1. Selelekela

Ho sa tsotellehe lilemo tse mashome tsa lipatlisiso, heteroepitaxial 3C-SiC e hōlileng ka li-silicon substrates ha e e-s'o fihlele boleng bo lekaneng ba kristale bakeng sa lisebelisoa tsa elektronike tsa indasteri. Khōlo e atisa ho etsoa ho li-substrates tsa Si(100) kapa Si(111), e 'ngoe le e 'ngoe e hlahisa liphephetso tse fapaneng: libaka tse khahlanong le mekhahlelo bakeng sa (100) le ho senya bakeng sa (111). Le hoja lifilimi tse shebaneng le [111] li bontša litšoaneleho tse tšepisang tse kang ho fokotsa sekoli, ho ntlafatsa morphology ea holim'a metsi, le khatello e tlaase, mekhoa e meng e kang (110) le (211) e lula e sa ithutoe. Lintlha tse teng li fana ka maikutlo a hore maemo a ntlafetseng a kholo e ka 'na ea e-ba mokhoa o ikhethileng, o thatafatsang lipatlisiso tse hlophisitsoeng. Ha e le hantle, tšebeliso ea li-substrates tsa Si tse phahameng-Miller-index (mohlala, (311), (510)) bakeng sa 3C-SiC heteroepitaxy ha e e-s'o tlalehoe, e siea sebaka sa bohlokoa sa lipatlisiso tsa lipatlisiso mabapi le mekhoa ea ho hōla e itšetlehileng ka mokhoa.

2. Teko

Likarolo tsa 3C-SiC li ile tsa kenngoa ka sepakapaka-khatello ea lik'hemik'hale tsa mouoane (CVD) ho sebelisoa likhase tsa pele tsa SiH4/C3H8/H2. Li-substrates li ne li le 1 cm² Si wafers tse nang le mekhoa e fapaneng: (100), (111), (110), (211), (311), (331), (510), (553), le (995). Li-substrates tsohle li ne li le holim'a axis ntle le (100), moo li-wafers tse sehiloeng tse 2 ° li ileng tsa lekoa hape. Ho hloekisa pele ho khōlo ho ne ho kenyelletsa ho theoha ha ultrasonic ho methanol. Protocol ea ho hōla e ne e e-na le ho tlosoa ha oxide ea tlhaho ka H2 annealing ho 1000 ° C, e lateloa ke mokhoa o tloaelehileng oa mehato e 'meli: carburization bakeng sa metsotso ea 10 ho 1165 ° C le 12 sccm C3H8, ebe epitaxy bakeng sa metsotso ea 60 ho 1350 ° C (C / Si ratio = 4) ho sebelisa 2 sccm 8 C3H sccm le 4) ho sebelisa 1. Lebelo le leng le le leng la kholo le ne le kenyelletsa mekhoa e mene ho isa ho e mehlano e fapaneng ea Si, e nang le bonyane sephaphatha se le seng (100).

3. Liphetho le Puisano

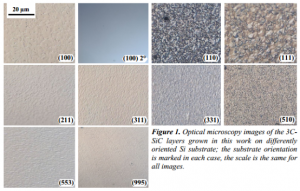

Morphology ea 3C-SiC layers e hōlileng ka li-substrates tse sa tšoaneng tsa Si (setšoantšo sa 1) e bontšitse likarolo tse fapaneng tsa holim'a metsi le ho ba thata. Ka pono, lisampole tse hōlileng ho Si(100), (211), (311), (553), le (995) li ne li bonahala li tšoana le seipone, ha tse ling li ne li tloha ho milky ((331), (510)) ho ea ho lerootho ((110), (111)). Libaka tse boreleli (tse bonts'ang sebopeho se setle ka ho fetisisa sa microstructure) li fumanoe ka (100)2 ° off le (995) substrates. Ho makatsang ke hore likarolo tsohle li ile tsa lula li se na mats'oants'o ka mor'a ho pholile, ho kenyeletsoa le 3C-SiC (111) e atisang ho ba le khatello ea maikutlo. Saese e lekantsoeng ea sampole e kanna ea thibela ho peperana, leha lisampole tse ling li bonts'itse ho inama (30-60 μm ho kheloha ho tloha bohareng ho isa pheletsong) tse bonoang ka tlas'a microscope ea 1000 × magnification ka lebaka la khatello ea maikutlo e bokelletsoeng. Likarolo tse kobehileng haholo tse holisitsoeng ho Si(111), (211), le (553) libopeho tse bonts'itsoeng tse bonts'ang khatello ea maikutlo, e hlokang mosebetsi o mong oa liteko le oa khopolo-taba hore o hokahane le sebopeho sa crystallographic.

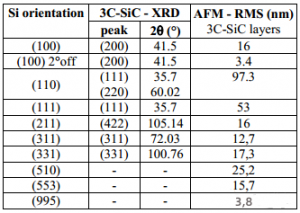

Setšoantšo sa 1 se akaretsa liphetho tsa XRD le AFM (ho hlahloba 20 × 20 μ m2) tsa likarolo tsa 3C-SC tse hōlileng ho li-substrates tsa Si tse nang le mekhoa e fapaneng.

