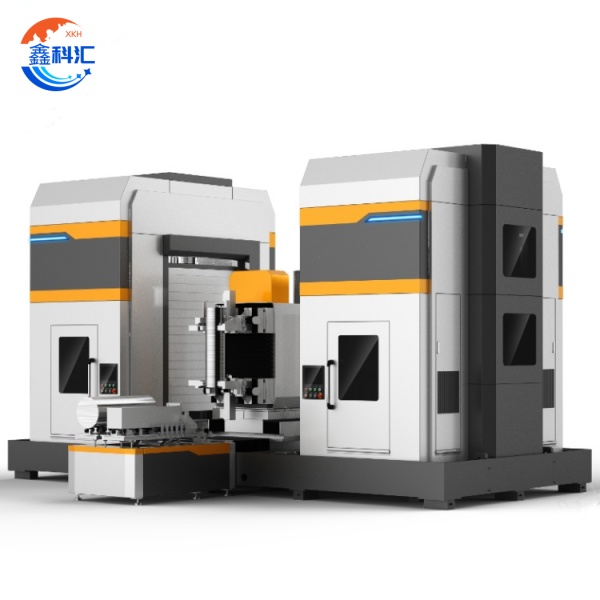

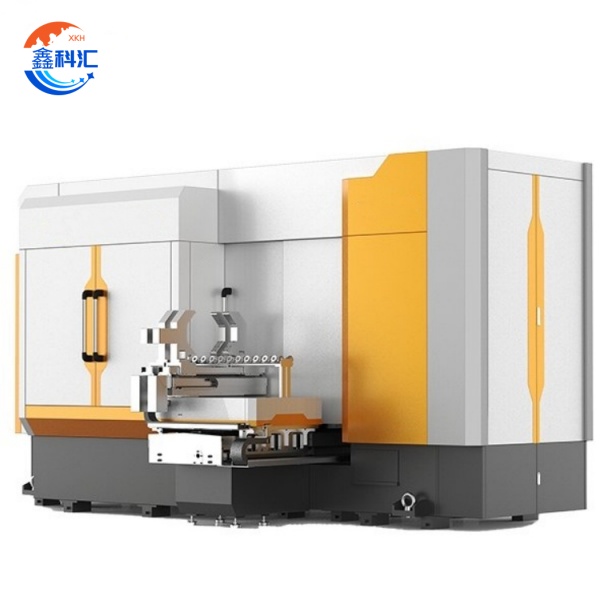

Mochini o habeli oa lisekoere mochini oa monocrystalline silicon rod process 6/8/12 inch surface flatness Ra≤0.5μm

Litšobotsi tsa lisebelisoa:

(1) Double station synchronous processing

· Ho sebetsa ka makhetlo a mabeli: Ho sebetsa ka nako e le 'ngoe ha lithupa tse peli tsa silicon (Ø6"-12") ho eketsa tlhahiso ka 40% -60% khahlanong le lisebelisoa tsa Simplex.

· Taolo e ikemetseng: Seteishene se seng le se seng se ka ikemela ka mokhoa o ikemetseng ho fetola litekanyo tsa ho itšeha (khatello, lebelo la phepelo) ho ikamahanya le lintlha tse fapaneng tsa molamu oa silicon.

(2) Ho itšeha ka mokhoa o phahameng

· Ho nepahala ha dimensional: mamello ea lisekoere tsa mahlakore a lisekoere ± 0.15mm, mefuta ≤0.20mm.

· Boleng ba bokaholimo: ho robeha ha sekhahla <0.5mm, fokotsa palo ea ho sila ka mor'a moo.

(3) Taolo e bohlale

· Ho itšeha ka mokhoa o itekanetseng: ho lekola ka nako ea 'nete ea silicon rod morphology, phetoho e matla ea tsela ea ho itšeha (joalo ka ho lokisa molamu o kobehileng oa silicon).

* Ts'ebetso ea data: rekota liparamente tsa ts'ebetso ea molamu o mong le o mong oa silicon ho ts'ehetsa tsamaiso ea MES.

