Kenyelletso ea silicon carbide

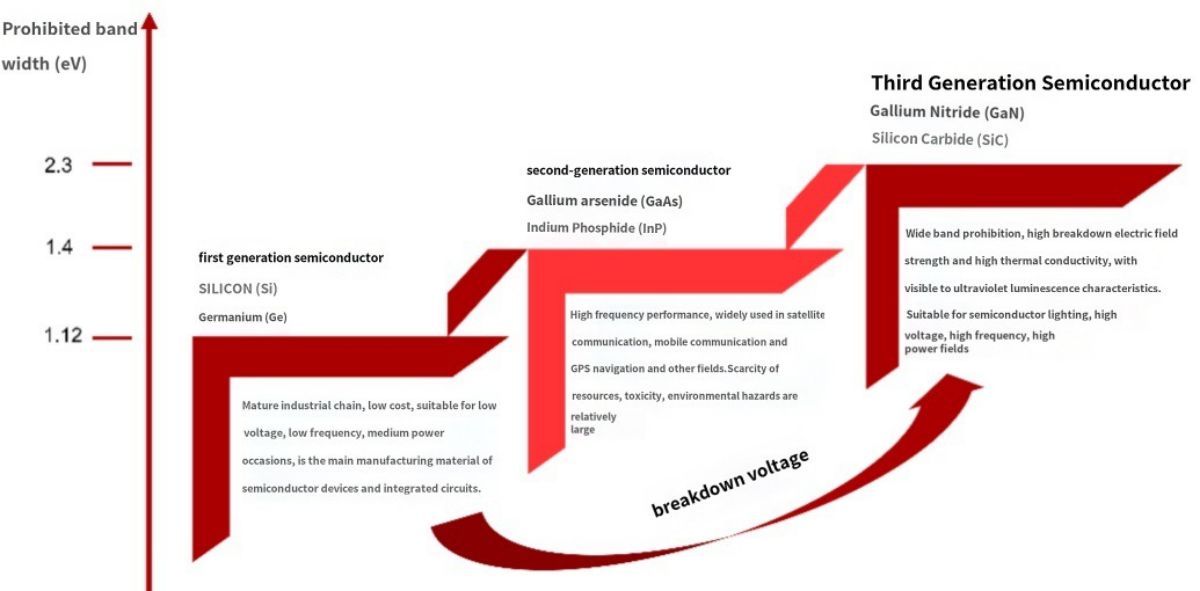

Silicon carbide (SiC) ke sesebelisoa sa semiconductor se entsoeng ka carbon le silicon, e leng e 'ngoe ea lisebelisoa tse loketseng ho etsa mocheso o phahameng, maqhubu a phahameng, matla a phahameng le lisebelisoa tse phahameng tsa motlakase. Ha ho bapisoa le thepa e tloaelehileng ea silicon (Si), lekhalo la sehlopha sa silicon carbide ke makhetlo a 3 ho feta a silicon. The conductivity ea mocheso ke makhetlo a 4-5 a silicon; Matla a ho senya ke makhetlo a 8-10 a silicon; Sekhahla sa ho hoholeha ha elektroniki ke makhetlo a 2-3 ho feta a silicon, e fihlelang litlhoko tsa indasteri ea sejoale-joale bakeng sa matla a phahameng, matla a phahameng le maqhubu a phahameng. E sebelisoa haholo-holo bakeng sa tlhahiso ea lisebelisoa tsa elektronike tse potlakileng, tse phahameng, tse matla le tse hlahisang leseli. Libaka tsa kopo tse tlase ho metsi li kenyelletsa marang-rang a bohlale, likoloi tse ncha tsa matla, matla a moea a photovoltaic, puisano ea 5G, joalo-joalo. Li-silicon carbide diode le MOSFET li sebelisitsoe khoebong.

Ho hanyetsa mocheso o phahameng. Lekhalo la sehlopha sa silicon carbide ke makhetlo a 2-3 ho feta a silicon, lielektrone ha li bonolo ho fetoha ka mocheso o phahameng, 'me li ka mamella mocheso o phahameng oa ho sebetsa,' me mocheso oa mocheso oa silicon carbide ke makhetlo a 4-5 ho feta a silicon, ho etsa hore mocheso oa mochine o fokotsehe habonolo le moeli o sebetsang oa mocheso o phahameng. Ho hanyetsa mocheso o phahameng ho ka eketsa matla a matla haholo ha ho ntse ho fokotsa litlhoko tsa tsamaiso ea ho pholisa, ho etsa hore terminal e be bobebe hape e be nyane.

