Mochini o benyang oa Ion Beam bakeng sa sapphire SiC Si

Setšoantšo se qaqileng

Tlhaloso ea Sehlahisoa sa Mochini oa Ion Beam polishing

The Ion Beam Figuring and polishing Machine e thehiloe holim'a molao-motheo oa ion sputtering. Ka har'a phaposi e nang le vacuum e phahameng, mohloli oa ion o hlahisa plasma, e potlakisang ho ba lebone la ion le nang le matla a phahameng. Lehlakore lena le otla bokaholimo ba karolo ea optical, le tlosa lisebelisoa ka sekala sa athomo ho fihlela tokiso e nepahetseng le ho qetela.

Joalo ka ts'ebetso e sa amaneng le batho, ho pholisa beam ea ion ho felisa khatello ea maikutlo le ho qoba tšenyo e ka tlas'a lefatše, ho etsa hore e be se loketseng bakeng sa ho etsa li-optics tse nepahetseng haholo tse sebelisoang bonoheng ba linaleli, sefofane, li-semiconductors le lits'ebetso tse tsoetseng pele tsa lipatlisiso.

Molao-motheo o sebetsang oa Mochini oa Ion Beam polishing

Moloko oa Ion

Khase e sa sebetseng (mohlala, argon) e kenngoa ka kamoreng ea vacuum 'me e kenngoa ka ionized ka ho tsoa ha motlakase ho etsa plasma.

Acceleration & Beam Formation

Li-ion li potlakisetsoa ho li-volts tse likete tse 'maloa kapa tse likete (eV) ebe li bōptjoa hore e be sebaka se tsitsitseng, se tsepamisitsoeng.

Ho Tlosa Lintho

Beam ea ion e fafatsa liathomo ho tsoa holimo ntle le ho qala tšebetso ea lik'hemik'hale.

Ho Fumana Phoso & Rero ea Tsela

Ho kheloha ha lipalo tsa bokaholimo ho lekanyetsoa ka interferometry. Mesebetsi ea ho tlosa e sebelisoa ho khetholla nako ea ho lula le ho hlahisa litsela tse ntlafalitsoeng tsa lisebelisoa.

Koala-Loop e Koetsoeng

Liphetoho tse pheta-phetoang tsa ho sebetsa le ho metha li tsoela pele ho fihlela lipehelo tse nepahetseng tsa RMS/PV li finyelloa.

Lintlha tsa Bohlokoa tsa Mochini oa Ion Beam polishing

Tšebelisano ea Universal Surface- E sebetsana le libaka tse bataletseng, tse chitja, tse aspherical le tse sa fetoheng

Sekhahla sa ho Tlosa se tsitsitseng haholo- E thusa ho lokisa palo ea sub-nanometer

Tshebetso e sa Senyeheng- Ha ho na bofokoli bo ka tlas'a lefatše kapa liphetoho tsa sebopeho

Tshebetso e tsitsitseng- E sebetsa ka mokhoa o ts'oanang hantle lisebelisoa tsa boima bo fapaneng

Tokiso ea Maqhubu a Tlase/Mahareng- E felisa liphoso ntle le ho hlahisa li-artifacts tsa mahareng / tse phahameng

Tlhokahalo e Tlaase ea Tlhokomelo- Ts'ebetso e telele e tsoelang pele e nang le nako e fokolang

Litlhaloso tse ka Sehloohong tsa Teknoloji ea Mochini oa Ion Beam polishing

| Ntho | Tlhaloso |

| Mokhoa oa ho sebetsa | Ho fafatsa hoa ion sebakeng se nang le vacuum e phahameng |

| Mofuta oa Ts'ebetso | Sebapali le ho bentša ha batho ba sa kopane |

| Boholo ba Workpiece | Φ4000 limilimithara |

| Lilepe Tsa Motsamao | 3-axis / 5-axis |

| Ho Tlosa Botsitso | ≥95% |

| Ho Nepaha ha Sebaka | PV <10 nm; RMS ≤ 0.5 nm (e tloaelehileng RMS <1 nm; PV <15 nm) |

| Bokhoni ba ho lokisa khafetsa | E tlosa liphoso tsa maqhubu a tlase-bohareng ntle le ho hlahisa liphoso tsa maqhubu a mahareng/a holimo |