(4) Theko e tlaase e ka sebelisoang

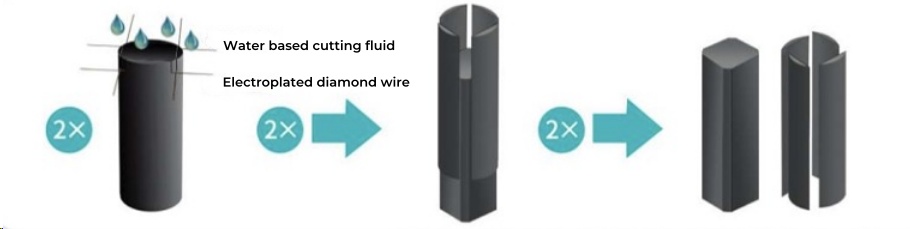

· Tšebeliso ea terata ea Diamond: ≤0.06m/mm (bolelele ba molamu oa silicon), bophara ba terata ≤0.30mm.

· Ho potoloha ha metsi a pholileng: Sistimi ea ho hloekisa e lelefatsa bophelo ba ts'ebeletso mme e fokotsa ho lahla litšila.

Theknoloji le melemo ea nts'etsopele:

(1) Ho fokotsa optimization ea theknoloji

- Ho itšeha ka mela e mengata: 100-200 mela ea litaemane e sebelisoa ka tsela e tšoanang, 'me lebelo la ho itšeha ke ≥40mm / min.

- Taolo ea tsitsipano: Sistimi e koetsoeng ea ho lokisa loop (± 1N) ho fokotsa kotsi ea ho robeha ha terata.

(2) Katoloso ea ho lumellana

- Ho ikamahanya le lintho tse bonahalang: Tšehetsa silicon ea mofuta oa P-mofuta / N-monocrystalline, e lumellanang le TOPCon, HJT le lithupa tse ling tsa silicon tse sebetsang hantle haholo.

- Boholo bo feto-fetohang: bolelele ba molamu oa silicon ke 100-950mm, sebaka sa 166-233mm se ka fetolehang.

(3) Ntlafatso ea boiketsetso

- Ho kenya le ho laolla roboto: ho kenya / ho laolla melamu ea silicon, otla metsotso e ≤3.

- Tlhahlobo e bohlale: Tlhokomelo e boletsoeng esale pele ho fokotsa nako e sa reroang.

