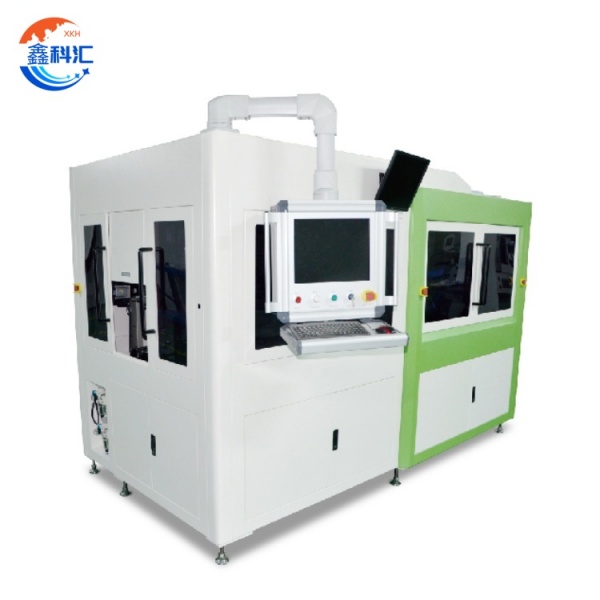

Mochini oa ho cheka oa laser o phahameng ka ho fetesisa bakeng sa thepa ea safire ea ceramic e nang le lehakoe le nang le nozzle

Kenyelletso ea Sehlahisoa

Lisebelisoa tse sebetsang: E loketse tšepe ea tlhaho, tšepe ea polycrystalline, ruby, safire, koporo, li-ceramics, rhenium, tšepe e sa hloekang, carbon steel, alloy steel le tse ling tse matla haholo, lisebelisoa tse phahameng tsa mocheso bakeng sa libopeho tse fapaneng, bophara, botebo le ho cheka taper.

Maemo a mosebetsi

1. E loketse ho sebetsa tlas'a mocheso o potolohileng oa 18℃-28℃ le mongobo o lekanyelitsoeng oa 30% -60%.

2. E loketse ho fana ka matla a mekhahlelo e 'meli /220V/50HZ/10A.

3. Hlophisa li-plug tse fihlelang litlhoko tsa maemo a amehang a Sechaena. Haeba ho se na plug e joalo, ho lokela ho fanoa ka adaptara e loketseng.

4. E sebelisoa haholo setšoantšong sa terata ea daemane, terata e liehang ho shoa, lesoba la moferefere, lesoba la nale, ho jara lehakoe, nozzle le liindasteri tse ling tsa perforating.

Litekanyetso tsa tekheniki

| Lebitso | Lintlha | Mosebetsi |

| Optical maser wavelength | 354.7nm kapa 355nm | E khetha matla a kabo ea matla le matla a ho kenella a lebone la laser, 'me e ama sekhahla sa ho monya ha thepa le phello ea ts'ebetso. |

| Karolelano ea matla a hlahisoang | 10.0 / 12.0/15.0 w@40khz | E ama ts'ebetso ea ts'ebetso le lebelo la ho otla, ha matla a phahame, lebelo la ho sebetsa le potlakile. |

| Pulse bophara | Ka tlase ho 20ns@40KHz | Bophara bo khuts'oane ba pulse bo fokotsa sebaka se amehileng ke mocheso, bo ntlafatsa ho nepahala ha machining, 'me bo qoba tšenyo ea mocheso oa thepa. |

| Sekhahla sa ho pheta-pheta sekhahla | 10 ~ 200KHz | Lekola maqhubu a phetisetso le bokhoni ba ho phunya ba lebone la laser, ha maqhubu a phahama, lebelo la ho phunya le potlakile. |

| boleng ba khanya ea optical | M²<1.2 | Maballo a boleng bo phahameng a netefatsa ho nepahala ha ho cheka le boleng bo holimo, ho fokotsa tahlehelo ea matla. |

| Letheba bophara | 0.8±0.1mm | Etsa qeto ea bonyane ba sebaka le ho nepahala ha machining, sebaka se senyenyane, sebaka se senyenyane, se phahamisa ho nepahala. |

| lehlakoreng la ho fapanyetsana ha beam | E kholo ho feta 90% | Bokhoni ba ho tsepamisa maikutlo le botebo ba ho phunya ba lebone la laser lia ameha. Ha Angle ea ho fapana e nyane, matla a ho tsepamisa maikutlo a matla. |

| Beam ellipticity | Ka tlase ho 3% RMS | Ha e le ellipticity e nyane, sebopeho sa lesoba se haufi le selikalikoe, se phahamisa ho nepahala ha machining. |

