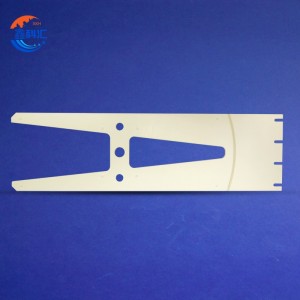

Alumina Ceramic End Effector ea Tšebetso e Phahameng (Fork Arm) bakeng sa Semiconductor le Cleanroom Automation

Setšoantšo se qaqileng

Kenyelletso ea Sehlahisoa

The Alumina Ceramic End Effector, eo hape e bitsoang letsoho la fork ea ceramic kapa letsoho la robotic ceramic, ke karolo ea ho sebetsana ka nepo e phahameng e etselitsoeng lits'ebetso tse ikemetseng tsa semiconductor, photovoltaic, ponts'o ea liphanele, le libaka tsa laboratori tse hloekileng haholo. E etselitsoe ho fana ka botsitso bo ikhethang ba mocheso, ho tiea ha mochini, le ho hanyetsa lik'hemik'hale, ho fana ka lipalangoang tse hloekileng, tse ka tšeptjoang le tse bolokehileng tsa thepa e bobebe joalo ka li-wafers tsa silicon, substrates tsa khalase le likaroloana tsa elektroniki.

Joalo ka mofuta oa phello ea ho qetela ea liroboto, karolo ena ea ceramic ke sehokelo sa ho qetela lipakeng tsa sistimi ea othomathike le sesebelisoa sa mosebetsi. E bapala karolo ea bohlokoa phetisong e nepahetseng, ho tsamaisana, ho laolla / ho laolla, le ho beha mesebetsi libakeng tse hloekileng le libakeng tse sa hloekang.

Kakaretso ea lintho tse bonahalang – Alumina Ceramic (Al₂O₃)

Alumina ceramic ke thepa ea ceramic e tsitsitseng haholo le e sa sebetseng ka lik'hemik'hale e tsebahalang ka thepa ea eona e ntle ea mochini le ea motlakase. Bohloeki bo phahameng (≥ 99.5%) alumina e sebelisitsoeng ho litlamorao tsena e netefatsa:

-

Boima bo phahameng (Mohs 9): Ea bobeli feela ho daemane, alumina e fana ka khanyetso e feteletseng ea ho apara.

-

Bokgoni ba mocheso o phahameng: E boloka botšepehi ba sebopeho ka holimo ho 1600 ° C.

-

Boiketlo ba lik'hemik'hale: E hanana le li-acids, alkalis, solvents, le tikoloho ea plasma etching.

-

Tšireletso ea motlakase: Ka matla a phahameng a dielectric le tahlehelo e tlase ea dielectric.

-

Katoloso e tlase ea mocheso: E netefatsa botsitso bo boholo libakeng tsa libaesekele tse futhumetseng.

-

Ho hlahisa likaroloana tse tlase: Bohlokoa bakeng sa ho lumellana ha kamore e hloekileng (Sehlopha sa 10 ho ea ho Sehlopha sa 1000).

Likarolo tsena li etsa hore alumina ceramic e be e loketseng bakeng sa ts'ebetso ea bohlokoa ea thōmo liindastering tse sa tsotelleng ts'oaetso.

Lisebelisoa tse sebetsang

Sesebelisoa sa ho qetela sa alumina ceramic se amoheloa haholo lits'ebetsong tsa theknoloji e phahameng ea indasteri, haholo moo lisebelisoa tsa tšepe kapa tsa polasetiki tsa setso li haellang ka lebaka la ho hola ha mocheso, tšilafalo kapa mathata a kutu. Libaka tsa bohlokoa tsa kopo li kenyelletsa:

- Phetiso ea semiconductor wafer

- Photolithography ho kenya le ho laolla sistimi

- Ho sebetsana le likhalase tsa khalase ka mela ea OLED le LCD

- Crystalline silicon wafer phetiso tlhahiso ea lisele tsa letsatsi

- Tlhahlobo e ikemetseng ea optical kapa microelectronic

- Mehlala ea lipalangoang ka har'a lab tsa tlhahlobo kapa tsa biomedical

- Sistimi e ikemetseng ea tikoloho ea vacuum

Bokhoni ba eona ba ho sebetsa ntle le ho hlahisa likaroloana kapa tjhaja e tsitsitseng e etsa hore e be ea bohlokoa haholo bakeng sa ts'ebetso e nepahetseng ea liroboto ho mochini o hloekileng oa kamore.

Likarolo tsa Moqapi & Boiketlo

Sesebelisoa se seng le se seng sa ho qetela sa ceramic se entsoe hore se lekane le letsoho le itseng la robotiki kapa sistimi ea ho ts'oara sephaphatha. Re ts'ehetsa ho itlhophisa ka botlalo ho ipapisitse le:

-

Khokahano ea boholo ba Wafer: 2", 4", 6", 8", 12" le ho feta

-

Slot geometry le sebaka: E lumellana le ho ts'oaroa ka bohale, tšehetso ea lehlakoreng le ka morao, kapa meralo ea notched wafer

-

Likou tsa suction: Likoti tse kopantsoeng tsa vacuum kapa likanale bakeng sa ho sebetsana le batho bao e seng bao u kopanang le bona

-

Tlhophiso ea ho kenya: Likoti, likhoele, li-slots tse lumellanang le flange ea sesebelisoa sa roboto sa hau

-

Phekolo ea bokaholimo: Qetello e bentšitsoeng, e lapiloeng, kapa e hahelletsoeng hantle (Ra <0.2 µm e fumaneha)

-

Tšireletso ea moeli: Likhutlo tse pota-potiloeng kapa li-chamfering ho qoba tšenyo ea liphaphatha

Ka ho sebelisa litšoantšo tsa CAD kapa mefuta ea 3D e fanoeng ke bareki, baenjiniere ba rona ba ka ntlafatsa letsoho le leng le le leng la fereko bakeng sa boima ba 'mele, matla le bohloeki.

