Sistimi ea ho Seha Laser e Tataisoang ke Metsi ea Microjet bakeng sa Lisebelisoa tse Tsoetseng Pele

Top Melemo

1. Tsepamiso ea Matla e ke keng ea Baptjoa ka Tataiso ea Metsi

Ka ho sebelisa jete ea metsi e hatelitsoeng hantle e le leqhubu la laser waveguide, sistimi e felisa tšitiso ea moea mme e netefatsa ho tsepamisa maikutlo ho felletseng ka laser. Sephetho ke bophara bo sehiloeng ka mokhoa o moqotetsane - bo nyane joalo ka 20μm - bo nang le mapheo a bohale, a hloekileng.

2. Minimal Thermal Footprint

Taolo ea nako ea 'nete ea mocheso ea sistimi e netefatsa hore sebaka se anngoeng ke mocheso ha se fete 5μm, se bohlokoa bakeng sa ho boloka ts'ebetso ea thepa le ho qoba li-microcracks.

3. Bophara ba Material Compatibility

Phatlalatso ea maqhubu a mabeli (532nm/1064nm) e fana ka tokiso e ntlafalitsoeng ea ho monya, e etsa hore mochini o ikamahanye le mefuta e fapaneng ea li-substrates, ho tloha ho likristale tse bonaletsang ho isa ho lirafshoa tse opaque.

4. Lebelo le Phahameng, Taolo ea Motion ea Phahameng ka ho Fetisisa

Ka likhetho tsa li-motor tse tsamaeang ka kotloloho le tse otlolohileng, sistimi e ts'ehetsa litlhoko tse phahameng ntle le ho senya ho nepahala. Ho sisinyeha ha li-axis tse hlano ho thusa hape ho etsa mokhoa o rarahaneng oa ho etsa lipaterone le ho fokotsa likarolo tse ngata.

5. Moqapi oa Modular le Scalable

Basebelisi ba ka hlophisa litlhophiso tsa sistimi ho ipapisitse le litlhoko tsa ts'ebeliso - ho tloha ho prototyping e thehiloeng ho lab ho isa lits'ebetsong tsa tekanyo ea tlhahiso-ho etsa hore e tšoanelehe hohle libakeng tsa R&D le tsa indasteri.

Libaka tsa Kopo

Li-Semiconductors tsa Moloko oa Boraro:

E nepahetse bakeng sa li-wafers tsa SiC le GaN, sistimi e etsa dicing, trenching le slicing ka bots'epehi bo ikhethang.

Diamond le Oxide Semiconductor Machining:

E sebelisetsoa ho seha le ho cheka lisebelisoa tse thata haholo joalo ka daemane ea kristale e le 'ngoe le Ga₂O₃, e se nang carbonization kapa thermal deformation.

Likarolo tse Tsoetseng Pele tsa Sefofane:

E ts'ehetsa sebopeho sa sebopeho sa li-composite tsa ceramic tse matla haholo le li-superalloys bakeng sa enjine ea jete le likarolo tsa satellite.