Mamella khatello e phahameng. Matla a ho senyeha ha silicon carbide ke makhetlo a 10 a silicon, e khonang ho mamella maqhubu a phahameng 'me e loketse lisebelisoa tse phahameng tsa motlakase.

Ho hanyetsa maqhubu a phahameng. Silicon carbide e na le sekhahla sa ho hoholeha ha elektronike habeli ho feta sa silicon, e leng se bakang ho ba sieo ha mohatla nakong ea ts'ebetso ea ho koala, e ka ntlafatsang ka nepo maqhubu a sesebelisoa le ho hlokomela ho fokotseha ha sesebelisoa.

Tahlehelo e tlase ea matla. Ha ho bapisoa le thepa ea silicon, silicon carbide e na le khanyetso e tlase haholo le tahlehelo e tlase. Ka nako e ts'oanang, bophara ba lekhalo le phahameng la silicon carbide bo fokotsa haholo ho lutla ha hona joale le tahlehelo ea matla. Ho phaella moo, sesebelisoa sa silicon carbide ha se na ts'ebetso ea morao-rao ea morao-rao nakong ea ts'ebetso ea ho koala, 'me tahlehelo ea ho fetola e tlaase.

Ketane ea indasteri ea silicon carbide

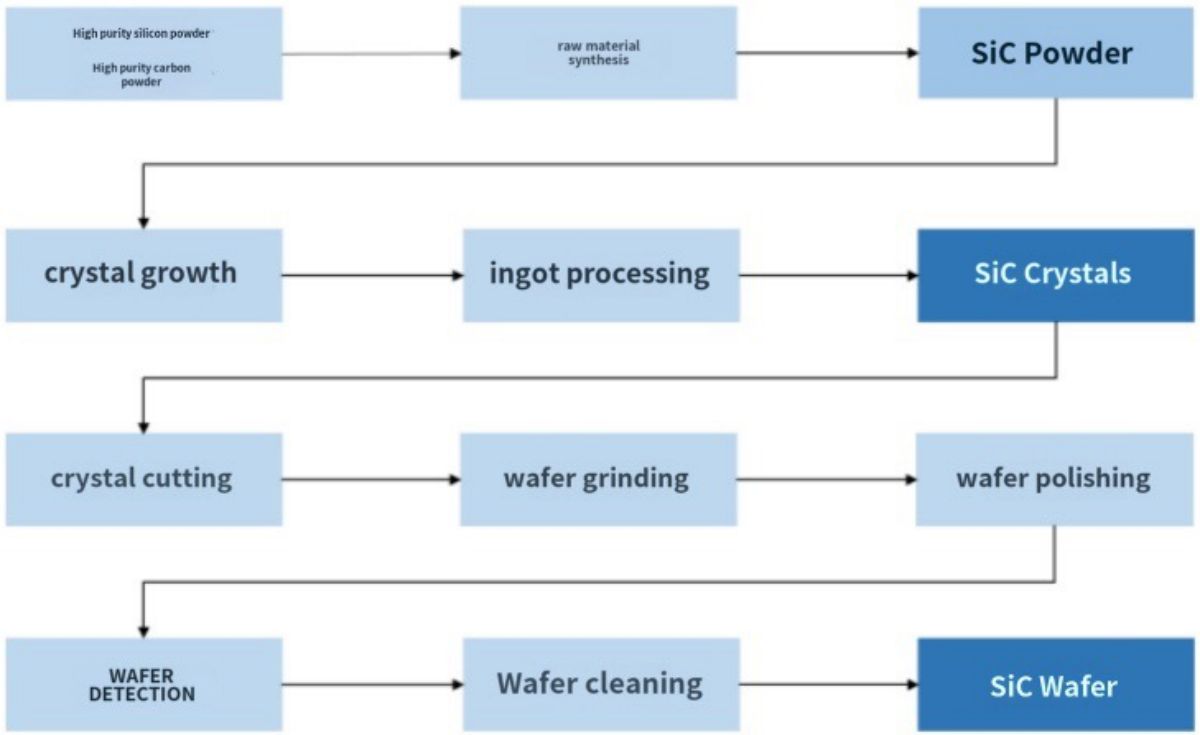

Haholo-holo e kenyelletsa substrate, epitaxy, moralo oa lisebelisoa, tlhahiso, ho tiisa joalo-joalo. Silicon carbide ho tloha ho thepa ho ea ho sesebelisoa sa matla sa semiconductor e tla ba le kholo ea kristale e le 'ngoe, ho qhekella ha ingot, kholo ea epitaxial, moralo oa wafer, tlhahiso, ho paka le mekhoa e meng. Ka mor'a ho qaptjoa ha silicon carbide powder, silicon carbide ingot e etsoa pele, ebe substrate ea silicon carbide e fumanoa ka ho khaola, ho sila le ho bentsa, 'me letlapa la epitaxial le fumanoa ka kgolo ea epitaxial. Epitaxial wafer e entsoe ka silicon carbide ka lithography, etching, implantation ea ion, passivation ea tšepe le lits'ebetso tse ling, sephaphatha se khaoloa ho shoa, sesebelisoa se pakoa, 'me sesebelisoa se kopantsoe ka khetla e khethehileng ebe se bokelloa mojuleng.

