HPSI SiC wafer dia:3inch botenya:350um± 25 µm bakeng sa Power Electronics

Kopo

Li-wafers tsa HPSI SiC li sebelisoa mefuteng e mengata ea lisebelisoa tsa elektroniki, ho kenyelletsa:

Li-Semiconductors tsa Matla:Li-wafers tsa SiC hangata li sebelisoa ho hlahisa li-diode tsa matla, li-transistors (MOSFETs, IGBTs), le thyristors. Li-semiconductors tsena li sebelisoa haholo lits'ebetsong tsa phetolo ea matla tse hlokang ts'ebetso e phahameng le ts'epahalo, joalo ka li-drive tsa liindasteri, lisebelisoa tsa motlakase le li-inverters bakeng sa lits'ebetso tsa matla a ka nchafatsoang.

Likoloi tsa Motlakase (EVs):Likarolong tsa motlakase tsa likoloi tsa motlakase, lisebelisoa tsa motlakase tse thehiloeng ho SiC li fana ka lebelo la ho fetoha ka potlako, matla a phahameng a matla, le tahlehelo e fokotsehileng ea mocheso. Likarolo tsa SiC li loketse lits'ebetso tsa lits'ebetso tsa taolo ea betri (BMS), lits'ebetso tsa ho tjhaja, le li-charger tsa on-board (OBCs), moo ho fokotsa boima ba 'mele le ho eketsa ts'ebetso e nepahetseng ea ho fetola matla ho bohlokoa.

Sistimi ea Matla a Tsosolositsoeng:Li-wafers tsa SiC li ntse li sebelisoa haholo ho li-inverters tsa letsatsi, lijenereithara tsa turbine tsa moea, le lits'ebetso tsa polokelo ea matla, moo ts'ebetso e phahameng le matla a hlokahalang. Likarolo tse thehiloeng ho SiC li thusa matla a phahameng a matla le ts'ebetso e ntlafetseng lits'ebetsong tsena, ho ntlafatsa katleho ea ho fetola matla ka kakaretso.

Electronics Power Electronics:Lits'ebetsong tse sebetsang hantle tsa indasteri, joalo ka likoloi tsa makoloi, liroboto, le lisebelisoa tse kholo tsa motlakase, tšebeliso ea li-wafers tsa SiC e lumella ts'ebetso e ntlafetseng mabapi le ts'ebetso, ts'epahalo le taolo ea mocheso. Lisebelisoa tsa SiC li khona ho sebetsana le maqhubu a phahameng a ho fetoha le mocheso o phahameng, ho etsa hore li tšoanelehe bakeng sa maemo a boima.

Litsi tsa Mehala le Boitsebiso:SiC e sebelisoa phepelong ea motlakase bakeng sa lisebelisoa tsa mehala ea mehala le litsi tsa data, moo ho ts'eptjoang haholo le phetoho e sebetsang ea matla e leng bohlokoa. Lisebelisoa tsa motlakase tse thehiloeng ho SiC li etsa hore ho be le ts'ebetso e phahameng ka boholo bo nyane, e fetolelang tšebeliso e fokotsehileng ea matla le ts'ebetso e ntle ea ho pholisa lits'ebetsong tse kholo.

Matla a phahameng a ho senyeha, ho hanyetsa ho fokolang, le tsamaiso e ntle ea mocheso oa li-wafers tsa SiC li li etsa sebaka se loketseng bakeng sa lisebelisoa tsena tse tsoetseng pele, tse nolofalletsang nts'etsopele ea moloko o latelang oa lisebelisoa tsa motlakase tse sebetsang hantle.

Thepa

| Thepa | Boleng |

| Wafer Diameter | 3 inche (76.2 mm) |

| Botenya ba Wafer | 350 µm ± 25 µm |

| Wafer Orientation | <0001> on-axis ± 0.5° |

| Boima ba Micropipe (MPD) | ≤ 1 cm⁻² |

| Ho hanyetsa Motlakase | ≥ 1E7 Ω·cm |

| Dopant | E butsoe |

| Maemo a Motheo a Flat | {11-20} ± 5.0° |

| Bolelele ba Phatlalatso ba Pele | 32.5 limilimithara ± 3.0 limilimithara |

| Bolelele ba Bokhabane ba Bobeli | 18.0 limilimithara ± 2.0 limilimithara |

| Boemo ba Bobeli ba Flat | Ho shebana holimo: 90 ° CW ho tloha foleteng ea mantlha ± 5.0 ° |

| Kenyelletso ea Edge | 3 limilimithara |

| LTV/TTV/Bow/Warp | 3 µm / 10 µm / ±30 µm / 40 µm |

| Bokhopo ba Sekaho | C-sefahleho: e bentšitsoe, Si-sefahleho: CMP |

| Mapetso (a hlahlojoa ke khanya e phahameng) | Ha ho letho |

| Hex Plates (e hlahlobiloe ka leseli le phahameng haholo) | Ha ho letho |

| Libaka tsa Polytype (tse hlahlobiloeng ke khanya e phahameng) | Sebaka sa Koketso 5% |