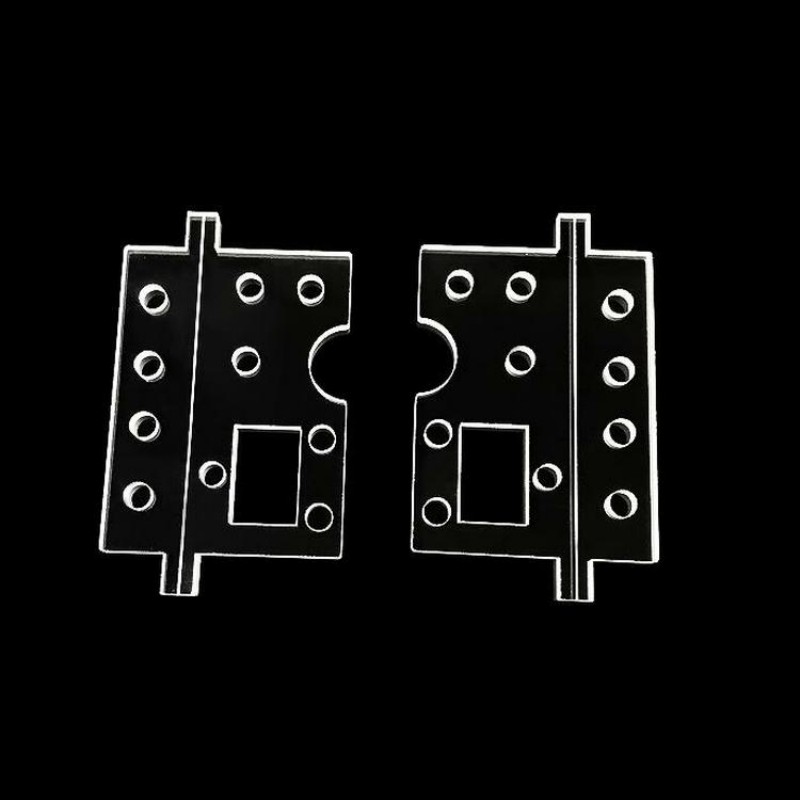

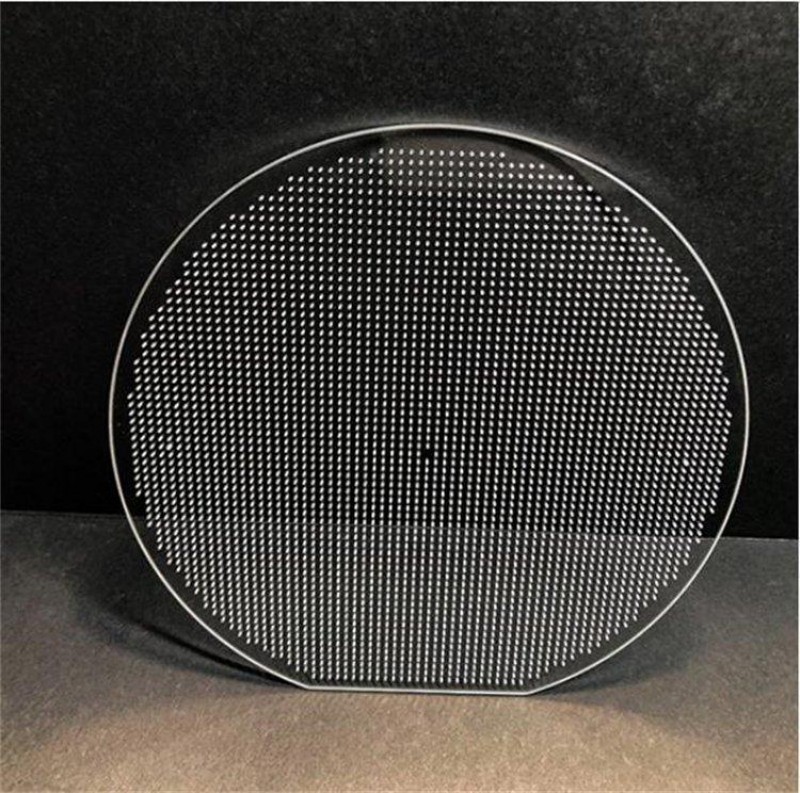

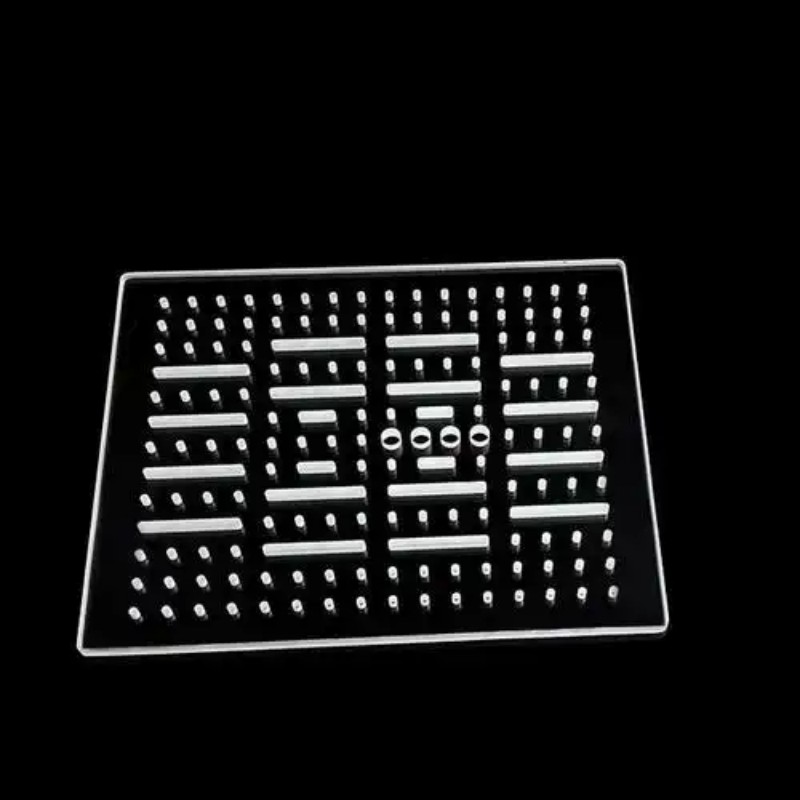

Lisebelisoa tsa Photovoltaic le Ceramic:

E nolofalletsa ho seha li-wafers tse tšesaane tse se nang li-burr le li-substrate tsa LTCC, ho kenyeletsoa likoti le li-slot milling bakeng sa likhokahano.

Li-scintillators le likarolo tsa Optical:

E boloka boreleli le phetisetso ea thepa ea optical e senyehang joalo ka Ce: YAG, LSO, le tse ling.

Tlhaloso

| Sebopeho | Tlhaloso |

| Mohloli oa Laser | DPSS Nd:YAG |

| Likhetho tsa Wavelength | 532nm / 1064nm |

| Maemo a Matla | 50/100/200 Watts |

| Nepahalo | ±5μm |

| Khaola Bophara | E moqotetsane joalo ka 20μm |

| Sebaka se Ametsoeng ke Mocheso | ≤5μm |

| Mofuta oa Motsamao | Linear / Direct Drive |

| Lisebelisoa tse Tšehetsoeng | SiC, GaN, Diamond, Ga₂O₃, joalo-joalo. |

Ke Hobane'ng ha U Khetha Sisteme ee?

● E felisa mathata a tloaelehileng a laser machining joalo ka ho phatloha ha mocheso le ho phunya

● E ntlafatsa tlhahiso le botsitso bakeng sa thepa ea theko e phahameng

● E khona ho ikamahanya le maemo bakeng sa tšebeliso ea lifofane le indasteri

● Sethala sa bopaki ba bokamoso bakeng sa mahlale a ntlafatso a thepa

Q&A

Q1: Ke lisebelisoa life tse ka sebetsang tsamaisong ee?

A: Sistimi e etselitsoe lisebelisoa tse thata le tse brittle tsa boleng bo holimo. E ka sebetsana ka katleho le silicon carbide (SiC), gallium nitride (GaN), diamond, gallium oxide (Ga₂O₃), LTCC substrates, aerospace composite, photovoltaic wafers, le scintillator crystals tse kang Ce: YAG kapa LSO.

