Mokhoa oa CVD oa ho hlahisa lisebelisoa tse tala tsa SiC ka har'a sebōpi sa silicon carbide synthesis ho 1600 ℃.

Molao-motheo oa tshebetso:

1. Phepelo ea pele. Mohloli oa silicon (mohlala, SiH₄) le mohloli oa carbon (mohlala, C₃H₈) likhase li tsoakoa ka tekanyo 'me li kenngoa ka kamoreng ea ho arabela.

2. Ho senyeha ha mocheso o phahameng: Ka mocheso o phahameng oa 1500 ~ 2300 ℃, ho senyeha ha khase ho hlahisa liathomo tse sebetsang tsa Si le C.

3. Boitšoaro ba bokaholimo: Liathomo tsa Si le C li behiloe holim'a substrate ho etsa lera la kristale la SiC.

4. Khōlo ea Crystal: Ka taolo ea mocheso oa mocheso, phallo ea khase le khatello, ho finyella kholo ea tataiso ho latela c axis kapa axis.

Lintlha tsa bohlokoa:

· Mocheso: 1600 ~ 2200 ℃ (> 2000 ℃ bakeng sa 4H-SiC)

Khatello: 50 ~ 200mbar (khatello e tlase ea ho fokotsa nucleation ea khase)

· Karo-karolelano ea khase: Si/C≈1.0~1.2 (ho qoba liphoso tsa ntlafatso ea Si kapa C)

Lintlha tse ka sehloohong:

(1) Boleng ba kristale

Bophahamo bo tlase: boima ba microtubule <0.5cm ⁻², botenya ba ho kheloha <10⁴ cm⁻².

Taolo ea mofuta oa Polycrystalline: e ka hōla 4H-SiC (ka sehloohong), 6H-SiC, 3C-SiC le mefuta e meng ea kristale.

(2) Ts'ebetso ea lisebelisoa

Botsitso bo phahameng ba mocheso: ho futhumala ha graphite kapa ho futhumatsa ho hanyetsa, mocheso> 2300 ℃.

Taolo ea ho tšoana: ho feto-fetoha ha mocheso ± 5 ℃, sekhahla sa kholo 10 ~ 50μm/h.

Sisteme ea khase: Phallo e phahameng ea boima bo nepahetseng (MFC), bohloeki ba khase ≥99.999%.

(3) Melemo ea theknoloji

Bohloeki bo phahameng: Tšisinyeho ea litšila e ka morao <10¹⁶ cm⁻³ (N, B, joalo-joalo).

Boholo bo boholo: Tšehetsa kholo ea substrate ea 6 "/8" SiC.

(4) Tšebeliso ea matla le litšenyehelo

Tšebeliso e phahameng ea matla (200 ~ 500kW · h ka sebōpi), e ikarabellang bakeng sa 30% ~ 50% ea litšenyehelo tsa tlhahiso ea SiC substrate.

Lisebelisoa tsa mantlha:

1. Power semiconductor substrate: SiC MOSFETs bakeng sa ho etsa likoloi tsa motlakase le li-inverters tsa photovoltaic.

2. Sesebelisoa sa Rf: 5G setsi sa setsi sa GaN-on-SiC epitaxial substrate.

3.Disebediswa tsa tikoloho tse feteletseng: disensara tsa mocheso o phahameng bakeng sa sepakapaka le dipolante tsa matla a nyutlelie.

Tlhaloso ea tekheniki:

