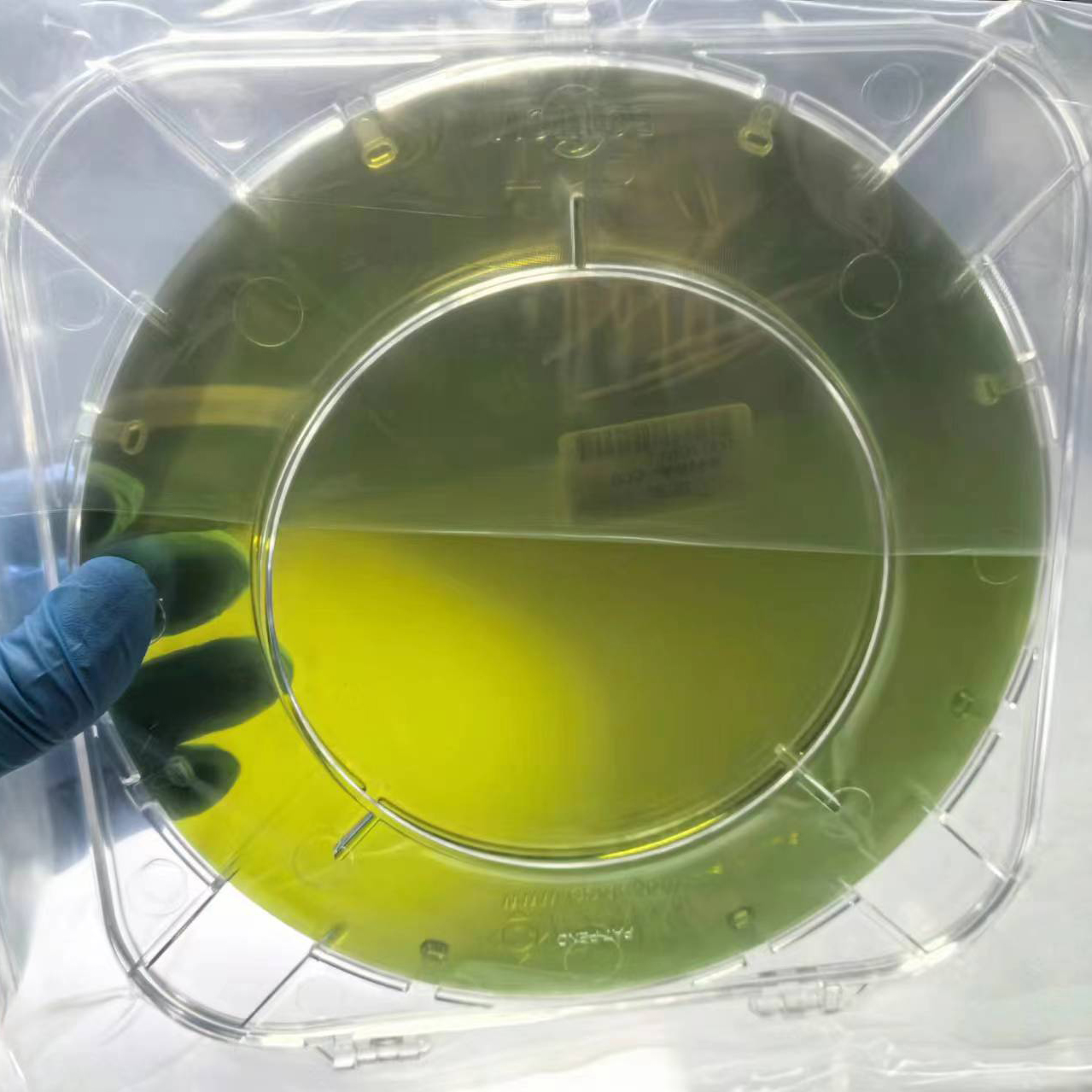

8Inch 200mm 4H-N SiC Wafer Conductive dummy grade research

Ka lebaka la thepa ea eona e ikhethang ea 'mele le ea elektroniki, lisebelisoa tsa 200mm SiC wafer semiconductor li sebelisoa ho theha lisebelisoa tsa elektroniki tse sebetsang hantle, tse phahameng haholo, tse hananang le radiation le tsa maqhubu a phahameng. Theko ea substrate ea 8inch SiC e ntse e fokotseha butle butle ha theknoloji e ntse e tsoela pele le tlhokahalo e ntse e hola. Lintlafatso tsa morao-rao tsa theknoloji li lebisa tlhahisong ea tlhahiso ea li-wafers tsa 200mm SiC. Melemo e ka sehloohong ea lisebelisoa tsa SiC wafer semiconductor ha li bapisoa le li-wafers tsa Si le GaAs: Matla a tšimo ea motlakase a 4H-SiC nakong ea ho senyeha ha leholiotsoana a feta taelo ea boholo bo phahameng ho feta litekanyetso tse tsamaellanang tsa Si le GaAs. Sena se lebisa ho fokotseha ho hoholo ha mohanyetsi oa mmuso oa Ron. Restivity e tlase ea boemo bo tlase, e kopantsoeng le sekhahla se phahameng sa hona joale le conductivity ea mocheso, e lumella tšebeliso ea lisebelisoa tse nyane haholo bakeng sa lisebelisoa tsa motlakase. Mocheso o phahameng oa mocheso oa SiC o fokotsa ho hanyetsa mocheso oa chip. Thepa ea elektronike ea lisebelisoa tse thehiloeng ho li-wafers tsa SiC li tsitsitse haholo ha nako e ntse e ea le ka mocheso o tsitsitseng, e leng se tiisang ho tšepahala ho phahameng ha lihlahisoa. Silicon carbide e hanyetsana haholo le mahlaseli a thata, a sa nyenyefatse thepa ea