| Mekhoro (e hlahlobjoa ke khanya e matla haholo) | ≤ Mengoallo e 5, bolelele bo akaretsang ≤ 150 mm |

| Edge Chipping | Ha e lumelloe ≥ 0.5 mm bophara le botebo |

| Surface Contamination (e hlahlobjoa ke khanya e matla haholo) | Ha ho letho |

Melemo ea Bohlokoa

High Thermal Conductivity:Li-wafers tsa SiC li tsejoa ka bokhoni ba tsona bo ikhethang ba ho qhala mocheso, e leng se lumellang lisebelisoa tsa matla hore li sebetse ka katleho e phahameng le ho sebetsana le maqhubu a phahameng ntle le mocheso o feteletseng. Karolo ena e bohlokoa ho lisebelisoa tsa elektroniki moo taolo ea mocheso e leng phephetso e kholo.

Motlakase o Felletseng:Lekhalo le pharaletseng la SiC le nolofalletsa lisebelisoa ho mamella maemo a phahameng a motlakase, e leng se etsang hore e be tse loketseng lits'ebetso tse phahameng haholo tse kang li-grid tsa motlakase, likoloi tsa motlakase le mechini ea indasteri.

Sebetsa se Phahameng:Motsoako oa maqhubu a phahameng a ho feto-fetoha le maemo a tlase a ho hanyetsa ho fella ka lisebelisoa tse nang le tahlehelo e tlase ea matla, ho ntlafatsa katleho e akaretsang ea phetolo ea matla le ho fokotsa tlhoko ea litsamaiso tse rarahaneng tsa ho pholisa.

Ho Tšepahala Mabakeng a Mathata:SiC e khona ho sebetsa ka mocheso o phahameng (ho fihla ho 600 ° C), e leng se etsang hore e loketse ho sebelisoa libakeng tse ka senyang lisebelisoa tsa setso tse thehiloeng ho silicon.

Ho Boloka Matla:Lisebelisoa tsa motlakase tsa SiC li ntlafatsa ts'ebetso ea phetolo ea matla, e leng bohlokoa ho fokotsa tšebeliso ea matla, haholo lits'ebetsong tse kholo joalo ka li-converter tsa matla a indasteri, likoloi tsa motlakase, le lisebelisoa tsa motlakase tse nchafalitsoeng.