(4) Boetapele ba indasteri

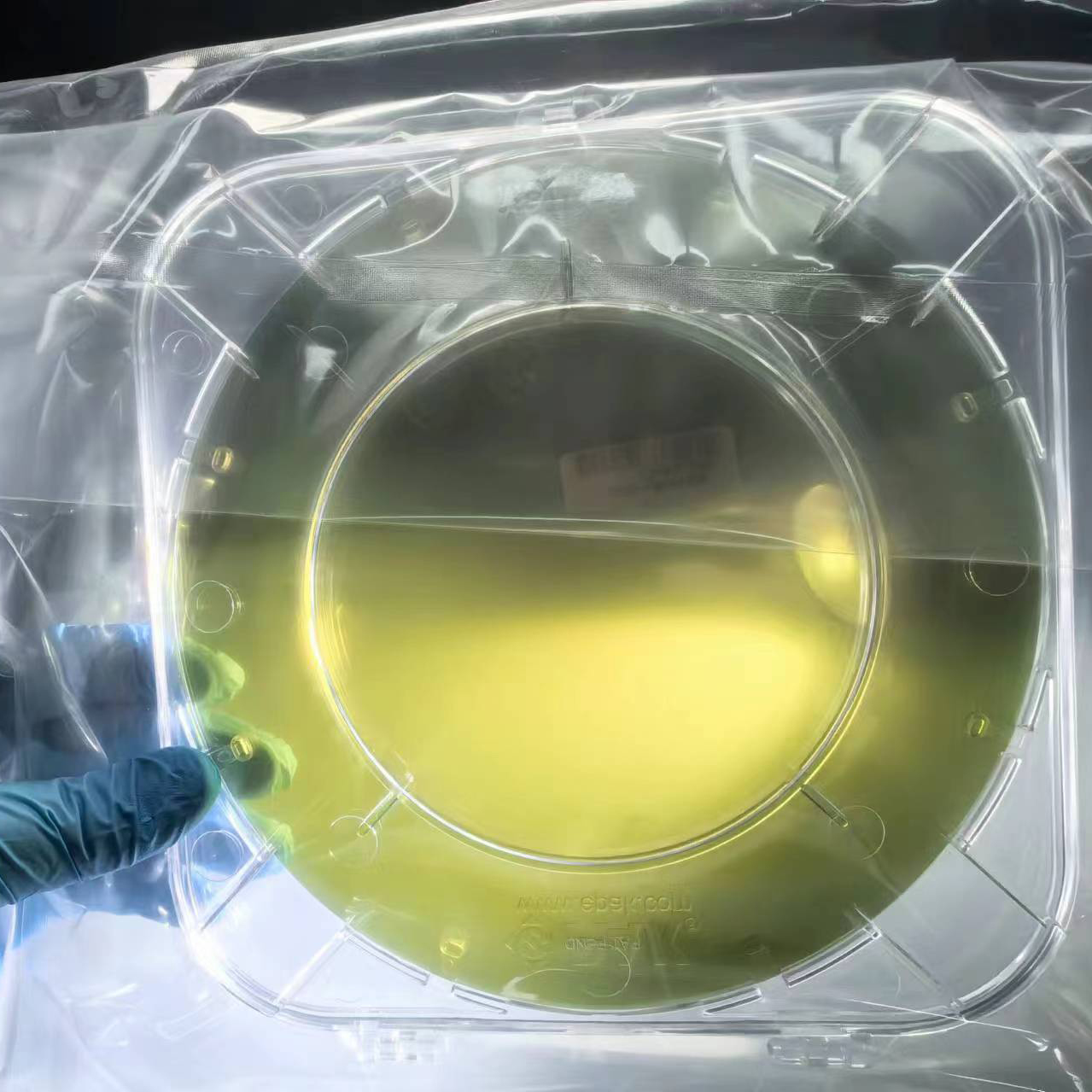

- Tšehetso ea Wafer: e ka sebetsana le ≥100μm silicon e tšesaane haholo ka melamu e sekoere, sekhahla sa ho arohana <0.5%.

- Ntlafatso ea tšebeliso ea matla: Tšebeliso ea matla ka unit e 'ngoe ea molamu oa silicon e fokotsehile ka 30% (ha e bapisoa le lisebelisoa tsa setso).

Litekanyetso tsa tekheniki:

| Lebitso la parameter | Boleng ba index |

| Palo ea mekoallo e sebetsitsoeng | 2 likotoana/sete |

| Sebaka sa bolelele ba ho sebetsa | 100-950 limilimithara |

| Sebaka sa marang-rang sa mochini | 166-233 limilimithara |

| Ho poma lebelo | ≥40mm/mots |

| Lebelo la terata ea daemane | 0~35m/s |

| Diaemane bophara | 0.30 limilimithara kapa ka tlase |

| Tšebeliso ea linear | 0.06 m/mm kapa ka tlase ho moo |

| Bophara ba molamu o chitja o lumellanang | E phethiloe bophara ba molamu oa lisekoere +2mm, Etsa bonnete ba hore sekhahla sa ho feta sa polishing |

| Taolo ea ho robeha ka sekhahla | Moeli o motala ≤0.5mm, Ha ho na ho phunya, boleng bo holimo |

| Arc bolelele bo ts'oanang | Sebaka sa projeke <1.5mm, Ntle le ho sotha molamu oa silicon |

| Litekanyo tsa mochini (mochini o le mong) | 4800×3020×3660mm |

| Kakaretso ea matla a lekantsoeng | 56kW |

| Boima bo shoeleng ba lisebelisoa | 12t |

Tafole ea index ea ho nepahala ha mochini:

| Ntho e nepahetseng | Boemo ba mamello |

| Mamello ea "square bar margin" | ± 0.15 limilimithara |

| Sebaka sa moeli oa square bar | ≤0.20mm |

| Angle ka mahlakoreng 'ohle a molamu oa lisekoere | 90°±0.05° |

| Bophahapha ba molamu o sekoere | ≤0.15 limilimithara |

| Ho nepahala ha boemo ba roboto | ± 0.05 limilimithara |

Litšebeletso tsa XKH:

XKH e fana ka lits'ebeletso tse felletseng bakeng sa mochini oa mono-crystalline silicon dual-station, ho kenyeletsoa ho etsa lisebelisoa (tse lumellanang le lithupa tse kholo tsa silicon), ts'ebetso ea ts'ebetso (ho itšeha paramethara), koetliso ea ts'ebetso le tšehetso ea morao-rao ea thekiso (phepelo ea likarolo tsa bohlokoa, tlhahlobo e hole), ho etsa bonnete ba hore bareki ba fumana chai e ngata (> 99%) le tlhahiso e tlase ea theko e tlase, le ho fana ka ntlafatso ea tekheniki ea AI (ho itšeha). Nako ea ho pepa ke likhoeli tse 2-4.

Setšoantšo se qaqileng