6 inch Conductive single crystal SiC holim'a polycrystalline SiC composite substrate Diameter 150mm P mofuta oa N mofuta

Litekanyetso tsa tekheniki

| Boholo: | 6 intshi |

| Diameter: | 150 limilimithara |

| Botenya: | 400-500 μm |

| Monocrystalline SiC Film Parameters | |

| Polytype: | 4H-SiC kapa 6H-SiC |

| Ho tsepamisa maikutlo ho Doping: | 1×10¹⁴ - 1×10¹⁸ cm⁻³ |

| Botenya: | 5-20 μm |

| Ho hanyetsa Leqephe: | 10-1000 Ω/sq |

| Elektrone Mobility: | 800-1200 cm²/Vs |

| Hole Mobility: | 100-300 cm²/Vs |

| Polycrystalline SiC Buffer Layer Parameters | |

| Botenya: | 50-300 μm |

| Thermal Conductivity: | 150-300 W/m·K |

| Monocrystalline SiC Substrate Parameters | |

| Polytype: | 4H-SiC kapa 6H-SiC |

| Ho tsepamisa maikutlo ho Doping: | 1×10¹⁴ - 1×10¹⁸ cm⁻³ |

| Botenya: | 300-500 μm |

| Boholo ba lijo-thollo: | > 1 limilimithara |

| Bokhopo ba Bokahohle: | <0.3 limilimithara RMS |

| Thepa ea Mechini le Motlakase | |

| Ho thatafala: | 9-10 Mohs |

| Matla a Khatetsang: | 3-4 GPA |

| Matla a tšepe: | 0.3-0.5 GPA |

| Karohano ea Matla a Tšimo: | > 2 MV/cm |

| Kakaretso ea Mamello ea Lethal dose: | > 10 Mong |

| Ketsahalo e le 'Ngoe ea Resistance: | > 100 MeV·cm²/mg |

| Thermal Conductivity: | 150-380 W/m·K |

| Sebaka sa Mocheso oa Ts'ebetso: | -55 ho isa ho 600°C |

Litšobotsi Tsa Sehlooho

SiC ea 6-inch conductive monocrystalline SiC holim'a polycrystalline SiC composite substrate e fana ka tekanyo e ikhethang ea sebopeho sa thepa le ts'ebetso, e etsa hore e tšoanelehe bakeng sa maemo a boima a indasteri:

1.Cost-Effectiveness: The polycrystalline SiC base e fokotsa haholo litšenyehelo ha e bapisoa le SiC e tletseng monocrystalline, ha monocrystalline SiC e sebetsang lera e tiisang ts'ebetso ea lisebelisoa tsa lisebelisoa, e loketseng bakeng sa lits'ebetso tse hlokang litšenyehelo.

2. Thepa e Ikhethileng ea Motlakase: Lera la SiC la monocrystalline le bonts'a motsamao o phahameng oa sepalangoang (> 500 cm²/V·s) le sekoli se tlase, se ts'ehetsa ts'ebetso ea lisebelisoa tsa maqhubu a holimo le tse matla haholo.

3.Botsitso bo Phahameng ba Mocheso: Ho hanyetsa mocheso oa tlhaho oa SiC (> 600 ° C) ho tiisa hore substrate e kopantsoeng e lula e tsitsitse tlas'a maemo a feteletseng, e leng se etsang hore e tšoanelehe bakeng sa likoloi tsa motlakase le lisebelisoa tsa motlakase tsa indasteri.

4.6-inch Standardized Wafer Size: Ha e bapisoa le li-substrates tsa khale tsa 4-inch SiC, sebopeho sa 6-inch se eketsa tlhahiso ea chip ka ho feta 30%, e fokotsa litšenyehelo tsa sesebelisoa ka unit.

5.Moqapi oa Conductive: Likarolo tsa mofuta oa N-e entsoeng esale pele kapa P-mofuta li fokotsa mehato ea ho kenngoa ha ion tlhahisong ea lisebelisoa, ho ntlafatsa katleho ea tlhahiso le chai.

6.Superior Thermal Management: The polycrystalline SiC base's conductivity thermal conductivity (~ 120 W / m·K) e atamela SiC ea monocrystalline, e sebetsana ka katleho le mathata a ho senya mocheso ho lisebelisoa tse phahameng tsa matla.