Holimo ho ketane ea indasteri 1: substrate - kholo ea kristale ke sehokelo sa mantlha sa ts'ebetso

Silicon carbide substrate e nka hoo e ka bang 47% ea litšenyehelo tsa lisebelisoa tsa silicon carbide, lithibelo tse phahameng ka ho fetisisa tsa theknoloji, boleng bo boholo ka ho fetisisa, ke motheo oa bokamoso bo boholo ba indasteri ea SiC.

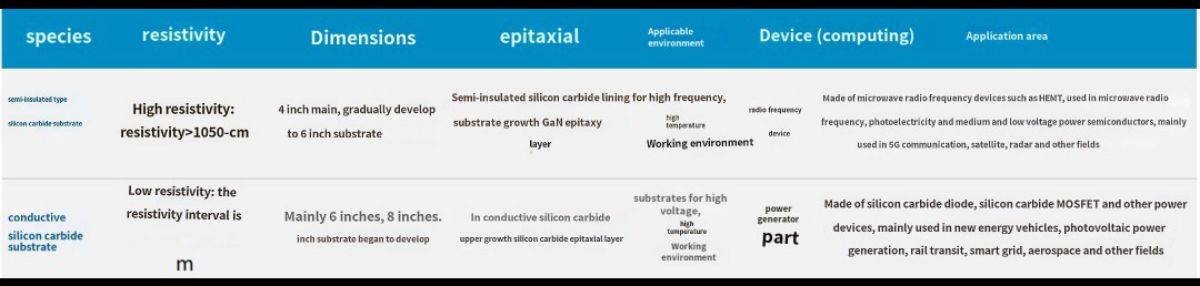

Ho ea ka pono ea liphapang tsa thepa ea electrochemical, lisebelisoa tsa silicon carbide substrate li ka aroloa ka li-conductive substrates (resistivity region 15 ~ 30mΩ·cm) le li-semi-insulated substrates (resistivity e phahameng ho feta 105Ω · cm). Mefuta ena e 'meli ea li-substrates e sebelisetsoa ho etsa lisebelisoa tse sa tšoaneng tse kang lisebelisoa tsa motlakase le lisebelisoa tsa maqhubu a seea-le-moea ka ho latellana ka mor'a kholo ea epitaxial. Har'a tsona, substrate ea semi-insulated silicon carbide e sebelisoa haholo ho etsa lisebelisoa tsa RF tsa gallium nitride, lisebelisoa tsa photoelectric joalo-joalo. Ka ho holisa gan epitaxial layer holim'a semi-insulated SIC substrate, ho lokisoa poleiti ea sic epitaxial, e ka lokisoang ho feta lisebelisoa tsa HEMT gan iso-nitride RF. Conductive silicon carbide substrate e sebelisoa haholo ha ho etsoa lisebelisoa tsa motlakase. Ho fapana le mokhoa o tloaelehileng oa ho etsa lisebelisoa tsa motlakase oa silicon, sesebelisoa sa matla sa silicon carbide se ke ke sa etsoa ka ho toba holim'a silicon carbide substrate, silicon carbide epitaxial layer e hloka ho holisoa holim'a substrate ea conductive ho fumana silicon carbide epitaxial sheet, le epitaxial layer e etsoa ho Schottky diode ea matla, MOS le lisebelisoa tse ling tsa matla.

