Thepa ea ho Pholisetsa ka Lehlakoreng le le Leng le Phahameng ka ho Feta

Video ea Thepa ea ho Phontša ka Lehlakore le le Leng

Kenyelletso ea Thepa e Pholisitsoeng ka Lehlakore le le Leng

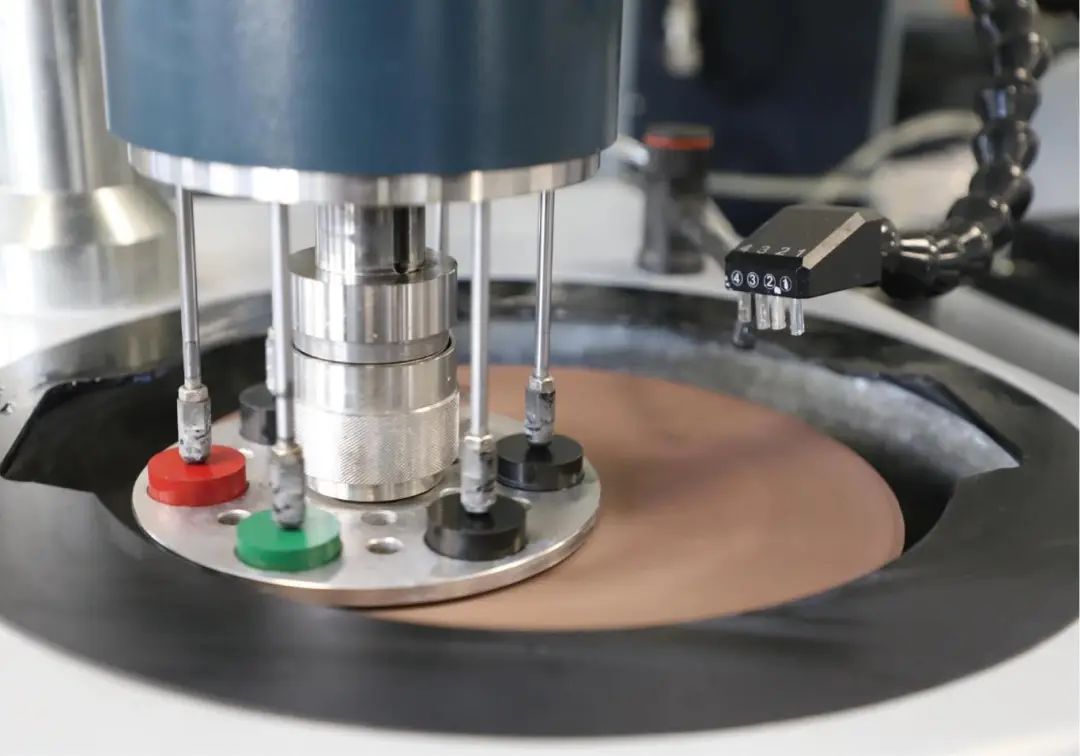

Mochini oa ho bentša o lehlakoreng le le leng ke sesebelisoa se ikhethileng haholo se etselitsoeng ho phethela ka nepo lisebelisoa tse thata le tse brittle. Ka nts'etsopele e potlakileng ea indasteri ea semiconductor, optoelectronics, optical components, le lisebelisoa tse tsoetseng pele tsa lisebelisoa, tlhokahalo ea lisebelisoa tsa ho bentša tse nepahetseng haholo le tse phahameng e ntse e eketseha ka potlako. Mochini o benyang o lehlakoreng le le leng o sebelisa motsamao o lekanyelitsoeng lipakeng tsa diski e benyang le lipoleiti tsa ceramic ho hlahisa khatello e ts'oanang holim'a sebaka sa mosebetsi, ho etsa hore ho be le planarization e ntle haholo le ho phethela joalo ka seipone.

Ho fapana le mechini e tloaelehileng ea ho bentša mahlakoreng a mabeli, mochini o benyang o lehlakoreng le le leng o fana ka phetoho e kholo ea ho sebetsana le boholo bo fapaneng le botenya ba liphaphatha kapa li-substrates. Sena se etsa hore e tšoanelehe ka ho khetheha bakeng sa lisebelisoa tsa ho sebetsa tse kang li-wafers tsa silicon, silicon carbide, sapphire, gallium arsenide, germanium flakes, lithium niobate, lithium tantalate, le khalase ea optical. Ho nepahala ho fihletsoeng ka mofuta ona oa lisebelisoa ho netefatsa hore likarolo tse sebetsitsoeng li fihlela litlhoko tse tiileng tsa li-microelectronics, li-substrates tsa LED, le li-optics tse sebetsang hantle.

