Li-ceramics tsa High-purity silicon carbide (SiC) li hlahile e le lisebelisoa tse loketseng bakeng sa likarolo tsa bohlokoa indastering ea semiconductor, aerospace, le lik'hemik'hale ka lebaka la tšebetso ea tsona e ikhethang ea mocheso, botsitso ba lik'hemik'hale le matla a mochini. Ka tlhokahalo e ntseng e eketseha ea lisebelisoa tsa ceramic tse sebetsang hantle, tse nang le tšilafalo e tlase, nts'etsopele ea mahlale a matle le a kotsi a ho lokisa lirafshoa tsa SiC tse hloekileng haholo e se e le sepheo sa lipatlisiso tsa lefats'e. Pampiri ena e hlahloba ka mokhoa o hlophisitsoeng mekhoa e meholo ea ho itokisa bakeng sa li-ceramics tsa SiC tse hloekileng haholo, tse kenyelletsang recrystallization sintering, sinteringless sintering (PS), hot pressing (HP), spark plasma sintering (SPS), le additive production (AM), ka ho hatisa ho buisana ka mekhoa ea sintering, lintlha tsa bohlokoa, thepa ea thepa, le mathata a teng a tshebetso ka 'ngoe.

Tšebeliso ea lirafshoa tsa SiC libakeng tsa sesole le tsa boenjiniere

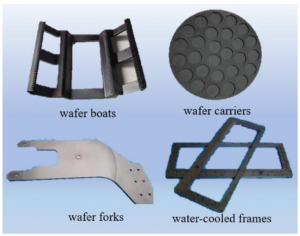

Hajoale, likarolo tsa ceramic tse hloekileng haholo tsa SiC li sebelisoa haholo lisebelisoa tsa tlhahiso ea silicon, tse nkang karolo lits'ebetsong tsa mantlha tse kang oxidation, lithography, etching, le ion implantation. Ka tsoelo-pele ea theknoloji ea li-wafer, ho eketseha ha boholo ba li-wafer ho fetohile mokhoa oa bohlokoa. Bophahamo ba hona joale ba li-wafer bo boholo ke 300 mm, bo fihlella ho leka-lekana pakeng tsa litšenyehelo le bokhoni ba tlhahiso. Leha ho le joalo, e susumetsoa ke Molao oa Moore, tlhahiso e boima ea li-wafers tse 450 mm e se e ntse e le lenaneong. Li-wafer tse kholo hangata li hloka matla a phahameng a sebopeho ho hanela ho loana le ho senyeha, ho tsoela pele ho tsamaisa tlhokahalo e ntseng e hola ea likarolo tsa ceramic tsa SiC tsa boholo bo boholo, tse matla, tse hloekileng haholo. Lilemong tsa morao tjena, tlhahiso e eketsehileng (khatiso ea 3D), e le theknoloji e potlakileng ea ho etsa li-prototyping e sa hlokeng hlobo, e bontšitse bokhoni bo boholo ba ho etsoa ha likarolo tse rarahaneng tsa SiC ceramic ka lebaka la kaho ea eona-ka-layer le bokhoni ba moralo o bonolo, ho hohela tlhokomelo e atileng.

Pampiri ena e tla sekaseka ka mokhoa o hlophisehileng mekhoa e mehlano ea ho itokisetsa li-ceramics tsa SiC tse hloekileng - recrystallization sintering, sintering e se nang khatello, ho hatella ho chesang, spark plasma sintering, le ho eketsa tlhahiso-e shebane le mekhoa ea bona ea sintering, maano a ho ntlafatsa ts'ebetso, litšoaneleho tsa ts'ebetso ea thepa, le menyetla ea ts'ebeliso ea indasteri.