| Ts'ebetso e Tsoelang Pele | Libeke tse 3-5 ntle le tlhokomelo ea vacuum |

| Litšenyehelo tsa Tlhokomelo | Tlase |

Bokhoni ba Ts'ebetso ea Mochini oa Ion Beam polishing

Mefuta e Tšehetsoeng ea Bokaholimo

E bonolo: E bataletse, e chitja, e prism

Complex: Symmetric/asymmetric asphere, off-axis asphere, cylindrical

E khethehileng: Ultra-thin optics, slat optics, hemispherical optics, conformal optics, phase plates, freeform surfaces

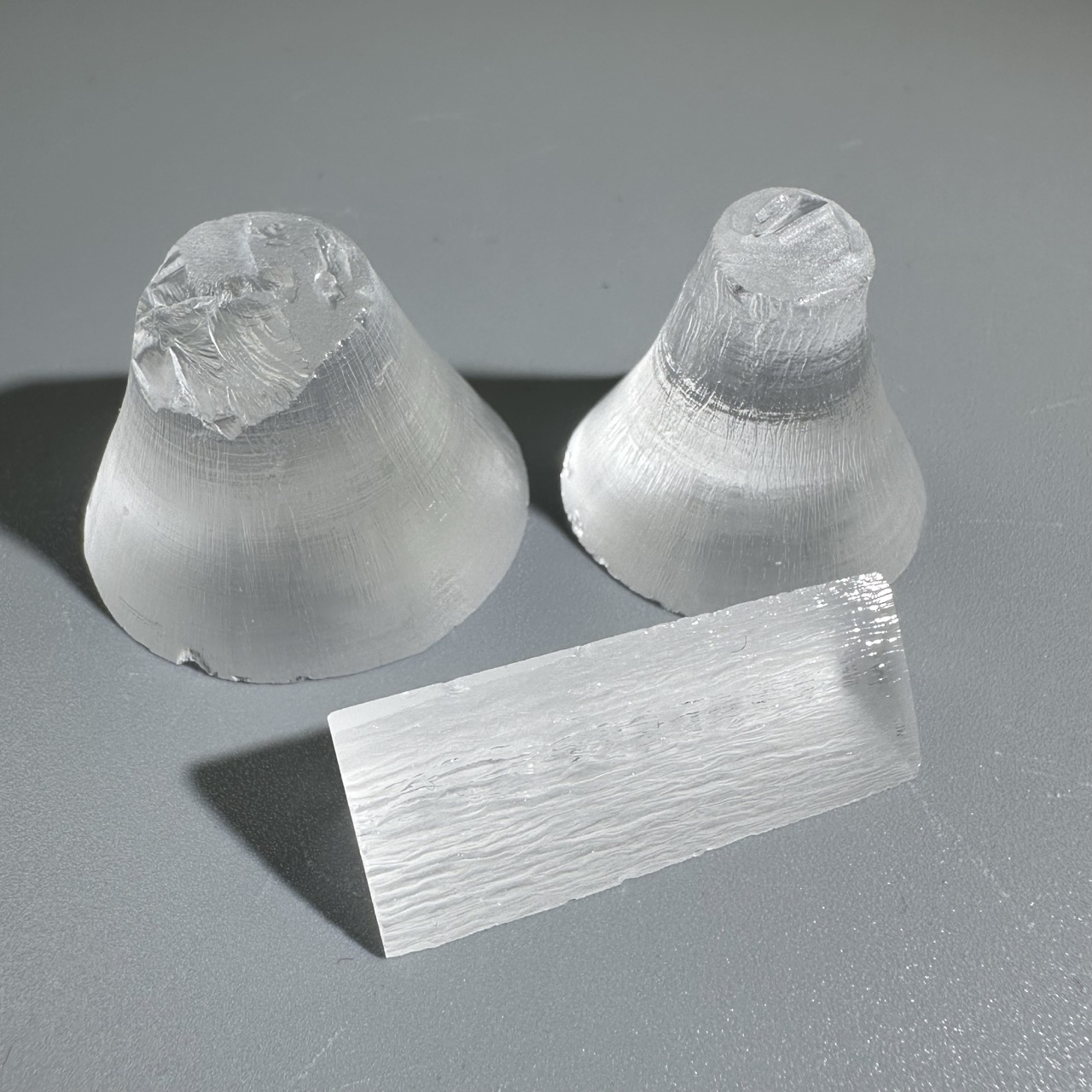

Lisebelisoa tse Tšehetsoeng

Khalase ea optical: Quartz, microcrystalline, K9, joalo-joalo.

