Ho hloekisa metsi (Wet Clean) ke e 'ngoe ea mehato ea bohlokoa ts'ebetsong ea tlhahiso ea semiconductor, e reretsoeng ho tlosa litšila tse fapa-fapaneng holim'a sekoti ho netefatsa hore mehato e latelang ea ts'ebetso e ka etsoa sebakeng se hloekileng.

Ha boholo ba lisebelisoa tsa semiconductor bo ntse bo fokotseha le litlhoko tse nepahetseng li eketseha, litlhoko tsa tekheniki tsa lits'ebetso tsa ho hloekisa li-wafer li ntse li le thata le ho feta. Esita le likaroloana tse nyenyane ka ho fetisisa, lisebelisoa tsa tlhaho, li-ion tsa tšepe, kapa masala a oxide holim'a sekoti a ka ama ts'ebetso ea sesebelisoa haholo, kahoo a ama chai le ho tšepahala ha lisebelisoa tsa semiconductor.

Melao-motheo ea Motheo ea ho Hloekisa Wafer

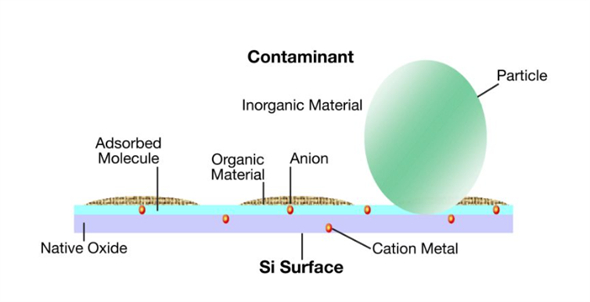

Ntho ea mantlha ea ho hloekisa liphaephe ke ho tlosa litšila tse fapaneng ka nepo ka mokhoa oa 'mele, lik'hemik'hale le mekhoa e meng ho netefatsa hore sephaphatha se na le bokaholimo bo hloekileng bo loketseng ts'ebetso e latelang.

Mofuta oa Tšilafalo

Litšusumetso tse ka Sehloohong ho Litšobotsi tsa Sesebelisoa

| thipa Tšilafalo | Mefokolo ea mohlala

Litšitiso tsa ho kenngoa ha ion

Litšitiso tsa ho senyeha ha lifilimi

| |

| Tšilafalo ea tšepe | Litšepe tsa Alkali | Ho se tsitse ha MOS transistor

Ho senyeha ha filimi ea heke ea oxide / ho senyeha

|

| Litšepe tse boima | Keketseho ea PN junction reverse leakage ea hajoale

Litšitiso tsa ho senyeha ha filimi ea heke ea oxide

Ho senyeha ha mojari ea fokolang bophelo bohle

Ho hlahisa sekoli sa lera la oksijene

| |

| Tšilafalo ea Lik'hemik'hale | Lintho Tse Hlahang | Litšitiso tsa ho senyeha ha filimi ea heke ea oxide

Phapang ea lifilimi tsa CVD (linako tsa incubation)

Mefuta e fapaneng ea botenya ba filimi ea thermal oxide (oxidation e potlakileng)

Ketsahalo ea haze (wafer, lense, seipone, maske, reticle)

|

| Li-Inorganic Dopants (B, P) | Liphetoho tsa MOS transistor Vth

Si substrate le liphapano tse phahameng tsa ho hanyetsa lakane ea poly-silicon

| |

| Metheo ea Inorganic (amines, ammonia) & Acids (SOx) | Ho senyeha ha tharollo ea lik'hemik'hale tse matlafatsang lik'hemik'hale

Ho ba teng ha tšilafalo le moholi ka lebaka la ho hlahisa letsoai

| |

| Lifilimi tsa Native le Chemical Oxide Ka lebaka la Mongobo, Moea | Keketseho ea khanyetso

Ho senyeha ha filimi ea heke ea oxide / ho senyeha

| |

Haholo-holo, merero ea ts'ebetso ea ho hloekisa li-wafer e kenyelletsa:

Ho tlosoa ha Particle: Ho sebelisa mekhoa ea 'mele kapa ea lik'hemik'hale ho tlosa likaroloana tse nyenyane tse khomaretsoeng holim'a metsi. Likaroloana tse nyane li thata haholo ho li tlosa ka lebaka la matla a matla a electrostatic pakeng tsa bona le bokaholimo ba sephaphatha, bo hlokang kalafo e khethehileng.

