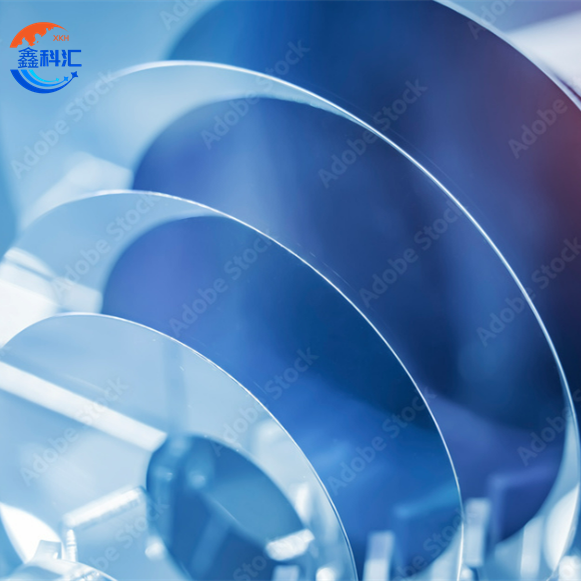

HPSI SiCOI sephaphatha 4 6inch Hydropholic Bonding

SiCOI Wafer (Silicon Carbide-on-Insulator) Overview Properties

Li-wafers tsa SiCOI ke moloko o mocha oa semiconductor substrate e kopanyang Silicon Carbide (SiC) e nang le lesela le sireletsang, hangata SiO₂ kapa safire, ho ntlafatsa ts'ebetso ea motlakase oa motlakase, RF, le photonics. Ka tlase ke kakaretso e felletseng ea thepa ea bona e arotsoeng ka likarolo tsa bohlokoa:

| Thepa | Tlhaloso |

| Sebopeho sa Lintho | Lera la Silicon Carbide (SiC) le tlanngoeng holim'a substrate e sireletsang (hangata SiO₂ kapa safire) |

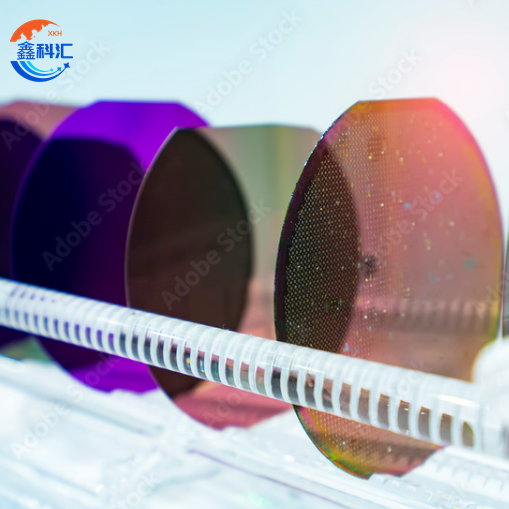

| Sebopeho sa Crystal | Ka tloaelo 4H kapa 6H polytypes ea SiC, e tsejoang ka boleng bo phahameng ba kristale le ho tšoana |

| Thepa ea Motlakase | Tšimo e phahameng ea motlakase e robehileng (~3 MV/cm), lekhalo le pharaletseng (~3.26 eV bakeng sa 4H-SiC), ho lutla ho tlase hona joale |

| Thermal Conductivity | Thermal conductivity e phahameng (~ 300 W/m·K), e nolofalletsang ho ntša mocheso o sebetsang hantle |

| Lera la Dielectric | Insulating layer (SiO₂ kapa safire) e fana ka karohano ea motlakase le ho fokotsa matla a likokoana-hloko. |

| Thepa ea Mechini | Boima bo phahameng (~9 Mohs scale), matla a babatsehang a mochine, le botsitso ba mocheso |

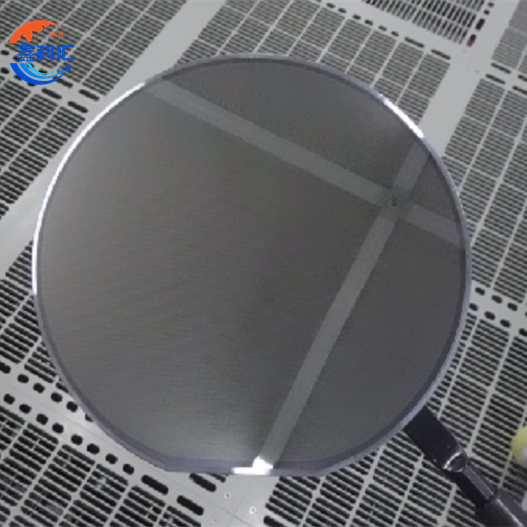

| Surface Finish | Ka tloaelo e boreleli e boreleli e nang le sekoli se tlase, e loketseng ho etsoa ha lisebelisoa |

| Lisebelisoa | Lisebelisoa tsa motlakase, lisebelisoa tsa MEMS, lisebelisoa tsa RF, li-sensor tse hlokang mocheso o phahameng le mamello ea motlakase |