Litlhoko tsa thepa e tala ea silicon carbide e phahameng

I. Recrystallization Sintering

Recrystallized silicon carbide (RSiC) ke thepa e hloekileng ea SiC e lokiselitsoeng ntle le lithuso tsa sintering mocheso o phahameng oa 2100-2500 ° C. Ho tloha ha Fredriksson a qala ho sibolla ketsahalo ea recrystallization qetellong ea lekholo la 19th, RSiC e hapile tlhokomelo e kholo ka lebaka la meeli ea eona e hloekileng ea lijo-thollo le ho ba sieo ha likhalase tsa khalase le litšila. Ka mocheso o phahameng, SiC e bonts'a khatello e batlang e phahame ea mouoane, 'me mochine oa eona oa sintering o kenyelletsa ts'ebetso ea mouoane-condensation: lithollo tse ntle li fetoha mouoane ebe li khutlisetsoa holim'a lithollo tse kholoanyane, ho khothalletsa ho hōla ha molala le ho tlamahanngoa ka ho toba pakeng tsa lijo-thollo, kahoo ho matlafatsa matla a lintho tse bonahalang.

Ka 1990, Kriegesmann o ile a lokisa RSiC ka sekhahla se lekanyelitsoeng sa 79.1% a sebelisa slip casting ho 2200 ° C, 'me karolo ea sefapano e bonts'a microstructure e entsoeng ka lijo-thollo tse mahoashe le li-pores. Ka mor'a moo, Yi et al. e sebelitse ho lahla li-gel ho lokisa 'mele e tala le ho e tšela ka 2450 ° C, ho fumana lirafshoa tsa RSiC tse nang le boholo ba 2.53 g/cm³ le matla a flexural a 55.4 MPa.

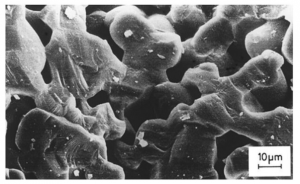

SEM e robehileng holim'a RSiC

Ha e bapisoa le SiC e teteaneng, RSiC e na le boima bo tlase (hoo e ka bang 2.5 g/cm³) le porosity e ka bang 20%, e fokotsang ts'ebetso ea eona lits'ebetsong tse matla haholo. Ka hona, ho ntlafatsa boleng le thepa ea mochini ea RSiC e fetohile taba ea bohlokoa ea lipatlisiso. Sung le al. e reriloeng ho kenya silicon e qhibilihisitsoeng ka har'a carbon / β-SiC metsoako e tsoakiloeng le recrystallizing ho 2200 ° C, ka katleho ho haha mohaho oa marang-rang o entsoeng ka lithollo tsa α-SiC tse mahoashe. RSiC e hlahisitsoeng e fihletse boima ba 2.7 g/cm³ le matla a feto-fetohang a 134 MPa, ho boloka botsitso bo botle ba mochini mochesong o phahameng.

Ho ntlafatsa le ho feta, Guo et al. Theknoloji ea ho kenella ka polymer le pyrolysis (PIP) bakeng sa liphekolo tse ngata tsa RSiC. Ho sebelisa litharollo tsa PCS/xylene le SiC/PCS/xylene slurries joalo ka ba kenang, kamora 3-6 PIP cycles, sekhahla sa RSiC se ile sa ntlafatsoa haholo (ho fihla ho 2.90 g/cm³), hammoho le matla a eona a ho feto-fetoha. Ho phaella moo, ba ile ba etsa tlhahiso ea leano la cyclic ho kopanya PIP le recrystallization: pyrolysis ho 1400 ° C e lateloa ke recrystallization ho 2400 ° C, ka katleho ho hlakola li-blockages le ho fokotsa porosity. Thepa ea ho qetela ea RSiC e fihletse boima ba 2.99 g/cm³ le matla a feto-fetohang a 162.3 MPa, ho bonts'a ts'ebetso e phethahetseng e phethahetseng.

Litšoantšo tsa SEM tsa phetoho ea microstructure ea RSiC e betliloeng ka mor'a ho kenngoa ha polymer le pyrolysis (PIP) -recrystallization cycles: RSiC ea pele (A), ka mor'a potoloho ea pele ea PIP-recrystallization (B), le ka mor'a potoloho ea boraro (C)

II. Khatello ea Sintering

Li-ceramics tsa silicon carbide (SiC) tse nang le khatello ea kelello hangata li lokisoa ka phofo ea SiC e hloekileng haholo, ea ultrafine e le lisebelisoa tse tala, tse nang le lisebelisoa tse nyenyane tsa sintering tse kentsoeng, 'me li tšeloa sebakeng se sa sebetseng kapa se hloekileng ka 1800-2150 ° C. Mokhoa ona o loketse ho hlahisa likarolo tsa ceramic tse nang le boholo bo boholo le bo rarahaneng. Leha ho le joalo, kaha SiC e hokahane ka kopanelo, coefficient ea eona ea ho itšehla thajana e tlase haholo, e etsa hore ho be thata ho tiisa ntle le lithuso tsa sintering.