Silicon carbide powder e entsoe ka phofo ea carbon e hloekileng le phofo e phahameng ea silicon e hloekileng, 'me boholo bo fapaneng ba silicon carbide ingot bo ile ba lengoa tlas'a tšimo e khethehileng ea mocheso,' me joale silicon carbide substrate e hlahisoa ka mekhoa e mengata ea ho sebetsa. Ts'ebetso ea mantlha e kenyelletsa:

Tšimoloho ea lisebelisoa tse tala: Thepa e phahameng ea silicon phofo + toner e kopantsoe ho ea ka foromo, 'me karabelo e etsoa ka kamoreng ea karabelo tlas'a mocheso o phahameng oa mocheso o ka holimo ho 2000 ° C ho kopanya likaroloana tsa silicon carbide ka mofuta o itseng oa kristale le boholo ba likaroloana. Ebe ka ho silakanya, ho hlahloba, ho hloekisa le mekhoa e meng, ho finyella litlhoko tsa bohloeki bo phahameng ba silicon carbide phofo e tala.

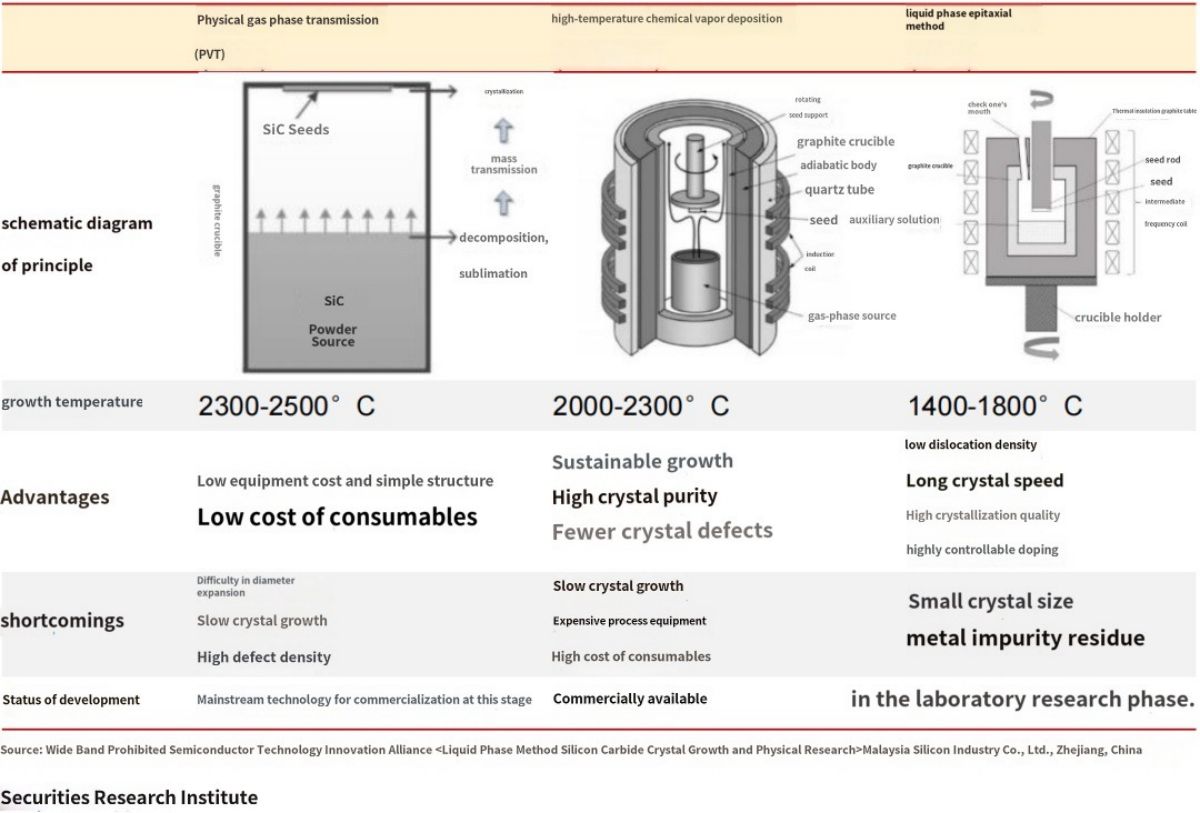

Khōlo ea Crystal ke ts'ebetso ea mantlha ea tlhahiso ea silicon carbide substrate, e khethollang thepa ea motlakase ea silicon carbide substrate. Hona joale, mekhoa e ka sehloohong ea ho hōla ha kristale ke phetiso ea mouoane oa 'mele (PVT), mocheso o phahameng oa lik'hemik'hale oa mouoane (HT-CVD) le epitaxy ea mokelikeli (LPE). Har'a bona, mokhoa oa PVT ke mokhoa o ka sehloohong oa kholo ea khoebo ea SiC substrate hajoale, e nang le khōlo e phahameng ka ho fetisisa ea theknoloji le e sebelisoang haholo ho boenjiniere.

