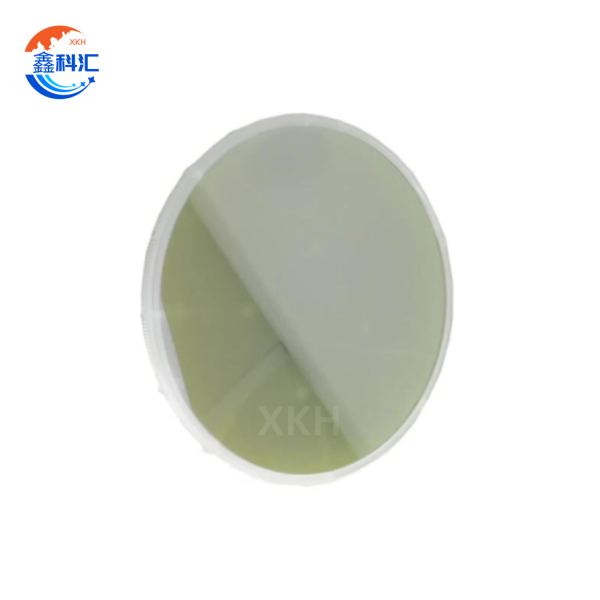

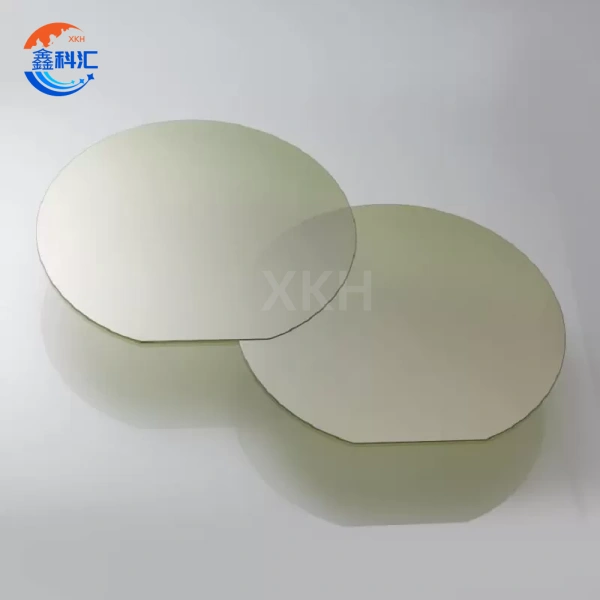

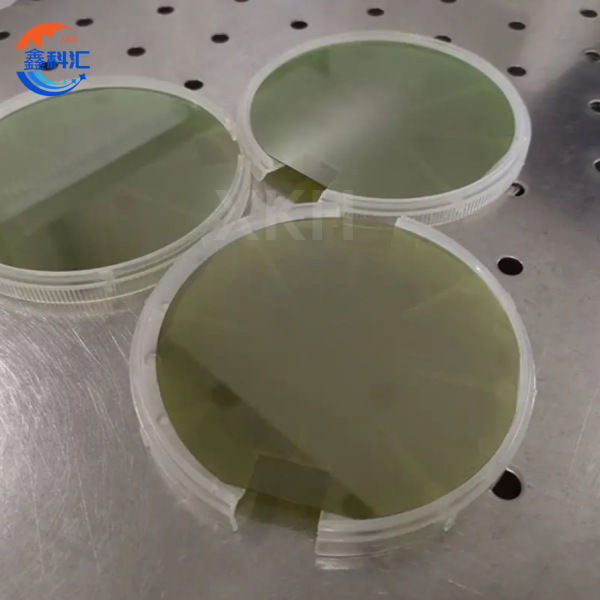

Custom N Type SiC Seed Substrate Dia153/155mm Bakeng sa Motlakase oa Motlakase

Tsebisa

Li-substrates tsa peō tsa Silicon Carbide (SiC) li sebetsa e le lisebelisoa tsa motheo bakeng sa li-semiconductors tsa moloko oa boraro, tse khetholloang ka mokhoa oa tsona o phahameng oa mocheso o phahameng, matla a maholo a ho senyeha ha motlakase, le ho tsamaea ha elektronike e phahameng. Thepa ena e etsa hore e be ea bohlokoa bakeng sa lisebelisoa tsa elektroniki tsa motlakase, lisebelisoa tsa RF, likoloi tsa motlakase (EVs), le lits'ebetso tsa matla a tsosolositsoeng. XKH e sebetsa ka ho khetheha ho R&D le tlhahiso ea likaroloana tsa peo tsa SiC tsa boleng bo holimo, e sebelisa mekhoa e tsoetseng pele ea kholo ea kristale joalo ka Physical Vapor Transport (PVT) le High-Temperature Chemical Vapor Deposition (HTCVD) ho netefatsa boleng ba kristale bo etelletseng pele indastering.

