Seed SiC Seed Crystal Substrates tsa Customized Dia 205/203/208 4H-N Mofuta oa Optical Communications

Litekanyetso tsa tekheniki

Sephaphatha sa peo ea silicon carbide | |

Polytype | 4H |

Phoso ea ho shebana le bokaholimo | 4° ho leba<11-20>±0.5º |

Ho hanyetsa | tlhophiso |

Diameter | 205±0.5mm |

Botenya | 600±50μm |

Boqhobane | CMP, Ra≤0.2nm |

Boima ba Micropipe | ≤1 e/cm2 |

Mengwapo | ≤5, Bolelele Bohle≤2* Bophara |

Lits'oants'o / li-indents | Ha ho letho |

Ho tšoaea ka laser ka pele | Ha ho letho |

Mengwapo | ≤2, Kakaretso ea Bolelele≤Diameter |

Lits'oants'o / li-indents | Ha ho letho |

Libaka tsa polytype | Ha ho letho |

Ho tšoaea ka morao laser | 1mm (ho tloha pheletsong e ka holimo) |

Qetello | Chamfer |

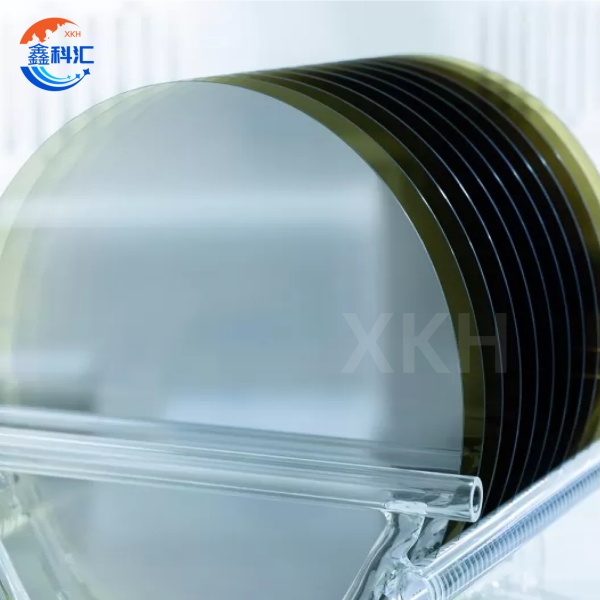

Sephutheloana | Multi-wafer cassette |

Litšobotsi Tsa Sehlooho

1. Sebopeho sa Crystal le Ts'ebetso ea Motlakase

· Crystallographic Stability: 100% 4H-SiC polytype dominance, zero multicrystalline inclusions (mohlala, 6H / 15R), e nang le XRD rocking curve e tletseng bophara ba halofo-maximum (FWHM) ≤32.7 arcsec.

· High Carrier Mobility: Motsamao oa elektrone oa 5,400 cm²/V·s (4H-SiC) le motsamao oa masoba a 380 cm²/V·s, o nolofalletsang meralo ea lisebelisoa tsa maqhubu a holimo.

·Radiation Hardness: E mamella mabone a 1 MeV a neutron a nang le moeli oa ts'enyo ea phalliso ea 1×10¹⁵ n/cm², e loketseng sebaka sa sefofane le lisebelisoa tsa nyutlelie.

2. Thermal le Mechanical Thepa

· Exceptional Thermal Conductivity: 4.9 W/cm·K (4H-SiC), tse tharo tsa silicon, ts'ebetso e tšehetsang ka holimo ho 200 ° C.

· Mocheso o Motla oa Katoloso ea Mocheso: CTE ea 4.0 × 10⁻⁶/K (25-1000 ° C), ho netefatsa ho lumellana le liphutheloana tse thehiloeng ka silicon le ho fokotsa khatello ea mocheso.

3. Taolo ea Bofokoli le Ts'ebetso e nepahetseng

· Boima ba Micropipe: <0.3 cm⁻² (li-wafers tse 8-inch), density deslocation <1,000 cm⁻² (e netefalitsoe ka KOH etching).

· Boleng ba Bokahohle: CMP e bentšitsoe ho Ra <0.2 nm, e finyella litlhoko tsa EUV lithography-grade flatness.