| Tlhaloso | Lintlha |

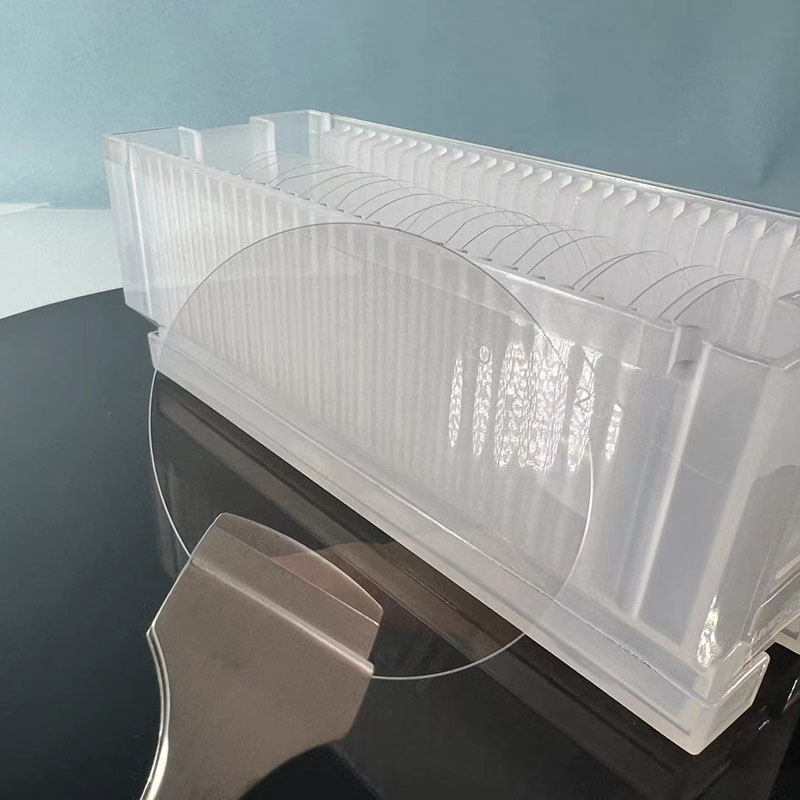

| Litekanyo (L × W × H) | 4000 x 3400 x 4300 limilimithara kapa u iketsetse khetho |

| Bophara ba kamore ea sebōpi | 1100mm |

| Bokhoni ba ho kenya | 50kg |

| Moeli oa vacuum degree | 10-2Pa (2h ka mor'a hore pompo ea molek'hule e qale) |

| Sekhahla sa khatello ea kamore | ≤10Pa/h(kamora calcination) |

| Sekoahelo se ka tlase sa sebōpi se phahamisang stroke | 1500 limilimithara |

| Mokhoa oa ho futhumatsa | Ho futhumatsa ho kenya letsoho |

| Mocheso o phahameng ka ho fetisisa seboping | 2400°C |

| Phepelo ea matla a futhumatsang | 2X40kW |

| Tekanyo ea mocheso | Tekanyo ea mocheso oa infrared ea mebala e 'meli |

| Boemo ba mocheso | 900 ~ 3000 ℃ |

| Ho nepahala ha taolo ea mocheso | ±1°C |

| Laola khatello e fapaneng | 1 ~ 700 mr |

| Ho Nepaha ha Taolo ea Khatello | 1 ~ 5mbar ± 0.1mbar; 5 ~ 100mbar ± 0.2mbar; 100 ~ 700mbar ± 0.5mbar |

| Ho kenya mokhoa | Tlaase loading; |

| Phetoho ea boikhethelo | Sebaka sa ho lekanya mocheso habeli, forklift ea ho theola. |

Litšebeletso tsa XKH:

XKH e fana ka lits'ebeletso tse felletseng bakeng sa libono tsa silicon carbide CVD, ho kenyeletsoa mokhoa oa ho etsa thepa (mocheso oa libaka, moralo oa tsamaiso ea khase), nts'etsopele ea ts'ebetso (taolo ea kristale, ts'ebetso ea sekoli), koetliso ea botekgeniki (ts'ebetso le tlhokomelo) le ts'ehetso ea morao-rao ea thekiso (likarolo tse ling tsa phepelo ea likarolo tsa bohlokoa, tlhahlobo e hole) ho thusa bareki ho fihlela tlhahiso ea boima ba SiC substrate ea boleng bo holimo. Le ho fana ka lits'ebeletso tsa ntlafatso ea ts'ebetso ho tsoela pele ho ntlafatsa chai ea kristale le katleho ea kholo.