elektronike ea chip. Mocheso o phahameng oa ho sebetsa oa kristale (ho feta 6000C) o u lumella ho etsa lisebelisoa tse tšepahalang haholo bakeng sa maemo a thata a ts'ebetso le lisebelisoa tse khethehileng. Hajoale, re ka fana ka liphaephe tse nyane tsa 200mmSiC ka mokhoa o tsitsitseng le ka mokhoa o tsoelang pele 'me ra ba le setoko se seng ka ntlong ea polokelo.

Tlhaloso

| Nomoro | Ntho | Yuniti | Tlhahiso | Patlisiso | Dummy |

| 1. Mekhahlelo | |||||

| 1.1 | polytype | -- | 4H | 4H | 4H |

| 1.2 | tshepediso ya bokahodimo | ° | <11-20>4±0.5 | <11-20>4±0.5 | <11-20>4±0.5 |

| 2. Parameter ea motlakase | |||||

| 2.1 | dopant | -- | n-mofuta oa Nitrojene | n-mofuta oa Nitrojene | n-mofuta oa Nitrojene |

| 2.2 | ho hanyetsana | ohm ·cm | 0.015~0.025 | 0.01~0.03 | NA |

| 3. Mechini parameter | |||||

| 3.1 | bophara | mm | 200±0.2 | 200±0.2 | 200±0.2 |

| 3.2 | botenya | μm | 500±25 | 500±25 | 500±25 |

| 3.3 | Notch orientation | ° | [1- 100]±5 | [1- 100]±5 | [1- 100]±5 |

| 3.4 | Botebo ba Notch | mm | 1 ~ 1.5 | 1 ~ 1.5 | 1 ~ 1.5 |

| 3.5 | LTV | μm | ≤5(10mm*10mm) | ≤5(10mm*10mm) | ≤10(10mm*10mm) |

| 3.6 | TTV | μm | ≤10 | ≤10 | ≤15 |

| 3.7 | Inamela | μm | -25 ~ 25 | - 45-45 | - 65-65 |

| 3.8 | Warp | μm | ≤30 | ≤50 | ≤70 |

| 3.9 | AFM | nm | Ra≤0.2 | Ra≤0.2 | Ra≤0.2 |

| 4. Sebopeho | |||||

| 4.1 | boima ba micropipe | e/cm2 | ≤2 | ≤10 | ≤50 |

| 4.2 | dikahare tsa tshepe | liathomo/cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | TSD | e/cm2 | ≤500 | ≤1000 | NA |

