Microjet tham mong bang laser thekenoloji thepa sephaha seha SiC thepa sebetsa

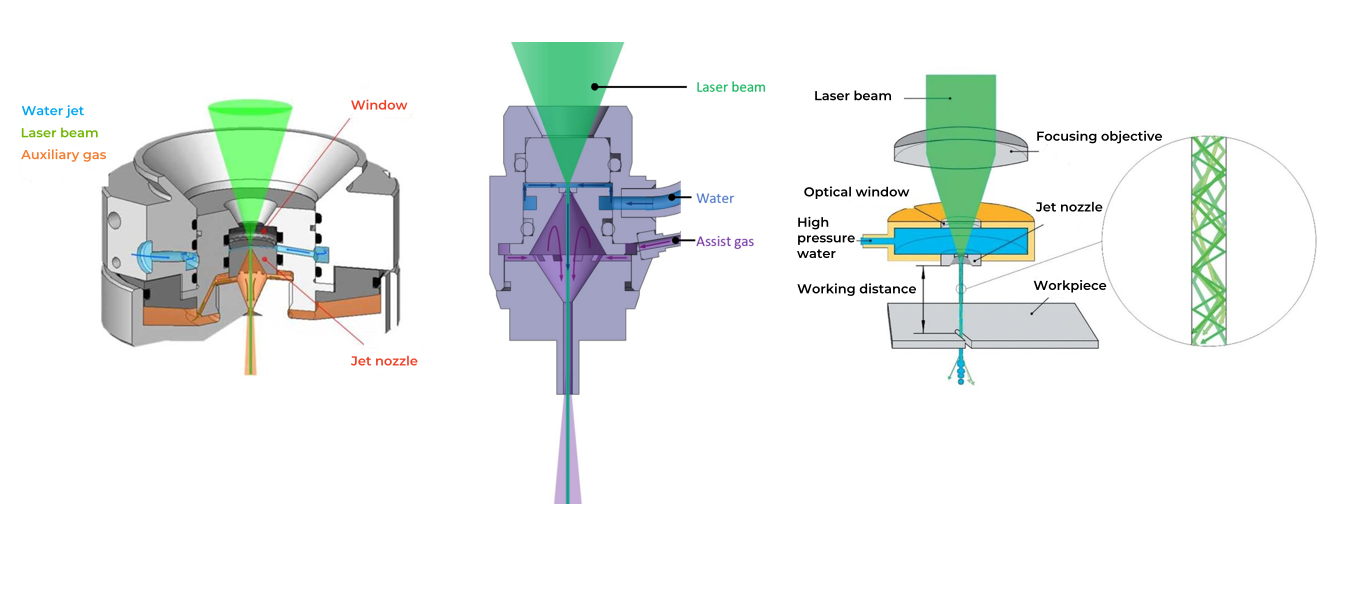

Molao-motheo oa tshebetso:

1. Laser coupling: pulsed laser (UV / green / infrared) e tsepamisitsoe ka hare ho jete ea metsi ho theha mocha o tsitsitseng oa phetisetso ea matla.

2. Tataiso ea mokelikeli: jete ea lebelo le phahameng (sekhahla sa phallo ea 50-200m / s) se pholisa sebaka sa ho sebetsa le ho tlosa litšila ho qoba ho bokella mocheso le tšilafalo.

3. Ho tlosoa ha thepa: Matla a laser a baka phello ea cavitation ka mokelikeli ho finyella ts'ebetso e batang ea thepa (mocheso o amehang sebakeng <1μm).

4. Taolo ea matla: phetoho ea nako ea sebele ea lisebelisoa tsa laser (matla, maqhubu) le khatello ea jete ho finyella litlhoko tsa lisebelisoa le mehaho e fapaneng.

Lintlha tsa bohlokoa:

1. Matla a Laser: 10-500W (e ka fetoloang)

2. Jet bophara: 50-300μm

3.Machining ho nepahala: ± 0.5μm (ho itšeha), botebo ho isa bophara karo-karolelano 10: 1 (ho phunya)

Melemo ea tekheniki:

(1) Ho senya mocheso hoo e ka bang lefela

- Pholiso ea jet ea metsi e laola sebaka se amehileng ke mocheso (HAZ) ho **<1μm**, ho qoba mapetsong a manyenyane a bakoang ke ts'ebetso e tloaelehileng ea laser (HAZ hangata> 10μm).