Litšobotsi tsena li beha 6-inch conductive monocrystalline SiC holim'a polycrystalline SiC composite substrate e le tharollo ea tlhōlisano bakeng sa liindasteri tse kang matla a tsosolositsoeng, lipalangoang tsa terene le sefofane.

Lisebelisoa tsa mantlha

SiC ea 6-inch conductive monocrystalline SiC holim'a polycrystalline SiC composite substrate e kentsoe ka katleho masimong a 'maloa a batloang haholo:

1.Motlakase oa Likoloi tsa Motlakase: E sebelisoa ho SiC MOSFETs le diode tse nang le matla a phahameng a matla ho matlafatsa inverter e sebetsang hantle le ho atolosa mefuta ea betri (mohlala, mehlala ea Tesla, BYD).

2.Industrial Motor Drives: E nolofalletsa li-modules tsa matla a mocheso o phahameng, o feto-fetohang-hangata, ho fokotsa tšebeliso ea matla ka mechine e boima le li-turbine tsa moea.

Li-Inverters tsa 3.Photovoltaic: Lisebelisoa tsa SiC li ntlafatsa katleho ea ho fetola letsatsi (> 99%), ha substrate e kopantsoeng e fokotsa litšenyehelo tsa tsamaiso.

Lipalangoang tsa 4.Rail: E sebelisoa ho li-converter tsa literene bakeng sa litsamaiso tsa terene tse lebelo le tsamaeang ka tlas'a lefatše, tse fanang ka khanyetso e phahameng ea motlakase (> 1700V) le lintlha tsa li-compact form.

5.Aerospace: E loketse lisebelisoa tsa matla tsa sathelaete le li-circuits tsa taolo ea enjene ea lifofane, tse khonang ho mamella mocheso o feteletseng le mahlaseli.

Ka mokhoa o sebetsang, 6-inch conductive monocrystalline SiC holim'a polycrystalline SiC composite substrate e lumellana ka botlalo le mekhoa e tloaelehileng ea lisebelisoa tsa SiC (mohlala, lithography, etching), e sa hlokeng matsete a eketsehileng a lichelete.

Litšebeletso tsa XKH

XKH e fana ka ts'ehetso e felletseng bakeng sa 6-inch conductive monocrystalline SiC ho polycrystalline SiC composite substrate, e koahelang R&D ho tlhahiso ea bongata:

1.Customization: Fetola botenya ba monocrystalline layer (5–100 μm), mahloriso a doping (1e15–1e19 cm⁻³), le mokhoa oa kristale (4H/6H-SiC) ho fihlela litlhoko tse fapaneng tsa lisebelisoa.

