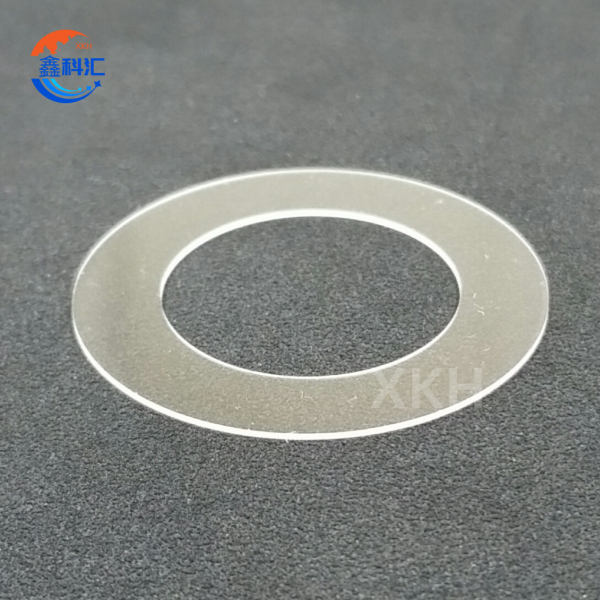

Likarolo tsa Sapphire tse Hlophisitsoeng tsa Shaped Shaped Optical Windows tse nang le Precision Polishing

Litekanyetso tsa tekheniki

| Fensetere ea safire | |

| Boemo | 8-400mm |

| Mamello ya dimensional | +0/-0.05mm |

| Boleng ba bokaholimo(mongoa & cheka) | 40/20 |

| Ho nepahala ha bokaholimo | λ/10per@633nm |

| Aperture e Hlakileng | >85%, ~90% |

| Ho mamellana ka ho tšoana | ±2''-±3'' |

| Bevel | 0.1-0.3mm |

| Ho roala | AR/AF/ka kopo ya moreki |

Likarolo tsa Bohlokoa

1.Material Superiority

· Thepa e ntlafetseng ea Thermal: E bonts'a mocheso oa mocheso oa 35 W / m·K (ho 100 ° C), o nang le coefficient e tlaase ea ho atolosa mocheso (5.3 × 10⁻⁶/K) e thibelang ho senyeha ha optical tlas'a ho palama baesekele e potlakileng ea mocheso. Boitsebiso bo boloka botšepehi ba sebopeho esita le nakong ea phetoho ea mocheso oa mocheso ho tloha ho 1000 ° C ho ea mocheso oa kamore ka metsotsoana.

· Ho tsitsa ha Lik'hemik'hale: E bonts'a ho senyeha ha zero ha e pepesehetse ho concentrated acids (HF e sa kenyelelitsoe) le alkalis (pH 1-14) ka nako e telele, e leng se etsang hore e be se loketseng bakeng sa lisebelisoa tsa ho lokisa lik'hemik'hale.

· Optical Refinement: Ka khōlo e tsoetseng pele ea kristale ea C-axis, e finyella> phetiso ea 85% ka mokhoa o bonahalang (400-700nm) ka tahlehelo ea ho hasanya ka tlase ho 0.1% / cm.

· Ho belisoa ha hyper-hemispherical ka boikhethelo ho fokotsa likhakanyo tsa bokaholimo ho <0.2% sebakeng se le seng ho 1064nm.

2.Bokhoni ba Boenjiniere bo nepahetseng

· Nanoscale Surface Control: Ho sebelisa magnetorheological finishing (MRF), ho finyella ho hlaka holimo <0.3nm Ra, e bohlokoa bakeng sa lisebelisoa tsa laser tse matla haholo moo LIDT e fetang 10J / cm² ho 1064nm, 10ns pulses.

· Complex Geometry Fabrication: E kenyelletsa 5-axis ultrasonic machining bakeng sa ho theha mechine ea microfluidic (50μm bophara ba mamello) le diffractive optical elements (DOE) e nang le <100nm tharollo ea likarolo.

· Metrology Integration: E kopanya interferometry ea khanya e tšoeu le atomic force microscopy (AFM) bakeng sa sebopeho sa bokaholimo ba 3D, ho netefatsa ho nepahala ha foromo <100nm PV ho pholletsa le substrates tse 200mm.

