Ho tloha lilemong tsa bo-1980, boima ba ho kopanya ba lipotoloho tsa elektroniki bo ntse bo eketseha ka sekhahla sa selemo sa 1.5× kapa kapele. Ho kopanya ho phahameng ho lebisa ho li-density tse kholo tsa hona joale le ho hlahisa mocheso nakong ea ts'ebetso.Haeba e sa felisoe hantle, mocheso ona o ka baka ho hloleha ha mocheso le ho fokotsa nako ea bophelo ea likarolo tsa elektronike.

Ho fihlela litlhoko tse ntseng li eketseha tsa taolo ea mocheso, lisebelisoa tse tsoetseng pele tsa ho paka tsa elektroniki tse nang le conductivity e phahameng ea mocheso li ntse li etsoa lipatlisiso tse ngata le ho ntlafatsoa.

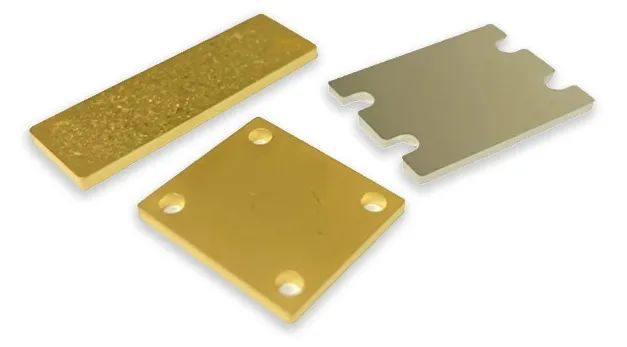

Lintho tse entsoeng ka daemane / koporo

01 Taemane le Koporo

Lisebelisoa tsa setso tsa ho paka li kenyelletsa li-ceramics, polasetiki, litšepe le li-alloys tsa tsona. Li-ceramics tse kang BeO le AlN li bonts'a li-CTE tse ts'oanang le li-semiconductors, botsitso bo botle ba lik'hemik'hale, le mocheso o itekanetseng oa mocheso. Leha ho le joalo, ts'ebetso ea bona e rarahaneng, litšenyehelo tse phahameng (haholo-holo chefo ea BeO), le lits'ebetso tse fokotsang brittleness. Liphutheloana tsa polasetiki li fana ka litšenyehelo tse tlase, boima bo bobebe, le ho kenya letsoho empa li na le ts'ebetso e mpe ea mocheso le ho se tsitse ha mocheso o phahameng. Lisebelisoa tse hloekileng (Cu, Ag, Al) li na le conductivity e phahameng ea mocheso empa CTE e feteletseng, ha li-alloys (Cu-W, Cu-Mo) li senya ts'ebetso ea mocheso. Ka hona, lisebelisoa tse ncha tsa ho paka tse lekanyang conductivity e phahameng ea mocheso le CTE e nepahetseng li hlokahala ka potlako.

| Matlafatso | Thermal Conductivity (W/(m·K)) | CTE (×10⁻⁶/℃) | Boima ba 'mele (g/cm³) |

| Taemane | 700–2000 | 0.9–1.7 | 3.52 |

| Likaroloana tsa BeO | 300 | 4.1 | 3.01 |

| Likaroloana tsa AlN | 150–250 | 2.69 | 3.26 |

| Likaroloana tsa SiC | 80–200 | 4.0 | 3.21 |

| Likaroloana tsa B₄C | 29–67 | 4.4 | 2.52 |

| Fiber ea boron | 40 | ~5.0 | 2.6 |

| Likaroloana tsa TiC | 40 | 7.4 | 4.92 |

| Al₂O₃ likaroloana | 20–40 | 4.4 | 3.98 |

| Litelu tsa SiC | 32 | 3.4 | - |

| Si₃N₄ likaroloana | 28 | 1.44 | 3.18 |

| TiB₂ likaroloana | 25 | 4.6 | 4.5 |

| SiO₂ likaroloana | 1.4 | <1.0 | 2.65 |

Taemane, thepa ea tlhaho e thata ka ho fetisisa e tsejoang (Mohs 10), le eona e na le e ikhethangthermal conductivity (200–2200 W/(m·K)).

Powder ea daemane

Koporo, ka matla a phahameng a mocheso/motlakase (401 W/(m·K)), ductility, le litšenyehelo tse sebetsang hantle, li sebelisoa haholo ho ICs.

Ho kopanya likarolo tsena,diaemane/koporo (Dia/Cu) metsoako-Ka Cu e le matrix le taemane e le matlafatso-li hlaha e le lisebelisoa tsa tsamaiso ea mocheso oa moloko o latelang.

02 Mekhoa ea Bohlokoa ea ho Etsa

Mekhoa e tloaelehileng ea ho lokisa taemane / koporo e kenyelletsa: metallurgy ea phofo, mokhoa oa mocheso o phahameng le oa khatello e phahameng, mokhoa oa ho qoelisa oa metsi, mokhoa oa ho ntša metsi a plasma, mokhoa oa ho fafatsa ka serame, joalo-joalo.