Ho ipapisitsoe le mochini oa sintering, sintering e se nang khatello e ka aroloa ka mekhahlelo e 'meli: sintering ea metsi a se nang khatello ea metsi (PLS-SiC) le sintering e se nang khatello e matla (PSS-SiC).

1.1 PLS-SiC (Liquid-Phase Sintering)

PLS-SiC hangata e sintered ka tlase ho 2000 ° C ka ho eketsa hoo e ka bang 10 wt.% ea li-eutectic sintering aid (tse kang Al₂O₃, CaO, MgO, TiO₂, le li-oxide tse sa tloaelehang RE₂O₃) ho theha mohato oa metsi, ho khothalletsa ho fokotseha ha karoloana le ho fetisetsa morao. Ts'ebetso ena e loketse lirafshoa tsa SiC tsa boemo ba indasteri, empa ha ho so be le litlaleho tsa SiC ea bohloeki bo phahameng bo fihlelletsoeng ka sintering ea mokelikeli.

1.2 PSS-SiC (Solid-State Sintering)

PSS-SiC e kenyelletsa ho tiisa boemo bo tiileng mochesong o ka holimo ho 2000 ° C ka hoo e ka bang 1 wt.% ea li-additives. Ts'ebetso ena e its'etleha haholo ho phallong ea athomo le tlhophiso ea lijo-thollo tse tsamaisoang ke mocheso o phahameng ho fokotsa matla a holim'a metsi le ho fihlela ho teteana. Tsamaiso ea BC (boron-carbon) ke motsoako o tloaelehileng oa tlatsetso, o ka fokotsang matla a moeli oa lijo-thollo le ho tlosa SiO₂ holim'a SiC. Leha ho le joalo, li-additives tsa setso tsa BC hangata li hlahisa litšila tse setseng, li fokotsa bohloeki ba SiC.

Ka ho laola li-additive content (B 0.4 wt.%, C 1.8 wt.%) le sintering ho 2150 ° C bakeng sa lihora tsa 0.5, li-ceramics tsa SiC tse hloekileng tse nang le bohloeki ba 99.6 wt.% le palo e lekanyelitsoeng ea 98.4% e fumanoe. The microstructure e ne e bontša lithollo tsa columnar (tse ling li feta 450 µm ka bolelele), tse nang le masoba a manyenyane moeling oa lijo-thollo le likaroloana tsa graphite ka hare ho lijo-thollo. Li-ceramics li ne li bonts'a matla a flexural a 443 ± 27 MPa, modulus ea elastic ea 420 ± 1 GPa, le coefficient ea ho atolosa mocheso oa 3.84 × 10⁻⁶ K⁻¹ mofuteng oa mocheso oa kamore ho ea ho 600 ° C, e bontšang tshebetso e babatsehang ka kakaretso.

Microstructure ea PSS-SiC: (A) SEM setšoantšo ka mor'a ho penta le NaOH etching; (BD) litšoantšo tsa BSD ka mor'a ho bentša le ho penya

III. Hot Pressing Sintering

Hot pressing (HP) sintering ke mokhoa oa densification o sebetsang ka nako e le 'ngoe mocheso le khatello ea uniaxial ho thepa ea phofo tlas'a maemo a phahameng a mocheso le khatello e phahameng. Khatello e phahameng e thibela haholo ho thehoa ha li-pore le ho fokotsa ho hōla ha lijo-thollo, ha mocheso o phahameng o khothalletsa ho kopanya lijo-thollo le ho thehoa ha mehaho e teteaneng, qetellong ho hlahisa li-ceramics tsa SiC tse phahameng, tse hloekileng. Ka lebaka la sebopeho sa ho hatella, ts'ebetso ena e na le ho hohela anisotropy ea lijo-thollo, e amang thepa ea mochini le ea ho apara.

