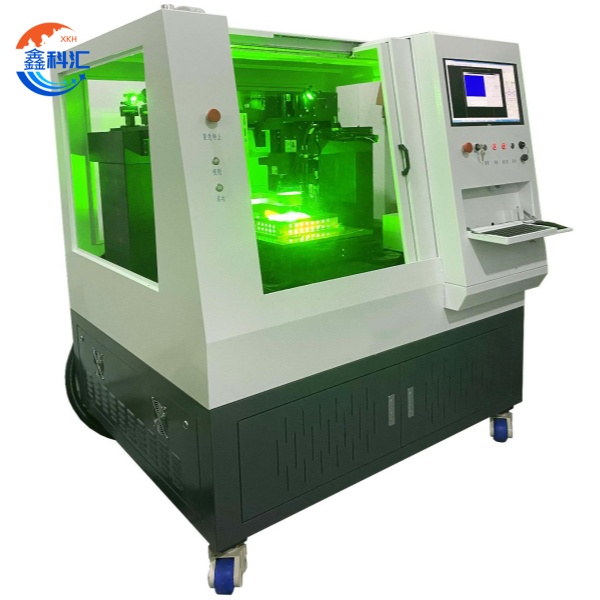

Thepa ea Infrared Nanosecond Laser Drilling bakeng sa Glass Drilling thick≤20mm

Parameter e kholo

| Mofuta oa laser | Infrared nanosecond |

| Boholo ba sethala | 800*600(mm) |

|

| 2000*1200(mm) |

| Botenya ba ho phunya | ≤20(mm) |

| Lebelo la ho phunya | 0-5000(mm/s) |

| Ho robeha ha moeli oa ho cheka | <0.5(mm) |

| Tlhokomeliso: Boholo ba sethala bo ka etsoa ka mokhoa o ikhethileng. | |

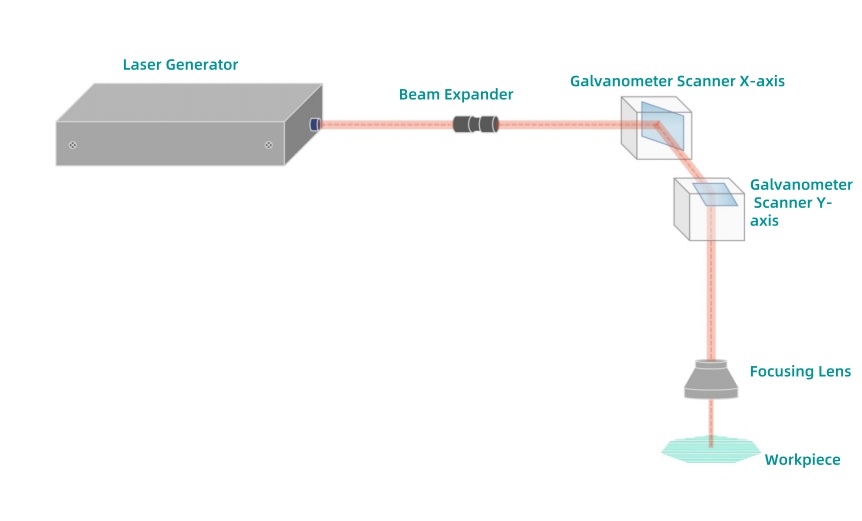

Laser Drilling Molao-motheo

Beam ea laser e tsepamisitsoe sebakeng se nepahetseng hantle ha e bapisoa le botenya ba sesebediswa sa mosebetsi, ebe e sheba litseleng tse boletsoeng esale pele ka lebelo le phahameng. Ka tšebelisano-'moho le lebone la laser le nang le matla a phahameng, thepa e shebiloeng e tlosoa lera-ka-lera ho etsa liteishene tse sehang, ho fihlela sebopeho se nepahetseng (se chitja, lisekoere, kapa li-geometri tse rarahaneng) ka karohano ea thepa e laoloang.

