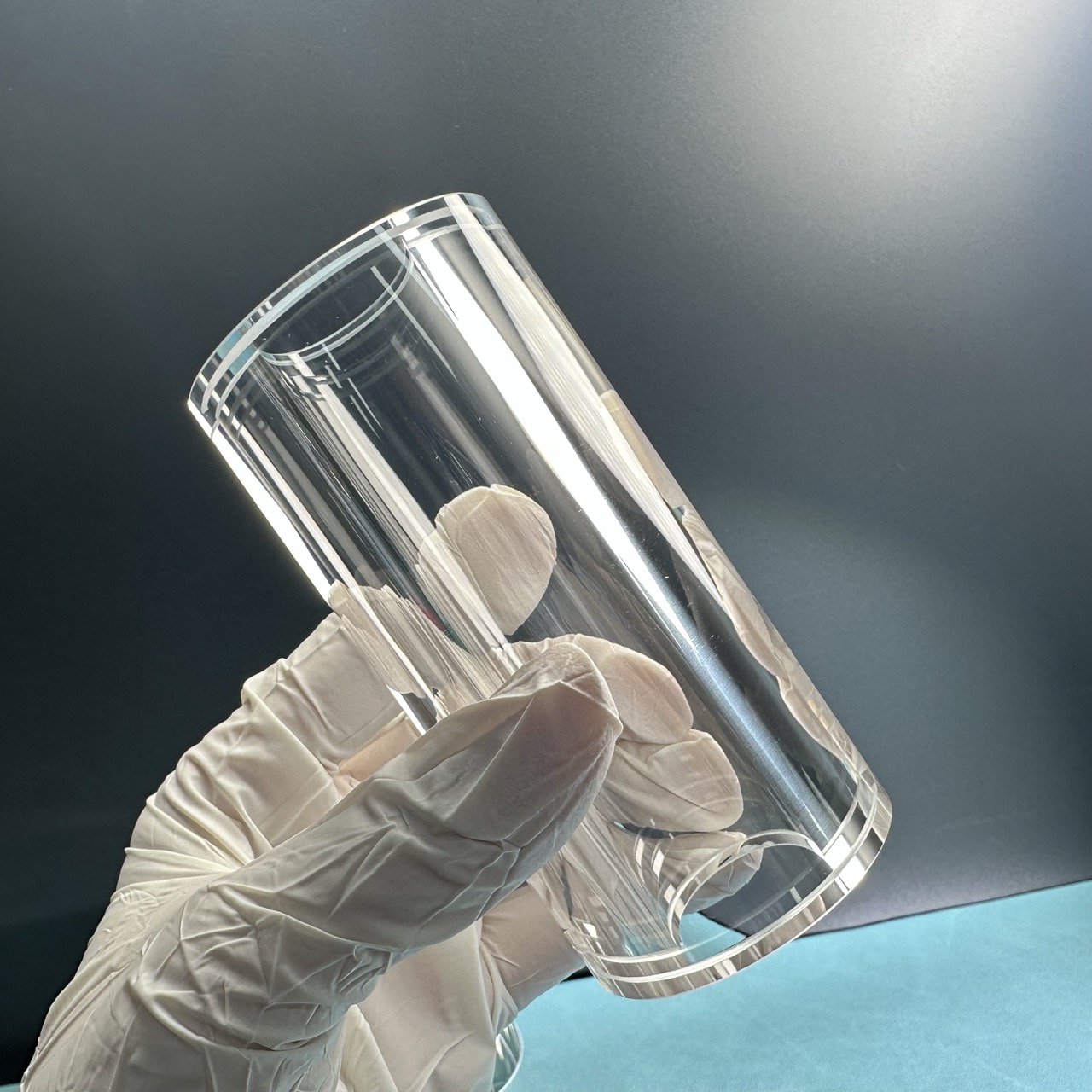

Li-Wafers tsa Quartz tsa High-Purity Fused Semiconductor, Photonics Optical Application 2″4″6″8″12″

Setšoantšo se qaqileng

Kakaretso ea Khalase ea Quartz

Li-wafer tsa quartz li etsa mokokotlo oa lisebelisoa tse ngata tsa sejoale-joale tse tsamaisang lefatše la kajeno la dijithale. Ho tloha ha u tsamaea ka smartphone ea hau ho ea mokokotlong oa liteishene tsa 5G, quartz e fana ka botsitso, bohloeki le ho nepahala ho hlokahalang ho lisebelisoa tsa elektroniki tse sebetsang hantle le tsa lifoto. Hore na e ts'ehetsa lipotoloho tse feto-fetohang, tse nolofalletsang li-sensor tsa MEMS, kapa ho theha motheo oa komporo ea quantum, litšobotsi tse ikhethang tsa quartz li etsa hore e be ea bohlokoa haholo indastering.

