Thepa ea Infrared Picosecond Dual-Platform Laser Cutting bakeng sa Optical Glass/Quartz/Sapphire Processing

Parameter e kholo

| Mofuta oa Laser | Infrared Picosecond |

| Boholo ba Sethala | 700×1200 (mm) |

| 900×1400 (mm) | |

| Botenya ba ho Seha | 0.03-80 (mm) |

| Ho poma Lebelo | 0-1000 (mm/s) |

| Karohano ea Khale | <0.01 (mm) |

| Tlhokomeliso: Boholo ba sethala bo ka etsoa ka mokhoa o ikhethileng. | |

Likarolo tsa Bohlokoa

1.Theknoloji ea Ultrafast Laser:

· Maqhubu a makhutšoane a boemo ba Picosecond (10⁻¹²s) a kopantsoeng le theknoloji ea tokiso ea MOPA a fihlella matla a mangata a matla >10¹² W/cm².

· Infrared wavelength (1064nm) e kenella ka har'a lisebelisoa tse bonaletsang ka ho monya ka mokhoa o sa tsitsang, ho thibela ho ntšoa ha bokaholimo.

· Proprietary multi-focus optical system e hlahisa libaka tse 'ne tse ikemetseng tsa ts'ebetso ka nako e le ngoe.

2.Sistimi ea Kamahanyo ea liteishene tse peli:

· Granite-base dual linear motor stages (ho nepahala ha maemo: ±1μm).

· Nako ea ho fetola seteishene <0.8s, e nolofalletsang ts'ebetso ea "processing-loading/download".

· Taolo e ikemetseng ea mocheso (23±0.5 ° C) seteisheneng ka seng e netefatsa botsitso ba nako e telele ba mochini.

3.Intelligent Process Control:

* Sebaka sa polokelo ea thepa se kopantsoeng (likhasete tse 200+) bakeng sa ho tsamaisana le paramethara.

· Tlhahlobo ea nako ea sebele ea plasma e fetola matla a laser ka matla (tharollo ea phetoho: 0.1mJ).

· Tšireletso ea lesira la moea e fokotsa mapetsong a manyenyane (<3μm).

Tabeng e tloaelehileng ea kopo e kenyelletsang 0.5mm-thick sapphire wafer dicing, tsamaiso e finyella lebelo la ho itšeha la 300mm / s ka litekanyo tsa ho phunya <10μm, e emelang ntlafatso ea 5x ho feta mekhoa ea setso.

Melemo ea ho sebetsa

1.Integrated dual-station cutting and splitting system for flexible operation;

2.Ho sebetsa ka lebelo le phahameng la li-geometri tse rarahaneng ho matlafatsa ts'ebetso ea phetoho ea ts'ebetso;

3.Taper-free cutting edges with minimal chipping (<50μm) le ts'ebetso e sireletsehileng ea opareitara;

Phetoho ea 4.Seamless pakeng tsa lihlahisoa tsa lihlahisoa tse nang le ts'ebetso e utloahalang;

5.Litšenyehelo tse tlase tsa ts'ebetso, litefiso tse phahameng tsa chai, ts'ebetso e se nang tšebeliso le ts'ilafalo;

6.Zero tlhahiso ea slag, litšila tse metsi kapa metsi a litšila ka botšepehi bo tiisitsoeng ba holim'a metsi;

Pontšo ea mohlala

Lisebelisoa tse Tloaelehileng

1.Consumer Electronics Manufacturing:

· Ho itšeha ka mokhoa o nepahetseng oa khalase ea sekoaelo sa smartphone 3D (ho nepahala ha R-angle: ± 0.01mm).

· Ho phunya masoba a manyenyane ka lilense tsa oache ea safire (bonyane aperture: Ø0.3mm).

· Ho phethela libaka tse fetisoang ka likhalase tsa optical bakeng sa lik'hamera tse sa bonts'itsoeng hantle.

Tlhahiso ea 2.Optical Component:

· Microstructure machining bakeng sa lihlopha tsa lense tsa AR/VR (boholo ba tšobotsi ≥20μm).

· Ho itšeha ka mahlakoreng a mabeli a li-quartz bakeng sa laser collimators (ho mamellana ha angular: ± 15").

· Sebopeho sa profil ea li-filters tsa infrared (taper e sehang <0.5 °).

3.Semiconductor Packaging:

· Khalase ka tsela (TGV) e sebetsa maemong a liphaephe (karolelano ea 1:10).

· Microchannel etching holim'a likhalase substrates bakeng sa microfluidic chips (Ra <0.1μm).

· Ho fokotsa makhetlo a mangata bakeng sa li-resonator tsa quartz tsa MEMS.