Melemo ea ho Epa Laser

· Khokahano e phahameng ea othomathike e nang le ts'ebeliso e nyane ea matla le ts'ebetso e nolofalitsoeng;

· Ts'ebetso e sa amaneng le batho e thusa li-geometri tse sa lekanyetsoang ho feta mekhoa e tloaelehileng;

· Ts'ebetso e sa sebelisoeng mahala e fokotsa litšenyehelo tsa ts'ebetso mme e ntlafatsa ts'ebetso ea tikoloho;

· Ho nepahala ho phahameng ka ho qhekella ho fokolang le ho felisa tšenyo ea mosebetsi oa bobeli;

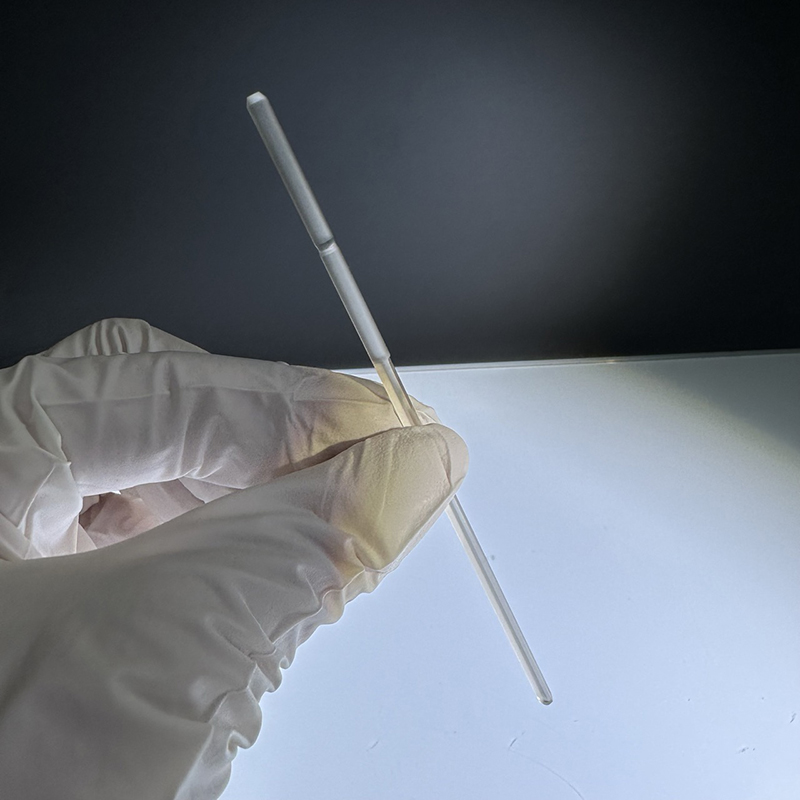

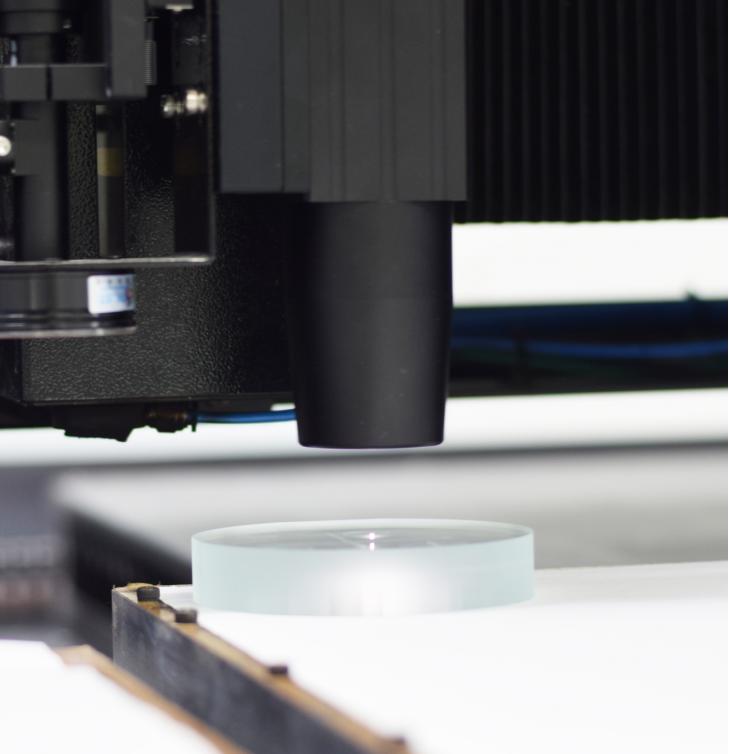

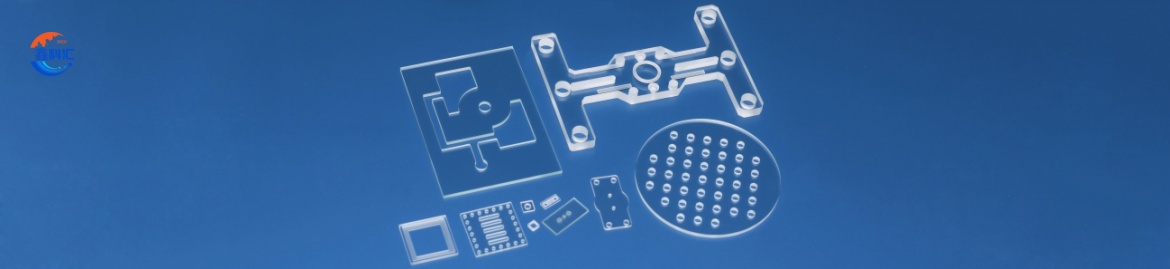

Pontšo ea mohlala

Ts'ebetso ea Ts'ebetso

Sistimi ena e entsoe bakeng sa ts'ebetso e nepahetseng ea lisebelisoa tse brittle / tse thata tse kenyelletsang ho cheka, ho phunya, ho tlosa filimi, le ho romella mongolo holimo. Lisebelisoa tse tloaelehileng li kenyelletsa:

1. Ho cheka le ho notlela likarolo tsa monyako oa shaoara

2. Perforation e nepahetseng ea lisebelisoa tsa khalase ea lisebelisoa

3. Solar panel ka ho cheka

4. Switch/socket cover plate perforation