"Fused Silica" kapa "Fused Quartz" e leng karolo ea amorphous ea quartz (SiO2). Ha e bapisoa le khalase ea borosilicate, silica e kopantsoeng ha e na li-additives; ka hona e teng ka sebopeho sa eona se hloekileng, SiO2. Silika e kopantsoeng e na le phetisetso e phahameng ho khanya ea infrared le ultraviolet ha e bapisoa le khalase e tloaelehileng. Silika e kopantsoeng e hlahisoa ka ho qhibiliha le ho tiisa SiO2 ea ultrapure. Ka lehlakoreng le leng, silica e kopantsoeng ea maiketsetso e entsoe ka li-precursors tsa lik'hemik'hale tse nang le silicon tse ngata tse kang SiCl4 tse nang le gasified ebe li kenngoa moeeng oa H2 + O2. Lerōle la SiO2 le entsoeng tabeng ena le kopantsoe le silika holim'a substrate. Li-silica blocks tse kopantsoeng li khaoloa ho ba liphaphatha, ka mor'a moo li-wafers li qetella li bentšitsoe.

Lintlha tsa Bohlokoa le Melemo ea Quartz Glass Wafer

-

Ultra-High Purity (≥99.99% SiO2)

E loketse lits'ebetso tsa semiconductor tse hloekileng haholo le tsa photonics moo tšilafalo ea lintho tse bonahalang e tlamehang ho fokotsoa. -

Sebaka se Sephara sa Ts'ebetso ea Thermal

E boloka botšepehi ba sebopeho ho tloha mocheso oa cryogenic ho fihlela ho feta 1100 ° C ntle le ho loana kapa ho senyeha. -

Phetiso e ikhethang ea UV le IR

E fana ka khanya e hlakileng ea optical ho tloha ho ultraviolet e tebileng (DUV) ka haufi le infrared (NIR), e tšehetsang lits'ebetso tse hlakileng tsa optical. -

Phaello e Tlase ea Katoloso ea Mocheso

E ntlafatsa botsitso ba dimensional tlas'a ho fetoha ha mocheso, ho fokotsa khatello ea kelello le ho ntlafatsa ts'episo ea ts'ebetso. -

Khanyetso e Phahameng ea Lik'hemik'hale

Ha e kenelle ho li-acids tse ngata, li-alkali, le lihlapolli—e leng se etsang hore e tšoanelehe bakeng sa tikoloho e mabifi ea lik'hemik'hale. -

Bokaholimo Qetella Ho Fetolana

E fumaneha ka mehala e boreleli e boreleli, e lehlakoreng le le leng kapa e nang le mahlakore a mabeli, e tsamaellanang le litlhoko tsa photonics le MEMS.

Ts'ebetso ea Tlhahiso ea Quartz Glass Wafer

Li-wafers tsa quartz tse kopantsoeng li hlahisoa ka letoto la mehato e laoloang le e nepahetseng:

-

Khetho ea Lintho tse tala

Khetho ea quartz ea tlhaho e hloekileng haholo kapa mehloli ea maiketsetso ea SiO₂. -

Ho qhibiliha le Fusion

Quartz e qhibilihisoa ho ~ 2000 ° C ka libōping tsa motlakase tlas'a sepakapaka se laoloang ho felisa li-inclusions le li-bubble. -

Thibelo Ho theha

Silika e qhibilihisitsoeng e pholisoe ka li-blocks tse tiileng kapa li-ingots. -

Wafer Slicing

Taemane e nepahetseng kapa lisakha tsa terata li sebelisoa ho seha li-ingots hore li be likheo tsa liphaephe. -

Lapping & polishing

Bokaholimo ka bobeli bo batalatsoa 'me bo bentšitsoe ho kopana le lintlha tse hlakileng tsa optical, botenya le ho ba makukuno. -

Ho Hloekisa le ho Hlahloba

Li-wafers li hloekisoa ka har'a likamore tse hloekileng tsa ISO Class 100/1000 'me li hlahlojoa ka thata bakeng sa mefokolo le ho lumellana ha maemo.