Bokhoni ba ho sebetsa

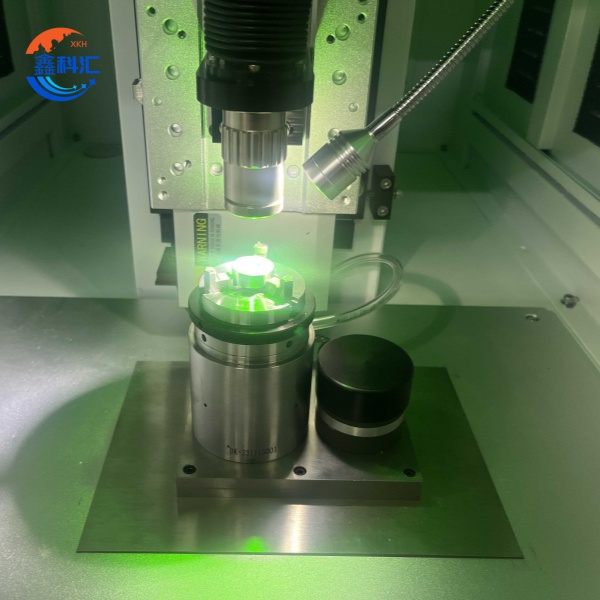

Mechini ea ho cheka ka laser e phahameng ka ho fetesisa e na le bokhoni bo matla ba ho sebetsa 'me e khona ho phunya masoba ho tloha ho li-micron tse' maloa ho isa ho limilimithara tse 'maloa ka bophara,' me sebopeho, boholo, boemo le Angle ea likoti li ka laoloa ka nepo. Ka nako e ts'oanang, lisebelisoa li ts'ehetsa ho cheka hohle ho pota-pota 360-degree, e ka finyellang litlhoko tsa ho cheka tsa libopeho le mekhoa e sa tšoaneng e rarahaneng. Ntle le moo, mochini o pharalletseng oa laser o phahameng o boetse o na le boleng bo holimo le pheletso e holimo, masoba a sebetsitsoeng ha a na burr, ha a na ho qhibiliha, 'me bokaholimo ba lesoba bo boreleli ebile bo bataletse.

Tšebeliso ea mochini o phunyang oa laser o nepahetseng haholo:

1. Indasteri ea elektroniki:

Boto ea potoloho e hatisitsoeng (PCB) : e sebelisetsoa ho sebetsana le microhole ho finyella litlhoko tsa ho hokahanya ha methapo e phahameng.

Sephutheloana sa semiconductor: Phunya masoba ka har'a li-wafers le lisebelisoa tsa ho paka ho ntlafatsa ts'ebetso ea sephutheloana le ts'ebetso.

2. Sepakapaka:

Likoti tse futhumatsang lehare la enjine: Likoti tse futhumatsang tse nyane li entsoe ka mahare a superalloy ho ntlafatsa ts'ebetso ea enjine.

Composite processing: Bakeng sa ho cheka ka mokhoa o nepahetseng haholo oa metsoako ea carbon fiber ho netefatsa matla a sebopeho.

3. Thepa ea Bongaka:

Lisebelisoa tse fokolang tsa ho buoa: Ho sebetsa li-microholes ka lisebelisoa tsa ho buoa ho ntlafatsa ho nepahala le polokeho.

Sistimi ea phepelo ea lithethefatsi: Phunya masoba sesebelisoa sa phano ea lithethefatsi ho laola sekhahla sa ho lokolloa ha lithethefatsi.

4. Ho Etsa Likoloi:

Sistimi ea ente ea mafura: Ho lokisa masoba a manyane holim'a molomo oa ente ea mafura ho ntlafatsa phello ea athomo ea mafura.

Ho etsa li-sensor: Ho phunya masoba karolong ea sensor ho ntlafatsa kutlo le lebelo la karabo.

5. Lisebelisoa tsa Optical:

Optical fiber connector: Ho lokisa li-microholes holim'a sehokelo sa fiber optical ho netefatsa boleng ba phetisetso ea lets'oao.

Sesefa sa Optical: Funya masoba ka har'a sefahla sa mahlo ho fihlela khetho e khethehileng ea wavelength.

6. Mechini e nepahetseng:

Precision hlobo: Ho etsa li-microholes ka har'a hlobo ho ntlafatsa ts'ebetso le bophelo ba ts'ebeletso ea hlobo.

Likarolo tse nyane: Phunya masoba likarolong tse nyane ho fihlela litlhoko tsa kopano e nepahetseng haholo.

XKH e fana ka mefuta e mengata e felletseng ea lits'ebeletso tsa mochini oa ho cheka ka laser, ho kenyeletsoa thekiso ea thepa, ts'ehetso ea tekheniki, litharollo tse ikhethileng, ho kenya le ho laela, koetliso ea ts'ebetso le tlhokomelo ea kamora ho rekisa, joalo-joalo, ho netefatsa hore bareki ba ts'ebeliso ea ts'ehetso ea litsebi, e sebetsang hantle le e felletseng.

Setšoantšo se qaqileng