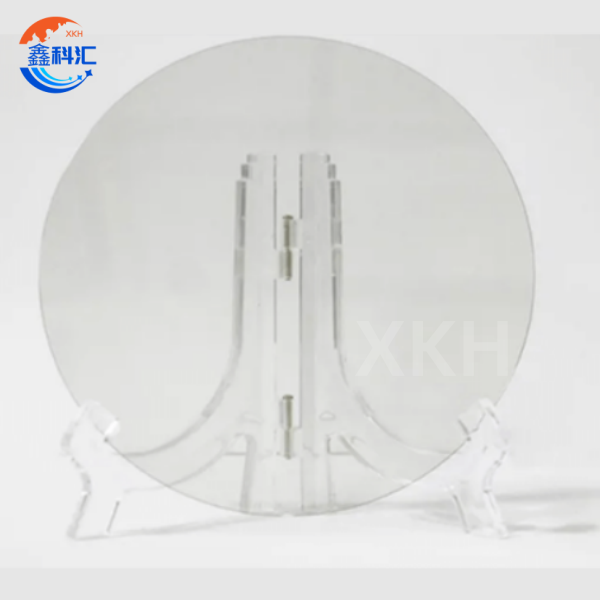

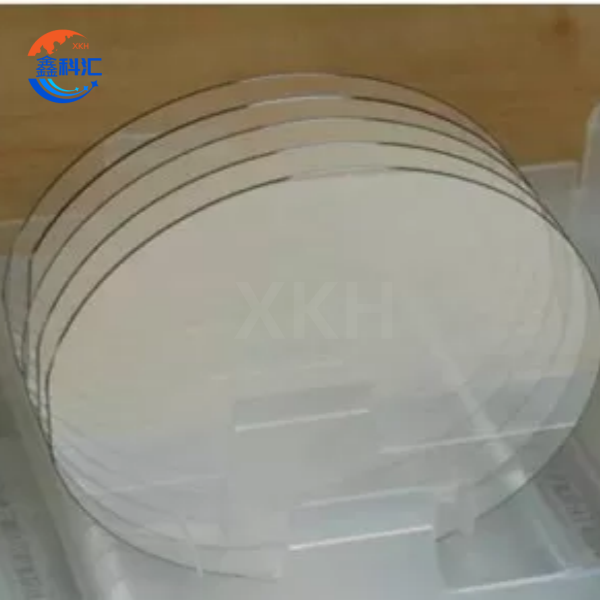

6 Inch 4H SEMI Type SiC composite substrate Thickness 500μm TTV≤5μm MOS grade

Litekanyetso tsa tekheniki

| Lintho | Tlhaloso | Lintho | Tlhaloso |

| Diameter | 150±0.2 limilimithara | Sefahleho se ka pele (si-face) /si-fahleng | Ra≤0.2 nm (5μm×5μm) |

| Polytype | 4H | Edge Chip, Scratch, Crack (tlhahlobo ea pono) | Ha ho letho |

| Ho hanyetsa | ≥1E8 Ω·cm | TTV | ≤5 μm |

| Fetisetsa lera Botenya | ≥0.4 μm | Warp | ≤35 μm |

| Lefela (2mm>D>0.5mm) | ≤5 ea/Wafer | Botenya | 500±25 μm |

Likarolo tsa Bohlokoa

1. Tshebetso e Ikgethileng ya High-Frequency

The 6-inch semi-insulating SiC composite substrate e sebelisa moralo o hlophisitsoeng oa dielectric layer, o netefatsa phapang ea kamehla ea dielectric ea <2% ho Ka-band (26.5-40 GHz) le ho ntlafatsa botsitso ba karolo ka 40%. Keketseho ea 15% ea katleho le 20% ea matla a tlase a sebelisoang ho li-module tsa T / R ho sebelisa substrate ena.

2. Phahamiso ea Thermal Management

Mohaho o ikhethang oa "borokho ba mocheso" o kopanyang o thusa lateral thermal conductivity ea 400 W/m·K. Li-modules tsa PA tsa 28 GHz 5G setsi sa motheo, mocheso oa matekoane o phahama ka 28 ° C feela ka mor'a lihora tsa 24 tsa ts'ebetso e tsoelang pele-50 ° C e tlase ho feta tharollo e tloaelehileng.

3. Superior Wafer Quality

Ka mokhoa o ntlafalitsoeng oa Physical Vapor Transport (PVT), re fihlela sekhahla sa dislocation <500/cm² le Total Thickness Variation (TTV) <3 μm.

4. Tlhahiso-Botsoalleng ho sebetsa

Ts'ebetso ea rona ea laser annealing e etselitsoeng "6-inch semi-insulating SiC composite substrate" e fokotsa sekhahla sa boemo ba leholimo ka liodara tse peli tsa boholo pele ho epitaxy.

