Silicon carbide (SiC) ha se feela theknoloji ea bohlokoa bakeng sa ts'ireletso ea naha empa hape ke thepa ea bohlokoa bakeng sa indasteri ea likoloi le matla a lefats'e. E le mohato oa pele oa bohlokoa ts'ebetsong ea kristale e le 'ngoe ea SiC, ho seha sephaephe ho supa ka kotloloho boleng ba ho sesa le ho belisoa. Mekhoa e tloaelehileng ea ho seha hangata e hlahisa mapetsong a ka holim'a metsi le a ka tlas'a lefatše, e eketsa litekanyetso tsa ho robeha ha li-wafer le litšenyehelo tsa tlhahiso. Ka hona, ho laola tšenyo ea crack holim'a metsi ho bohlokoa bakeng sa ho ntšetsa pele tlhahiso ea lisebelisoa tsa SiC.

Hajoale, SiC ingot slicing e tobane le mathata a mabeli a maholo:

- Tahlehelo e phahameng ea thepa ho sawing ea setso ea multi-wire:Ho thatafala ho feteletseng ha SiC le brittleness e etsa hore e sekamele ho sotha le ho petsoha nakong ea ho itšeha, ho sila le ho bentša. Ho latela lintlha tsa Infineon, ho sakha ka lithapo tse ngata tsa daemane ho fihlela 50% feela ea ts'ebeliso ea thepa ha ho itšeha, 'me tahlehelo ea sekoahelo se le seng e fihla ho ~ 250 μm ka mor'a ho bentša, e siea lisebelisoa tse nyane tse ka sebelisoang.

- Ts'ebetso e tlase le lipotoloho tse telele tsa tlhahiso:Lipalopalo tsa machaba tsa tlhahiso li bonts'a hore ho hlahisa li-wafers tse 10,000 ka ho sakha ka terata e mengata ea lihora tse 24 ho nka ~ matsatsi a 273. Mokhoa ona o hloka lisebelisoa tse ngata le lintho tse ka sebelisoang ha o ntse o hlahisa mafika a holimo le tšilafalo (lerōle, metsi a litšila).

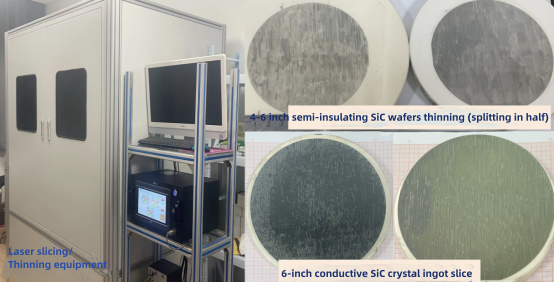

Ho rarolla mathata ana, sehlopha sa Moprofesa Xiu Xiangqian Univesithing ea Nanjing se thehile lisebelisoa tsa laser tse nepahetseng haholo bakeng sa SiC, tse sebelisang theknoloji ea laser e potlakileng ho fokotsa liphoso le ho matlafatsa tlhahiso. Bakeng sa engot ea SiC ea 20-mm, theknoloji ena e eketsa chai e habeli ha e bapisoa le terata ea setso. Ho feta moo, li-wafers tse entsoeng ka laser li bonts'a ho ts'oana ha botenya ho isa ho 200 μm ka sephaphatha le tlhahiso e ntseng e eketseha.

Melemo ea Bohlokoa:

- R&D e phethiloe lisebelisoa tse kholo tsa mohlala, tse netefalitsoeng bakeng sa ho seha li-wafer tsa SiC tse 4-6-inch le li-ingots tsa SiC tsa 6-inch conductive.

- 8-inch ingot slicing e ntse e netefatsoa.

- Nako e khuts'oane haholo ea ho seha, tlhahiso e phahameng ea selemo, le> 50% ea ntlafatso ea lihlahisoa.