| 4.4 | BPD | e/cm2 | ≤2000 | ≤5000 | NA |

| 4.5 | TED | e/cm2 | ≤7000 | ≤10000 | NA |

| 5. Boleng bo botle | |||||

| 5.1 | ka pele | -- | Si | Si | Si |

| 5.2 | pheletso e kahodimo | -- | Si-face CMP | Si-face CMP | Si-face CMP |

| 5.3 | karoloana | sekoahelo | ≤100(boholo≥0.3μm) | NA | NA |

| 5.4 | ngoapa | sekoahelo | ≤5, Kakaretso ea Bolelele≤200mm | NA | NA |

| 5.5 | Qetello li-chips/indents/cracks/ stains/tshilafatso | -- | Ha ho letho | Ha ho letho | NA |

| 5.6 | Libaka tsa polytype | -- | Ha ho letho | Sebaka ≤10% | Sebaka ≤30% |

| 5.7 | tshoao ka pele | -- | Ha ho letho | Ha ho letho | Ha ho letho |

| 6. Morao boleng | |||||

| 6.1 | qetellong qetellong | -- | MP ea sefahleho sa C | MP ea sefahleho sa C | MP ea sefahleho sa C |

| 6.2 | ngoapa | mm | NA | NA | NA |

| 6.3 | Bokooa bo ka morao li-chips/li-indent | -- | Ha ho letho | Ha ho letho | NA |

| 6.4 | Bokhopo ba mokokotlo | nm | Ra≤5 | Ra≤5 | Ra≤5 |

| 6.5 | Ho tšoaea ka morao | -- | Notch | Notch | Notch |

| 7. Ntlheng | |||||

| 7.1 | bohale | -- | Chamfer | Chamfer | Chamfer |

| 8. Sephutheloana | |||||

| 8.1 | phutheloana | -- | Epi-ready with vacuum phutheloana | Epi-ready with vacuum phutheloana | Epi-ready with vacuum phutheloana |

| 8.2 | phutheloana | -- | Multi-wafer sephuthelo sa khasete | Multi-wafer sephuthelo sa khasete | Multi-wafer sephuthelo sa khasete |