Lisebelisoa tsa infrared: Silicon, germanium, joalo-joalo.

Litšepe: Aluminium, tšepe e sa hloekang, motsoako oa titanium, joalo-joalo.

Likristale: YAG, single-crystal silicon carbide, joalo-joalo.

Lisebelisoa tse thata / tse brittle: Silicon carbide, joalo-joalo.

Boleng ba Bokahohle / Precision

PV <10 nm

RMS ≤ 0.5 nm

Lithuto tsa Case tsa Ion Beam Polishing Machine

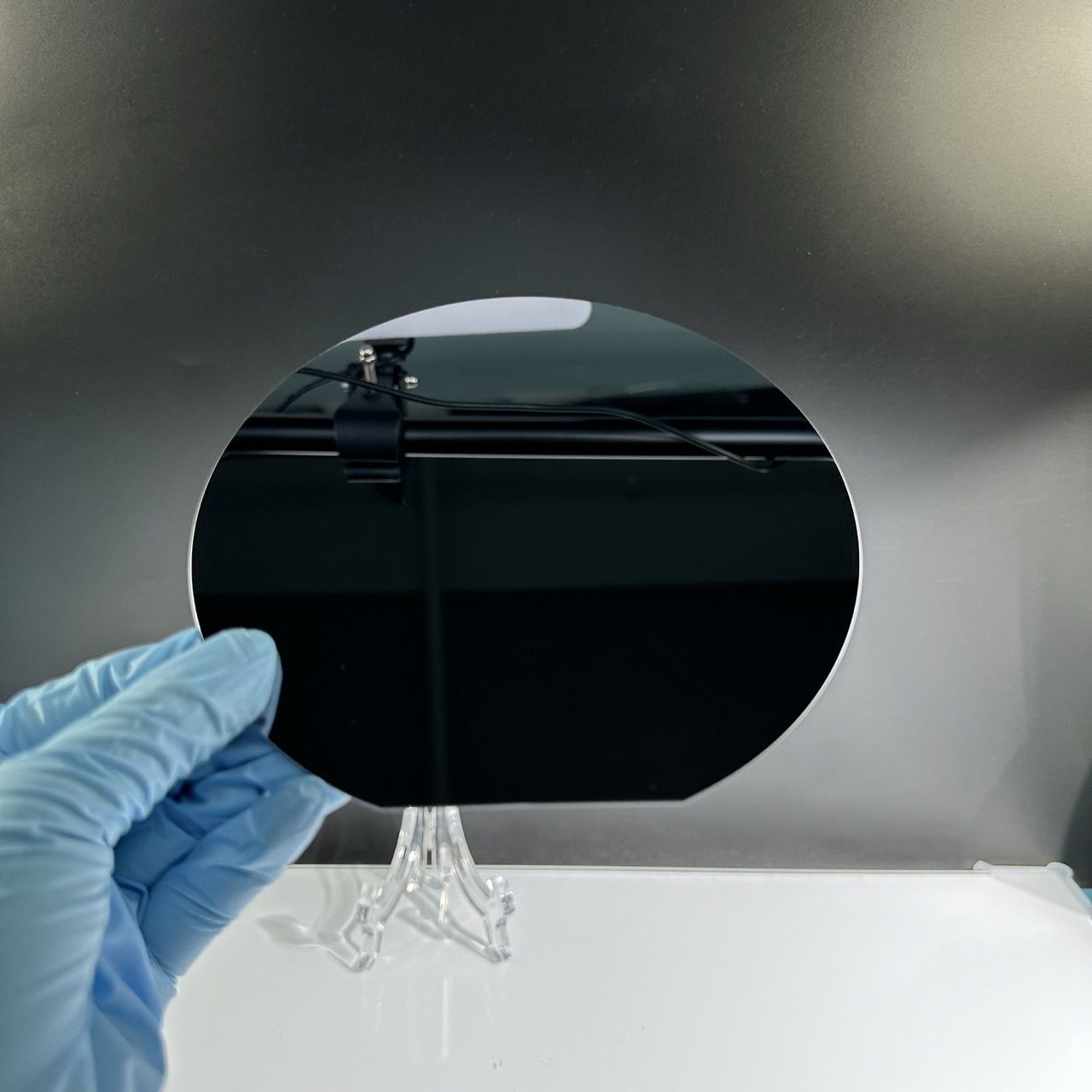

Taba ea 1 - Seipone se Tloaelehileng sa Flat

Sebaka sa mosebetsi: D630 mm quartz flat

Sephetho: PV 46.4 nm; RMS 4.63 nm

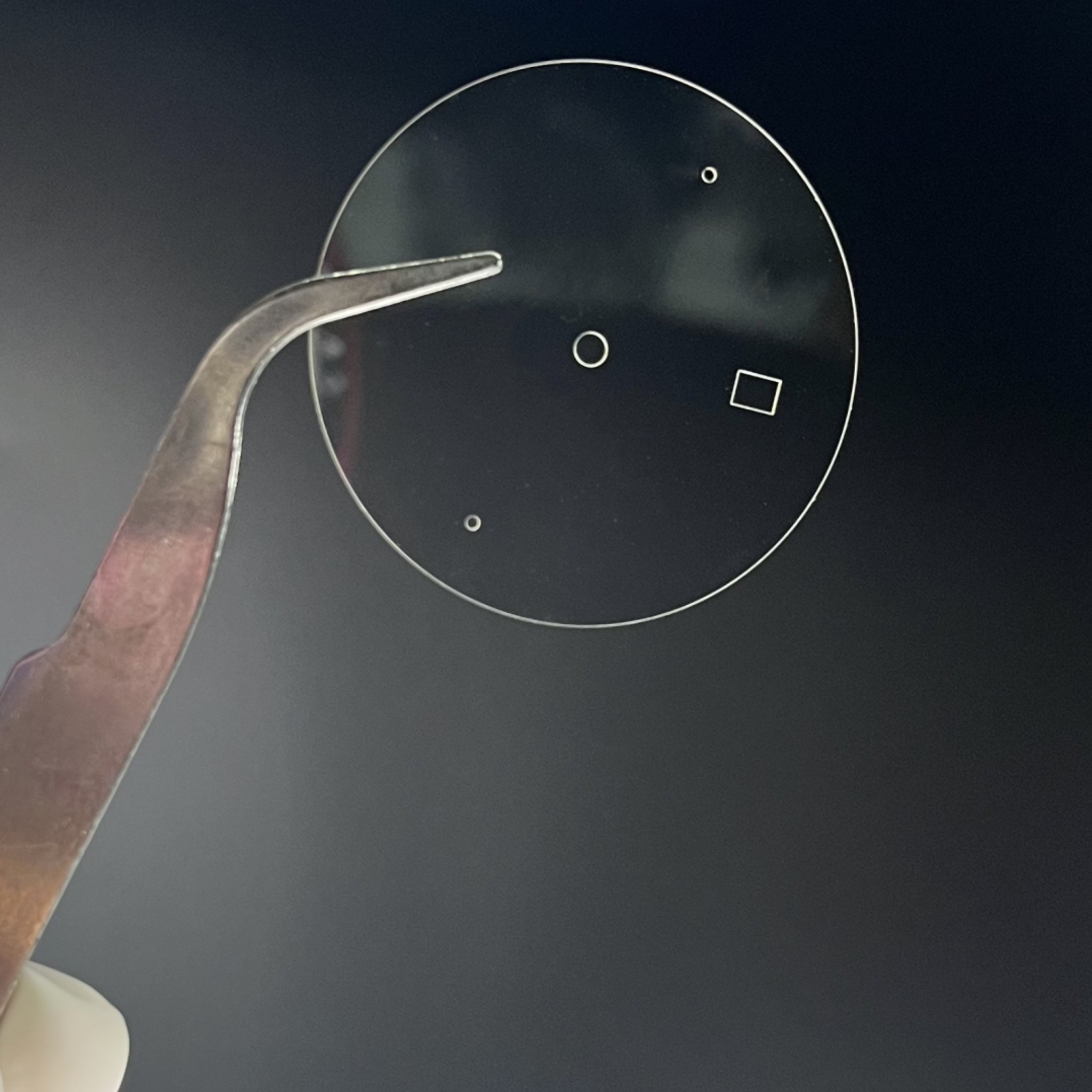

Taba ea 2 - Seipone se Reflective sa X-ray

Sesebelisoa sa mosebetsi: 150 × 30 mm silicon e bataletseng

Sephetho: PV 8.3 nm; RMS 0.379 nm; Moepa oa 0.13 µrad

Nyeoe ea 3 - Seipone sa Off-Axis

Sesebelisoa sa mosebetsi: D326 mm seipone sa fatše se ka thōko ho axis

Sephetho: PV 35.9 nm; RMS 3.9 nm

FAQ ea Likhalase tsa Quartz

FAQ - Mochini oa Ion Beam polishing

Q1: ion beam polishing ke eng?

