Thepa e Ikemetseng ka ho Fetisisa ea Wafer Ring-Cutting Size e sebetsang ka boholo ba 8inch/12inch Wafer Ring Cutting

Litekanyetso tsa tekheniki

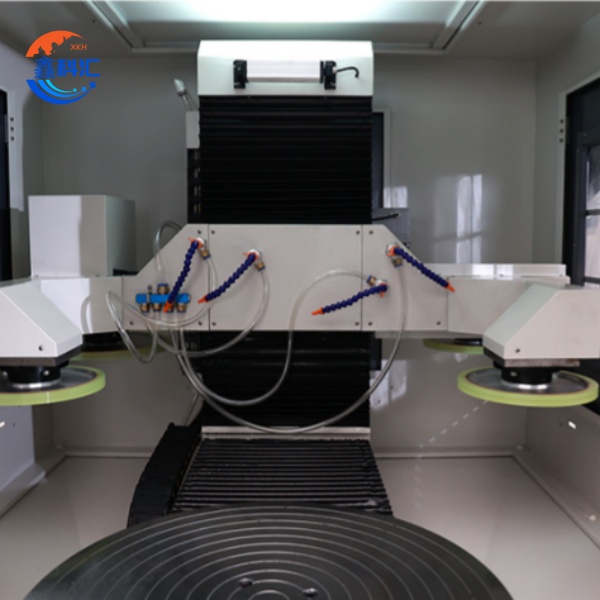

| Paramethara | Yuniti | Tlhaloso |

| Maximum Workpiece Size | mm | ø12" |

| Spindle | Tlhophiso | Spindle e le 'ngoe |

| Lebelo | 3,000-60,000 rpm | |

| Matla a Output | 1.8 kW (2.4 boikhethelo) ka 30,000 min⁻¹ | |

| Max Blade Dia. | Ø58 limilimithara | |

| X-Axis | Sekhahla Range | 310 limilimithara |

| Y-Axis | Sekhahla Range | 310 limilimithara |

| Keketseho ea Mohato | 0.0001 limilimithara | |

| Boemo bo Nepahetseng | ≤0.003 mm/310 mm, ≤0.002 mm/5 mm (phoso e le nngwe) | |

| Z-Axis | Qeto ea Motsamao | 0.00005 limilimithara |

| Pheta-pheta | 0.001 limilimithara | |

| θ-Axis | Phetoho e phahameng | 380 dig |

| Mofuta oa Spindle | Spindle e le 'ngoe, e nang le lehare le thata bakeng sa ho seha selikalikoe | |

| Ho nepahala ha Ring-Cutting | μm | ±50 |

| Ho Nepaha ha Wafer Positioning | μm | ±50 |

| Tšebeliso e Ntle ea Sekhechana se le Mong | min/sephaphatha | 8 |

| Katleho ea Multi-Wafer | Ho fihla ho li-wafers tse 4 tse sebetsitsoeng ka nako e le 'ngoe | |

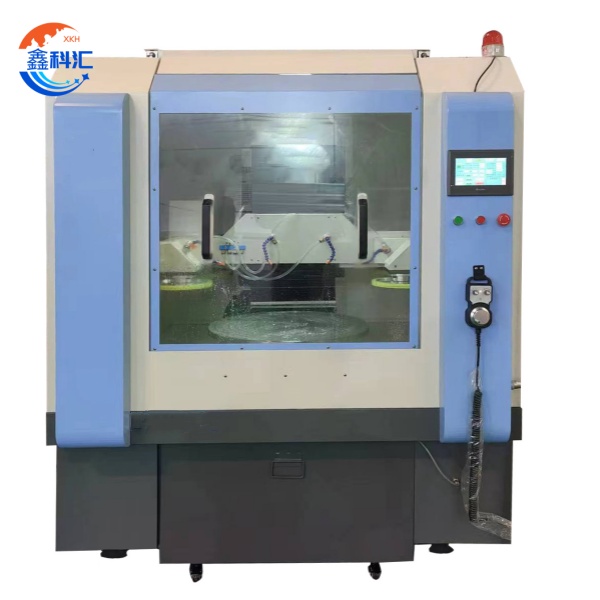

| Thepa Boima | kg | ≈3,200 |

| Litekanyo tsa Thepa (W×D×H) | mm | 2,730 × 1,550 × 2,070 |

Molao-motheo oa Ts'ebetso

Sistimi e fihlella ts'ebetso e ikhethang ea ho fokotsa ka mahlale ana a mantlha:

1.Intelligent Motion Control System:

· Koloi ea enjene e tsamaeang ka nepo e phahameng haholo (pheta ho nepahala ha boemo: ± 0.5μm)

· Taolo e lumellanang ea li-axis tse tšeletseng e tšehetsang moralo o rarahaneng oa litsela

· Li-algorithms tsa khatello ea nako ea 'nete tse netefatsang botsitso ba ho itšeha

2.Sistimi e tsoetseng pele ea ho lemoha:

· Sensor ea bophahamo ba laser e kopantsoeng ea 3D (ho nepahala: 0.1μm)

* Boemo ba pono ba CCD bo nang le qeto e phahameng (5 megapixels)

· Mojule oa tlhahlobo ea boleng ba inthaneteng

3.Fully Automated process:

· Ho kenya / ho laolla ka bohona (sebopeho se tloaelehileng sa FOUP se tsamaellana)

· Mokhoa o bohlale oa ho hlopha

· Setsi sa tlhoekiso se koetsoeng (bohloeki: Sehlopha sa 10)

