Alumina ceramic arm tloaelo Letsoho la robotic la Ceramic

Letsoho la ceramic le hlahisoang ke k'hamphani ea rona le entsoe ka lisebelisoa tse tala tsa ceramic tse hloekileng, tse entsoeng ka ho hatella isostatic, mocheso o phahameng oa sintering le machining a nepahetseng. Ho nepahala ha dimensional ho ka fihla ± 0.001mm, pheletso e ka fihla ho Ra0.1, mme mocheso oa tšebeliso o ka fihla ho 1600 ℃. Khamphani ea rona e sebelisa theknoloji e ikhethang ea bonding ea ceramic, mocheso oa ts'ebeliso ea letsoho le se nang letho ka mor'a hore tlamahano e fihle ho 800 ℃.

Alumina ceramics ke thepa e khethehileng ea ceramic, ka har'a sehlopha sa ceramic ke ceramic e khethehileng, ke ea oxide ceramics, hardness ea eona ea Rockwell ke HRA80-90, boima ba eona ke ea bobeli ho daemane, ho feta ho ts'oaroa ha tšepe e sa keneleng tšepe le tšepe e sa hloekang, boima ba eona ke 3.5g / cm3, e bobebe ho feta tšepe, boima bo bobebe, litšoaneleho tse sa tloaelehang tsa mocheso hammoho le mefuta e mengata ea mocheso. 'me e be lisebelisoa tse sebelisoang ka ho fetisisa tsa ceramic ka oxide ceramics.

Ka ts'ebetso ea mocheso o phahameng oa mocheso, alumina e etsa sebopeho se thata, se ts'oanang sa kristale. Sebopeho sena se e fa boima bo phahameng, ntlha e phahameng ea ho qhibiliha le botsitso bo botle ba lik'hemik'hale. Lihlahisoa tse sebelisoang tšimong ea elektronike li tlameha ho ba le sekhahla se setle, e le ho etsa bonnete ba ho phutha hantle le ho hanyetsa ho apara.

Lefapheng la tlhahiso ea li-micro le nano, boima ba sehlahisoa bo ama ka ho toba khanyetso ea eona ea ho kobeha le ho hanyetsa ho apara. Tabeng ea letsoho la robotiki, sebopeho sa eona se teteaneng sa sintered se e fa matla a flexural a matla le boima bo phahameng. Microstructure ena e nolofalletsa letsoho la mochine ho boloka thepa e tsitsitseng ea mechine libakeng tse sa tšoaneng tse rarahaneng tsa ho sebetsa, ho etsa bonnete ba hore e na le bokhoni bo babatsehang ba ho jara mojaro le ho atolosa haholo bophelo ba eona ba tšebeletso. Ho phaella moo, lihlahisoa tse nang le libopeho tse teteaneng tsa sintered, tse kang matsoho a mechine, li boetse li hlahella ka ho hanyetsa ha tsona, tse ka fokotsang ka katleho monyetla oa ho hlahisa likaroloana nakong ea tšebeliso le ho boloka bohloeki ba tikoloho ea tlhahiso.

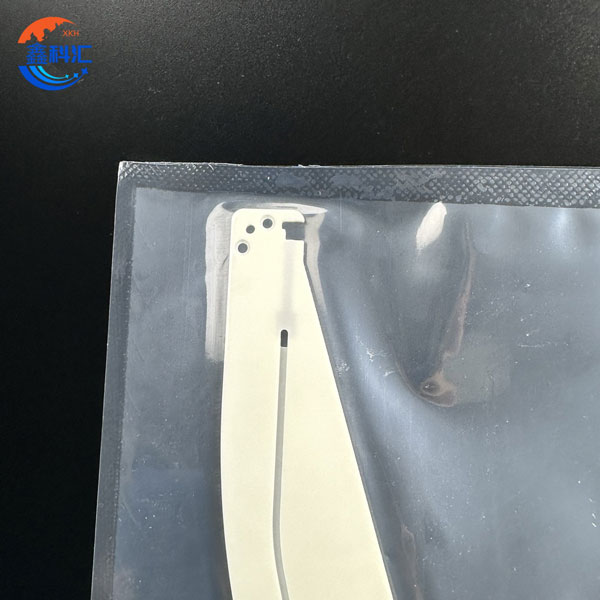

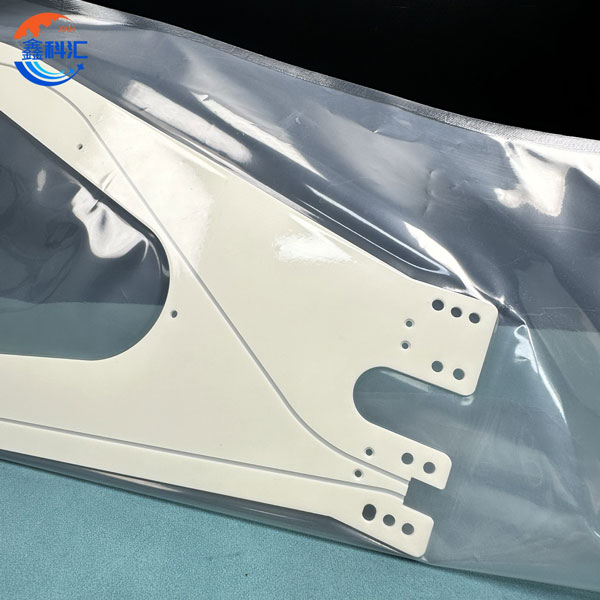

Setšoantšo se qaqileng