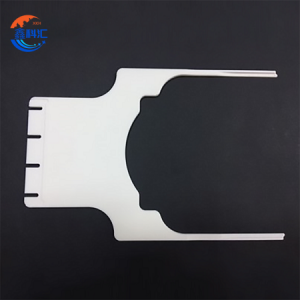

Alumina Ceramic End Effector / Fork Arm bakeng sa Wafer le Substrate Handling

Setšoantšo se qaqileng

Kakaretso ea Alumina Ceramic End Effector

The Alumina Ceramic End Effector, eo hangata e bitsoang letsoho la fork ea ceramic kapa gripper ea ceramic, ke sesebelisoa sa bohlokoa se sebelisoang ho liroboto le mehala ea tlhahiso ea likamore tse hloekileng. Alumina Ceramic End Effector e kentsoe letsohong la robotiki e le sebopeho sa ho qetela le sehlahisoa, se ikarabellang bakeng sa ho khetha, ho ts'oara, ho hokahanya le ho fetisa likarolo tse bobebe tse kang li-wafers tsa silicon, liphanele tsa khalase kapa likarolo tsa microelectronic.

E entsoe ka ultra-pure alumina ceramic (Al2O3), letsoho lena la fereko le fana ka tharollo e khethehileng e hloekileng le e tsitsitseng bakeng sa libaka tseo tšilafalo ea tšepe, deformation ea polasetiki, kapa tlhahiso ea likaroloana e ke keng ea mamelloa.

Thepa Thepa - Hobaneng Alumina

About Alumina Ceramic End Effector,Alumina (Al2O3) ke e 'ngoe ea tse thehiloeng ka ho fetisisa le tse ka tšeptjoang ka ho fetisisa.li-ceramics tsa boenjiniere tse tsoetseng pele. Kereiti eo re e sebelisang (≥99.5% bohloeki) e fana ka motsoako o ikhethang oa litšoaneleho tsa 'mele le tsa lik'hemik'hale tse etsang hore e be thepa ea khetho bakeng sa lisebelisoa tsa semiconductor le vacuum:

-

Bothata bo feteletseng- Ka tekanyo ea boima ba Mohs ea 9, e fana ka ts'ebetso e tšoarellang nako e telele le khanyetso ea pele.

-

Mamello ea mocheso- E boloka botšepehi ba sebopeho ho feta 1600 ° C, litšepe tse sebetsang hantle ka ho fetisisa le li-polymer.

-

Tšireletso ea motlakase- E felisa static buildup mme e fana ka tšireletso e feletseng ea dielectric.

-

Ho itšireletsa ka lik'hemik'hale- Ha e amehe ke li-acids, alkalis, likhase tsa plasma le litharollo tse matla tsa ho hloekisa.

-

Kotsi ea tšoaetso e tlase haholo- Sebaka se sa phekoleheng, se nang le likhohlano tse tlase se fokotsang ho lokolloa ha likaroloana ka likamoreng tse hloekileng.

Litšobotsi tsena li lumella lisebelisoa tsa ho qetela tsa alumina ceramic ho sebetsa ka mokhoa o se nang sekoli libakeng tse thata, tse nepahetseng haholo.

Lisebelisoa tsa mantlha tsa Alumina Ceramic End Effector

Ho feto-fetoha ha matsoho a alumina ceramic end effectorfork ho etsa hore e be tsa bohlokoa liindastering tse ngata tsa theknoloji e phahameng:

-

Sistimi ea lipalangoang tsa semiconductor- Ho tsamaisa li-wafers tsa silicon ka mokhoa o sireletsehileng ho tloha ts'ebetsong ho ea ho ts'ebetso ntle le li-micro-scratches.

-

Tlhahiso ea ponts'o ea phanele e bataletseng- Ho sebetsana le likhalase tse senyehang tsa khalase bakeng sa tlhahiso ea OLED, LCD kapa microLED.

-

Tlhahiso ea Photovoltaic (PV).- E ts'ehetsa ho kenya le ho laolla sephaphatha sa solar tlas'a lipotoloho tsa liroboto tse lebelo haholo.

-

Kopano ea karolo ea Optical le ea elektroniki- Ho tšoara likarolo tse bonojoana joalo ka li-sensor, li-resistors le li-chips tse nyane.

-

Vacuum le mochini o hloekisang oa kamore- Ho etsa mesebetsi e nepahetseng maemong a hloekileng haholo, a laoloang ke likaroloana.

Boemong bo bong le bo bong, Alumina Ceramic End Effector e fana ka sehokelo sa bohlokoa lipakeng tsa boits'oaro ba liroboto le sehlahisoa se sisinyehang.

Likhetho tsa Moralo le Boiketlo ba Alumina Ceramic End Effector

Mohala o mong le o mong oa tlhahiso o na le litlhoko tse ikhethang. Ka hona, re fana ka tharollo ea Alumina Ceramic End Effector e entsoeng ka mokhoa o ikhethileng bakeng sa boholo bo fapaneng ba liphaephe, litsamaiso tsa liroboto le mekhoa ea ho sebetsana:

Khokahano ea Wafer: E tšoara liphaphatha ho tloha ho 2 "ho ea ho 12" 'me e ka fokotsoa bakeng sa likarolo tse tloaelehileng.

Likhetho tsa geometry: Fork e le 'ngoe, fereko e habeli, li-slot tse ngata, kapa libopeho tse ikhethileng tse nang le likheo tse kopaneng.