Papiso ea mekhoa e fapaneng ea ho itokisa, lits'ebetso le thepa ea likaroloana tsa taemane / koporo ea boholo bo le bong

| Paramethara | Metallurgy ea phofo | Vacuum Hot-Presing | Spark Plasma Sintering (SPS) | Mocheso o Phahameng ka ho Fetisisa (HPHT) | Cold Spray Deposition | Qhibiliha Infiltration |

| Mofuta oa Taemane | MBD8 | HFD-D | MBD8 | MBD4 | PDA | MBD8/HHD |

| Matrix | 99.8% Cu phofo | 99.9% electrolytic Cu phofo | 99.9% Cu phofo | Alloy/pure Cu phofo | Pure Cu phofo | Pure Cu bongata/thupa |

| Phetoho ea Sefahleho | - | - | - | B, Ti, Si, Cr, Zr, W, Mo | - | - |

| Boholo ba Karolo (μm) | 100 | 106–125 | 100–400 | 20–200 | 35–200 | 50–400 |

| Karolo ea Bolumo (%) | 20–60 | 40–60 | 35–60 | 60–90 | 20–40 | 60–65 |

| Mocheso (°C) | 900 | 800–1050 | 880–950 | 1100–1300 | 350 | 1100–1300 |

| Khatello (MPa) | 110 | 70 | 40–50 | 8000 | 3 | 1–4 |

| Nako (mets) | 60 | 60–180 | 20 | 6–10 | - | 5–30 |

| Boima ba Kamano (%) | 98.5 | 99.2–99.7 | - | - | - | 99.4–99.7 |

| Tshebetso | ||||||

| Optimal Thermal Conductivity (W/(m·K)) | 305 | 536 | 687 | 907 | - | 943 |

Mekhoa e tloaelehileng ea metsoako ea Dia/Cu e kenyelletsa:

(1)Metallurgy ea phofo

Li-powders tse tsoakiloeng tsa daemane / Cu lia kopanngoa 'me lia chesoa. Le hoja mokhoa ona o boloka chelete ebile o le bonolo, o fana ka boholo bo fokolang, li-microstructures tse sa tšoaneng, le litekanyo tse lekanyelitsoeng tsa sampole.

Suniting intering

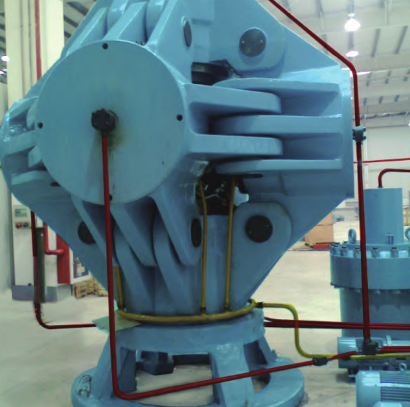

(1)Mocheso o Phahameng ka ho Fetisisa (HPHT)

Ka ho sebelisa mechine ea khatiso e nang le li-anvil tse ngata, Cu e qhibilihisitsoeng e kenella ka har'a li-lattice tsa daemane tlas'a maemo a feteletseng, e hlahisang metsoako e teteaneng. Leha ho le joalo, HPHT e hloka hlobo e theko e boima 'me ha e tšoanelehe bakeng sa tlhahiso e kholo.

Cubic tobetsa

(1)Qhibiliha Infiltration

Molten Cu e kenella ka har'a li-preforms tsa daemane ka ho kenella ka thuso ea khatello kapa ka capillary. Likarolo tse hlahisoang li fihlella>446 W/(m·K) mocheso oa mocheso.

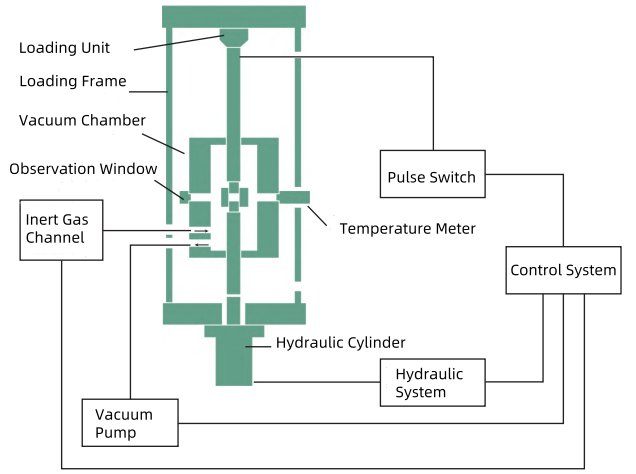

(2)Spark Plasma Sintering (SPS)

Pulsed hona joale ka potlako sinter kopanya phofo tlas'a khatello. Leha e sebetsa hantle, ts'ebetso ea SPS e theola likaroloana tsa litaemane> 65 vol%.

Setšoantšo sa moralo oa tsamaiso ea ho ntša metsi ka plasma

(5) Cold Spray Deposition

Li-powders lia potlakisoa ebe li beoa holim'a li-substrates. Mokhoa ona oa nascent o tobana le liphephetso taolong ea ho qetela le ho netefatsa ts'ebetso ea mocheso.