Ho tlosoa ha lintho tse phelang: Lintho tse silafatsang tse kang mafura le masala a photoresist li ka 'na tsa khomarela holim'a sekoti. Lintho tsena tse silafatsang hangata li tlosoa ho sebelisoa li-oxidizing agents kapa solvents.

Ho tlosoa ha Metal Ion: Masala a ion a tšepe holim'a sekoti a ka senya ts'ebetso ea motlakase esita le ho ama mehato e latelang ea ts'ebetso. Ka hona, litharollo tse khethehileng tsa lik'hemik'hale li sebelisoa ho tlosa li-ion tsena.

Ho tlosoa ha Oxide: Mekhoa e meng e hloka hore bokaholimo bo se ke ba e-ba le likarolo tsa oxide, joalo ka silicon oxide. Maemong a joalo, likarolo tsa tlhaho tsa oxide li hloka ho tlosoa nakong ea mehato e itseng ea ho hloekisa.

Phephetso ea theknoloji ea ho hloekisa liphaephe e holim'a ho tlosa litšila ka nepo ntle le ho senya bokaholimo ba liphaephe, joalo ka ho thibela ho putlama ha bokaholimo, ho bola kapa tšenyo e 'ngoe ea 'mele.

2. Wafer Cleaning Process Flow

Mokhoa oa ho hloekisa oafer hangata o kenyelletsa mehato e mengata ea ho netefatsa ho tlosoa ka ho feletseng ha litšila le ho finyella sebaka se hloekileng ka ho feletseng.

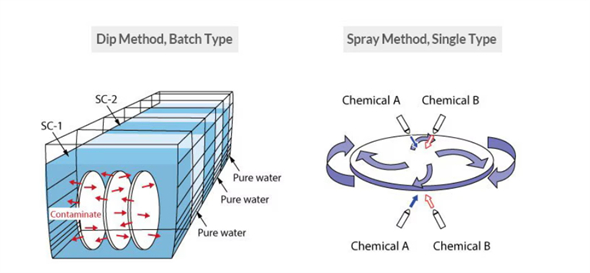

Setšoantšo: Papiso pakeng tsa Batch-Type le Single-Wafer Cleaning

Mokhoa o tloaelehileng oa ho hloekisa oafer o kenyelletsa mehato e latelang:

1. Ho Hloekisa Pele (Pele ho Hloeka)

Sepheo sa ho hloekisa pele ke ho tlosa litšila tse hlephileng le likaroloana tse kholo ho tloha holim'a sephaphatha, seo hangata se finyelloang ka metsi a hloekisitsoeng (DI Water) ho hlatsoa le ho hloekisa ka ultrasonic. Metsi a deionized a ka qala ho tlosa likaroloana le litšila tse qhibilihisitsoeng ho tloha holim'a sephaphatha, ha ho hloekisa ka ultrasonic ho sebelisa liphello tsa cavitation ho senya maqhama pakeng tsa likaroloana le holim'a metsi, ho etsa hore ho be bonolo ho li tlosa.

2. Ho Hloekisa Lik'hemik'hale

Ho hloekisa ka lik'hemik'hale ke o mong oa mehato ea mantlha ts'ebetsong ea ho hloekisa, ho sebelisa litharollo tsa lik'hemik'hale ho tlosa lintho tse phelang, li-ion tsa tšepe le li-oxide ho tloha holim'a metsi.

Ho tlosoa ha lintho tse phelang: Ka tloaelo, acetone kapa motsoako oa ammonia / peroxide (SC-1) o sebelisetsoa ho qhaqha le ho oxidize litšila tse phelang. Karolelano e tloaelehileng ea tharollo ea SC-1 ke NH₄OH

₂O₂

₂O = 1:1:5, ka mocheso o sebetsang o ka bang 20°C.