(2) Ho sebetsa ka mokhoa o nepahetseng haholo

- Ho seha / ho cheka ho nepahala ho fihlela ho ** ± 0.5μm **, bohale bo bohale Ra<0.2μm, ho fokotsa tlhokahalo ea ho belisoa ho latelang.

- Ts'ehetsa ts'ebetso e rarahaneng ea sebopeho sa 3D (joalo ka masoba a conical, slots tse nang le sebopeho).

(3) Ho lumellana ho pharaletseng

- Lisebelisoa tse thata le tse brittle: SiC, safire, khalase, ceramics (mekhoa ea setso e bonolo ho pshatla).

- Lisebelisoa tse nang le mocheso oa mocheso: li-polymers, li-tissue tsa likokoana-hloko (ha ho na kotsi ea ho senyeha ha mocheso).

(4) Tšireletso le katleho ea tikoloho

- Ha ho tšilafalo ea lerōle, mokelikeli o ka sebelisoa hape le ho sefuoa.

- 30% -50% e eketseha ka lebelo la ho sebetsa (khahlanong le machining).

(5) Taolo e bohlale

- Boemo bo kopaneng ba pono le ts'ebetso ea paramethara ea AI, botenya ba lintho tse feto-fetohang le bofokoli.

Lintlha tsa tekheniki:

| Molumo oa countertop | 300*300*150 | 400*400*200 |

| Linear axis XY | Enjene ea mola. Enjene ea mola | Enjene ea mola. Enjene ea mola |

| Linear axis Z | 150 | 200 |

| Ho beha ho nepahala μm | +/-5 | +/-5 |

| Ho nepahala ha maemo a phetoang μm | +/-2 | +/-2 |

| Ho potlakisa G | 1 | 0.29 |

| Taolo ya dipalo | 3 axis /3+1 axis /3+2 axis | 3 axis /3+1 axis /3+2 axis |

| Mofuta oa taolo ea linomoro | DPSS Nd:YAG | DPSS Nd:YAG |

| Wavelength nm | 532/1064 | 532/1064 |

| Matla a lekantsoeng W | 50/100/200 | 50/100/200 |

| Jete ea metsi | 40-100 | 40-100 |

| Nozzle khatello ea bar | 50-100 | 50-600 |

| Litekanyo (sesebelisoa sa mochini) (bophara * bolelele * bophahamo) limilimithara | 1445*1944*2260 | 1700*1500*2120 |

| Boholo (khabinete ea taolo) (W * L * H) | 700*2500*1600 | 700*2500*1600 |

| Boima (sesebediswa) T | 2.5 | 3 |

| Boima (control cabinet) KG | 800 | 800 |

| Bokhoni ba ho sebetsa | Bokhopo bo holimo Ra≤1.6um Lebelo la ho bula ≥1.25mm/s Ho itšeha ka selikalikoe ≥6mm/s Linear seha lebelo ≥50mm/s | Bokhopo bo holimo Ra≤1.2um Lebelo la ho bula ≥1.25mm/s Ho itšeha ka selikalikoe ≥6mm/s Linear seha lebelo ≥50mm/s |

| Bakeng sa gallium nitride crystal, ultra-wide band gap semiconductor materials (diamond/Gallium oxide), thepa e khethehileng ea aerospace, LTCC carbon ceramic substrate, photovoltaic, scintillator crystal le lisebelisoa tse ling tse sebetsang. Tlhokomeliso: Bokhoni ba ho sebetsa bo fapana ho latela litšobotsi tsa thepa