Li-ceramics tsa SiC tse hloekileng li thata ho tiisa ntle le li-additives, tse hlokang hore ho be le ultrahigh-pressure sintering. Nadeau et al. ho lokisoa ka katleho SiC e teteaneng ka botlalo ntle le li-additives ho 2500 ° C le 5000 MPa; Letsatsi le al. e fumane lisebelisoa tse ngata tsa β-SiC tse nang le boima ba Vickers bo fihlang ho 41.5 GPa ho 25 GPa le 1400 ° C. Ho sebelisa khatello ea 4 GPa, li-ceramics tsa SiC tse nang le likhahla tse lekanang tsa hoo e ka bang 98% le 99%, boima ba 35 GPa, le modulus elastic ea 450 GPa li lokiselitsoe ho 1500 ° C le 1900 ° C, ka ho latellana. Sintering micron-size SiC powder ho 5 GPa le 1500 ° C e ile ea fana ka li-ceramics tse nang le boima ba 31.3 GPa le boima bo lekanyelitsoeng ba 98.4%.

Leha liphetho tsena li bonts'a hore khatello e phahameng haholo e ka fihlella tšubuhlellano ntle le tlatsetso, ho rarahana le litšenyehelo tse phahameng tsa lisebelisoa tse hlokahalang li fokotsa lits'ebetso tsa indasteri. Ka hona, boitokisetsong bo sebetsang, li-trace additives kapa granulation ea phofo hangata li sebelisoa ho matlafatsa matla a ho khanna.

Ka ho eketsa 4 wt.% phenolic resin e le motsoako le sintering ho 2350 ° C le 50 MPa, li-ceramics tsa SiC tse nang le sekhahla sa 92% le bohloeki ba 99.998%. Ho sebelisa li-additives tse fokolang (boric acid le D-fructose) le sintering ho 2050 ° C le 40 MPa, SiC e hloekileng e nang le sekhahla se lekanyelitsoeng> 99.5% le lihlahisoa tse setseng tsa B tsa 556 ppm feela li lokiselitsoe. Litšoantšo tsa SEM li bontšitse hore, ha li bapisoa le lisampole tse sa hatelletsoeng, lisampole tse hatelitsoeng ka ho chesa li ne li e-na le lijo-thollo tse nyenyane, li-pores tse fokolang, le boima bo phahameng. Matla a flexural e ne e le 453.7 ± 44.9 MPa, 'me modulus ea elastic e fihlile 444.3 ± 1.1 GPa.

Ka ho eketsa nako ea ho tšoara 1900 ° C, boholo ba lijo-thollo bo eketsehile ho tloha ho 1.5 μm ho ea ho 1.8 μm, 'me conductivity ea mocheso e ntlafetse ho tloha ho 155 ho ea ho 167 W · m⁻¹·K⁻¹, ha e ntse e matlafatsa ho hanyetsa ho bola ha plasma.

Tlas'a maemo a 1850 ° C le 30 MPa, ho hatella ho chesang le ho hatelloa ka potlako ha SiC powder e nang le granulated le annealed e ile ea fana ka lirafshoa tse teteaneng tsa β-SiC ntle le li-additives, tse nang le boima ba 3.2 g/cm³ le mocheso oa sintering 150-200 ° C tlase ho feta mekhoa ea setso. Li-ceramics li ne li bontša ho thatafala ha 2729 GPa, ho tiea ha fracture ea 5.25–5.30 MPa·m^1/2, le khanyetso e babatsehang ea creep (likhahla tsa 9.9 × 10⁻¹⁰ s⁻¹ le 3.8 × 10⁻⁻⁹0 C1⁻⁻¹0 ° C1 ° 10 le C1⁻⁻¹0 ° C1 / 10 ° C1 / 10 ° C1 / 10 ° 10⁻¹0 100 MPa).