Thepa ea Quartz Glass wafer

| spec | unit | 4" | 6" | 8" | 10" | 12" |

|---|---|---|---|---|---|---|

| Diameter / boholo (kapa sekwere) | mm | 100 | 150 | 200 | 250 | 300 |

| Mamello (±) | mm | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Botenya | mm | 0.10 kapa ho feta | 0.30 kapa ho feta | 0.40 kapa ho feta | 0.50 kapa ho feta | 0.50 kapa ho feta |

| Folete ea litšupiso ea mantlha | mm | 32.5 | 57.5 | Karolo e nyane | Karolo e nyane | Karolo e nyane |

| LTV (5mm×5mm) | μm | <0.5 | <0.5 | <0.5 | <0.5 | <0.5 |

| TTV | μm | <2 | <3 | <3 | <5 | <5 |

| Inamela | μm | ±20 | ±30 | ±40 | ±40 | ±40 |

| Warp | μm | ≤30 | ≤40 | ≤50 | ≤50 | ≤50 |

| PLTV (5mm×5mm) <0.4μm | % | ≥95% | ≥95% | ≥95% | ≥95% | ≥95% |

| Edge Rounding | mm | E lumellana le SEMI M1.2 Standard / sheba ho IEC62276 | ||||

| Mofuta oa Sebaka | Lehlakore le le leng le bentšitsoeng / Mahlakore a mabeli a bentšitsoeng | |||||

| Lehlakore le benyang Ra | nm | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| Mekhahlelo ea Lehlakore la Morao | μm | kakaretso 0.2-0.7 kapa customized | ||||

Quartz vs. Lisebelisoa tse ling tse Transparent

| Thepa | Khalase ea Quartz | Khalase ea Borosilicate | Sapphire | Khalase e Tloaelehileng |

|---|---|---|---|---|

| Max Operating Temp | ~1100°C | ~500°C | ~2000°C | ~200°C |

| Phetiso ea UV | E ntle haholo (JGS1) | Mafutsana | E ntle | E futsanehileng haholo |

| Khanyetso ea Lik'hemik'hale | E kgabane | E itekanetseng | E kgabane | Mafutsana |

| Bohloeki | E phahameng haholo | Tlase ho isa mahareng | Phahameng | Tlase |

| Katoloso ea Mocheso | Tlase haholo | E itekanetseng | Tlase | Phahameng |

| Litšenyehelo | E mahareng ho isa hodimo | Tlase | Phahameng | Tlase haholo |

Lipotso-potso tsa Quartz Glass Wafer

Q1: Phapano ke efe lipakeng tsa quartz e kopaneng le silica e kopaneng?

Le hoja ka bobeli e le mefuta ea amorphous ea SiO₂, quartz e kopantsoeng hangata e tsoa mehloling ea tlhaho ea quartz, athe silika e kopantsoeng e hlahisoa ka maiketsetso. Ka ts'ebetso, li fana ka ts'ebetso e ts'oanang, empa silika e kopaneng e kanna ea ba le bohloeki bo phahameng hanyane le homogeneity.

Q2: Na li-wafers tsa quartz tse kopantsoeng li ka sebelisoa libakeng tse nang le vacuum e phahameng?

Ee. Ka lebaka la thepa ea bona e fokolang ea ho tsoa le ho hanyetsa mocheso o phahameng, li-wafers tse kopantsoeng tsa quartz li ntle haholo bakeng sa lisebelisoa tsa vacuum le lisebelisoa tsa sefofane.

Q3: Na li-wafers tsee li loketse lits'ebetso tsa laser tse tebileng tsa UV?

Ruri. Quartz e kopantsoeng e na le phetisetso e phahameng ho fihla ho ~ 185 nm, e etsa hore e be e loketseng bakeng sa lisebelisoa tsa DUV Optics, limaske tsa lithography, le lisebelisoa tsa laser tsa excimer.

Q4: Na u tšehetsa mokhoa oa ho etsa liphaphatha?

Ee. Re fana ka tlhophiso e felletseng ho kenyelletsa bophara, botenya, boleng ba bokaholimo, lifolete/notch, le mohlala oa laser, ho ipapisitsoe le litlhoko tsa hau tse ikhethileng tsa kopo.

Mabapi le rona

XKH e sebetsa ka ho khetheha ho nts'etsopele ea theknoloji e phahameng, tlhahiso, le thekiso ea likhalase tse khethehileng tsa optical le lisebelisoa tse ncha tsa kristale. Lihlahisoa tsa rona li fana ka lisebelisoa tsa elektroniki tsa optical, lisebelisoa tsa elektroniki tsa bareki le sesole. Re fana ka lisebelisoa tsa mahlo tsa Sapphire, likoahelo tsa lense tsa mohala oa thekeng, Ceramics, LT, Silicon Carbide SIC, Quartz, le liphaphatha tsa kristale tsa semiconductor. Ka boitseanape bo nang le boiphihlelo le lisebelisoa tse tsoetseng pele, re ipabola ts'ebetsong ea lihlahisoa tse sa tloaelehang, ka sepheo sa ho ba khoebo e etelletseng pele ea theknoloji e phahameng ea optoelectronic.