| ||

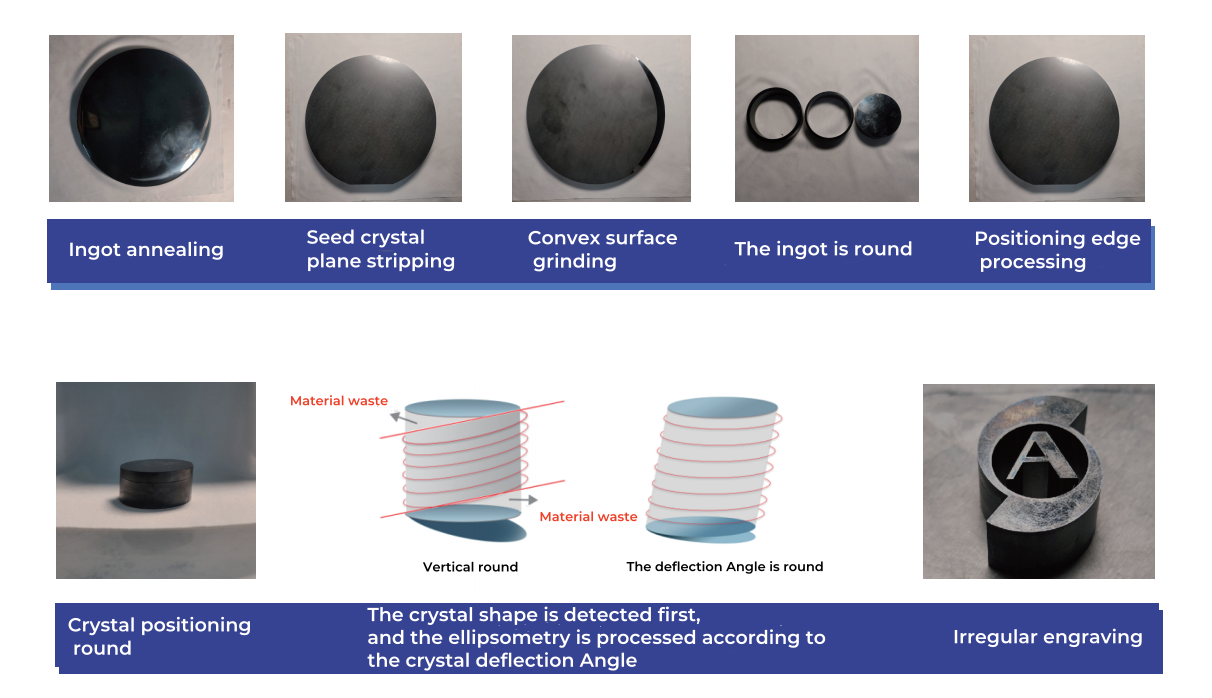

Taba ea ho sebetsa:

Litšebeletso tsa XKH:

XKH e fana ka ts'ehetso e felletseng ea ts'ebeletso ea bophelo bo felletseng bakeng sa lisebelisoa tsa thekenoloji ea laser ea microjet, ho tloha ts'ebetsong ea pele ea nts'etsopele le khetho ea lisebelisoa, ho isa ho kopantseng tsamaiso ea nako e bohareng (ho kenyeletsoa ho bapaloa ho khethehileng ha mohloli oa laser, sistimi ea jet le mochini oa othomathike), ho isa koetlisong ea morao-rao ea ts'ebetso le tlhokomelo le ts'ebetso e tsoelang pele ea ts'ebetso, ts'ebetso eohle e na le ts'ehetso ea sehlopha sa litsebi; Ho ipapisitsoe le lilemo tse 20 tsa boiphihlelo bo nepahetseng ba machining, re ka fana ka litharollo tsa sebaka se le seng ho kenyelletsa netefatso ea lisebelisoa, kenyelletso ea tlhahiso ea bongata le karabelo e potlakileng ea kamora thekiso (lihora tse 24 tsa tšehetso ea tekheniki + polokelo ea likarolo tsa bohlokoa) bakeng sa liindasteri tse fapaneng tse kang semiconductor le bongaka, mme re ts'episa likhoeli tse 12 tiisetso e telele le tlhokomelo ea bophelo bohle le ts'ebeletso ea ntlafatso. Netefatsa hore lisebelisoa tsa bareki li lula li boloka ts'ebetso e etelletseng pele indastering le botsitso.

Setšoantšo se qaqileng