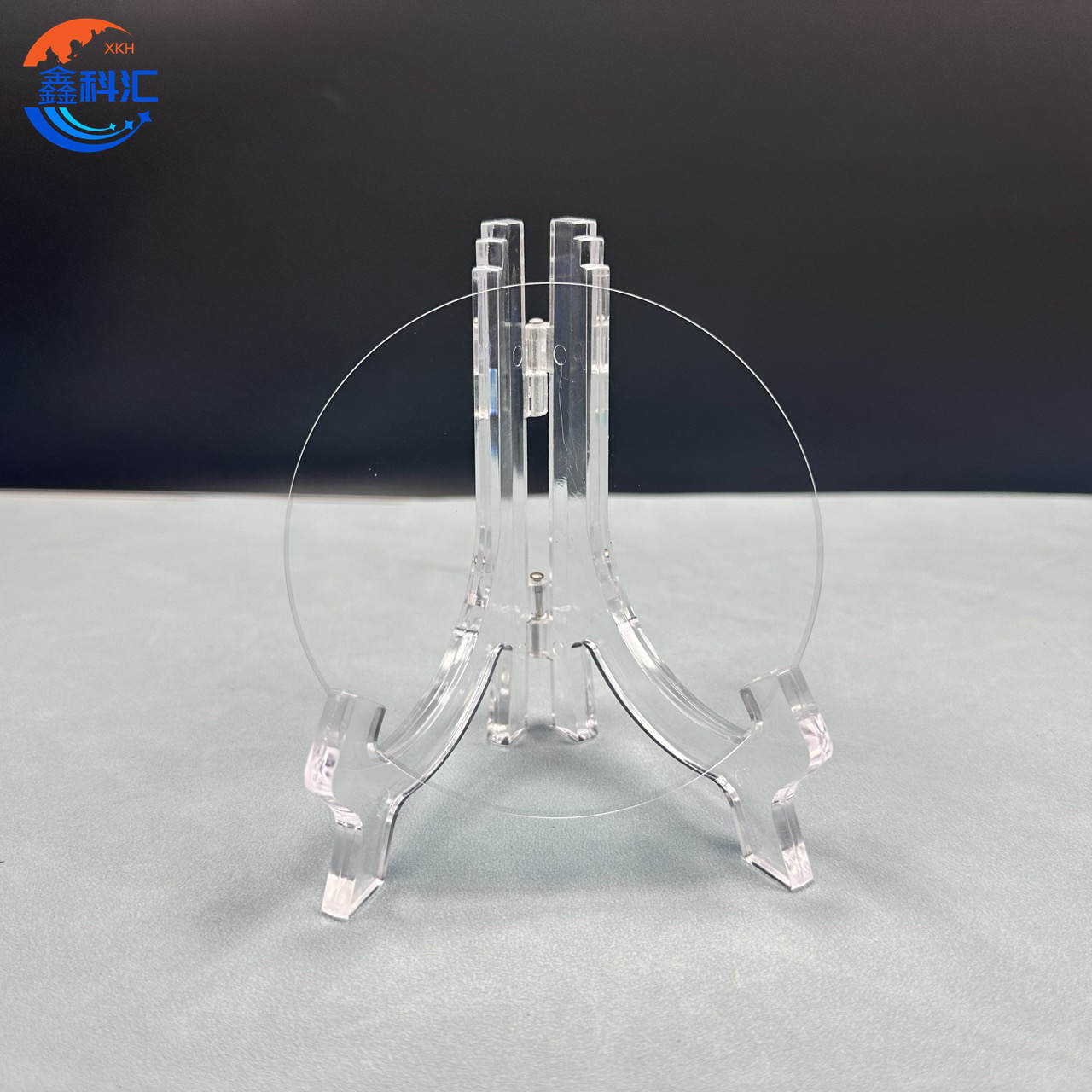

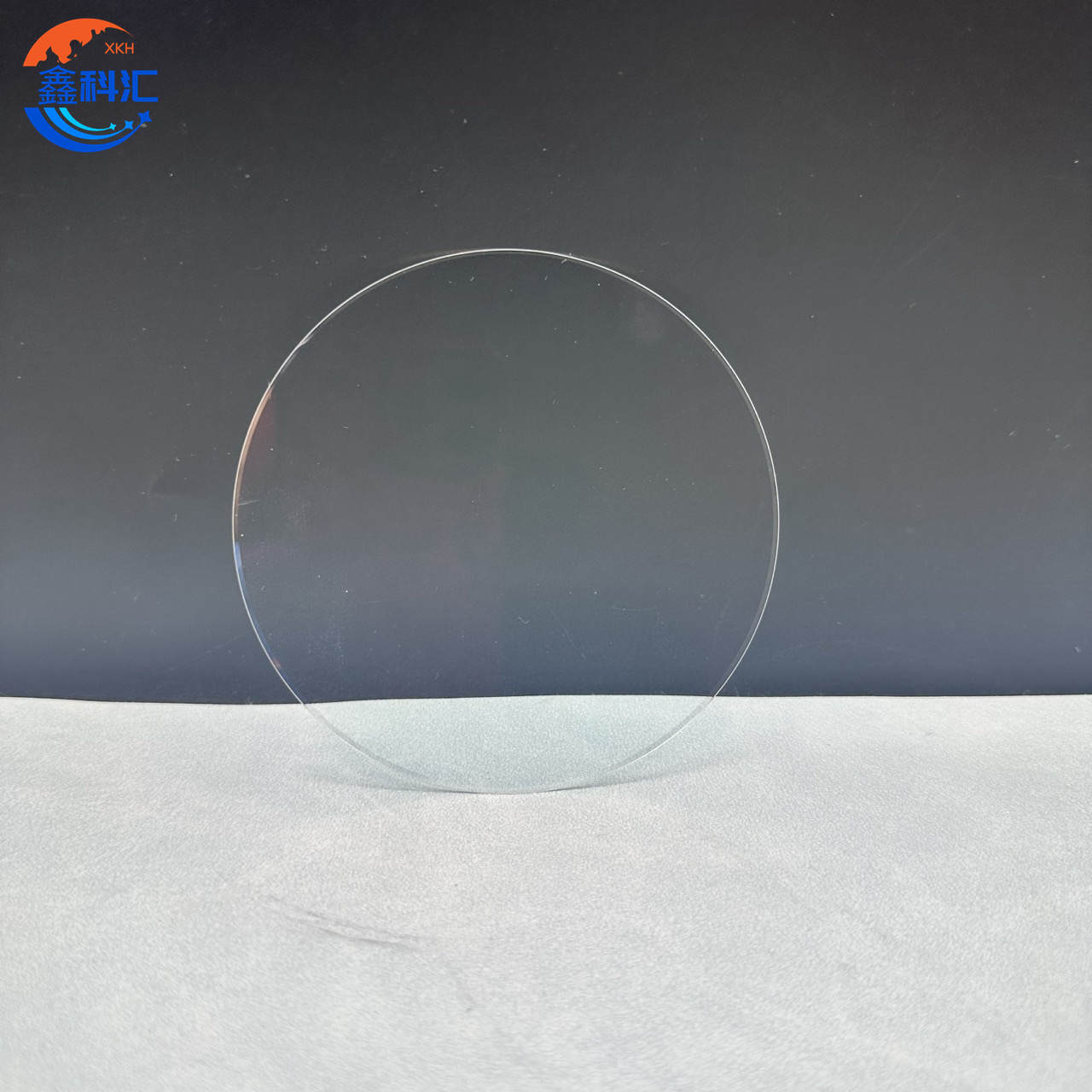

Setšoantšo se qaqileng