Ho tlosoa ha Metal Ion: Nitric acid kapa hydrochloric acid / peroxide metsoako (SC-2) e sebelisoa ho tlosa li-ion tsa tšepe ho tloha holim'a metsi. Karolelano e tloaelehileng ea tharollo ea SC-2 ke HCl

₂O₂

₂O = 1:1:6, thempereichara e bolokiloe hoo e ka bang 80°C.

Ho tlosoa ha Oxide: Mekhoeng e meng, ho tlosoa ha lesela la oxide la tlhaho ho tloha holim'a metsi hoa hlokahala, moo ho sebelisoang tharollo ea hydrofluoric acid (HF). Karolelano e tloaelehileng ea tharollo ea HF ke HF

₂O = 1:50, 'me e ka sebelisoa mocheso oa kamore.

3. Ho Hloeka ha ho Qetela

Ka mor'a ho hloekisa lik'hemik'hale, li-wafers hangata li kena mohato oa ho qetela oa ho hloekisa ho netefatsa hore ha ho na masala a lik'hemik'hale a setseng holim'a metsi. Ho hloekisa ho qetela ho sebelisoa haholo-holo metsi a hloekisitsoeng bakeng sa ho hlatsoa ka ho feletseng. Ho feta moo, ho hloekisa metsi a ozone (O₃/H₂O) ho sebelisoa ho tlosa litšila tse setseng holim'a metsi.

4. Ho omisa

Li-wafers tse hloekisitsoeng li tlameha ho omisoa kapele ho thibela li-watermark kapa ho hokelloa hape ha litšila. Mekhoa e tloaelehileng ea ho omisa e kenyelletsa ho omisa ka spin le nitrogen purging. Ea pele e tlosa mongobo holim'a bokaholimo ka ho bilika ka lebelo le phahameng, athe ea morao-rao e tiisa ho omella ka ho feletseng ka ho bululela khase e ommeng ea nitrogen ho pholletsa le bokaholimo ba sephaphatha.

Se silafatsa

Lebitso la Mokhoa oa ho Hloekisa

Tlhaloso ea Motsoako oa Lik'hemik'hale

Lik'hemik'hale

| Likaroloana | Piranha (SPM) | Asiti ea sulfuric / hydrogen peroxide / DI metsi | H2SO4/H2O2/H2O 3-4:1; 90°C |

| SC-1 (APM) | Ammonium hydroxide / hydrogen peroxide / DI metsi | NH4OH/H2O2/H2O 1:4:20; 80°C | |

| Litšepe (eseng koporo) | SC-2 (HPM) | Hydrochloric acid / hydrogen peroxide / DI metsi | HCl/H2O2/H2O1:1:6; 85°C |

| Piranha (SPM) | Asiti ea sulfuric / hydrogen peroxide / DI metsi | H2SO4/H2O2/H2O3-4:1; 90°C | |

| DHF | Hlakola hydrofluoric acid / DI metsi (e ke ke ea tlosa koporo) | HF/H2O1:50 | |

| Lintho tse phelang | Piranha (SPM) | Asiti ea sulfuric / hydrogen peroxide / DI metsi | H2SO4/H2O2/H2O 3-4:1; 90°C |

| SC-1 (APM) | Ammonium hydroxide / hydrogen peroxide / DI metsi | NH4OH/H2O2/H2O 1:4:20; 80°C | |

| DIO3 | Ozone ka metsing a de-ionized | O3/H2O Optimized Mixtures | |

| Native oxide | DHF | Hlakola hydrofluoric acid / DI metsi | HF/H2O 1:100 |

| BHF | Sehlahisoa sa hydrofluoric acid | NH4F/HF/H2O |

3. Mekhoa e Tloaelehileng ea ho Hloekisa Wafer

1. Mokhoa oa ho Hloekisa oa RCA

Mokhoa oa ho hloekisa oa RCA ke o mong oa mekhoa ea khale ka ho fetesisa ea ho hloekisa li-wafer indastering ea semiconductor, e ntlafalitsoeng ke RCA Corporation lilemong tse 40 tse fetileng. Mokhoa ona o sebelisoa haholo ho tlosa litšila tsa tlhaho le litšila tsa ion tsa tšepe 'me o ka phethoa ka mehato e' meli: SC-1 (Standard Clean 1) le SC-2 (Standard Clean 2).