Ho lokisoa ha substrate ea SiC ho thata, e lebisang ho theko ea eona e phahameng

Taolo ea tšimo ea mocheso e thata: Si khōlo ea molamu oa kristale e hloka feela 1500 ℃, ha molamu oa kristale oa SiC o hloka ho hōlileng ka mocheso o phahameng ka holimo ho 2000 ℃, 'me ho na le li-isomers tse fetang 250 tsa SiC, empa sebopeho sa kristale se le seng sa 4H-SiC bakeng sa tlhahiso ea lisebelisoa tsa matla, haeba e se taolo e nepahetseng, e tla fumana mekhoa e meng ea kristale. Ho phaella moo, mocheso gradient ka crucible etsa qeto ea tekanyo ea phetiso SiC sublimation le tlhophiso le kgolo mokgwa wa ea liathomo gaseous ka segokanyimmediamentsi sa sebolokigolo kristale, e amang sekhahla kristale kgolo le boleng ba kristale, kahoo ho ke ke ho hlokahala hore ho theha tsamaiso e hlophisitsoeng mocheso tšimong thekenoloji taolo. Ha ho bapisoa le lisebelisoa tsa Si, phapang ea tlhahiso ea SiC e boetse e le lits'ebetsong tse phahameng tsa mocheso tse kang ho kenngoa ha ion mocheso o phahameng, mocheso o phahameng oa oxidation, ts'ebetso ea mocheso o phahameng, le ts'ebetso ea mask e thata e hlokoang ke mekhoa ena ea mocheso o phahameng.

Khōlo e liehang ea kristale: sekhahla sa kholo ea molamu oa Si kristale se ka fihla ho 30 ~ 150mm / h, 'me tlhahiso ea 1-3m silicon crystal rod e nka feela ka letsatsi la 1; SiC crystal rod e nang le mokhoa oa PVT e le mohlala, sekhahla sa kgolo se ka bang 0.2-0.4mm / h, matsatsi a 7 ho hōla ka tlase ho 3-6cm, sekhahla sa khōlo se ka tlase ho 1% ea thepa ea silicon, matla a tlhahiso a fokotsehile haholo.

Lihlahisoa tse phahameng tsa lihlahisoa le lihlahisoa tse fokolang: likarolo tsa mantlha tsa substrate ea SiC li kenyelletsa bongata ba microtubule, letsoalo la dislocation, resistivity, warpage, holimo holimo, joalo-joalo Ke mokhoa o rarahaneng oa boenjiniere oa ho hlophisa liathomo ka kamoreng e koetsoeng ea mocheso o phahameng le kholo e feletseng ea kristale, ha o ntse o laola li-index tsa parameter.

Lintho tse bonahalang li na le boima bo phahameng, brittleness e phahameng, nako e telele ea ho itšeha le liaparo tse phahameng: SiC Mohs thata ea 9.25 ke ea bobeli ho daemane, e leng se lebisang keketseho e kholo ea bothata ba ho itšeha, ho sila le ho bentša, 'me ho nka lihora tse ka bang 120 ho khaola likotoana tse 35-40 tsa ingot e teteaneng ea 3cm. Ntle le moo, ka lebaka la bofokoli bo phahameng ba SiC, ho roala ha li-wafer ho tla ba ngata, 'me karolelano ea tlhahiso e ka ba 60% feela.