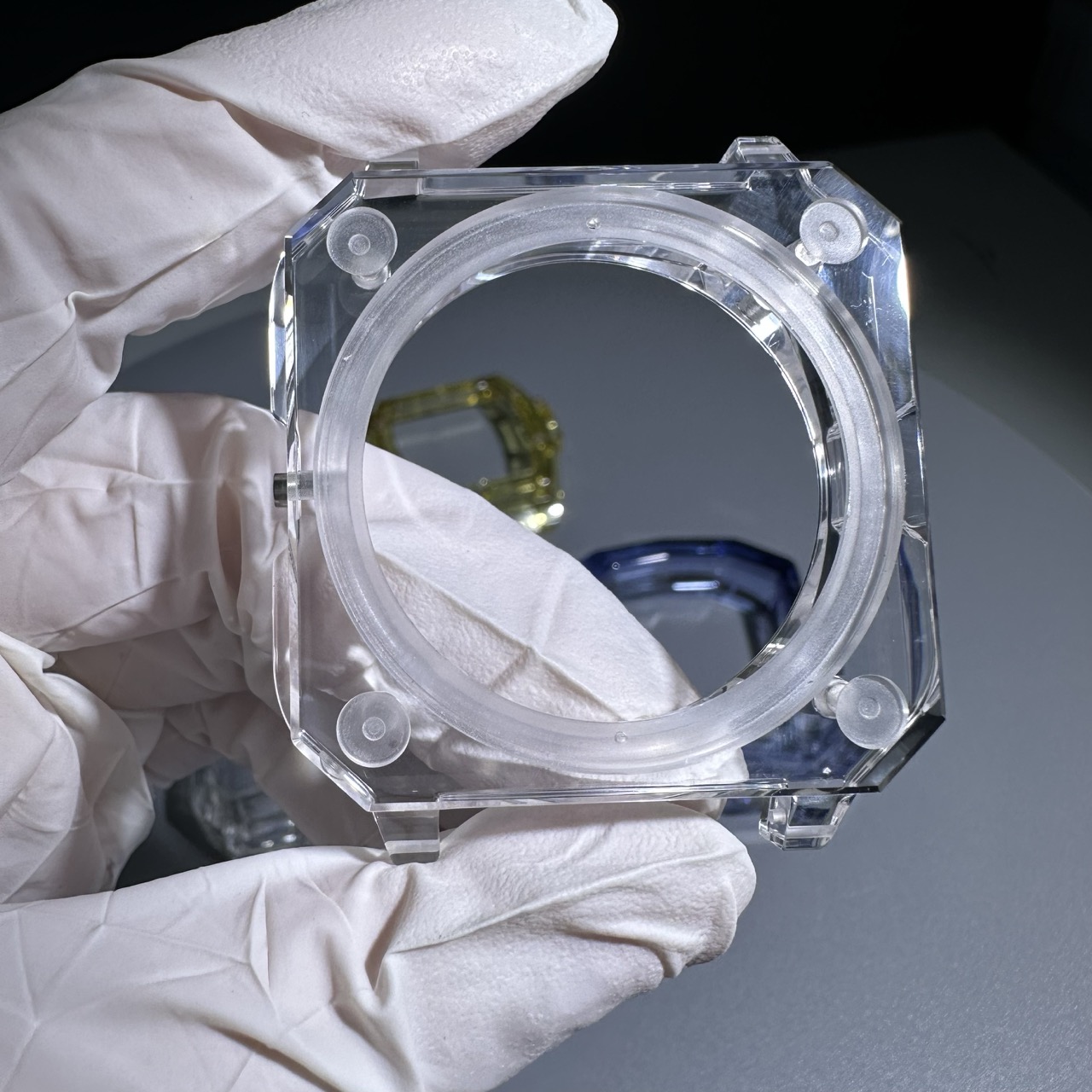

2.Wafer Processing: Phepelo e ngata ea li-substrates tsa 6-inch tse nang le lits'ebeletso tsa ho fokotsa mokokotlo le lits'ebeletso tsa metallization bakeng sa ho kopanya plug-and-play.

3.Technical Validation: E kenyelletsa tlhahlobo ea crystallinity ea XRD, tlhahlobo ea phello ea Holo, le tekanyo ea ho hanyetsa mocheso ho potlakisa litlhoko tsa thepa.

4.Rapid Prototyping: 2- 4-inch sampuli (mokhoa o tšoanang) bakeng sa mekhatlo ea lipatlisiso ho potlakisa lipotoloho tsa nts'etsopele.

5.Tlhahlobo ea ho hloleha le ho ntlafatsa: Litharollo tsa boemo ba lisebelisoa bakeng sa mathata a ho sebetsana le mathata (mohlala, bofokoli ba epitaxial layer).

Sepheo sa rona ke ho theha 6-inch conductive monocrystalline SiC holim'a polycrystalline SiC composite substrate e le tharollo e ratoang ea litšenyehelo bakeng sa lisebelisoa tsa motlakase tsa SiC, tse fanang ka tšehetso ea ho qetela ho tloha ho prototyping ho isa tlhahiso ea molumo.

Qetello

SiC ea 6-inch conductive monocrystalline SiC holim'a polycrystalline SiC composite substrate e finyella tekanyo e kholo pakeng tsa ts'ebetso le litšenyehelo ka sebopeho sa eona se secha sa mono/polycrystalline hybrid. Ha likoloi tsa motlakase li ntse li ata le tsoelo-pele ea indasteri ea 4.0, karoloana ena e fana ka motheo o tšepahalang oa lisebelisoa tsa motlakase tsa moloko o latelang. XKH e amohela litšebelisano-'moho ho tsoela pele ho hlahloba bokhoni ba theknoloji ea SiC.