A1:Ion beam polishing ke ts'ebetso e sa amaneng le batho e sebelisang seketsoana se tsepamisitsoeng sa li-ion (joalo ka li-ion tsa argon) ho tlosa thepa ho tloha sebakeng sa mosebetsi. Li-ion li potlakisoa 'me li lebisitsoe holimo, e leng se bakang ho tlosoa ha thepa ea boemo ba atomic, e leng se etsang hore ho be le liphetho tse boreleli haholo. Ts'ebetso ena e felisa khatello ea kelello ea mochini le tšenyo e ka tlas'a lefatše, e etsa hore e be e loketseng bakeng sa likarolo tse nepahetseng tsa optical.

Q2: Ke mefuta efe ea marulelo e ka etsoang ke mochini oa Ion Beam polishing Machine?

A2:TheMochini oa ho bentša oa Ion Beame ka sebetsana le mefuta e fapaneng ea bokaholimo, ho kenyelletsa le likarolo tse bonolo tsa optical joalo kaflats, spheres, le prism, hammoho le li-geometri tse rarahaneng joalokaaspheres, off-axis aspheres, lelibaka tse lokolohileng. E sebetsa ka ho khetheha linthong tse kang khalase ea optical, infrared optics, tšepe le lisebelisoa tse thata / tse brittle.

Q3: Ke lisebelisoa life tseo mochini oa Ion Beam polishing o ka sebetsang ka tsona?

A3:TheMochini oa ho bentša oa Ion Beame ka bentša mefuta e mengata ea lisebelisoa, ho kenyelletsa:

-

Khalase ea optical: Quartz, microcrystalline, K9, joalo-joalo.

-

Lisebelisoa tsa infrared: Silicon, germanium, joalo-joalo.

-

Litšepe: Aluminium, tšepe e sa hloekang, motsoako oa titanium, joalo-joalo.

-

Lisebelisoa tsa kristale: YAG, single-crystal silicon carbide, joalo-joalo.

-

Lisebelisoa tse ling tse thata / tse brittle: Silicon carbide, joalo-joalo.

Mabapi le rona

XKH e sebetsa ka ho khetheha ho nts'etsopele ea theknoloji e phahameng, tlhahiso, le thekiso ea likhalase tse khethehileng tsa optical le lisebelisoa tse ncha tsa kristale. Lihlahisoa tsa rona li fana ka lisebelisoa tsa elektroniki tsa optical, lisebelisoa tsa elektroniki tsa bareki le sesole. Re fana ka lisebelisoa tsa mahlo tsa Sapphire, likoahelo tsa lense tsa mohala oa thekeng, Ceramics, LT, Silicon Carbide SIC, Quartz, le liphaphatha tsa kristale tsa semiconductor. Ka boitseanape bo nang le boiphihlelo le lisebelisoa tse tsoetseng pele, re ipabola ts'ebetsong ea lihlahisoa tse sa tloaelehang, ka sepheo sa ho ba khoebo e etelletseng pele ea theknoloji e phahameng ea optoelectronic.