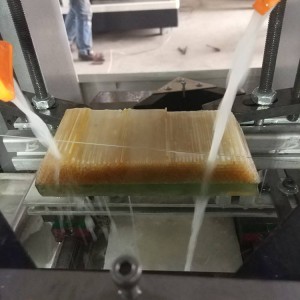

Diamond Wire Three-Station Three-Wire Setting Machine bakeng sa Si Wafer/Optical Glass Cutting Material Cutting

Kenyelletso ea Sehlahisoa

Mochini oa ho itšeha oa terata ea liteishene tse tharo tsa terata e le 'ngoe ke sesebelisoa sa ho itšeha se phahameng se nepahetseng le se phahameng se etselitsoeng lisebelisoa tse thata le tse brittle. E sebelisa terata ea daemane joalo ka mokhoa oa ho seha 'me e loketse ts'ebetso e nepahetseng ea lisebelisoa tse thata haholo joalo ka li-wafers tsa silicon, safire, silicon carbide (SiC), lirafshoa le likhalase tsa optical. E na le moqapi oa liteishene tse tharo, mochine ona o nolofalletsa ho khaola lisebelisoa tse ngata ka nako e le 'ngoe ka sesebelisoa se le seng, ho ntlafatsa haholo katleho ea tlhahiso le ho fokotsa litšenyehelo tsa tlhahiso.

Molao-motheo oa ho Sebetsa

- Diamond Wire Cutting: E sebelisa terata ea daemane e kentsoeng ka motlakase kapa e tlanngoeng ka resin ho etsa seha se thehiloeng ho sila ka motsamao oa lebelo le phahameng.

- Three-Station Synchronous Cutting: E na le li-workstations tse tharo tse ikemetseng, tse lumellang ho seha likotoana tse tharo ka nako e le 'ngoe ho ntlafatsa ts'ebetso.

- Taolo ea Tension: E kenyelletsa mokhoa o phahameng oa ho laola tsitsipano ho boloka tsitsipano e tsitsitseng ea terata ea daemane nakong ea ho itšeha, ho netefatsa ho nepahala.

- Sistimi ea ho Pholisa le ho Lubrication: E sebelisa metsi a silafalitsoeng kapa sepholisa se khethehileng ho fokotsa tšenyo ea mocheso le ho lelefatsa bophelo ba terata ea taemane.

Lisebelisoa

- Ho itšeha ka nepo e phahameng: Ho fihlella ho nepahala ha ± 0.02mm, ho loketse bakeng sa ts'ebetso ea li-wafer tse tšesaane haholo (mohlala, liphaephe tsa silicon tsa photovoltaic, liphaephe tsa semiconductor).

- Sebetsa se Phahameng: Moralo oa liteishene tse tharo o eketsa tlhahiso ka 200% ha e bapisoa le mechini ea seteishene se le seng.

- Tahlehelo e Tlase ea Lintho: Moralo o moqotetsane oa kerf (0.1-0.2mm) o fokotsa litšila tsa thepa.

- High Automation: E na le lisebelisoa tsa ho jarolla ka ho iketsa, ho tsamaisana, ho itšeha le ho theola litsamaiso, ho fokotsa ho kenella ka letsoho.

- Ho ikamahanya le maemo ho phahameng: E khona ho seha lisebelisoa tse fapaneng tse thata le tse brittle, ho kenyelletsa silicon ea monocrystalline, silicon ea polycrystalline, safire, SiC, le lirafshoa.