03 Phetoho ea Sehokelo

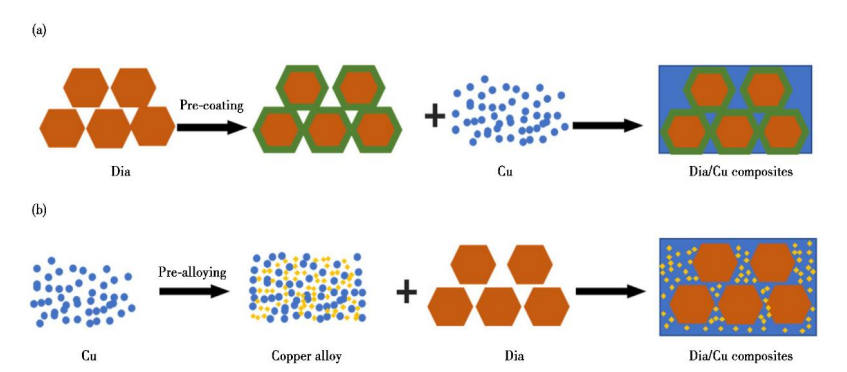

Bakeng sa ho lokisoa ha lisebelisoa tse kopantsoeng, ho kolobisa ka bobeli pakeng tsa likarolo ke ntho e hlokahalang bakeng sa ts'ebetso ea motsoako le ntlha ea bohlokoa e amang sebopeho sa sebopeho le boemo ba ho kopanya li-interface. Boemo ba bao e seng wetting ka segokanyimmediamentsi sa sebolokigolo pakeng tsa taemane le Cu isang segokanyimmediamentsi sa sebolokigolo mogote hanyetsa. Ka hona, ho bohlokoa haholo ho etsa lipatlisiso tsa phetoho mabapi le khokahano lipakeng tsa tse peli ka mekhoa e fapaneng ea tekheniki. Hona joale, haholo-holo ho na le mekhoa e 'meli ea ho ntlafatsa bothata ba sebopeho pakeng tsa taemane le Cu matrix: (1) Phekolo ea phetoho ea sefahleho sa daemane; (2) Kalafo ea alloying ea matrix ea koporo.

Sets'oants'o sa moralo oa phetoho: (a) Ho rala ka kotloloho holim'a taemane; (b) Matrix alloying

(1) Phetoho ea holim'a taemane

Ho roala lintho tse sebetsang tse kang Mo, Ti, W le Cr karolong e ka holimo ea karolo e matlafatsang ho ka ntlafatsa litšobotsi tsa daemane, ka tsela eo, ho ntlafatsa mocheso oa eona oa mocheso. Sintering e ka etsa hore lintlha tse ka holimo li sebetsane le carbon holim'a phofo ea daemane ho etsa lera la phetoho ea carbide. Sena se ntlafatsa boemo ba ho koloba pakeng tsa taemane le motheo oa tšepe, 'me ho roala ho ka thibela sebopeho sa daemane ho fetoha ha mocheso o phahameng.

(2) Ho kopanngoa ha matrix a koporo

Pele ho etsoa lisebelisoa tse entsoeng ka motsoako, phekolo ea pele ho alloying e etsoa ka koporo ea tšepe, e ka hlahisang lisebelisoa tse kopantsoeng ka kakaretso tse phahameng tsa mocheso oa mocheso. Doping e sebetsang ka har'a matrix ea koporo e ke ke ea fokotsa feela Angle ea ho koloba pakeng tsa daemane le koporo, empa hape e hlahisa lera la carbide le tiileng le qhibilihang ka har'a matrix a koporo sebopehong sa daemane / Cu kamora karabelo. Ka tsela ena, boholo ba likheo tse teng ka har'a sebopeho sa thepa li fetoloa le ho tlatsoa, ka hona ho ntlafatsa conductivity ea mocheso.

04 Qetello

Lisebelisoa tse tloaelehileng tsa ho paka ha li khone ho laola mocheso o tsoang ho li-chips tse tsoetseng pele. Li-composite tsa Dia/Cu, tse nang le CTE e fetolehang le ultrahigh thermal conductivity, li emela tharollo ea phetoho bakeng sa lisebelisoa tsa elektroniki tsa moloko o latelang.

Joalo ka khoebo ea theknoloji e phahameng e kopanyang indasteri le khoebo, XKH e tsepamisitse maikutlo ho lipatlisiso le nts'etsopele le tlhahiso ea metsoako ea daemane / koporo le likarolo tse phahameng tsa ts'ebetso ea tšepe tse kang SiC/Al le Gr/Cu, e fanang ka litharollo tse ncha tsa taolo ea mocheso ka conductivity ea mocheso e fetang 900W/(m·K) bakeng sa masimo a sepakapaka sa elektroniki sephutheloana.

XKH's Diamond koporo clad laminate composite lintho tse bonahalang:

Nako ea poso: May-12-2025