Mokhoa oa nts'etsopele: Keketseho ea boholo + ho fokotseha ha theko

Mmaraka oa lefats'e oa SiC mohala oa tlhahiso ea li-inch tse 6 o ntse o hola, mme lik'hamphani tse etelletseng pele li kene 'marakeng oa 8-inch. Merero ea ntlafatso ea lehae e boholo ba 6 inches. Hona joale, le hoja lik'hamphani tse ngata tsa malapeng li ntse li itšetlehile ka mela ea tlhahiso ea 4-inch, empa indasteri e ntse e eketseha butle-butle ho 6-inch, ka kholo ea theknoloji ea thepa ea 6-inch, theknoloji ea lehae ea SiC substrate e ntse e ntlafatsa moruo oa mela e meholo ea tlhahiso e tla bonahala, 'me lekhalo la hona joale la nako ea tlhahiso ea boima ba 6-inch le fokotsehile ho lilemo tse 7. Bongata bo boholo ba li-wafer bo ka tlisa keketseho ea palo ea lichifi tse le 'ngoe, ho ntlafatsa sekhahla sa chai, le ho fokotsa karolo ea li-chips tse bohale, 'me litšenyehelo tsa lipatlisiso le nts'etsopele le tahlehelo ea lihlahisoa li tla bolokoa ka hoo e ka bang 7%, kahoo ho ntlafatsa tšebeliso ea liphaphatha.

Ho ntse ho na le mathata a mangata moralong oa lisebelisoa

Khoebo ea SiC diode e ntse e ntlafala butle-butle, hona joale, bahlahisi ba bangata ba malapeng ba entse lihlahisoa tsa SiC SBD, lihlahisoa tse mahareng le tse phahameng tsa SiC SBD li na le botsitso bo botle, koloing ea OBC, tšebeliso ea SiC SBD + SI IGBT ho finyella boima bo tsitsitseng ba hona joale. Hajoale, ha ho na litšitiso ho moralo oa patent oa lihlahisoa tsa SiC SBD Chaena, 'me lekhalo le linaha tsa kantle ho naha le nyane.

SiC MOS e ntse e e-na le mathata a mangata, ho ntse ho e-na le lekhalo pakeng tsa SiC MOS le bahlahisi ba mose ho maoatle, 'me sethala se loketseng sa tlhahiso se ntse se hahoa. Hajoale, ST, Infineon, Rohm le tse ling tsa 600-1700V SiC MOS li fihletse tlhahiso ea bongata mme li saennoe le ho romelloa le liindasteri tse ngata tsa tlhahiso, ha moralo oa hajoale oa SiC MOS o se o phethiloe, bahlahisi ba bangata ba meralo ba sebetsa ka masela mothating oa phallo ea liphaephe, 'me hamorao netefatso ea bareki e ntse e hloka nako e telele, kahoo ho na le nako e telele ea khoebo.

Hona joale, sebopeho sa polane ke khetho e tloaelehileng, 'me mofuta oa foro o sebelisoa haholo tšimong ea khatello e phahameng nakong e tlang. Sebopeho sa Planar SiC MOS baetsi ba bangata, sebopeho sa polane ha se bonolo ho hlahisa mathata a ho senyeha ha libaka ha a bapisoa le groove, a amang botsitso ba mosebetsi, 'marakeng o ka tlaase ho 1200V o na le mefuta e mengata ea boleng ba kopo,' me sebopeho sa planar se batla se le bonolo qetellong ea tlhahiso, ho kopana le manufacturability le taolo ea litšenyehelo likarolong tse peli. Sesebelisoa sa groove se na le melemo ea inductance e tlase haholo ea parasitic, lebelo la ho switjha ka potlako, tahlehelo e tlase le ts'ebetso e batlang e phahame.

2--SiC wafer litaba

Tlhahiso ea 'maraka oa silicon carbide le kholo ea thekiso, ela hloko ho se leka-lekane ha sebopeho pakeng tsa phepelo le tlhoko

Ka kholo e potlakileng ea tlhokahalo ea mmaraka ea lisebelisoa tsa elektroniki tse tsamaeang khafetsa le tse matla haholo, moeli oa 'mele oa lisebelisoa tsa semiconductor tse thehiloeng ho silicon o se o ntse o hlahella,' me lisebelisoa tsa semiconductor tsa moloko oa boraro tse emeloang ke silicon carbide (SiC) butle-butle li fetohile indasteri. Ho ea ka pono ea ts'ebetso ea thepa, silicon carbide e na le makhetlo a 3 bophara ba lekhalo la lisebelisoa tsa silicon, makhetlo a 10 ho feta matla a matla a tšimo ea motlakase, makhetlo a 3 ho feta conductivity ea mocheso, kahoo lisebelisoa tsa matla tsa silicon carbide li loketse maqhubu a phahameng, khatello e phahameng, mocheso o phahameng le lisebelisoa tse ling, ho thusa ho ntlafatsa ts'ebetso le matla a matla a lisebelisoa tsa elektronike.

