: <0001> ± 0.5° | Ka lehlakoreng le leng: <0001> ± 2.0° | Ka lehlakoreng le leng: <0001> ± 2.0° |

| Boima ba Micropipe bakeng sa 95% ea Li-Wafers (MPD) | ≤ 1 cm⁻² | ≤ 5cm⁻² | ≤ 15 cm⁻² |

| Ho hanyetsa Motlakase | ≥ 1E7 Ω·cm | ≥ 1E6 Ω·cm | ≥ 1E5 Ω·cm |

| Dopant | E butsoe | E butsoe | E butsoe |

| Maemo a Motheo a Flat | {11-20} ± 5.0° | {11-20} ± 5.0° | {11-20} ± 5.0° |

| Bolelele ba Phatlalatso ba Pele | 32.5 limilimithara ± 3.0 limilimithara | 32.5 limilimithara ± 3.0 limilimithara | 32.5 limilimithara ± 3.0 limilimithara |

| Bolelele ba Bokhabane ba Bobeli | 18.0 limilimithara ± 2.0 limilimithara | 18.0 limilimithara ± 2.0 limilimithara | 18.0 limilimithara ± 2.0 limilimithara |

| Boemo ba Bobeli ba Flat | Ho shebana holimo: 90 ° CW ho tloha foleteng ea mantlha ± 5.0 ° | Ho shebana holimo: 90 ° CW ho tloha foleteng ea mantlha ± 5.0 ° | Ho shebana holimo: 90 ° CW ho tloha foleteng ea mantlha ± 5.0 ° |

| Kenyelletso ea Edge | 3 limilimithara | 3 limilimithara | 3 limilimithara |

| LTV/TTV/Bow/Warp | 3 µm / 10 µm / ±30 µm / 40 µm | 3 µm / 10 µm / ±30 µm / 40 µm | 5 µm / 15 µm / ± 40 µm / 45 µm |

| Bokhopo ba Sekaho | C-sefahleho: e bentšitsoe, Si-sefahleho: CMP | C-sefahleho: e bentšitsoe, Si-sefahleho: CMP | C-sefahleho: e bentšitsoe, Si-sefahleho: CMP |

| Mapetso (a hlahlojoa ke khanya e phahameng) | Ha ho letho | Ha ho letho | Ha ho letho |

| Hex Plates (e hlahlobiloe ka leseli le phahameng haholo) | Ha ho letho | Ha ho letho | Sebaka sa Koketso 10% |

| Libaka tsa Polytype (tse hlahlobiloeng ke khanya e phahameng) | Sebaka sa Koketso 5% | Sebaka sa Koketso 5% | Sebaka sa Koketso 10% |

| Mekhoro (e hlahlobjoa ke khanya e matla haholo) | ≤ Mengoallo e 5, bolelele bo akaretsang ≤ 150 mm | ≤ 10 mengoapo, cumulative bolelele ≤ 200 limilimithara | ≤ 10 mengoapo, cumulative bolelele ≤ 200 limilimithara |

| Edge Chipping | Ha e lumelloe ≥ 0.5 mm bophara le botebo | 2 e lumelletsoe, ≤ 1 mm bophara le botebo | 5 e lumelletsoe, ≤ 5 mm bophara le botebo |

| Surface Contamination (e hlahlojoa ke khanya e matla e phahameng) | Ha ho letho | Ha ho letho | Ha ho letho |

Melemo ea Bohlokoa

Ts'ebetso e Phahameng ea Thermal: Thermal conductivity e phahameng ea SiC e etsa bonnete ba hore mocheso o sebetsang hantle oa lisebelisoa tsa motlakase, o ba lumella ho sebetsa ka matla a phahameng le maqhubu ntle le ho chesa haholo. Sena se fetolela litsamaiso tse nyane, tse sebetsang hantle le nako e telele ea ts'ebetso.

High Breakdown Voltage: Ka bandgap e pharaletseng ha e bapisoa le silicon, li-wafers tsa SiC li tšehetsa lisebelisoa tsa motlakase o phahameng, li etsa hore e be tse loketseng bakeng sa lisebelisoa tsa motlakase tse hlokang ho mamella maqhubu a phahameng a ho senyeha, joalo ka likoloi tsa motlakase, tsamaiso ea matla a marang-rang, le lisebelisoa tsa matla a tsosolositsoeng.

Tahlehelo ea Matla e Fokotseng: Lebelo le tlase la ho hanyetsa le ho potlaka ha lisebelisoa tsa SiC li fella ka tahlehelo e fokotsehileng ea matla nakong ea ts'ebetso. Sena ha se ntlafatse ts'ebetso ea ts'ebetso feela empa se boetse se ntlafatsa ts'ebetso ea ho boloka matla ka kakaretso ea litsamaiso tseo li sebelisoang ho tsona.

Ho Tšepahala ho Ntlafetseng Mabakeng a Mathata: Thepa e matla ea SiC e e lumella ho sebetsa maemong a feteletseng, joalo ka mocheso o phahameng (ho fihla ho 600 ° C), maqhubu a phahameng, le maqhubu a phahameng. Sena se etsa hore li-wafers tsa SiC li tšoanelehe bakeng sa lits'ebetso tse batloang ke indasteri, likoloi le matla.

Matla a Matla: Lisebelisoa tsa SiC li fana ka matla a phahameng a matla ho feta lisebelisoa tsa khale tse thehiloeng ka silicon, li fokotsa boholo le boima ba lisebelisoa tsa motlakase tsa motlakase ha li ntse li ntlafatsa katleho ea tsona ka kakaretso. Sena se lebisa ho bolokoeng ha litšenyehelo le sebaka se senyenyane sa tikoloho lits'ebetsong tse kang matla a tsosolositsoeng le likoloi tsa motlakase.

Scalability: Bophara ba 3-inch le mamello e nepahetseng ea tlhahiso ea HPSI SiC wafer e netefatsa hore e ka senyeha bakeng sa tlhahiso e ngata, e kopanang le litlhoko tsa lipatlisiso le tsa khoebo.

Qetello

Sephaphatha sa HPSI SiC, se bophara ba 3-inch le botenya ba 350 µm ± 25 µm, ke thepa e nepahetseng bakeng sa moloko o latelang oa lisebelisoa tsa elektroniki tse sebetsang hantle haholo. Motsoako oa eona o ikhethang oa conductivity ea mocheso, matla a phahameng a ho senyeha, tahlehelo ea matla a fokolang, le ho tšepahala tlas'a maemo a feteletseng ho etsa hore e be karolo ea bohlokoa bakeng sa mekhoa e fapaneng ea ho fetola matla, matla a tsosolositsoeng, likoloi tsa motlakase, litsamaiso tsa indasteri le mehala ea puisano.

Sephaphatha sena sa SiC se loketse haholo liindasteri tse batlang ho fumana ts'ebetso e phahameng, ho boloka matla a maholo, le ts'epahalo e ntlafalitsoeng ea sistimi. Ha thekenoloji ea lisebelisoa tsa motlakase e ntse e tsoela pele ho fetoha, sephaphatha sa HPSI SiC se fana ka motheo bakeng sa nts'etsopele ea moloko o latelang, litharollo tse sebetsang hantle, tse tsamaisang phetoho ho bokamoso bo tsitsitseng, bo tlaase ba carbon.

Setšoantšo se qaqileng