Lisebelisoa tse Tloaelehileng

Sesebelisoa sena se fana ka boleng ba bohlokoa lits'ebetsong tsohle tsa tlhahiso ea semiconductor:

| Sebaka sa Kopo | Lisebelisoa tsa Ts'ebetso | Melemo ea Setsebi |

| IC Manufacturing | 8/12" "Silicon Wafers". | E ntlafatsa ho tsamaisana le lithography |

| Lisebelisoa tsa Matla | SiC/GaN Wafers | E thibela mefokolo ea moeli |

| Li-Sensors tsa MEMS | Likhoele tsa SOI | E netefatsa ts'epahalo ea sesebelisoa |

| Lisebelisoa tsa RF | Li-wafers tsa GaAs | E ntlafatsa ts'ebetso ea maqhubu a holimo |

| Packaging e tsoetseng pele | Li-wafers tse tsosolositsoeng | E eketsa tlhahiso ea liphutheloana |

Likaroloana

1.Setsi sa liteishene tse 'nè bakeng sa ts'ebetso e phahameng ea ts'ebetso;

2.Stable TAIKO lesale debonding le ho tloswa;

3.Ho lumellana ho phahameng le lisebelisoa tsa bohlokoa;

4.Multi-axis synchronous trimming technology e netefatsa ho itšeha ka nepo;

5.Fully automated process flow haholo e fokotsa litšenyehelo tsa basebetsi;

6.Customized worktable moralo thusa tshebetso e tsitsitseng ea mehaho e khethehileng;

Mesebetsi

1. Sistimi ea ho lemoha marotholi;

2.Automatic worktable hloekisa;

3.Intelligent UV debonding system;

4.Opereishene log rekota;

5.Factory automation module integration;

Boitlamo ba Tšebeletso

XKH e fana ka lits'ebeletso tse felletseng, tse felletseng tsa ts'ehetso ea bophelo bo botle tse etselitsoeng ho ntlafatsa ts'ebetso ea lisebelisoa le katleho ea ts'ebetso ho pholletsa le leeto la hau la tlhahiso.

1. Litšebeletso tsa Customization

· Tailored Equipment Configuration: Sehlopha sa rona sa boenjiniere se sebelisana haufi-ufi le bareki ho ntlafatsa mekhoa ea tsamaiso (lebelo la ho itšeha, khetho ea lehare, joalo-joalo) ho itšetlehile ka thepa e khethehileng ea thepa (Si / SiC / GaAs) le litlhoko tsa ts'ebetso.

· Tšehetso ea Nts'etsopele ea Ts'ebetso: Re fana ka mehlala ea ts'ebetso e nang le litlaleho tse qaqileng tsa tlhahlobo, ho kenyelletsa le tekanyo ea ho lekanya bofokoli le 'mapa oa liphoso.

· Nts'etsopele ea Co-Consumables: Bakeng sa lisebelisoa tse ncha (mohlala, Ga₂O₃), re sebelisana 'moho le bahlahisi ba ka rekoang ho nts'etsapele li-blades/laser optics tse ikhethileng.

2. Professional Technical Support

· Tšehetso e Ikemetseng ea Sebaka: Abela lienjineri tse netefalitsoeng bakeng sa maemo a bohlokoa a ho nyoloha (hangata libeke tse 2-4), tse koahelang:

Ho lekanya lisebelisoa le ho lokisa hantle

Koetliso ea bokhoni ba ho sebetsa

Tataiso ea ho kopanya kamoreng ea bohloeki ea ISO Class 5

· Tlhokomelo e reriloeng esale pele: Litlhahlobo tsa kotara ea bophelo bo botle ka tlhahlobo ea vibrate le tlhahlobo ea makoloi a servo ho thibela nako e sa reroang.

· Tlhokomelo ea Remote: Ts'ebetso ea ts'ebetso ea nako ea 'nete ka sethala sa rona sa IoT (JCFront Connect®) ka litemoso tse iketselitseng tse sa hlakang.

3. Litšebeletso tse ekelitsoeng ke boleng

* Setsi sa Tsebo ea Ts'ebetso: Fumana litlolo tse 300+ tse netefalitsoeng tsa ho itšeha bakeng sa lisebelisoa tse fapaneng (tse ntlafalitsoeng ka kotara).

• Tekanyo ea 'mapa oa Theknoloji: Bopaki ba nako e tlang ea matsete a hau ka mekhoa ea ntlafatso ea hardware/software (mohlala, module ea ho lemoha sekoli e thehiloeng ho AI).

· Karabelo ea Tšohanyetso: Ho netefalitsoe tlhahlobo ea lihora tse 4 hole le ts'ebetso ea lihora tse 48 sebakeng sa marang-rang (kabelo ea lefats'e).

4. Lisebelisoa tsa litšebeletso

· Tiisetso ea Ts'ebetso: Boitlamo ba konteraka ho ≥98% nako ea ho sebetsa ea lisebelisoa ka linako tsa karabelo tse tšehelitsoeng ke SLA.

Ntlafatso e Tsoelang Pele

Re etsa liphuputso tse peli tsa ho khotsofala ha bareki le ho kenya tšebetsong matsapa a Kaizen ho ntlafatsa phano ea litšebeletso. Sehlopha sa rona sa R&D se fetolela lintlha tse mabapi le ntlafatso ea lisebelisoa - 30% ea lintlafatso tsa firmware li tsoa maikutlong a bareki.