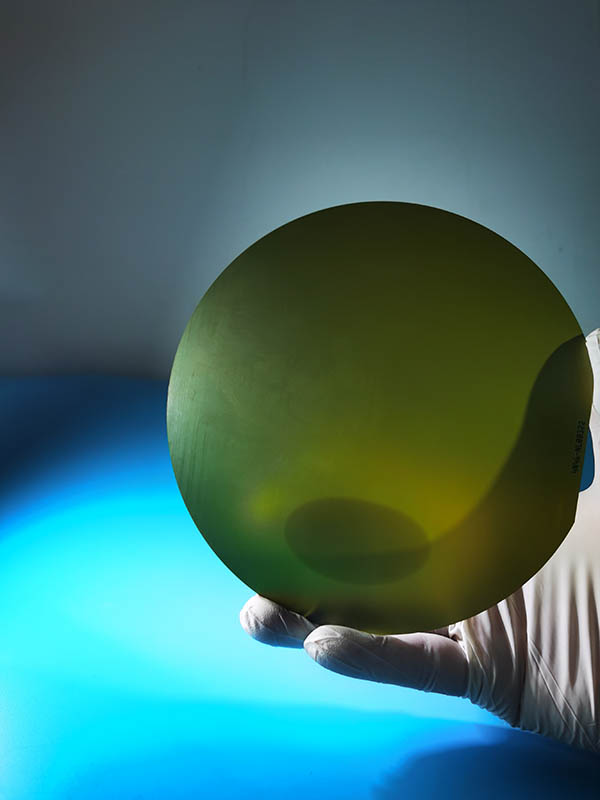

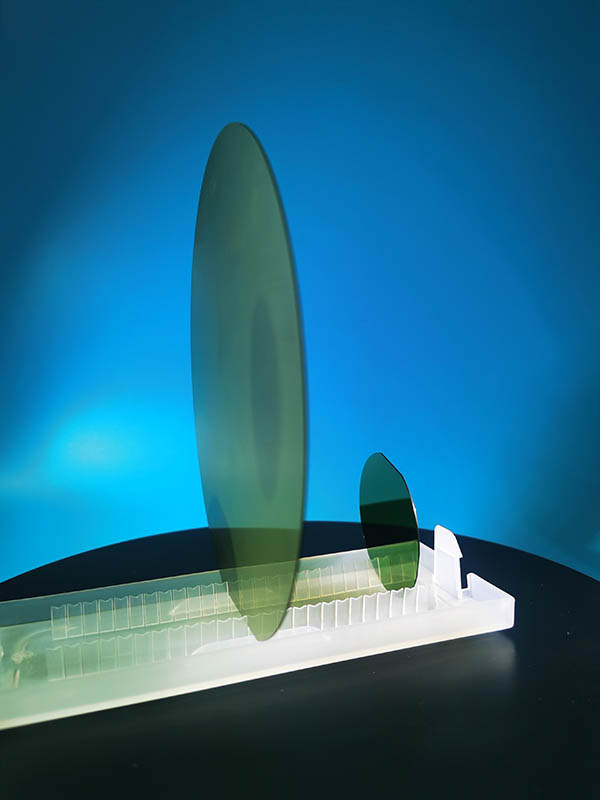

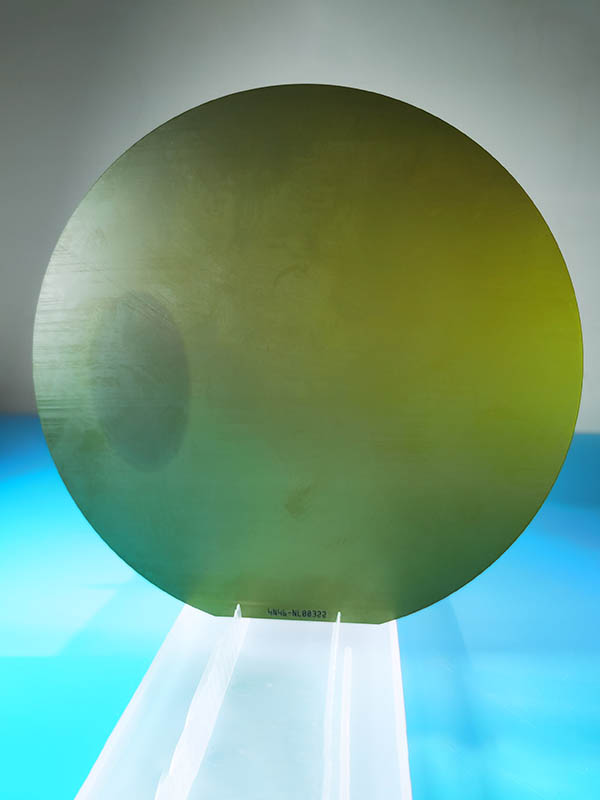

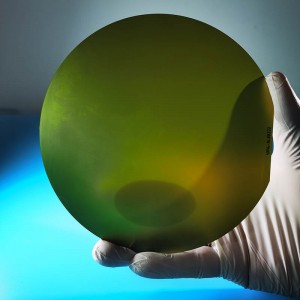

Setšoantšo se qaqileng