Li-wafers tsa SiCOI (Silicon Carbide-on-Insulator) li emela sebopeho se tsoetseng pele sa semiconductor substrate, se nang le lesela le tšesaane la boleng bo holimo la silicon carbide (SiC) le kopantsoeng le lera le sireletsang, hangata silicon dioxide (SiO₂) kapa safire. Silicon carbide ke semiconductor e nang le li-bandgap tse ngata e tsejoang ka bokhoni ba eona ba ho mamella maqhubu a phahameng a mocheso le mocheso o phahameng, hammoho le conductivity e ntle ea mocheso le boima bo phahameng ba mochine, e leng se etsang hore e be se loketseng bakeng sa lisebelisoa tsa elektronike tse matla, tse phahameng le tse phahameng haholo.

The insulating layer ho SiCOI wafers e fana ka karohano e sebetsang ea motlakase, e fokotsa haholo capacitance ea parasitic le maqhubu a lutla lipakeng tsa lisebelisoa, ka hona e matlafatsa ts'ebetso ea sesebelisoa ka kakaretso le ho ts'epahala. Bokaholimo bo bentšitsoe ka nepo ho fihlela boreleli bo boreleli bo nang le mefokolo e nyane, ho fihlela litlhoko tse thata tsa tlhahiso ea lisebelisoa tse nyane le nano-scale.

Sebopeho sena sa thepa ha se ntlafatse feela litšobotsi tsa motlakase tsa lisebelisoa tsa SiC empa hape se ntlafatsa haholo tsamaiso ea mocheso le botsitso ba mechine. Ka lebaka leo, li-wafers tsa SiCOI li sebelisoa haholo ho lisebelisoa tsa elektronike tsa matla, lisebelisoa tsa maqhubu a seea-le-moea (RF), li-sensor tsa microelectromechanical system (MEMS) le lisebelisoa tsa elektronike tse nang le mocheso o phahameng. Ka kakaretso, li-wafers tsa SiCOI li kopanya thepa e ikhethang ea silicon carbide le melemo ea ho itšehla thajana ea motlakase ea lera la insulator, e fana ka motheo o nepahetseng bakeng sa moloko o latelang oa lisebelisoa tsa semiconductor tse sebetsang hantle haholo.

Sesebelisoa sa SiCOI safer

Lisebelisoa tsa Electronics tsa Matla

Li-switches tse nang le matla a phahameng le a phahameng, li-MOSFET le li-diode

Rua molemo ho tsoa ho bandgap e pharaletseng ea SiC, voltage e phahameng e senyehang, le botsitso ba mocheso

Ho fokotseha ha tahlehelo ea matla le ho ntlafatsa ts'ebetso ea ts'ebetso lits'ebetsong tsa phetolo ea matla

Likarolo tsa Radio Frequency (RF).

Li-transistors tsa maqhubu a phahameng le li-amplifiers

Matla a tlase a likokoana-hloko ka lebaka la lesela la insulate le ntlafatsa ts'ebetso ea RF

E loketse puisano ea 5G le litsamaiso tsa radar

Lisebelisoa tsa Microelectromechanical (MEMS)

Li-sensor le li-actuator tse sebetsang libakeng tse thata

Matla a mochini le ho se sebetse ha lik'hemik'hale ho eketsa nako ea bophelo ea sesebelisoa

E kenyelletsa lisensara tsa khatello, li-accelerometers, le li-gyroscopes

Lisebelisoa tsa Elektronike tsa Mocheso o Phahameng

Lisebelisoa tsa elektronike bakeng sa likoloi, sefofane, le lisebelisoa tsa indasteri