Monyetla oa Thepa e Pholisitsoeng ka Lehlakore le le Leng

Filosofi ea moralo oa mochini o benyang o lehlakoreng le le leng e totobatsa botsitso, ho nepahala le ho sebetsa hantle. 'Mele o ka sehloohong oa mochine hangata o entsoe ka tšepe e entsoeng ka tšepe le e entsoeng, e fanang ka botsitso bo matla ba mochine le ho fokotsa ho thothomela nakong ea ts'ebetso. Likarolo tsa boleng bo holimo tsa machaba li amoheloa bakeng sa litsamaiso tse bohlokoa joalo ka koloi ea ho potoloha, phetiso ea matla, le sistimi ea taolo, ho netefatsa ts'ebetso e tšepahalang le bophelo bo bolelele ba ts'ebeletso.

Molemo o mong oa bohlokoa o ho sebopeho sa eona sa ts'ebetso ea motho. Mechini ea sejoale-joale e bentšang lehlakoreng le le leng e na le liphanele tsa taolo tse bohlale, tse lumellang basebelisi ho fetola kapele maemo a ts'ebetso joalo ka lebelo la ho bentša, khatello le sekhahla sa ho potoloha. Sena se nolofalletsa maemo a ts'ebetso e ka hlahisoang haholo, e leng ntho ea bohlokoa bakeng sa liindasteri moo botsitso bo leng bohlokoa.

Ho ea ka pono ea ho feto-fetoha ha ts'ebetso, lisebelisoa li ka amohela mefuta e mengata ea boholo ba machining, hangata ho tloha ho 50mm ho isa ho 200mm kapa ho feta, ho latela mohlala. Sekhahla sa ho potoloha ha disc ea polishing hangata se oela pakeng tsa 50 ho isa ho 80 rpm, ha matla a matla a fapana ho tloha ho 11kW ho feta 45kW. Ka mefuta e mengata hakana ea litlhophiso, basebelisi ba ka khetha mofuta o lumellanang hantle le litlhoko tsa bona tsa tlhahiso, ebang ke lilaboratori tsa lipatlisiso kapa tlhahiso e kholo ea indasteri.

Ho feta moo, mefuta e tsoetseng pele e na le lihlooho tse ngata tsa polishing, tse hokahanngoang ke litsamaiso tsa taolo ea elektroniki tsa servo. Sena se tiisa hore lihlooho tsohle tsa polishing li boloka lebelo le tsitsitseng nakong ea ts'ebetso, kahoo li ntlafatsa boleng ba ho sebetsa le lihlahisoa. Ho phaella moo, mekhoa ea ho pholile le ea ho laola mocheso e kopantsoeng mochine o tiisa botsitso ba mocheso, e leng ntho ea bohlokoa ha u sebetsana le lisebelisoa tse thibelang mocheso.

Mochini o nang le lehlakore le le leng oa polishing o emela karolo ea bohlokoa ea lisebelisoa tsa tlhahiso mehleng ea kajeno ea theknoloji e phahameng. Motsoako oa eona oa moralo o matla oa mochini, taolo e bohlale, tšebelisano ea lisebelisoa tse ngata, le ts'ebetso e phahameng ea ho qeta bokaholimo e etsa hore e be sesebelisoa sa bohlokoa bakeng sa lik'hamphani le litsi tsa lipatlisiso tse hlokang ho lokisoa ha thepa e tsoetseng pele ka nepo.

Likarolo tsa Sehlahisoa sa Thepa ea ho bentša ka lehlakore le le leng

-

Botsitso bo Phahameng: 'Mele oa mochini o entsoe le ho etsoa ho netefatsa ho tiea ha sebopeho le botsitso bo botle ba ts'ebetso.

-

Likarolo tse nepahetseng: Li-bearings tsa maemo a machaba, li-motor, le likarolo tsa taolo ea elektroniki li netefatsa bophelo bo bolelele ba ts'ebeletso le ts'ebetso e tšepahalang.

-

Mehlala e Fetohang: E fumaneha ka lihlopha tse ngata (305, 36D, 50D, 59D, le X62 S59D-S) ho finyella litlhoko tse fapaneng tsa tlhahiso.