(A) Setšoantšo sa SEM sa bokaholimo bo bentšitsoeng; (B) Setšoantšo sa SEM sa sebaka sa fracture; (C, D) Setšoantšo sa BSD sa bokaholimo bo bentšitsoeng

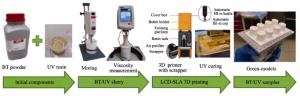

Lipatlisisong tsa khatiso tsa 3D bakeng sa lirafshoa tsa piezoelectric, ceramic slurry, joalo ka ntlha ea mantlha e susumetsang ho etsoa le ts'ebetso, e se e le eona ntho e ka sehloohong e tsepamisisang maikutlo ka har'a naha le machabeng. Boithuto ba hajoale ka kakaretso bo bonts'a hore likarolo tse joalo ka boholo ba karolo ea phofo, viscosity ea slurry, le litaba tse tiileng li ama haholo boleng ba sebopeho le thepa ea piezoelectric ea sehlahisoa sa ho qetela.

Lipatlisiso li fumane hore li-ceramic slurries tse lokiselitsoeng ho sebelisoa li-micron-, submicron-, le nano-size barium titanate powders li bontša phapang e kholo mekhoeng ea stereolithography (mohlala, LCD-SLA). Ha boholo ba likaroloana bo fokotseha, slurry viscosity e eketseha haholo, ka li-nano-size powders tse hlahisang li-slurries tse nang le li-viscosity tse fihlang libilione tsa mPa·s. Li-slurries tse nang le li-powders tse boholo ba micron li na le tšekamelo ea ho delamination le ho ebola nakong ea khatiso, ha li-submicron le li-nano-size powders li bontša boitšoaro bo tsitsitseng haholoanyane. Kamora ho chesa mocheso o phahameng, lisampole tsa ceramic tse hlahisitsoeng li fihletse boima ba 5.44 g/cm³, piezoelectric coefficient (d₃₃) ea hoo e ka bang 200 pC/N, le mabaka a tahlehelo e tlase, a bonts'a thepa e ntle ea karabo ea electromechanical.

Ho feta moo, lits'ebetsong tsa micro-stereolithography, ho lokisa litaba tse tiileng tsa li-slurries tsa mofuta oa PZT (mohlala, 75 wt.%) e fane ka 'mele e sintered e nang le boima ba 7.35 g/cm³, ho fihlela piezoelectric constant ho fihla ho 600 pC/N tlasa masimo a motlakase a poling. Lipatlisiso mabapi le puseletso ea li-micro-scale deformation li ntlafalitse haholo ho nepahala ha sebopeho, ho ntlafatsa ho nepahala ha sebopeho ka 80%.

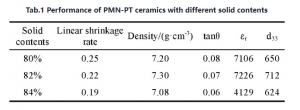

Boithuto bo bong ho PMN-PT piezoelectric ceramics e senoletse hore litaba tse tiileng li ama haholo sebopeho sa ceramic le thepa ea motlakase. Ho 80 wt.% litaba tse tiileng, lihlahisoa tsa lihlahisoa li ile tsa hlaha habonolo ka lirapeng tsa letsopa; ha litaba tse tiileng li ntse li eketseha ho fihla ho 82 wt.% le ho feta, lihlahisoa li ile tsa nyamela butle-butle, 'me mohaho oa ceramic o ile oa hloeka, ka ts'ebetso e ntlafetseng haholo. Ho 82 wt.%, li-ceramics li bonts'itse lisebelisoa tse nepahetseng tsa motlakase: piezoelectric constant ea 730 pC/N, tumello e amanang le 7226, le tahlehelo ea dielectric ea 0.07 feela.

Ka kakaretso, boholo ba likaroloana, lintho tse tiileng, le thepa ea rheological ea li-slurries tsa ceramic ha li ame feela botsitso le ho nepahala ha mokhoa oa khatiso empa hape li khetholla ka ho toba karabelo ea 'mele e sirelelitsoeng le piezoelectric ea' mele e sintered, e leng se etsang hore e be likarolo tsa bohlokoa bakeng sa ho finyella lirafshoa tsa piezoelectric tse hatisitsoeng ka 3D.