Lisebelisoa tsa mantlha

1. Ntlafatso ea Mekhoa ea Tšireletso

· Hypersonic Vehicle Domes: E etselitsoe ho mamella meroalo ea aerothermal ea Mach 5+ ha e ntse e boloka phetiso ea MWIR bakeng sa lihlooho tsa ba batlang. Litiiso tse khethehileng tsa nanocomposite li thibela delamination tlas'a meroalo ea vibration ea 15G.

· Li-Platform tsa Quantum Sensing: Liphetolelo tsa Ultra-low birefringence (<5nm/cm) li nolofalletsa magnetometry e nepahetseng lits'ebetsong tsa ho lemoha ka tlas'a metsi.

2.Industrial Process Innovation

· Semiconductor Extreme UV Lithography: Lifensetere tse bentšitsoeng tsa Grade AA tse nang le <0.01nm surface roughness li fokotsa tahlehelo ea EUV (13.5nm) e hasanyang litsamaisong tsa stepper.

· Tlhokomelo ea Nuclear Reactor: Mefuta e fapaneng ea Neutron-transparent (Al₂O₃ isotopically purified) e fana ka tlhahlobo ea pono ea nako ea 'nete ho li-cores tsa Gen IV.

3.Emerging Technology Integration

· Space-Based Optical Comms: Liphetolelo tse thatafalitsoeng ke mahlaseli (kamora ho pepeseha ha 1Mrad gamma) li boloka >80% ea phetiso bakeng sa LEO satellite laser crosslinks.

· Li-interfaces tsa Biophotonics: Litlhare tsa Bio-inert li thusa lifensetere tse kentsoeng tsa Raman spectroscopy bakeng sa ho lekola tsoekere e tsoelang pele.

4.Mekhoa e tsoetseng pele ea Matla

· Fusion Reactor Diagnostics: Multi-layer conductive coatings (ITO-AlN) e fana ka pono ea plasma le ts'ireletso ea EMI litsing tsa tokamak.

· Sebopeho sa Hydrogen: Liphetolelo tsa Cryogenic-grade (tse lekiloeng ho 20K) li thibela ho kenngoa ha haedrojene libakeng tsa polokelo tsa metsi tsa H₂.

Lits'ebeletso tsa XKH le Matla a Phepelo

Litšebeletso tsa 1.Custom Manufacturing

· Tloaelo e thehiloeng ho Metako: E ts'ehetsa meralo e sa tloaelehang (1 mm ho isa ho 300 mm litekanyo), thomello e potlakileng ea matsatsi a 20, le prototyping ea lekhetlo la pele nakong ea libeke tse 4.

· Litharollo tsa Coating: Anti-reflection (AR), anti-fouling (AF), le wavelength-specific coatings (UV/IR) ho fokotsa tahlehelo ea ho bonahatsa.

· Ho hloekisoa ka mokhoa o nepahetseng le ho lekoa: Ho belisoa ha boemo ba atomic ho finyella ≤0.5 nm holim'a bokhabane, ka interferometry e netefatsang ho lumellana ha λ/10.

2.Supply Chain & Tšehetso ea Theknoloji

· Khokahano e otlolohileng: Taolo ea ts'ebetso e felletseng ho tloha kholong ea kristale (mokhoa oa Czochralski) ho isa ho seha, ho bentša, le ho roala, ho netefatsa bohloeki ba lintho tse bonahalang (ho se na letho-/ho se na moeli) le ho tsitsa ha batch.

· Tšebelisano-'moho ea indasteri: E netefalitsoe ke borakonteraka ba sepakapaka; e sebelisane le CAS ho nts'etsapele meaho e meholo ea li-heterostructures bakeng sa sebaka sa lehae.

3.Product Portfolio & Logistics

· Sebopeho se tloaelehileng: 6-inch ho isa ho 12-inch wafer formats; litheko tsa yuniti ho tloha ho 43to82 (boholo / bo itšetlehileng ka ho roala), ka thomello ea letsatsi le le leng.

· Therisano ea tekheniki mabapi le meralo e ikhethileng ea ts'ebeliso (mohlala, lifensetere tse nang le litepisi bakeng sa likamore tsa vacuum, meaho e hananang le mocheso oa mocheso).