-

Humanized Interface: Phanele e bonolo ea ts'ebetso e nang le li-setting tsa dijithale bakeng sa paramente ea polishing, e nolofalletsang liphetoho tse potlakileng tsa risepe.

-

Pholiso e Sebetsang: Mekhoa e kopantsoeng ea metsi a pholileng ka metsi a nang le lisebelisoa tse nepahetseng tsa mocheso ho boloka maemo a tsitsitseng a polishing.

-

Kamahanyo ya Dihlooho tse ngata: Taolo ea elektroniki ea Servo e netefatsa lebelo le lumellanang la lihlooho tse ngata tsa polishing bakeng sa liphetho tse ts'oanang.

Litlhaloso tsa Tekheniki tsa Thepa ea ho Pholisa ka Lehlakore le le Leng

| Sehlopha | Ntho | 305 Letoto | 36D Series | 50D Series | Letoto la 59D |

|---|---|---|---|---|---|

| Sesepa sa ho bentša | Diameter | 820 limilimithara | 914 limilimithara | 1282 limilimithara | 1504 limilimithara |

| Lipoleiti tsa Ceramic | Diameter | 305 limilimithara | 360 limilimithara | 485 limilimithara | 576 limilimithara |

| Optimum Machining | Boholo ba Workpiece | 50-100 limilimithara | 50-150 limilimithara | 150-200 limilimithara | 200 limilimithara |

| Matla | Main Motor | 11kW | 11kW | 18.5 kW | 30 kW |

| Sekhahla sa ho potoloha | Sesepa sa ho bentša | 80 rpm | 65 rpm | 65 rpm | 50 rpm |

| Litekanyo (L×W×H) | - | 1920×1125×1680 limilimithara | 1360×1330×2799 limilimithara | 2334×1780×2759 limilimithara | 1900×1900×2700 limilimithara |

| Boima ba Mochini | - | 2000 lik'hilograma | 3500 lik'hilograma | 7500 lik'hilograma | 11826 lik'hilograma |

| Ntho | Paramethara | Lintho tse bonahalang |

|---|---|---|

| Diameter of Main Polishing Disc | Φ1504 × 40 limilimithara | SUS410 |

| Diameter of polishing Disc (Hlooho) | Φ576 × 20 limilimithara | SUS316 |

| Lebelo le Leholo la Sesepa se Seholo sa ho Pholisa | 60 rpm | - |

| Lebelo le Leholo la Hlooho e Lahlelang ka Holimo | 60 rpm | - |

| Palo ea Lihlooho Tse Phontšang | 4 | - |

| Litekanyo (L×W×H) | 2350 × 2250 × 3050 limilimithara | - |

| Thepa Boima | 12 t | - |

| Boemo ba Khatello e Phahameng | 50–500 ± kg | - |

| Kakaretso ea Matla a Mochini Oohle | 45kW | - |

| Loading Capacity (ka hlooho) | 8 h/φ 150 mm (6”) kapa 5 h/φ 200 mm (8”) | - |

Mefuta e fapaneng ea Kopo ea Lisebelisoa tsa ho Pholisa ka Lehlakore le le Leng

Mochine o etselitsoeho bentsha ka lehlakore le le lengea mefuta e mengata e fapaneng ea thepa e thata le e brittle, ho kenyelletsa:

-

Li-wafers tsa silicon bakeng sa lisebelisoa tsa semiconductor

-

Silicon carbide bakeng sa lisebelisoa tsa elektroniki tsa matla le li-substrates tsa LED