5. Ho tlosoa ho roala ka seipone ka ho phunya

6. Tloaelo holim'a texturing le grooving bakeng sa lihlahisoa tse khethehileng

Melemo ea ho sebetsa

1. Sethala sa sebopeho se seholo se amohela mefuta e fapaneng ea lihlahisoa ho pholletsa le indasteri

2. Ho cheka li-contour tse rarahaneng ho fihletsoeng ts'ebetsong ea pase e le 'ngoe

3. Moeli o monyane oa ho cheka ka mokhoa o phahameng oa holimo (Ra <0.8μm)

4. Phetoho e se nang moeli pakeng tsa litlhaloso tsa sehlahisoa ka ts'ebetso e hlakileng

5. Ts'ebetso e baballang litšenyehelo e nang le:

· Lihlahisoa tse phahameng (> 99.2%)

· Consumable-mahala sebetsa

· Mesi e silafatsang e se nang letho

Ts'ebetso ea 6.Non-contact e tiisa ho boloka botšepehi holim'a metsi

Likarolo tsa Bohlokoa

1. Theknoloji ea Precision Thermal Management:

· E sebelisa ts'ebetso ea ho cheka ka makhetlo a mangata ka matla a lekoang a le mong (0.1–50 mJ)

· Sistimi e ncha ea tšireletso ea likharetene tsa moea e koalla sebaka se anngoeng ke mocheso ho isa ho 10% ea bophara ba lesoba.