Mokhoa o ka sehloohong oa khatiso ea LCD-SLA 3D ea disampole tsa BT/UV

Thepa ea lirafshoa tsa PMN-PT tse nang le litaba tse fapaneng tse tiileng

IV. Spark Plasma Sintering

Spark plasma sintering (SPS) ke theknoloji e tsoetseng pele ea sintering e sebelisang khatello ea hona joale le ea mochini ka nako e le 'ngoe e sebelisoang ho phofo ho fihlela sekhahla se potlakileng. Ts'ebetsong ena, hona joale e chesa ka ho toba hlobo le phofo, e hlahisang mocheso oa Joule le plasma, e leng ho nolofalletsang ho sintering ka nako e khutšoanyane (hangata ka hare ho metsotso ea 10). Ho futhumala ka potlako ho khothalletsa ho ata ha holim'a metsi, athe ho tsoa ha spark ho thusa ho tlosa likhase tsa adsorbed le oxide layers sebakeng sa phofo, ho ntlafatsa ts'ebetso ea sintering. Phello ea electromigration e hlahisoang ke masimo a motlakase le eona e ntlafatsa phallo ea athomo.

Ha ho bapisoa le mokhoa o tloaelehileng oa ho chesa, SPS e sebelisa ho futhumatsa ka ho toba, e nolofalletsang ho tiisa mocheso o tlase ha e ntse e thibela ka katleho kholo ea lijo-thollo ho fumana li-microstructures tse ntle le tse tšoanang. Ka mohlala:

- Ntle le li-additives, ho sebelisa phofo ea fatše ea SiC e le lisebelisoa tse tala, ho sintering ho 2100 ° C le 70 MPa bakeng sa metsotso ea 30 ho ile ha fana ka lisampole tse nang le 98% ea boima bo lekanang.

- Sintering ka 1700 ° C le 40 MPa bakeng sa metsotso e 10 e hlahisitse cubic SiC e nang le 98% density le boholo ba lijo-thollo tsa 30-50 nm feela.

- Ho sebelisa 80 µm granular SiC powder le sintering ho 1860 ° C le 50 MPa bakeng sa metsotso e 5 ho felletse ka lirafshoa tsa SiC tse sebetsang hantle tse nang le 98.5% ea boima bo lekanang, Vickers microhardness ea 28.5 GPa, matla a flexural a 395 MPa, le fracture ^ 1/2 MPa·m.

Tlhahlobo ea microstructural e bontšitse hore ha mocheso oa sintering o ntse o eketseha ho tloha ho 1600 ° C ho ea ho 1860 ° C, porosity ea lintho tse bonahalang e ile ea fokotseha haholo, e atamela boima bo feletseng ka mocheso o phahameng.

The microstructure ea SiC ceramics sintered ka mocheso fapaneng: (A) 1600°C, (B) 1700°C, (C) 1790°C le (D) 1860°C.

V. Keketso ya Tlhahiso

Additive Production (AM) e sa tsoa bonts'a bokhoni bo boholo ba ho etsa likarolo tse rarahaneng tsa ceramic ka lebaka la ts'ebetso ea eona ea kaho ea kaho. Bakeng sa li-ceramics tsa SiC, ho entsoe theknoloji e mengata ea AM, ho kenyelletsa le jetting ea binder (BJ), 3DP, selective laser sintering (SLS), ho ngola enke e tobileng (DIW), le stereolithography (SL, DLP). Leha ho le joalo, 3DP le DIW li na le ho nepahala ho tlase, ha SLS e atisa ho baka khatello ea mocheso le mapetsong. Ka lehlakoreng le leng, BJ le SL li fana ka melemo e meholo ea ho hlahisa lirafshoa tse rarahaneng tse hloekileng, tse nepahetseng haholo.

- Binder Jetting (BJ)

Theknoloji ea BJ e kenyelletsa ho fafatsa ka lera-ka-layer ea binder ho phofo ea bond, e lateloa ke ho debinding le sintering ho fumana sehlahisoa sa ho qetela sa ceramic. Ho kopanya BJ le ho kenngoa ha mouoane oa lik'hemik'hale (CVI), li-ceramics tsa SiC tse hloekileng ka ho feletseng, tse hloekisitsoeng ka ho feletseng li ile tsa lokisoa ka katleho. Mokhoa ona o kenyelletsa:

① Ho theha 'mele o motala oa SiC ceramic o sebelisa BJ.