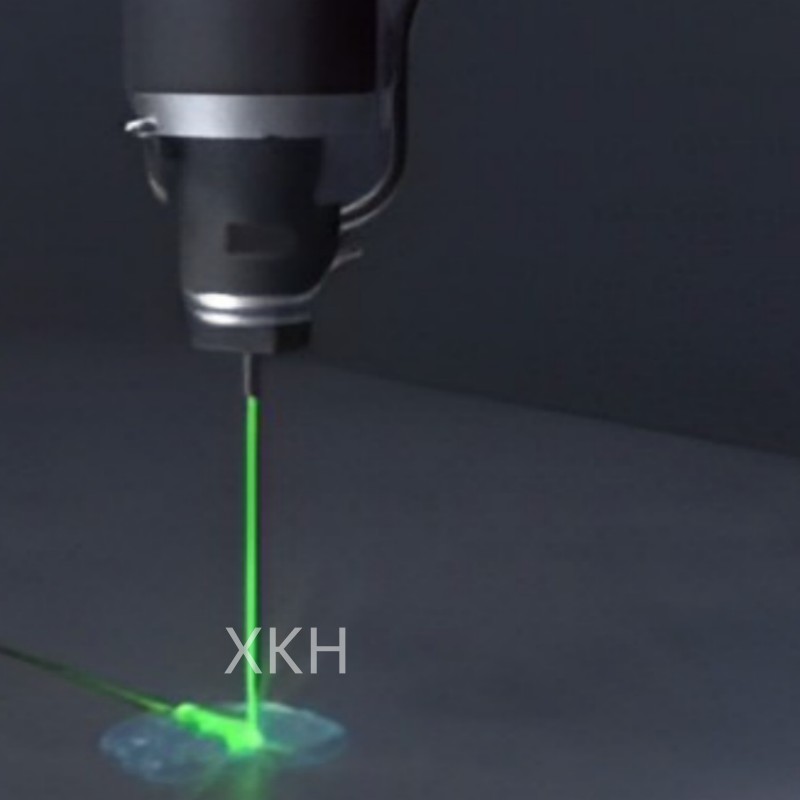

Q2: Theknoloji ea laser e tataisoang ke metsi e sebetsa joang?

A: E sebelisa microjet ea metsi e nang le khatello e phahameng ho tataisa lebone la laser ka ponahatso e felletseng ea kahare, e tsamaisa matla a laser ka mokhoa o atlehileng ka ho hasanya ho fokolang. Sena se tiisa ho tsepamisa maikutlo ho hoholo, mojaro o tlase oa mocheso, le ho fokotsa ho nepahala ka bophara ba mela ho fihla ho 20μm.

Q3: Litlhophiso tsa matla a laser tse fumanehang ke life?

A: Bareki ba ka khetha ho tloha ho 50W, 100W, le 200W khetho ea matla a laser ho itšetlehile ka lebelo la bona la ho sebetsa le litlhoko tsa tharollo. Likhetho tsohle li boloka botsitso bo phahameng ba mabone le ho pheta-pheta.

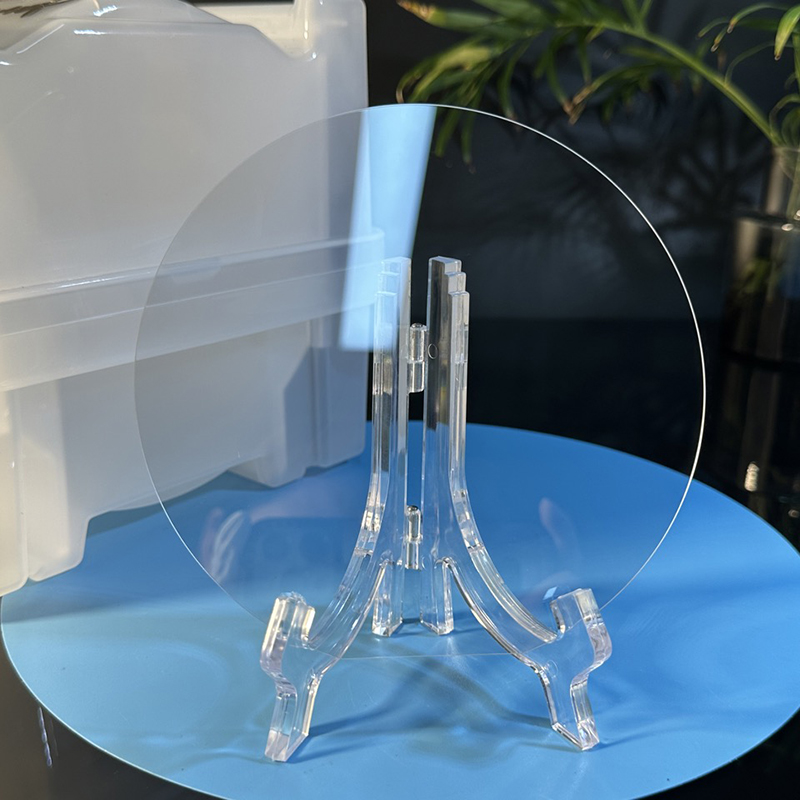

Setšoantšo se qaqileng