XKH e fana ka likaroloana tsa peo tsa 4-inch, 6-inch, le 8-inch SiC tse nang le doping ea mofuta oa N-type/P, e fihlelang maemo a ho hanyetsa a 0.01-0.1 Ω·cm le densities ea dislocation e ka tlase ho 500 cm⁻², e leng se etsang hore e be tse loketseng bakeng sa ho etsa li-MOSFET, Schottky Barriers Barriers (Schottky Barrier Digital). Ts'ebetso ea rona ea tlhahiso e otlolohileng e akaretsa kholo ea kristale, ho seha liphaephe, ho bentša le ho hlahloba, ka matla a tlhahiso ea khoeli le khoeli a fetang li-wafers tse 5,000 ho fihlela litlhoko tse fapaneng tsa litsi tsa lipatlisiso, baetsi ba li-semiconductor le lik'hamphani tsa matla a ka nchafatsoang.

Ho feta moo, re fana ka litharollo tse ikhethileng, ho kenyelletsa:

Crystal orientation customization (4H-SiC, 6H-SiC)

Doping e khethehileng (Aluminium, Nitrogen, Boron, joalo-joalo)

Pholishe e boreleli haholo (Ra <0.5 nm)

XKH e tšehetsa ts'ebetso e thehiloeng ho lisampole, lipuisano tsa tekheniki, le prototyping ea li-batch tse nyane ho fana ka tharollo e ntlafalitsoeng ea SiC substrate.

Litekanyetso tsa tekheniki

| Sephaphatha sa peo ea silicon carbide | |

| Polytype | 4H |

| Phoso ea ho shebana le bokaholimo | 4° ho leba<11-20>±0.5º |

| Ho hanyetsa | tlhophiso |

| Diameter | 205±0.5mm |

| Botenya | 600±50μm |

| Boqhobane | CMP, Ra≤0.2nm |

| Boima ba Micropipe | ≤1 e/cm2 |

| Mengwapo | ≤5, Bolelele Bohle≤2* Bophara |

| Lits'oants'o / li-indents | Ha ho letho |

| Ho tšoaea ka laser ka pele | Ha ho letho |

| Mengwapo | ≤2, Kakaretso ea Bolelele≤Diameter |

| Lits'oants'o / li-indents | Ha ho letho |

| Libaka tsa polytype | Ha ho letho |

| Ho tšoaea ka morao laser | 1mm (ho tloha pheletsong e ka holimo) |

| Qetello | Chamfer |

| Sephutheloana | Multi-wafer cassette |

SiC Peo Substrates - Litšobotsi tsa Bohlokoa

1. Thepa e Ikhethang ea 'Mele

· Thermal conductivity e phahameng (~ 490 W / m · K), e fetang silicon (Si) haholo le gallium arsenide (GaAs), e leng se etsang hore e be se loketseng bakeng sa ho pholisa sesebelisoa sa matla a phahameng.

· Ho senya matla a tšimo (~ 3 MV / cm), ho nolofalletsa ts'ebetso e tsitsitseng tlas'a maemo a phahameng a motlakase, a bohlokoa bakeng sa li-inverters tsa EV le li-module tsa matla a indasteri.

* Wide bandgap (3.2 eV), ho fokotsa maqhubu a lutla ka mocheso o phahameng le ho matlafatsa ts'epo ea sesebelisoa.

2. Boleng bo phahameng ba Crystalline

· Theknoloji ea kholo e nyalisitsoeng ea PVT + HTCVD e fokotsa mefokolo ea micropipe, e boloka ho teteana ha sebaka se ka tlase ho 500 cm⁻².

· Wafer seqha / warp <10 μm le bokaholimo ba Ra <0.5 nm, ho netefatsa ho lumellana le mekhoa e metle ea lithography le filimi e tšesaane.

3. Likhetho tse fapaneng tsa Doping

·N-mofuta (Nitrogen-doped): Restivity e tlase (0.01-0.02 Ω·cm), e ntlafalitsoeng bakeng sa lisebelisoa tse phahameng tsa RF.

· Mofuta oa P (Aluminium-doped): E loketse bakeng sa li-MOSFET tsa matla le li-IGBT, ho ntlafatsa motsamao oa bajari.

· Semi-insulating SiC (Vanadium-doped): Resistivity > 10⁵ Ω·cm, e etselitsoeng li-module tsa 5G RF tse ka pele.

4. Botsitso ba Tikoloho

· Ho hanyetsa mocheso o phahameng (> 1600°C) le matla a mahlaseli a kotsi, a loketseng sebaka sa sefofane, thepa ea nyutlelie, le libaka tse ling tse feteletseng.