Ho sebetsana le vacuum: Likanale tsa boikhethelo tsa vacuum tse monyang bakeng sa ts'ehetso ea li-wafer tse se nang mabitso.

Likarolo tse ntseng li eketseha: Likoti tse iketselitsoeng tsa bolt, li-flanges kapa meralo e kentsoeng ho lekana letsoho lefe kapa lefe la robotiki.

Likarolo tse kaholimo: Libaka tse bentšitsoeng kapa tse feliloeng haholo (ho fihla ho Ra <0.15 μm).

Profiles tsa Edge: Methati e chamfer kapa e chitja bakeng sa tšireletso e phahameng ka ho fetisisa.

Sehlopha sa rona sa boenjiniere sa Alumina Ceramic End Effector se ka sebetsa ho tsoa ho lits'oants'o tsa bareki tsa CAD kapa likarolo tsa sampole, ho netefatsa ho hokahana ka mokhoa o se nang moeli ho litsamaiso tse teng tsa othomathike.

Melemo ea Bohlokoa ea Baetsi ba Bofelo ba Alumina Ceramic

| Sebopeho | Lebaka Leo e Leng Bohlokoa |

|---|---|

| Ho nepahala ha dimensional | E boloka teka-tekano e phethahetseng esita le ka lebelo le phahameng, le ipheta-phetang. |

| E sa silafatsang | Ha e hlahise likotoana, e kopana le litlhoko tse tiileng tsa phaposi ea bohloeki. |

| Bopaki ba mocheso le kutu | E mamella mehato e matla ea ts'ebetso le ts'oaetso ea mocheso. |

| Ha ho tefo e tsitsitseng | E sireletsa li-wafers le likaroloana tse tsoang kotsing ea electrostatic. |

| E bobebe empa e thata | E fana ka boima bo phahameng ntle le ho senya letsoho la robotic. |

| Bophelo ba tšebeletso bo atolositsoeng | E feta matsoho a tšepe le a polymer ka nako ea bophelo le ho ts'epahala. |

Thepa Papiso ea Alumina Ceramic End Effector

| Tšobotsi | Letsoho la fereko la polasetiki | Aluminium / Metal Fork Arm | Alumina Ceramic Fork Arm |

|---|---|---|---|

| Ho thatafala | Tlase | Mahareng | Holimo Haholo |

| Thermal Range | ≤ 150°C | ≤ 500°C | Ho fihlela ho 1600°C |

| Botsitso ba Lik'hemik'hale | Mafutsana | E itekanetseng | E kgabane |

| Tekanyo ea Kamore ea Bohloeki | Tlase | Karolelano | E loketse Sehlopha sa 100 kapa ho feta |

| Apara Resistance | Moedi | E ntle | E ikhethang |

| Boemo ba ho Itloaetsa | E itekanetseng | Moedi | E pharaletseng |

Lipotso Tse Botsoang Khafetsa (FAQ) tsa Alumina Ceramic End Effector

Q1: Ke eng e etsang hore phello ea ho qetela ea alumina ceramic e fapane le ea tšepe?

A1:Ho fapana le matsoho a aluminium kapa a tšepe, alumina ceramic ha e senyehe, ha e senyehe, kapa ha e hlahise li-ion tsa tšepe lits'ebetsong tsa semiconductor. E lula e tsitsitse ka mokhoa o itekanetseng tlas'a maemo a feteletseng 'me e ntša hoo e batlang e se na likaroloana.

Q2: Na li-Alumina Ceramic End Effect li ka sebelisoa ka likamoreng tse nang le vacuum e phahameng le ea plasma?

A2:Ee. Alumina ceramic kee sa lahleng'me e hanyetsana le plasma, e etsang hore e be thepa e ratoang bakeng sa lisebelisoa tsa vacuum le etching.

Q3: Matsoho aa a Alumina Ceramic End Effector a ka tloaeleha hakae?

A3:Sehlopha se seng le se seng se ka ba tenge hlophisitsoeng ka botlalo- ho kenyeletsoa sebopeho, li-slots, masoba a hohelang, setaele sa ho hola, le pheletso - ho tsamaisana le litlhoko tsa sistimi ea hau ea liroboto.

Q4: Na lia fokola?

A4:Le ha ceramic e na le brittleness ea tlhaho, boenjiniere ba rona ba moralo bo tsamaisa mojaro ka ho lekana le ho fokotsa lintlha tsa khatello. Ha e sebetsoa ka nepo, hangata bophelo ba ts'ebeletso bo feta ba mefuta e meng ea tšepe kapa ea polymer.

Mabapi le rona

XKH e sebetsa ka ho khetheha ho nts'etsopele ea theknoloji e phahameng, tlhahiso, le thekiso ea likhalase tse khethehileng tsa optical le lisebelisoa tse ncha tsa kristale. Lihlahisoa tsa rona li fana ka lisebelisoa tsa elektroniki tsa optical, lisebelisoa tsa elektroniki tsa bareki le sesole. Re fana ka lisebelisoa tsa mahlo tsa Sapphire, likoahelo tsa lense tsa mohala oa thekeng, Ceramics, LT, Silicon Carbide SIC, Quartz, le liphaphatha tsa kristale tsa semiconductor. Ka boitseanape bo nang le boiphihlelo le lisebelisoa tse tsoetseng pele, re ipabola ts'ebetsong ea lihlahisoa tse sa tloaelehang, ka sepheo sa ho ba khoebo e etelletseng pele ea theknoloji e phahameng ea optoelectronic.