Melemo ea Setsebi

| Molemo

| Tlhaloso

|

| Multi-Station Synchronous Cutting

| Liteishene tse tharo tse laoloang ka boikemelo li thusa ho seha li-workpieces tse nang le botenya kapa thepa e fapaneng, ho ntlafatsa ts'ebeliso ea lisebelisoa.

|

| Bohlale Taolo ea Khatello

| Taolo e koetsoeng e nang le li-motor tsa servo le li-sensor e netefatsa tsitsipano e sa feleng ea mohala, e thibela ho robeha kapa ho kheloha.

|

| Sebopeho se thata haholo

| Litaelo tse nepahetseng tse phahameng le lits'ebetso tse tsamaisoang ke servo li netefatsa ho itšeha ho tsitsitseng le ho fokotsa litlamorao tsa vibrate.

|

| Katleho ea Matla le Eco-Friendliness

| Ha ho bapisoa le mokhoa oa khale oa ho seha seretse, ho seha terata ea litaemane ha ho na tšilafalo, 'me se pholisang se ka sebelisoa hape, ho fokotsa litšenyehelo tsa ho hloekisa litšila.

|

| Tlhokomelo e Bohlale

| E na le PLC le litsamaiso tsa taolo ea li-touch-screen bakeng sa ho lekola nako ea 'nete ea lebelo la ho itšeha, tsitsipano, mocheso le liparamente tse ling, tse tšehetsang ho lateloa ha data. |

Tlhaloso ea Setsebi

| Mohlala | Mochini o sehang oa line ea litaemane tse tharo |

| Boholo ba boholo ba workpiece | 600 * 600mm |

| Lebelo la terata | 1000 (MIX) m/min |

| Diamond terata bophara | 0.25-0.48mm |

| Mohala oa polokelo ea mohala oa lebili la phepelo | 20km |

| Sekhahla sa botenya | 0-600 limilimithara |

| Ho seha ho nepahala | 0.01 limilimithara |

| E otlolohileng e phahamisa sekhahla sa setsi sa mosebetsi | 800 limilimithara |

| Mokhoa oa ho khaola | Thepa e eme, 'me terata ea daemane e thekesela le ho theoha |

| Ho fokotsa lebelo la phepelo | 0.01-10mm/min (Ho ea ka thepa le botenya) |

| Tanka ea metsi | 150L |

| Mokelikeli o sehang | Mokelikeli o thibelang mafome o sebetsang hantle haholo |

| Swing angle | ±10° |

| Lebelo la ho sisinyeha | 25°/s |

| Khatello e phahameng ea ho itšeha | 88.0N (Beha bonyane yuniti0.1n) |

| Botebo ba ho seha | 200-600 limilimithara |

| Etsa lipoleiti tse tsamaellanang ho ea ka mefuta ea ho itšeha ea moreki | - |

| Setsi sa mosebetsi | 3 |

| Phepelo ea motlakase | Mehato e meraro ea terata ea AC380V/50Hz |

| Kakaretso ea matla a sesebelisoa sa mochini | ≤32kw |

| Enjene e ka sehloohong | 1*2kw |

| Wiring motor | 1*2kw |

| Workbench swing motor | 0.4*6kw |

| Enjene ea taolo ea tsitsipano | 4.4*2kw |

| Mohala oa ho lokolla le ho bokella motlakase | 5.5*2kw |

| Litekanyo tsa kantle (ntle le lebokose la letsoho la rocker) | 4859*2190*2184mm |

| Litekanyo tsa kantle (ho kenyeletsoa lebokose la letsoho la rocker) | 4859*2190*2184mm |

| Boima ba mochini | 3600ka |

Libaka tsa Kopo

- Indasteri ea Photovoltaic: Ho khaoha ha li-ingots tsa silicon tsa monocrystalline le polycrystalline ho ntlafatsa chai e ngata.

- Indasteri ea Semiconductor: Ho itšeha ka nepo ha li-wafers tsa SiC le GaN.

- Indasteri ea LED: Ho seha li-sapphire substrates bakeng sa tlhahiso ea LED chip.

- Li-Ceramics tse tsoetseng pele: Ho theha le ho seha lirafshoa tse sebetsang hantle joalo ka alumina le silicon nitride.

- Glass ea Optical: Ho sebetsa ka nepo ha khalase e tšesaane haholo bakeng sa lilense tsa khamera le lifensetere tsa infrared.