SiC Peo Substrates - Lisebelisoa tsa mantlha

1. Matla a Elektronike

· Likoloi tsa Motlakase (EVs): Li sebelisoa ka har'a li- charger (OBC) le li-inverters ho ntlafatsa ts'ebetso le ho fokotsa litlhoko tsa taolo ea mocheso.

· Mekhoa ea Matla a Liindasteri: E ntlafatsa li-inverters tsa photovoltaic le marang-rang a bohlale, ho finyella> 99% ea katleho ea ho fetola matla.

2. Lisebelisoa tsa RF

· 5G Base Stations: Li-substrates tsa Semi-insulating SiC li nolofalletsa li-amplifiers tsa matla tsa GaN-on-SiC RF, tse tšehetsang phetisetso ea maqhubu a phahameng, a matla a phahameng.

Satellite Communications: Litšobotsi tsa tahlehelo e tlase li etsa hore e tšoanele lisebelisoa tsa millimeter-wave.

3. Matla a Tsosolositsoeng le Polokelo ea Matla

· Matla a Letsatsi: SiC MOSFETs e matlafatsa matla a ho fetolela DC-AC ha a ntse a fokotsa litšenyehelo tsa tsamaiso.

· Energy Storage Systems (ESS): E ntlafatsa li-converter tse fapaneng le ho lelefatsa bophelo ba betri.

4. Tšireletso & Aerospace

· Lits'ebetso tsa Radar: Lisebelisoa tsa SiC tse matla a phahameng li sebelisoa ho lirada tsa AESA (Active Electronically Scanned Array).

· Taolo ea Matla a Sepakapaka: Likaroloana tsa SiC tse hananang le mahlaseli li bohlokoa bakeng sa misio ea sebaka se tebileng.

5. Research & Emerging Technologies

· Quantum Computing: High-purity SiC e nolofalletsa lipatlisiso tsa spin qubit.

· Li-Sensors tsa Mocheso o Phahameng: Li kentsoe tlhahlobong ea oli le ho lekola li-reactor tsa nyutlelie.

SiC Peo Substrates - XKH Services

1. Melemo ea Chain Chain

· Ho etsa lihlahisoa tse kopantsoeng ka ho toba: Taolo e feletseng ho tloha ho phofo ea SiC e hloekileng ho ea ho li-wafers tse phethiloeng, ho netefatsa linako tse etellang pele tsa libeke tsa 4-6 bakeng sa lihlahisoa tse tloaelehileng.

· Phadisano ya ditjeho: Meruo ya sekala e kgontsha 15-20% ditheko tse tlase ho feta bahlodisani, ka tshehetso ya Ditumellano tsa Nako e Telele (LTAs).

2. Litšebeletso tsa Customization

· Crystal orientation: 4H-SiC (e tloaelehileng) kapa 6H-SiC (likopo tse khethehileng).

· Ntlafatso ea li-doping: Lisebelisoa tsa mofuta oa N-type / P-semi-insulating.

· Pholiso e tsoetseng pele: ho bentša CMP le phekolo ea holim'a epi-ready (Ra <0.3 nm).

3. Tšehetso ea Theknoloji

· Teko ea sampole ea mahala: E kenyelletsa litlaleho tsa litekanyetso tsa XRD, AFM, le Hall effect.

· Thuso ea papiso ea sesebelisoa: E tšehetsa kholo ea epitaxial le ntlafatso ea moralo oa sesebelisoa.

4. Karabelo e Potlako

· Prototyping ea molumo o tlase: Bonyane odara ea li-wafers tse 10, tse tlisoang nakong ea libeke tse 3.

· Tsamaiso ea lefats'e: Likamano le DHL le FedEx bakeng sa ho fana ka ntlo le ntlo.

5. Tiisetso ea Boleng

· Tlhahlobo e feletseng ea ts'ebetso: E akaretsa X-ray topography (XRT) le tlhahlobo ea bokooa ba bokooa.

· Litifikeiti tsa machaba: Ho latela maemo a IATF 16949 (automotive-grade) le AEC-Q101.

Qetello

XKH's SiC peō substrates e ipabola ka boleng ba kristale, botsitso ba phepelo ea thepa, le ho feto-fetoha ha maemo, ho fana ka lisebelisoa tsa motlakase, likhokahano tsa 5G, matla a ka nchafatsoang, le mahlale a ts'ireletso. Re tsoela pele ho ntšetsa pele theknoloji ea tlhahiso ea boima ba 8-inch SiC ho ntšetsa pele indasteri ea semiconductor ea moloko oa boraro.