Lisebelisoa tsa Bohlokoa

| Domain | Scenarios ea Kopo | Melemo ea Technical |

| Lipuisano tsa Optical | 100G/400G lasers, silicon photonics hybrid modules | Li-substrates tsa peo ea InP li nolofalletsa sehlopha se otlolohileng (1.34 eV) le Si-based heteroepitaxy, ho fokotsa tahlehelo ea ho kopanya mahlo. |

| Likoloi tse Ncha tsa Matla | Li-inverters tse phahameng tsa 800V, li-charger tsa onboard (OBC) | Li-substrates tsa 4H-SiC li mamella> 1,200 V, li fokotsa tahlehelo ea conduction ka 50% le bophahamo ba tsamaiso ka 40%. |

| 5G Communications | Lisebelisoa tsa RF tsa millimeter-wave (PA/LNA), li-amplifiers tsa motlakase tsa setsi sa motheo | Semi-insulating SiC substrates (resistivity >10⁵ Ω·cm) e thusa ho kopanya maqhubu a phahameng (60 GHz+). |

| Lisebelisoa tsa Indasteri | Li-sensor tsa mocheso o phahameng, li-transformer tsa hajoale, li-monitor tsa reactor ea nyutlelie | Li-substrates tsa peo ea InSb (0.17 eV bandgap) li fana ka maikutlo a khoheli ho fihla ho 300%@10 T. |

Melemo ea Bohlokoa

Li-crystal substrates tsa SiC (silicon carbide) li fana ka ts'ebetso e ke keng ea lekanngoa le 4.9 W / cm·K conductivity ea mocheso, 2-4 MV / cm matla a masimo a ho senya, le 3.2 eV bandgap e pharaletseng, e nolofalletsang matla a phahameng, maqhubu a phahameng le mocheso o phahameng. E na le "zero micropipe density" le <1,000 cm⁻² dislocation density, substrates tsena li netefatsa ho ts'epahala maemong a feteletseng. Lik'hemik'hale tsa bona tsa lik'hemik'hale le libaka tse lumellanang le CVD (Ra <0.2 nm) li tšehetsa khōlo e tsoetseng pele ea heteroepitaxial (mohlala, SiC-on-Si) bakeng sa lisebelisoa tsa matla a optoelectronics le EV.

Litšebeletso tsa XKH:

1. Tlhahiso e ikhethileng

· Flexible Wafer Formats: 2–12-inch wafers tse nang le selikalikoe, khutlonnetsepa, kapa likheo tsa sebopeho sa tloaelo (± 0.01 mm mamello).

· Taolo ea Doping: Naetrojene e nepahetseng (N) le aluminium (Al) doping ka CVD, ho finyella methati ea ho hanyetsa ho tloha ho 10⁻³ ho ea ho 10⁶ Ω·cm.

2. Mekhoa e tsoetseng pele ea Ts'ebetso.

· Heteroepitaxy: SiC-on-Si (e lumellana le melapo ea silicon ea 8-inch) le SiC-on-Diamond (conductivity ea mocheso> 2,000 W / m · K).

Ho Fokotsa Bofokoli: Ho tšeka ha haedrojene le ho annaaling ho fokotsa bofokoli ba micropipe/density, ho ntlafatsa chai ea liphaephe ho fihla ho >95%.

3. Mekhoa ea Tsamaiso ea Boleng.

· Tlhahlobo ea ho Qetela: Raman spectroscopy (polytype verification), XRD (crystallinity), le SEM (tlhahlobo ea bofokoli).

· Litifikeiti: E lumellana le AEC-Q101 (likoloi), JEDEC (JEDEC-033), le MIL-PRF-38534 (sesole sa boemo ba sesole).

4. Tšehetso ea Global Supply Chain.

· Bokhoni ba Tlhahiso: Phallo ea khoeli le khoeli> li-wafers tse 10,000 (60% 8-inch), tse nang le phano ea tšohanyetso ea lihora tse 48.

· Logistics Network: Kakaretso Europe, Amerika Leboea, le Asia-Pacific ka thepa ea moea/ea leoatle e nang le liphutheloana tse laoloang ke mocheso.

5. Theknoloji Co-Development.

· Li-Labs tse Kopanetsoeng tsa R&D: Sebelisana 'moho ho ntlafatsa mojule oa matla oa SiC (mohlala, kopanyo ea karoloana ea DBC).

· IP Licensing: Fana ka laesense ea GaN-on-SiC RF epitaxial growth technology ho fokotsa litšenyehelo tsa R&D tsa bareki.

Kakaretso

Li-crystal substrates tsa SiC (silicon carbide), joalo ka lisebelisoa tsa maano, li nchafatsa liketane tsa indasteri ea lefats'e ka katleho ea kholo ea kristale, taolo ea bofokoli le kopanyo e fapaneng. Ka ho tsoela pele ho ntlafatsa phokotso ea sekoli, ho eketsa tlhahiso ea 8-inch, le ho holisa li-platform tsa heteroepitaxial (mohlala, SiC-on-Diamond), XKH e fana ka litharollo tse tšepahalang, tse theko e tlaase bakeng sa optoelectronics, matla a macha le tlhahiso e tsoetseng pele. Boitlamo ba rona ho boqapi bo netefatsa hore bareki ba etella pele ho se nke lehlakore ka har'a khabone le lits'ebetso tse bohlale, ho tsamaisa nako e latelang ea li-bandgap semiconductor ecosystems.