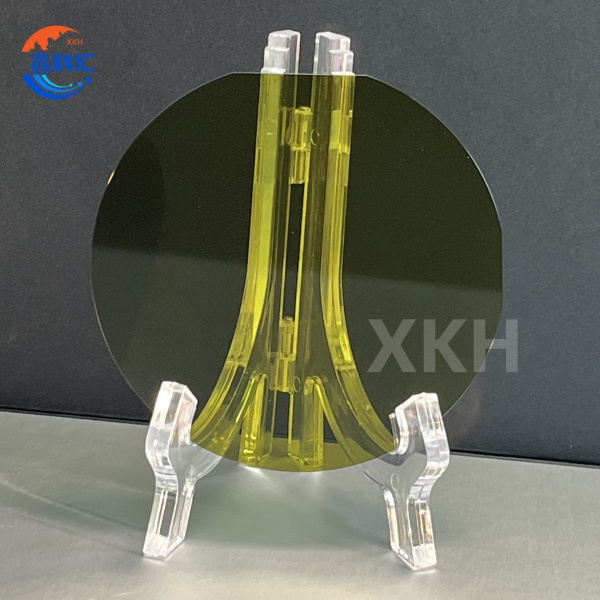

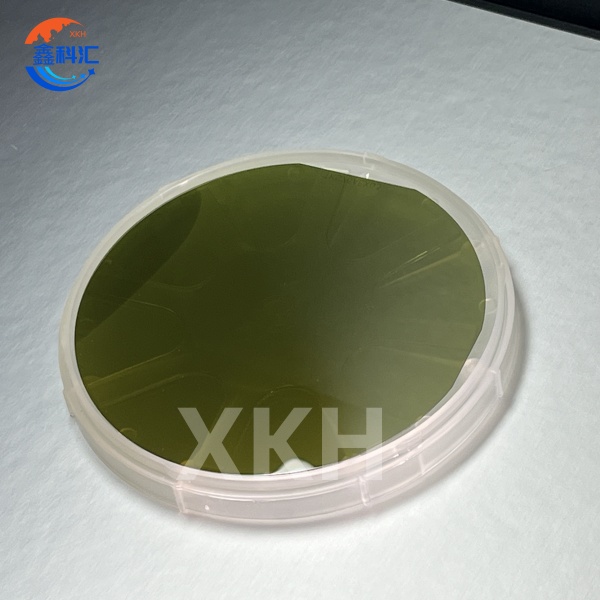

XKH's SiC substrate ea mofuta oa 4H-N

Monyetla oa Mmaraka:

Sesebelisoa sena se mothating oa ho ba tharollo ea mantlha bakeng sa 8-inch SiC ingot slicing, eo hajoale e busoang ke thepa e tsoang kantle ho naha ea Majapane ka litšenyehelo tse phahameng le lithibelo tsa kantle ho naha. Tlhokahalo ea lapeng ea lisebelisoa tsa laser slicing/thinning e feta li-unit tse 1,000, leha ho le joalo ha ho na mekhoa e meng e entsoeng ka machaena e seng e le teng. Theknoloji ea Univesithi ea Nanjing e na le boleng bo boholo ba 'maraka le bokhoni ba moruo.

Ho lumellana ha lintho tse ngata:

Ka ntle ho SiC, lisebelisoa li ts'ehetsa ts'ebetso ea laser ea gallium nitride (GaN), aluminium oxide (Al₂O₃), le daemane, ho atolosa lits'ebetso tsa eona tsa indasteri.

Ka ho fetola ts'ebetso ea SiC wafer, mokhoa ona o mocha o sebetsana le mathata a bohlokoa tlhahisong ea li-semiconductor ha o ntse o hokahana le mekhoa ea lefats'e ea ho sebetsa ka mokhoa o phahameng, le lisebelisoa tse baballang matla.

Qetello

Joaloka moetapele oa indasteri ea tlhahiso ea li-silicon carbide (SiC), XKH e sebetsa ka ho khetheha ho fana ka li-substrate tsa SiC tse 2-12-inch (ho kenyeletsoa mofuta oa 4H-N / SEMI-mofuta, 4H / 6H / 3C-mofuta) e etselitsoeng likarolo tse kholo tse kang likoloi tse ncha tsa matla (taic, 5G), photovol Ka ho sebelisa thekenoloji ea ho seha e nang le tahlehelo e tlase ea "large-dimension wafer low-slicing technology" le theknoloji ea ho sebetsa ka mokhoa o nepahetseng haholo, re fihletse tlhahiso e kholo ea li-substrates tse 8-inch le katleho ea theknoloji ea kholo ea 12-inch conductive SiC crystal, e fokotsa haholo litšenyehelo tsa yuniti ka 'ngoe. Ha re hatela pele, re tla tsoelapele ho ntlafatsa slicing ea laser ea ingot-level le mekhoa e bohlale ea ho laola khatello ea maikutlo, ho nyolla chai ea substrate ea 12-inch ho ea maemong a tlholisano ea lefats'e, ho matlafatsa indasteri ea SiC ea lapeng ho felisa mebuso ea machabeng le ho potlakisa lits'ebetso tse mpe libakeng tse phahameng joalo ka lisebelisoa tsa motlakase tsa AI.

XKH's SiC substrate ea mofuta oa 4H-N

Nako ea poso: Aug-15-2025