Hona joale, SiC diode le SiC MOSFETs butle-butle ba falletse 'marakeng,' me ho na le lihlahisoa tse hōlileng tsebong, tseo har'a tsona li-diode tsa SiC li sebelisoang haholo ho e-na le li-diode tse thehiloeng ka silicon likarolong tse ling hobane ha li na molemo oa ho khutlisa tefo ea ho khutlisa; SiC MOSFET e boetse e sebelisoa butle-butle ho likoloi, polokelo ea matla, qubu ea ho tjhaja, photovoltaic le masimo a mang; Sebakeng sa likopo tsa likoloi, mokhoa oa ho etsa modularization o ntse o hlahella le ho feta, ts'ebetso e phahameng ea SiC e hloka ho itšetleha ka lits'ebetso tse tsoetseng pele tsa ho paka ho fihlela, ka botekgeniki ka ho tiisa likhetla tse batlang li holile joalo ka tse ka sehloohong, bokamoso kapa ho nts'etsopele ea tiiso ea polasetiki, litšobotsi tsa eona tsa nts'etsopele tse hlophisitsoeng li loketse li-module tsa SiC.

Theko ea Silicon carbide e theoha ka lebelo kapa ho feta monahano

Ts'ebeliso ea lisebelisoa tsa silicon carbide e lekanyelitsoe haholo ke litšenyehelo tse phahameng, theko ea SiC MOSFET tlas'a boemo bo tšoanang e phahame ka makhetlo a 4 ho feta ea Si-based IGBT, ke hobane ts'ebetso ea silicon carbide e rarahane, moo kholo ea kristale e le 'ngoe le epitaxial e seng mpe feela tikolohong, empa le sekhahla sa kholo se lieha,' me ts'ebetso e le 'ngoe ea kristale e lokela ho kena ka har'a ts'ebetso ea ho itšeha. Ho ipapisitsoe le litšoaneleho tsa eona tsa thepa le thekenoloji e sa sebetseng ea ts'ebetso, tlhahiso ea substrate ea lapeng e ka tlase ho 50%, 'me lintlha tse fapaneng li lebisa ho litheko tse phahameng tsa substrate le epitaxial.

Leha ho le joalo, litšenyehelo tsa lisebelisoa tsa silicon carbide le lisebelisoa tse thehiloeng ho silicon li fapane ka ho feletseng, litšenyehelo tsa substrate le epitaxial tsa akhaonto e ka pele ea mochine bakeng sa 47% le 23% ea sesebelisoa sohle ka ho latellana, hoo e ka bang 70%, moralo oa lisebelisoa, ho etsa le ho tiisa lihokelo tsa akhaonto ea morao bakeng sa 30% feela, litšenyehelo tsa tlhahiso ea lisebelisoa tsa morao-rao ke lisebelisoa tsa morao-rao tse entsoeng ka silicon-based. 50%, 'me litšenyehelo tsa substrate li etsa 7% feela. Ketsahalo ea bohlokoa ba ketane ea indasteri ea silicon carbide ka holimo e bolela hore baetsi ba li-epitaxy tse ka holimo ba na le tokelo ea mantlha ea ho bua, e leng senotlolo sa moralo oa likhoebo tsa lehae le tsa kantle ho naha.

Ho tloha sebakeng se matla sa pono ea 'maraka, ho fokotsa litšenyehelo tsa silicon carbide, ntle le ho ntlafatsa silicon carbide nako e telele ea kristale le ts'ebetso ea slicing, ke ho atolosa boholo ba liphaephe, tseo hape e leng tsela e tsoetseng pele ea nts'etsopele ea semiconductor nakong e fetileng, lintlha tsa Wolfspeed li bontša hore silicon carbide substrate e ntlafatsa ho tloha ho 6 lisenthimithara ho isa ho 80% ea tlhahiso ea 80% e ka thusang ntlafatsa chai. E ka fokotsa litšenyehelo tse kopaneng tsa yuniti ka 50%.

2023 e tsejoa e le "selemo sa pele sa 8-inch SiC", selemong sena, baetsi ba silicon carbide ba malapeng le ba kantle ho naha ba potlakisa sebopeho sa silicon carbide ea 8-inch, joalo ka matsete a bohlanya a Wolfspeed ea lidolara tse limilione tse likete tse 14.55 bakeng sa katoloso ea tlhahiso ea silicon carbide, karolo ea bohlokoa eo e leng kaho ea semela sa 8-inch sa SiC. ho lik'hamphani tse ngata; Tianyue Advanced le Tianke Heda le bona ba saenetse litumellano tsa nako e telele le Infineon ho fana ka li-substrates tsa silicon carbide tsa 8-inch nakong e tlang.