-

Sapphire wafers bakeng sa optoelectronics le likristale tsa ho shebella

-

Gallium arsenide bakeng sa lits'ebetso tsa elektroniki tsa maqhubu a holimo

-

Li-flakes tsa Jeremane bakeng sa infrared optics

-

Lithium niobate le lithium tantalate bakeng sa likarolo tsa piezoelectric

-

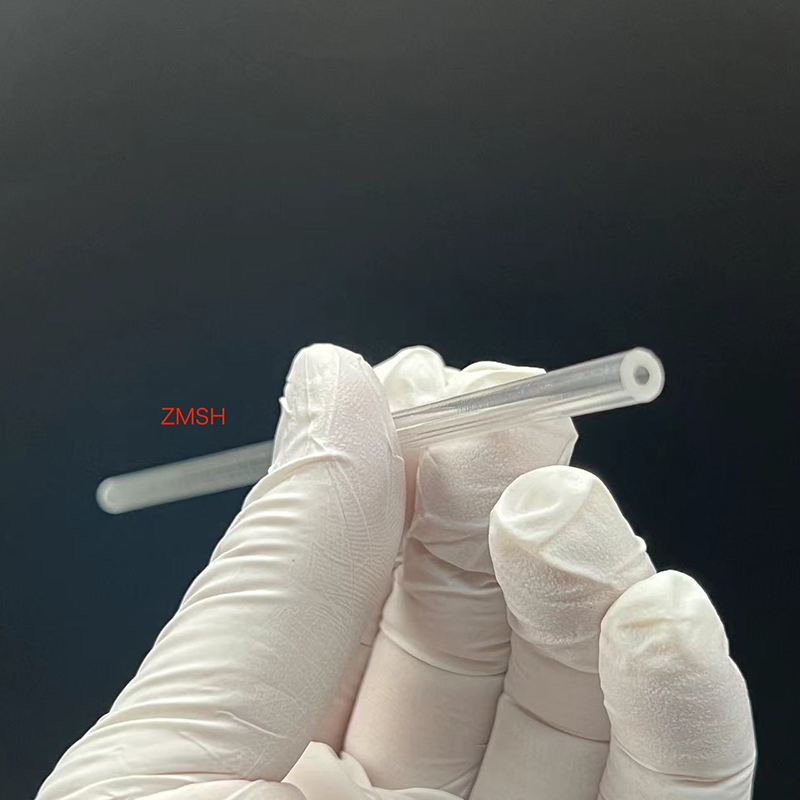

Li-substrates tsa khalase bakeng sa lisebelisoa tsa optic tse nepahetseng le lisebelisoa tsa puisano

Lipotso Tse Botsoang Khafetsa (FAQ) ea Thepa ea ho Pholisa ka Lehlakore le le Leng

Q1: Ke lisebelisoa life tse ka sebelisoang mochining o le mong oa polishing?

Mochini o loketse li-wafers tsa silicon, safire, silicon carbide, gallium arsenide, khalase le lisebelisoa tse ling tse brittle.(Mantsoe a bohlokoa: mochini o benyang, lisebelisoa tse brittle)

Q2: Ke mefuta efe e tloaelehileng ea li-disc tsa polishing tse fumanehang?

Ho ipapisitsoe le letoto, li-discs tsa polishing li tloha ho 820 mm ho isa ho 1504 mm ka bophara.(Mantsoe a bohlokoa: disc ea polishing, boholo ba mochini)

Q3: Sekhahla sa ho potoloha ha disc ea polishing ke eng?

Sekhahla sa ho potoloha se fapana ho tloha ho 50 ho isa ho 80 rpm, ho latela mohlala.(Mantsoe a bohlokoa: sekhahla sa ho potoloha, lebelo la ho bentša)

Q4: Sistimi ea taolo e ntlafatsa boleng ba polishing joang?

Mochine o sebelisa taolo ea elektroniki ea servo bakeng sa ho potoloha ha hlooho ho hokahaneng, ho netefatsa khatello e ts'oanang le liphetho tse tsitsitseng.(Mantsoe a bohlokoa: sistimi ea taolo, hlooho e benyang)

Q5: Boima le maoto a mochini ke eng?

Boima ba mochini bo tloha ho lithane tse 2 ho isa ho tse 12, ka maoto a pakeng tsa 1360 × 1330 × 2799 mm le 2350 × 2250 × 3050 limilimithara.(Mantsoe a bohlokoa: boima ba mochini, boholo)

Mabapi le rona

XKH e sebetsa ka ho khetheha ho nts'etsopele ea theknoloji e phahameng, tlhahiso, le thekiso ea likhalase tse khethehileng tsa optical le lisebelisoa tse ncha tsa kristale. Lihlahisoa tsa rona li fana ka lisebelisoa tsa elektroniki tsa optical, lisebelisoa tsa elektroniki tsa bareki le sesole. Re fana ka lisebelisoa tsa mahlo tsa Sapphire, likoahelo tsa lense tsa mohala oa thekeng, Ceramics, LT, Silicon Carbide SIC, Quartz, le liphaphatha tsa kristale tsa semiconductor. Ka boitseanape bo nang le boiphihlelo le lisebelisoa tse tsoetseng pele, re ipabola ts'ebetsong ea lihlahisoa tse sa tloaelehang, ka sepheo sa ho ba khoebo e etelletseng pele ea theknoloji e phahameng ea optoelectronic.