Bakeng sa tlhahiso ea lifensetere tsa optical tsa LiDAR tsa koloi, sisteme e thusa ho seha likhalase tsa quartz tse botenya ba 2mm ka mokhoa o sehiloeng oa 89.5 ± 0.3 °, ho fihlela litlhoko tsa tlhahlobo ea vibrate ea boemo ba likoloi.

Ts'ebetso ea Ts'ebetso

E etselitsoe ka ho khetheha bakeng sa ho itšeha ka nepo ea lisebelisoa tse brittle / tse thata ho kenyelletsa:

1.Khalase e tloaelehileng & likhalase tsa optical (BK7, silica e kopantsoeng);

2. Likristale tsa quartz & substrates tsa safire;

3. Khalase e futhumetseng le li-filters tsa optical

4. Li-substrates tsa seipone

E khona ho cheka likoti ka bobeli le ho cheka mekoti e ka hare (bonyane Ø0.3mm)

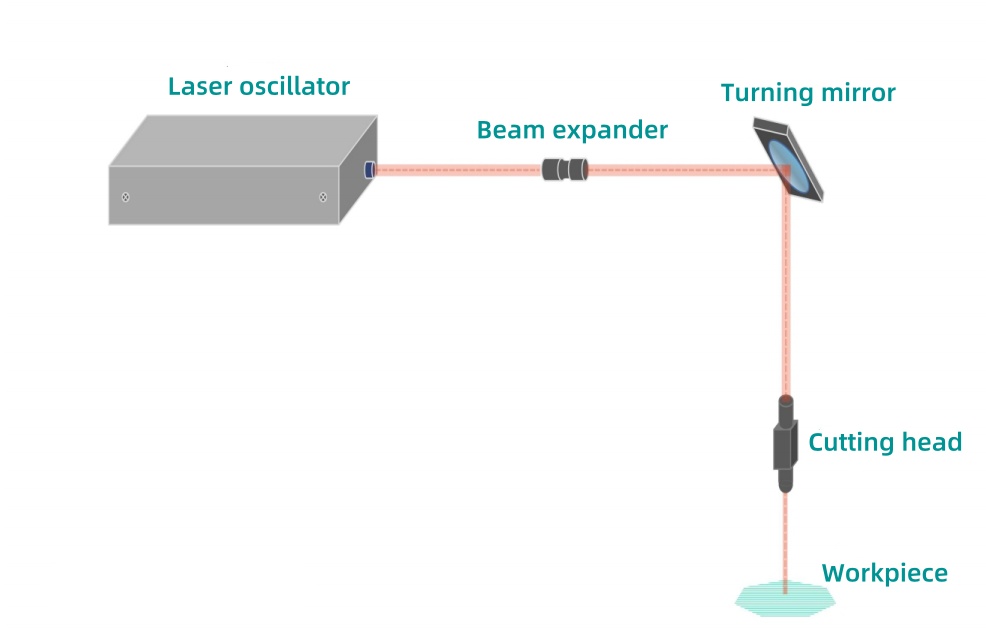

Laser Cutting Molao-motheo

Laser e hlahisa li-pulse tsa ultrashort tse nang le matla a phahameng haholo a hokahanang le sesebelisoa sa mosebetsi ka har'a li-timescales tsa femtosecond-to-picosecond. Nakong ea ho phatlalatsoa ka thepa, sefate se senya sebopeho sa sona sa khatello ea kelello ho etsa likoti tsa micron-scale filamentation. Optimized hole spacing hlahisa li-micro-cracks tse laoloang, tse kopanang le theknoloji ea ho phunya ho finyella karohano e nepahetseng.

Laser Cutting Melemo

1.High automation integration (ts'ebetso e kopantsoeng ea ho itšeha / ho phunya) ka tšebeliso e tlaase ea matla le ts'ebetso e bonolo;

Ts'ebetso ea 2.Non-contact e nolofalletsa bokhoni bo ikhethang bo ke keng ba finyelloa ka mekhoa e tloaelehileng;

Ts'ebetso ea 3.Consumable-free e fokotsa litšenyehelo tsa ho tsamaisa le ho ntlafatsa ts'ebetso ea tikoloho;

4.Superior e nepahetseng ka zero taper angle le ho felisa tšenyo ea mosebetsi oa bobeli;

XKH e fana ka lits'ebeletso tse felletseng tsa ho ikamahanya le maemo bakeng sa litsamaiso tsa rona tsa ho itšeha ka laser, ho kenyeletsoa tlhophiso ea sethala, nts'etsopele e ikhethileng ea ts'ebetso, le litharollo tse ikhethileng tsa ts'ebeliso ho fihlela litlhoko tse ikhethang tsa tlhahiso ho pholletsa le liindasteri tse fapaneng.