· Mojule oa nako ea 'nete oa ho lekola mocheso oa infrared ka bohona o lefa liparamente tsa matla (± 2% botsitso)

2. Sethala sa Ts'ebetso se Bohlale:

· E na le sethala sa enjene se nepahetseng hantle se phahameng haholo (pheta ho nepahala ha boemo: ± 2 μm)

· Sistimi e kopaneng ea ho hokahanya pono (CCD ea 5-megapixel, ho nepahala ha tlhokomeliso: ± 5 μm)

· Database ea ts'ebetso e kentsoeng esale pele e nang le liparamente tse ntlafalitsoeng bakeng sa mefuta e fetang 50 ea lisebelisoa tsa khalase

3. Moralo oa Tlhahiso e Phahameng ka ho Fetisisa:

· Mokhoa oa ho sebetsa oa liteishene tse peli o nang le nako ea phetoho ea thepa ≤3 metsotsoana

* Potoloho e tloaelehileng ea ho sebetsa ea 1 lesoba/0.5 sec (Φ0.5 mm ka lesoba)

· Moralo oa modular o thusa ho fapanyetsana ka potlako ha lik'hamera tsa lense tse tsepamisitsoeng (sebaka sa ho sebetsa: Φ0.1–10 mm)

Lisebelisoa tsa Brittle Hard Material Processing

| Mofuta oa Boitsebiso | Boemo ba Kopo | Ho sebetsa litaba |

| Khalase ea soda-kalaka | Mamati a shaoara | Ho kenya likoti le likanale tsa drainage |

| Liphanele tsa taolo ea lisebelisoa | Mekhahlelo ea mekoti ea ho ntša metsi | |

| Khalase e futhumetseng | Lifensetere tse shebileng ka ontong | Ventilation lesoba arrays |

| Li-cooktops tsa induction | Likanale tse pholileng tse nang le angled | |

| Khalase ea Borosilicate | Liphanele tsa letsatsi | Likoti tse kenyang |

| Lisebelisoa tsa khalase tsa laboratori | Likanale tse tloahelehileng tsa drainage | |

| Khalase-ceramic | Libaka tsa ho pheha | Likoti tse behang mollo |

| Li-coahi tsa induction | Sensor mounting lesoba array | |

| Sapphire | Lisebelisoa tse bohlale tsa lisebelisoa | Likoti tsa moea |

| Libaka tsa pono tsa indasteri | Likoti tse matlafalitsoeng | |

| Khalase e apesitsoeng | Liipone tsa kamore ea ho hlapela | Ho kenya likoti (ho tlosa koae + ho phunya) |

| Mabota a lesira | Khalase e tlase-E e patileng masoba a drainage | |

| Khalase ea Ceramicized | Switch/socket covers | Libaka tsa polokeho + masoba a terata |

| Mekoallo ea mollo | Likoti tsa liphallelo tsa maemo a tšohanyetso |

XKH e fana ka ts'ehetso e felletseng ea tekheniki le lits'ebeletso tse ekelitsoeng boleng bakeng sa lisebelisoa tsa ho cheka likhalase tsa infrared nanosecond laser ho netefatsa ts'ebetso e nepahetseng nakong eohle ea bophelo ba lisebelisoa. Re fana ka lits'ebeletso tsa ntlafatso ea ts'ebetso moo sehlopha sa rona sa boenjiniere se sebelisanang haufi-ufi le bareki ho theha lilaeborari tse ikhethileng tsa lisebelisoa, ho kenyeletsoa le mananeo a khethehileng a ho cheka lisebelisoa tse thata tse kang safire le khalase e futhumetseng e nang le mefuta e fapaneng ea botenya ho tloha ho 0.1mm ho isa ho 20mm. Bakeng sa ntlafatso ea tlhahiso, re etsa tlhahlobo ea lisebelisoa tsa setšeng le liteko tsa netefatso ea ts'ebetso, ho netefatsa metrics ea bohlokoa joalo ka ho mamella bophara ba lesoba (± 5μm) le boleng ba moeli (Ra <0.5μm) li kopana le maemo a indasteri.