② Densifying ka CVI ho 1000 ° C le 200 Torr.

③ SiC ceramic ea ho qetela e ne e na le boima ba 2.95 g/cm³, mocheso oa mocheso oa 37 W/m·K, le matla a feto-fetohang a 297 MPa.

Setšoantšo sa schematic sa khatiso ea jet e khomarelang (BJ). (A) Moetso o thusoang ke khomphutha (CAD), (B) setšoantšo sa moralo oa BJ principle, (C) khatiso ea SiC by BJ, (D) densification of SiC by chemical vapor infiltration (CVI)

- Stereolithography (SL)

SL ke theknoloji ea ho etsa ceramic e thehiloeng ho UV e nang le bokhoni bo phahameng haholo le bo rarahaneng ba ho etsa sebopeho. Mokhoa ona o sebelisa li-slurries tsa ceramic tse nang le li-photosensitive tse nang le lintho tse tiileng tse phahameng le viscosity e tlaase ho theha 'mele o motala oa 3D oa ceramic ka photopolymerization, e lateloa ke debinding le mocheso o phahameng oa mocheso ho fumana sehlahisoa sa ho qetela.

Ho sebelisoa 35 vol.% SiC slurry, 'mele o motala oa boleng bo holimo oa 3D o ile oa lokisoa tlas'a mahlaseli a 405 nm UV le ho feta ka ho chesa ka polymer ho 800 ° C le phekolo ea PIP. Liphetho li bonts'itse hore lisampole tse lokisitsoeng ka 35 vol.% slurry li fihletse sekhahla se lekanyelitsoeng sa 84.8%, se fetang lihlopha tsa taolo tsa 30% le 40%.

Ka ho hlahisa lipophilic SiO₂ le phenolic epoxy resin (PEA) ho fetola slurry, ts'ebetso ea photopolymerization e ile ea ntlafatsoa ka katleho. Ka mor'a ho sintering ka 1600 ° C bakeng sa 4 h, phetoho e haufi-ufi e feletseng ho SiC e ile ea finyelloa, e nang le oksijene ea ho qetela ea 0.12% feela, e leng ho nolofalletsang ho etsoa ha mohato o le mong oa li-ceramics tsa SiC tse hloekileng, tse rarahaneng tse sa sebetseng pele ho oxidation kapa mehato ea ho kenella pele.

Setšoantšo sa sebopeho sa khatiso le ts'ebetso ea eona ea sintering. Ponahalo ea sampole ka mor'a ho omella ho (A) 25°C, pyrolysis ho (B) 1000°C, le sintering ho (C) 1600°C.

Ka ho rala li-slurries tsa letsopa tsa Si₃N₄ tsa stereolithography tsa khatiso ea 3D le ho sebelisa mekhoa ea botsofali e thibelang botsofali le mocheso o phahameng, Si₃N₄ ceramics e nang le 93.3% theory density, tensile strength of 279.8 MPa, 3303. Liphuputso li fumane hore tlas'a maemo a 45 vol.%. Mokhoa o fokolang oa mocheso o tlase o nang le sekhahla sa mocheso oa 0.1 °C/min o thusitse ho hlahisa 'mele o motala o se nang mapheo.

Sintering ke mohato oa bohlokoa o amang ts'ebetso ea ho qetela ho stereolithography. Patlisiso e bonts'a hore ho kenyelletsa lithuso tsa sintering ho ka ntlafatsa ka nepo letsoalo la ceramic le thepa ea mochini. Ho sebelisa CeO₂ e le thuso ea sintering le theknoloji ea sintering e thusang masimong a motlakase ho lokisa li-ceramics tsa Si₃N₄ tse phahameng haholo, CeO₂ e ile ea fumanoa e arola meeli ea lijo-thollo, e khothalletsang ho thella ha lijo-thollo le densification. Li-ceramics tse hlahisitsoeng li bonts'itse ho thatafala ha Vickers ea HV10/10 (1347.9 ± 2.4) le ho tiea ha ho robeha ha (6.57 ± 0.07) MPa·m¹/². Ka MgO-Y₂O₃ e le li-additives, homogeneity ea ceramic microstructure e ile ea ntlafatsoa, ea ntlafatsa ts'ebetso haholo. Ka kakaretso ea boemo ba doping ea 8 wt.%, matla a flexural le conductivity ea mocheso e fihlile ho 915.54 MPa le 59.58 W·m⁻¹·K⁻¹, ka ho latellana.