SC-1 Cleaning: Mohato ona o sebelisoa haholo ho tlosa litšila le likaroloana. Tharollo ke motsoako oa ammonia, hydrogen peroxide, le metsi, e leng se etsang lera le lesesaane la silicon oxide holim'a sephaphatha.

SC-2 Cleaning: Mohato ona o sebelisoa haholo-holo ho tlosa litšila tsa ion tsa tšepe, ho sebelisoa motsoako oa hydrochloric acid, hydrogen peroxide, le metsi. E siea karolo e tšesaane ea passivation holim'a bokaholimo ho thibela tšoaetso hape.

2. Mokhoa oa ho Hloekisa oa Piranha (Piranha Etch Clean)

Mokhoa oa ho hloekisa Piranha ke mokhoa o atlehang haholo oa ho tlosa lisebelisoa tsa tlhaho, ho sebelisoa motsoako oa sulfuric acid le hydrogen peroxide, hangata ka karolelano ea 3: 1 kapa 4: 1. Ka lebaka la matla a matla a oxidative ea tharollo ena, e ka tlosa bongata bo bongata ba lintho tse phelang le litšila tse manganga. Mokhoa ona o hloka taolo e tiileng ea maemo, haholo-holo mabapi le mocheso le mohopolo, ho qoba ho senya sephaphatha.

Ho hloekisa ka mokhoa oa Ultrasonic ho sebelisa phello ea cavitation e hlahisoang ke maqhubu a molumo a phahameng-frequency ka mokelikeli ho tlosa litšila ho tloha holim'a metsi. Ha ho bapisoa le ho hloekisa ka mokhoa o tloaelehileng oa ultrasonic, ho hloekisa ka megasonic ho sebetsa ka lebelo le phahameng, ho nolofalletsang ho tlosoa ha likaroloana tse nyenyane tsa micron ntle le ho baka tšenyo holim'a metsi.

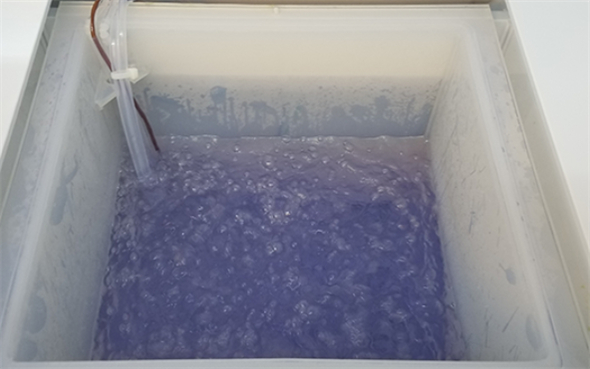

4. Ho Hloekisa Ozone

Theknoloji ea ho hloekisa Ozone e sebelisa matla a oxidizing ea ozone ho bola le ho tlosa litšila tse tsoang holim'a metsi, 'me qetellong li li fetole carbon dioxide le metsi a se nang kotsi. Mokhoa ona ha o hloke tšebeliso ea li-reagents tsa lik'hemik'hale tse theko e boima 'me o baka tšilafalo e fokolang ea tikoloho, e leng se etsang hore e be theknoloji e hlahang tšimong ea ho hloekisa liphaphatha.