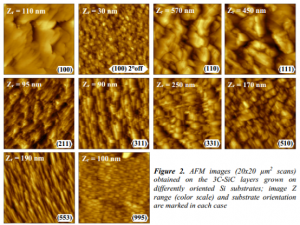

Litšoantšo tsa atomic force microscopy (AFM) (setšoantšo sa 2) li tiisitse maikutlo a optical. Litekanyetso tsa Root-mean-square (RMS) li netefalitse libaka tse boreleli ho (100)2 ° off le (995) substrates, tse nang le meaho e kang lijo-thollo e nang le 400-800 nm lateral litekanyo. Lera (110)-e hōlileng ka ho fetisisa e ne e le e boima ka ho fetisisa, ha likarolo tse telele le / kapa tse bapileng tse nang le meeli e bohale ka linako tse ling li ne li hlaha ka mekhoa e meng ((331), (510)). X-ray diffraction (XRD) θ-2θ scans (e akarelitsoeng ho Lethathamo la 1) e senotse heteroepitaxy e atlehileng bakeng sa substrates e tlaase-Miller-index, ntle le Si (110) e bontšitseng litlhōrō tsa 3C-SiC (111) le (110) tse fapaneng tse bontšang polycrystallinity. Mokhoa ona oa ho kopanya o 'nile oa tlalehoa bakeng sa Si(110), leha liphuputso tse ling li hlokometse 3C-SiC e khethehileng (111), e fana ka maikutlo a hore ntlafatso ea boemo ba kgolo e bohlokoa. Bakeng sa li-indices tsa Miller ≥5 ((510), (553), (995)), ha ho litlhōrō tsa XRD tse ileng tsa fumanoa ka mokhoa o tloaelehileng oa θ-2θ ho tloha ha lifofane tsena tse phahameng li sa fapane ho geometry ena. Ho ba sieo ha litlhōrō tse tlaase tsa 3C-SiC (mohlala, (111), (200)) ho fana ka maikutlo a khōlo e le 'ngoe ea kristale, e hlokang ho kheloha ha sampuli ho lemoha ho fapana ho tloha lifofane tse tlaase.

Setšoantšo sa 2 se bontša palo ea lebelo la sefofane ka har'a sebopeho sa kristale sa CFC.

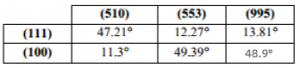

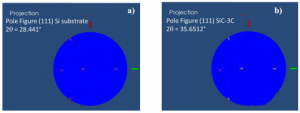

Li-angles tse baliloeng tsa crystallographic pakeng tsa lifofane tse phahameng le tse tlaase (Letlapa la 2) li bontšitse misorientations e kholo (> 10 °), e hlalosang ho ba sieo ha bona ka litekanyetso tse tloaelehileng tsa θ-2θ. Ka hona, tlhahlobo ea lipalo e ile ea etsoa ka sampuli e shebaneng le (995) ka lebaka la sebopeho sa eona se sa tloaelehang sa granular (mohlomong ho tloha kholomong ea kholo kapa mafahla) le boima bo tlase. Lipalo (111) tsa lipalo (setšoantšo sa 3) ho tloha ho Si substrate le 3C-SiC lera li ne li batla li tšoana, li tiisa kholo ea epitaxial ntle le twinning. Sebaka se bohareng se hlahile ho χ≈15 °, se ts'oanang le sekhutlo sa theoretical (111) - (995). Matheba a mararo a lekanang le a lekanang a hlahile maemong a lebeletsoeng (χ=56.2°/φ=269.4°, χ=79°/φ=146.7° le 33.6°), le hoja sebaka se fokolang se sa lebelloang ho χ=62°/φ=93.3° se hloka lipatlisiso tse ling. Boleng ba kristale, bo hlahlobiloeng ka bophara ba sebaka ho φ-scans, bo bonahala bo ts'episa, leha ho le joalo ho hlokahala litekanyo tsa curve curve bakeng sa palo. Lipalo tsa lipalo tsa (510) le (553) li sa ntse li lokela ho phethoa ho netefatsa tlhaho ea bona ea epitaxial.

Setšoantšo sa 3 se bonts'a setšoantšo sa tlhōrō ea XRD e tlalehiloeng sampuling e sekametseng (995), e bonts'ang lifofane tsa (111) tsa Si substrate (a) le 3C-SiC layer (b).

4. Qetello

Khōlo ea Heteroepitaxial 3C-SiC e atlehile ho mekhoa e mengata ea Si ntle le (110), e ileng ea fana ka thepa ea polycrystalline. Si(100)2° off le (995) substrates e hlahisitse masela a boreleli (RMS <1 nm), ha (111), (211), le (553) a bonts'itse ho inama ho hoholo (30-60 μm). Li-substrates tsa index e phahameng li hloka tlhaku e tsoetseng pele ea XRD (mohlala, lipalo) ho netefatsa epitaxy ka lebaka la tlhoro ea θ-2θ e sieo. Mosebetsi o tsoelang pele o kenyelletsa litekanyo tse sisinyehang, tlhahlobo ea khatello ea maikutlo ea Raman, le katoloso ea lipallo tse ling tse phahameng ho phethela thuto ena ea boithuto.

Joaloka moetsi o kopantsoeng ka ho otloloha, XKH e fana ka lits'ebeletso tsa ts'ebetso tse ikhethileng tse nang le potefolio e felletseng ea li-silicon carbide substrates, tse fanang ka mefuta e tloaelehileng le e ikhethang ho kenyelletsa 4H/6H-N, 4H-Semi, 4H/6H-P, le 3C-SiC, e fumanehang ka bophara ho tloha ho 2-inch ho isa ho 12-inch. Tsebo ea rona ea ho qetela ea kholo ea kristale, ho sebetsa ka nepo, le netefatso ea boleng e netefatsa litharollo tse lokiselitsoeng bakeng sa lisebelisoa tsa motlakase tsa motlakase, RF, le lits'ebetso tse hlahang.

Nako ea poso: Aug-08-2025