Ho tloha selemong sena, silicon carbide e tla potlakisa ho tloha ho lisenthimithara tse 6 ho isa ho lisenthimithara tse 8, Wolfspeed e lebeletse hore ka 2024, theko ea yuniti chip ea substrate ea 8 inches bapisoa le theko ea unit chip ea 6 inches substrate ka 2022 e tla fokotsoa ka ho feta 60%, 'me theko e fokotsehang e tla tsoela pele ho bula sebaka sa kopo ea Consul. Kabelo ea hajoale ea 'maraka ea lihlahisoa tse 8-inch e ka tlase ho 2%, mme karolo ea mmaraka e lebelletsoe ho hola ho fihla ho 15% ka 2026.

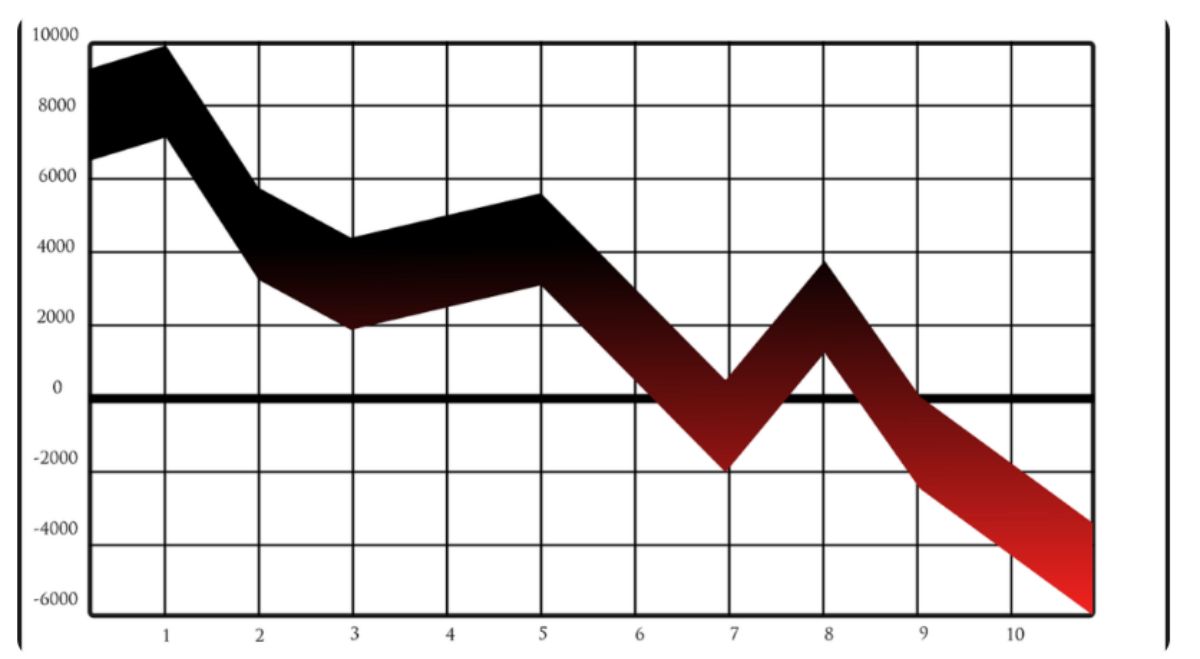

Ha e le hantle, tekanyo ea ho fokotseha ha theko ea silicon carbide substrate e ka 'na ea feta monahano oa batho ba bangata,' maraka oa hona joale oa 6-inch substrate ke 4000-5000 yuan / sengoathoana, ha o bapisoa le qalong ea selemo o oele haholo, o lebeletsoe ho oela ka tlase ho 4000 Yuan selemong se tlang, ke habohlokoa ho hlokomela hore theko ea pele e fokotsehile ho bahlahisi ba theko e tlaase. mohlala oa ntoa theko, haholo-holo concentrated ka silicon carbide substrate phepelo e se e batla e lekane tšimong e tlaase-voltage, baetsi ba malapeng le ba tsoang linaheng tse ling ba ntse ba eketsa matla a tlhahiso ea lihlahisoa, kapa ba lumelle silicon carbide substrate oversupply sethaleng pele ho moo ho nahanoang.

Nako ea poso: Jan-19-2024