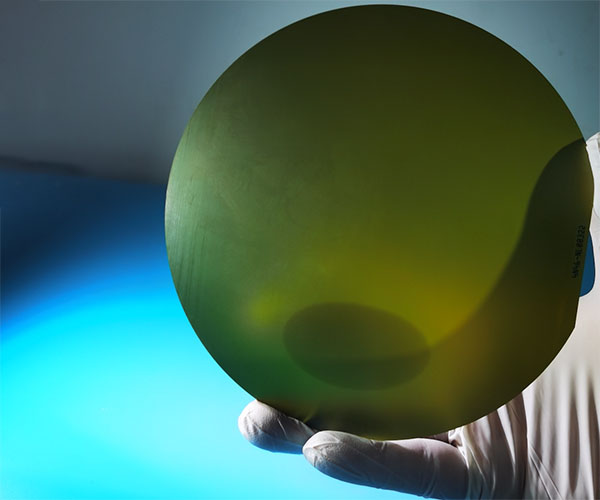

Hajoale, k'hamphani ea rona e ka tsoela pele ho fana ka liphaephe tse nyane tsa mofuta oa 8inchN SiC, haeba u na le litlhoko tsa mohlala, ka kopo ikutloe u lokolohile ho ikopanya le nna. Re na le li-wafers tse seng li loketse ho romelloa.

Sebakeng sa lisebelisoa tsa semiconductor, k'hamphani e entse katleho e kholo lipatlisisong le nts'etsopele ea likristale tse kholo tsa SiC. Ka ho sebelisa likristale tsa eona tsa peo ka mor'a ho atolosoa ka makhetlo a mangata, k'hamphani e atlehile ho holisa likristale tsa 8-inch N-type SiC, tse rarollang mathata a thata joalo ka mocheso o sa lekaneng oa mocheso, ho phatloha ha kristale le phepelo ea thepa e tala molemong oa kholo ea likristale tsa 8-inch SIC, mme e potlakisa kholo ea boholo bo boholo ba likristale tsa SIC le taolo e ikemetseng ea theknoloji. Ntlafatsa tlholisano ea mantlha ea k'hamphani indastering ea SiC single crystal substrate. Ka nako e ts'oanang, k'hamphani e khothalletsa ka matla ho bokella theknoloji le ts'ebetso ea boholo bo boholo ba silicon carbide substrate ho lokisetsa mohala oa liteko, ho matlafatsa phapanyetsano ea botekgeniki le tšebelisano-'moho ea indasteri libakeng tse ka holimo le tse ka tlaase ho noka, 'me e sebelisana le bareki ho tsoela pele ho pheta-pheta ts'ebetso ea sehlahisoa,' me ka kopanelo e khothalletsa lebelo la tšebeliso ea indasteri ea thepa ea silicon carbide.

| 8inch N-mofuta oa SiC DSP Litlhaloso | |||||

| Nomoro | Ntho | Yuniti | Tlhahiso | Patlisiso | Dummy |

| 1. Mekhahlelo | |||||

| 1.1 | polytype | -- | 4H | 4H | 4H |

| 1.2 | tshepediso ya bokahodimo | ° | <11-20>4±0.5 | <11-20>4±0.5 | <11-20>4±0.5 |

| 2. Parameter ea motlakase | |||||

| 2.1 | dopant | -- | n-mofuta oa Nitrojene | n-mofuta oa Nitrojene | n-mofuta oa Nitrojene |

| 2.2 | ho hanyetsa | ohm ·cm | 0.015~0.025 | 0.01~0.03 | NA |

| 3. Mechini parameter | |||||

| 3.1 | bophara | mm | 200±0.2 | 200±0.2 | 200±0.2 |

| 3.2 | botenya | μm | 500±25 | 500±25 | 500±25 |

| 3.3 | Notch orientation | ° | [1- 100]±5 | [1- 100]±5 | [1- 100]±5 |

| 3.4 | Botebo ba Notch | mm | 1 ~ 1.5 | 1 ~ 1.5 | 1 ~ 1.5 |

| 3.5 | LTV | μm | ≤5(10mm*10mm) | ≤5(10mm*10mm) | ≤10(10mm*10mm) |

| 3.6 | TTV | μm | ≤10 | ≤10 | ≤15 |

| 3.7 | Inamela | μm | -25 ~ 25 | - 45-45 | - 65-65 |

| 3.8 | Warp | μm | ≤30 | ≤50 | ≤70 |

| 3.9 | AFM | nm | Ra≤0.2 | Ra≤0.2 | Ra≤0.2 |

| 4. Sebopeho | |||||

| 4.1 | boima ba micropipe | e/cm2 | ≤2 | ≤10 | ≤50 |

| 4.2 | dikahare tsa tshepe | liathomo/cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | TSD | e/cm2 | ≤500 | ≤1000 | NA |

| 4.4 | BPD | e/cm2 | ≤2000 | ≤5000 | NA |

| 4.5 | TED | e/cm2 | ≤7000 | ≤10000 | NA |

| 5. Boleng bo botle | |||||

| 5.1 | ka pele | -- | Si | Si | Si |

| 5.2 | pheletso e kahodimo | -- | Si-face CMP | Si-face CMP | Si-face CMP |

| 5.3 | karoloana | sekoahelo | ≤100(boholo≥0.3μm) | NA | NA |

| 5.4 | ngoapa | sekoahelo | ≤5, Kakaretso ea Bolelele≤200mm | NA | NA |

| 5.5 | Qetello li-chips/indents/cracks/ stains/tshilafatso | -- | Ha ho letho | Ha ho letho | NA |

| 5.6 | Libaka tsa polytype | -- | Ha ho letho | Sebaka ≤10% | Sebaka ≤30% |

| 5.7 | tshoao ka pele | -- | Ha ho letho | Ha ho letho | Ha ho letho |

| 6. Morao boleng | |||||

| 6.1 | qetellong qetellong | -- | MP ea sefahleho sa C | MP ea sefahleho sa C | MP ea sefahleho sa C |

| 6.2 | ngoapa | mm | NA | NA | NA |

| 6.3 | Bokooa bo ka morao li-chips/li-indent | -- | Ha ho letho | Ha ho letho | NA |

| 6.4 | Bokhopo ba mokokotlo | nm | Ra≤5 | Ra≤5 | Ra≤5 |

| 6.5 | Ho tšoaea ka morao | -- | Notch | Notch | Notch |

| 7. Ntlheng | |||||

| 7.1 | bohale | -- | Chamfer | Chamfer | Chamfer |

| 8. Sephutheloana | |||||

| 8.1 | phutheloana | -- | Epi-ready with vacuum phutheloana | Epi-ready with vacuum phutheloana | Epi-ready with vacuum phutheloana |

| 8.2 | phutheloana | -- | Multi-wafer sephuthelo sa khasete | Multi-wafer sephuthelo sa khasete | Multi-wafer sephuthelo sa khasete |

Nako ea poso: Apr-18-2023