Melemo ea Ceramic End Effecters

| Sebopeho | Molemo |

|---|---|

| Phahameng Mechanical Rigidity | E boloka ho nepahala ha maemo tlas'a matla a ho kenya liroboto |

| Ts'ebetso e Ntle ea Thermal | E sebetsa ka mokhoa o ts'epahalang maemong a mocheso o phahameng kapa oa plasma |

| Zero Tšilafalo ea Metal | Ha ho na kotsi ea tšilafalo ea ion ts'ebetsong ea bohlokoa ea semiconductor |

| Sebaka se tlase sa Khohlano | E fokotsa kotsi ea ho koaheloa ho li-wafer kapa li-substrate tsa khalase |

| Anti-Static le Non-Magnetic | Ha e hohele lerole kapa ho ama likarolo tse utloang matla a khoheli |

| Bophelo bo Bolelele ba Tšebeletso | Khanyetso e phahameng ea ho roala lipotolohong tse iphetang ka lebelo le phahameng |

| Tšebelisano-'moho e Hloekileng | E loketse likamore tsa bohloeki tsa ISO 14644 (Sehlopha sa 100 le ka tlase) |

Ha ho bapisoa le matsoho a polasetiki kapa a aluminium, alumina ceramic e fana ka botsitso bo matla ba lik'hemik'hale le 'mele ka litlhoko tse fokolang tsa tlhokomelo.

| Thepa | Letsoho la tšepe | Letsoho la polasetiki | Alumina Ceramic Arm |

|---|---|---|---|

| Ho thatafala | E itekanetseng | Tlase | Holimo haholo (Mohs 9) |

| Thermal Stability | ≤ 500°C | ≤ 150°C | ≥ 1600°C |

| Khanyetso ea Lik'hemik'hale | E itekanetseng | Mafutsana | E kgabane |

| Ho Hloekisa Kamore ea ho Hloeka | Mahareng | Tlase | Holimo Haholo |

| Apara Resistance | Mahareng | Tlase | E ikhethang |

| Matla a Dielectric | Tlase | Mahareng | Phahameng |

| Custom Machining Precision | Moedi | E itekanetseng | Holimo (±0.01mm ho khoneha) |

Litlhaloso tsa Tekheniki

| Paramethara | Boleng |

|---|---|

| Lintho tse bonahalang | Alumina ea boleng bo holimo (≥ 99.5%) |

| Mocheso oa Mosebetsi | Ho fihlela ho 1600°C |

| Bokhopo ba Sekaho | Ra ≤ 0.2 µm (boikhethelo) |

| Li-Size tsa Wafer tse tsamaellanang | 2" ho isa ho 12" kapa tloaelo |

| Mamello ea Flatness | ±0.01 mm (e itshetlehile ka kopo) |

| Tšehetso ea Vacuum Suction | Likanale tseo u ka li khethang, tseo u ka li khethang |

| Mounting Options | Bolt-through, flange, likoti tse slotted |

Lipotso tse atisang ho botsoa (FAQ)

Q1: Na phello ea ho qetela e ka kopanngoa le mekhoa e teng ea robotic?

A1:Ee. Re ts'ehetsa ho itlhophisa ho ipapisitse le sebopeho sa hau sa robotiki. U ka re romella setšoantšo sa CAD kapa litekanyo tsa flange bakeng sa ho ikamahanya hantle le maemo.

Q2: Na matsoho a ceramic a tla robeha habonolo ha a sebelisoa?

A2:Leha ceramic e le brittle ka tlhaho, meralo ea rona e sebelisa geometry e ntlafalitsoeng ho fokotsa khatello ea maikutlo. Tlas'a maemo a ts'ebeliso e nepahetseng, ba fana ka bophelo bo bolelele ba ts'ebeletso ho feta tšepe kapa polasetiki.

Q3: Na hoa khonahala ho sebelisa see ka har'a vacuum e phahameng haholo kapa likamoreng tsa etching tsa plasma?

A3:Ee. Alumina ceramic ha e felise moea, e tsitsitse ka mocheso, 'me ha e rusoe-e loketse hantle bakeng sa libaka tse nang le vacuum e phahameng, khase e sebetsang kapa ea plasma.

Q4: Likarolo tsee li hloekisoa kapa li hlokomeloa joang?

A4:Li ka hloekisoa ka ho sebelisa metsi a DI, joala, kapa li-detergent tse lumellanang le kamore e hloekileng. Ha ho na tlhokomelo e khethehileng e hlokahalang ka lebaka la botsitso ba lik'hemik'hale tsa bona le sebaka sa inert.

Mabapi le rona

XKH e sebetsa ka ho khetheha ho nts'etsopele ea theknoloji e phahameng, tlhahiso, le thekiso ea likhalase tse khethehileng tsa optical le lisebelisoa tse ncha tsa kristale. Lihlahisoa tsa rona li fana ka lisebelisoa tsa elektroniki tsa optical, lisebelisoa tsa elektroniki tsa bareki le sesole. Re fana ka lisebelisoa tsa mahlo tsa Sapphire, likoahelo tsa lense tsa mohala oa thekeng, Ceramics, LT, Silicon Carbide SIC, Quartz, le liphaphatha tsa kristale tsa semiconductor. Ka boitseanape bo nang le boiphihlelo le lisebelisoa tse tsoetseng pele, re ipabola ts'ebetsong ea lihlahisoa tse sa tloaelehang, ka sepheo sa ho ba khoebo e etelletseng pele ea theknoloji e phahameng ea optoelectronic.