Lisebelisoa tse ka Sehloohong

1. Likarolo tsa mantlha tsa 5G Base Station

Ka mefuta e mengata ea li-antenna tsa MIMO, lisebelisoa tsa GaN HEMT ho li-substrates tse kopantsoeng tsa SiC tse 6-inch li fihlella matla a tlhahiso ea 200W le> 65% e sebetsang hantle. Liteko tsa masimong ho 3.5 GHz li bonts'itse keketseho ea 30% ea radius ea tšireletso.

2. Mekhoa ea puisano ea Satellite

Li-transceivers tsa satellite tsa Low-Earth orbit (LEO) tse sebelisang substrate ena li bonts'a 8 dB EIRP e phahameng ho Q-band (40 GHz) ha li ntse li fokotsa boima ba 'mele ka 40%. Li-terminals tsa SpaceX Starlink li e amohetse bakeng sa tlhahiso ea bongata.

3. Mekhoa ea Radar ea Sesole

Li-module tsa radar tsa T/R tse karolong e ka tlase ena li fihlella 6-18 GHz bandwidth le palo ea lerata e tlase joalo ka 1.2 dB, e atolosa sebaka sa ho lemoha ka 50 km lits'ebetsong tsa radar tse lemosang esale pele.

4. Likoloi tsa Millimeter-Wave Radar

Lichifi tsa radar tsa likoloi tsa 79 GHz tse sebelisang karoloana ena li ntlafatsa tharollo ea angular ho isa ho 0.5 °, li fihlela litlhoko tsa ho khanna ka boithaopo ba L4.

Re fana ka tharollo e felletseng ea litšebeletso bakeng sa likaroloana tse kopaneng tsa SiC tsa 6-inch semi-insulating. Mabapi le ho hlophisa liparamente tsa lisebelisoa, re ts'ehetsa taolo e nepahetseng ea ho hanyetsa ka har'a mefuta e fapaneng ea 10⁶-10¹⁰ Ω·cm. Haholo-holo bakeng sa lits'ebetso tsa sesole, re ka fana ka khetho ea khanyetso e phahameng haholo ea >10⁹ Ω·cm. E fana ka litlhaloso tse tharo tsa botenya ba 200μm, 350μm le 500μm ka nako e le 'ngoe, ka mamello e laoloang ka thata ka hare ho ± 10μm, e finyella litlhoko tse fapaneng ho tloha ho lisebelisoa tse phahameng tsa maqhubu ho ea ho lisebelisoa tsa matla a phahameng.

Mabapi le mekhoa ea phekolo ea holim'a metsi, re fana ka litharollo tse peli tsa setsebi: Chemical Mechanical Polishing (CMP) e ka finyella boemo ba atomic holim'a flatness ka Ra<0.15nm, ho finyella litlhoko tse boima ka ho fetisisa tsa kgolo ea epitaxial; Theknoloji ea phekolo ea epitaxial e lokiselitsoeng holim'a litlhoko tsa tlhahiso e potlakileng e ka fana ka libaka tse boreleli tse nang le Sq <0.3nm le botenya bo setseng ba oxide <1nm, e leng ho nolofatsang ts'ebetso ea pele ho nako qetellong ea mofani.

XKH e fana ka litharollo tse felletseng bakeng sa likaroloana tse kopaneng tsa SiC tse 6-inch.

1. Boitsebiso ba Parameter Customization

Re fana ka ts'ebetso e nepahetseng ea tokiso ka har'a sebaka sa 10⁶-10¹⁰ Ω·cm, ka likhetho tse ikhethileng tse phahameng ka ho fetesisa >10⁹ Ω·cm tse fumanehang bakeng sa ts'ebeliso ea sesole/sefofane.

2. Tema Litlhaloso

Likhetho tse tharo tse tloaelehileng tsa botenya:

200μm (e ntlafalitsoe bakeng sa lisebelisoa tsa maqhubu a holimo)

350μm (litlhaloso tse tloaelehileng)

500μm (e etselitsoeng lisebelisoa tsa matla a holimo)

* Mefuta eohle e fapaneng e boloka mamello e tiileng ea botenya ba ± 10μm.

3. Litheknoloji tsa Phekolo ea Bokaholimo

Chemical Mechanical Polishing (CMP): E fihlella ho batalla ha bokaholimo ba atomic ka Ra<0.15nm, ho fihlela litlhoko tse thata tsa kholo ea epitaxial bakeng sa RF le lisebelisoa tsa motlakase.

4. Epi-Ready Surface Processing

· E fana ka libaka tse boreleli tse nang le Sq<0.3nm e thata

· E laola botenya ba oxide ea tlhaho ho fihla ho <1nm

· E felisa mehato e ka bang 3 ea ho sebetsa pele ho lits'ebeletso tsa bareki