Sebetsa ka botshepehi maemong a phahameng a mocheso moo silicon e hlolehang

Lisebelisoa tsa Photonic

Ho kopanya le likarolo tsa optoelectronic ho li-insulator substrates

E lumella li-on-chip photonics ka taolo e ntlafalitsoeng ea mocheso

Lipotso le Likarabo tsa SiCOI oafer

P:sephaphatha sa SiCOI ke eng

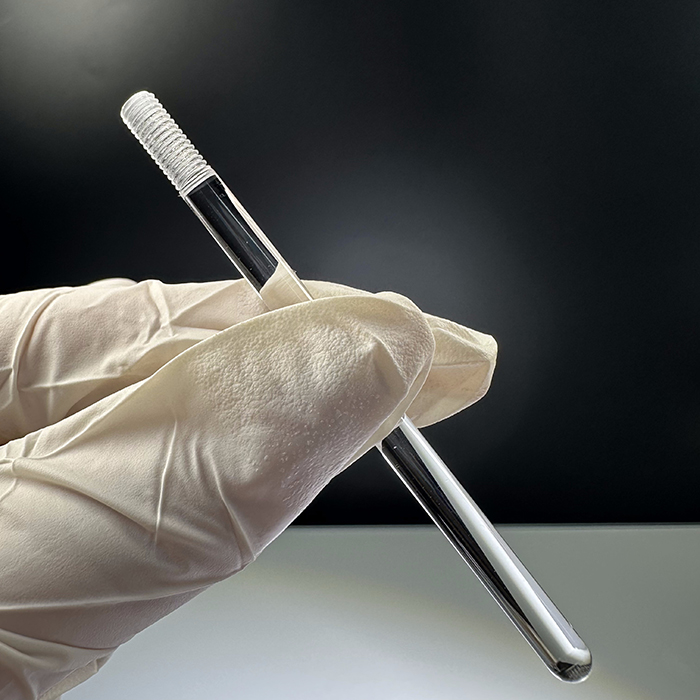

A:SiCOI wafer e emetse Silicon Carbide-on-Insulator wafer. Ke mofuta oa substrate ea semiconductor moo lesela le tšesaane la silicon carbide (SiC) le kopantsoeng le lera le sireletsang, hangata silicon dioxide (SiO₂) kapa ka linako tse ling safire. Sebopeho sena se ts'oana ka mohopolo ho li-wafers tse tsebahalang tsa Silicon-on-Insulator (SOI) empa se sebelisa SiC sebakeng sa silicon.

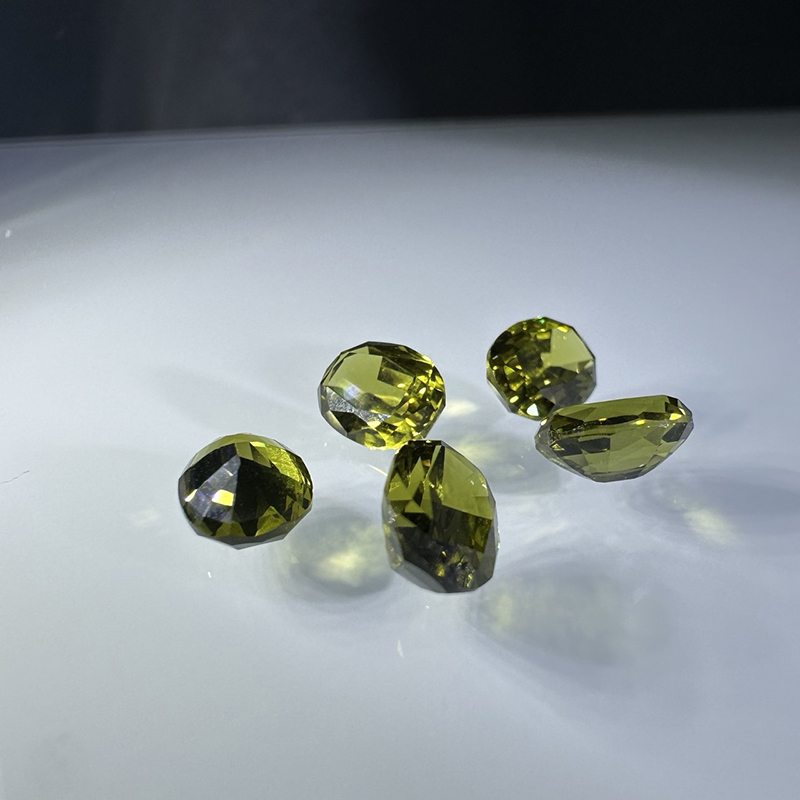

Setšoantšo