VI. Qetello

Ka bokhutšoanyane, li-ceramics tsa silicon carbide (SiC) tse phahameng haholo, e le lisebelisoa tse ikhethang tsa boenjiniere, li bonts'itse tebello e pharaletseng ea ts'ebeliso ho li-semiconductors, aerospace, le lisebelisoa tsa maemo a feteletseng. Pampiri ena e ile ea hlahlobisisa ka mokhoa o hlophisitsoeng litsela tse hlano tse tloaelehileng tsa ho itokisa bakeng sa li-ceramics tsa SiC tse hloekileng - recrystallization sintering, sinteringless sintering, hot pressing, spark plasma sintering, le additive production-ka lipuisano tse qaqileng mabapi le mekhoa ea bona ea densification, ts'ebetso ea bohlokoa ea parameter, ts'ebetso ea thepa, le melemo le mefokolo e fapaneng.

Ho totobetse hore mekhoa e fapaneng e 'ngoe le e' ngoe e na le litšobotsi tse ikhethang mabapi le ho finyella bohloeki bo phahameng, ho teteana haholo, mehaho e rarahaneng, le bokhoni ba indasteri. Theknoloji e eketsehileng ea tlhahiso, haholo-holo, e bontšitse bokhoni bo matla ba ho etsa likarolo tse rarahaneng le tse hlophisitsoeng, tse nang le katleho libakeng tse nyenyane tse kang stereolithography le binder jetting, e leng se etsang hore e be tataiso ea bohlokoa ea nts'etsopele bakeng sa bohloeki bo phahameng ba SiC ceramic.

Lipatlisiso tsa nakong e tlang mabapi le bohloeki bo phahameng ba ho lokisa SiC ceramic e hloka ho tebisa botebo, ho khothaletsa phetoho ho tloha ho laboratori ho ea ho tse kholo, tse tšepahalang haholo, ka ho fana ka tšehetso ea bohlokoa ea thepa bakeng sa tlhahiso ea lisebelisoa tsa boleng bo holimo le theknoloji ea tlhahiso-leseling ea moloko o latelang.

XKH ke khoebo ea theknoloji e phahameng e sebetsanang le lipatlisiso le tlhahiso ea lisebelisoa tsa ceramic tse sebetsang hantle. E inehetse ho fana ka litharollo tse ikhethileng bakeng sa bareki ka mokhoa oa li-ceramics tsa silicon carbide (SiC) tse phahameng haholo. Khamphani e na le mahlale a tsoetseng pele a ho lokisa thepa le bokhoni bo nepahetseng ba ho sebetsa. Khoebo ea eona e kenyelletsa lipatlisiso, tlhahiso, ts'ebetso e nepahetseng, le kalafo e holimo ea lirafshoa tsa SiC tse hloekileng, tse fihlelang litlhoko tse thata tsa semiconductor, matla a macha, sebaka sa sefofane le likarolo tse ling tsa likarolo tsa ceramic tse sebetsang hantle. Ka ho sebelisa lits'ebetso tsa sintering tse hōlileng tsebong le mahlale a tlatsetso, re ka fa bareki ts'ebeletso e le 'ngoe ho tloha ho optimization ea thepa, sebopeho se rarahaneng ho isa ts'ebetsong e nepahetseng, ho netefatsa hore lihlahisoa li na le thepa e ntle ea mochini, botsitso ba mocheso le ho hanyetsa kutu.

Nako ea poso: Jul-30-2025

-300x228.png)

1600°C、(B)1700°C、(C)1790°C-和(D)1860°C-300x223.png)

25°C-下干燥、(B)1000°C-下热解和(C)1600°C-下烧结后的外观-300x225.png)