4. Sesebelisoa sa ho Hloekisa Sephepana

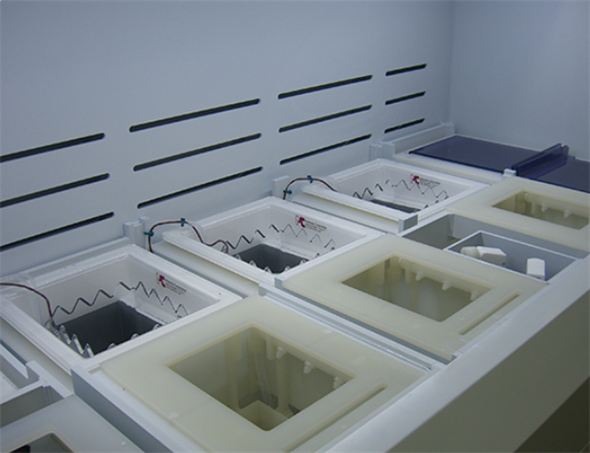

Ho netefatsa ts'ebetso le polokeho ea lits'ebetso tsa ho hloekisa li-wafer, ho sebelisoa lisebelisoa tse fapaneng tsa ho hloekisa tse tsoetseng pele tlhahisong ea semiconductor. Mefuta e ka sehloohong e kenyelletsa:

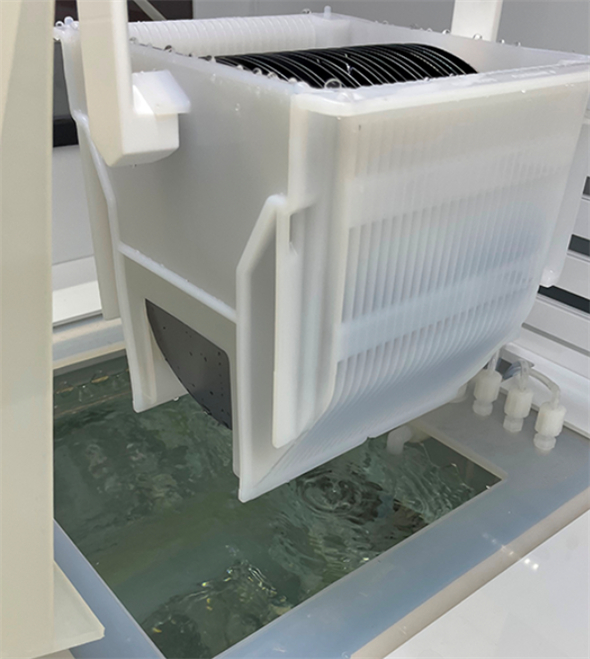

1. Metsi a Hloekisa Thepa

Lisebelisoa tsa ho hloekisa ka metsi li kenyelletsa litanka tse fapaneng tsa ho qoelisoa, litanka tsa ho hloekisa tsa ultrasonic, le li-spin dryer. Lisebelisoa tsena li kopanya matla a mechine le li-reagents tsa lik'hemik'hale ho tlosa litšila ho tloha holim'a sephaphatha. Litanka tsa ho qoelisoa hangata li na le lisebelisoa tsa ho laola mocheso ho netefatsa botsitso le katleho ea tharollo ea lik'hemik'hale.

2. Dry Cleaning Thepa

Thepa ea ho hloekisa e ommeng haholo-holo e kenyelletsa lihloekisi tsa plasma, tse sebelisang likaroloana tse nang le matla a phahameng ka har'a plasma ho arabela le ho tlosa masalla holim'a bokaholimo. Ho hloekisa plasma ho loketse ka ho khetheha bakeng sa lits'ebetso tse hlokang ho boloka botšepehi bo holimo ntle le ho hlahisa masala a lik'hemik'hale.

3. Mekhoa ea ho hloekisa e ikemetseng

Ka keketseho e tsoelang pele ea tlhahiso ea semiconductor, litsamaiso tsa ho hloekisa ka boiketsetso li fetohile khetho e ratoang bakeng sa tlhoekiso e kholo ea li-wafer. Litsamaiso tsena hangata li kenyelletsa mekhoa ea phetisetso e ikemetseng, lisebelisoa tsa ho hloekisa litanka tse ngata, le litsamaiso tse nepahetseng tsa taolo ho netefatsa liphetho tse tsitsitseng tsa tlhoekiso bakeng sa sephaphatha ka seng.

5. Mekhoa ea Bokamoso

Ha lisebelisoa tsa semiconductor li ntse li tsoela pele ho honyela, theknoloji ea ho hloekisa liphaephe e ntse e tsoela pele ho fihlela litharollo tse sebetsang hantle le tse baballang tikoloho. Theknoloji ea nakong e tlang ea ho hloekisa e tla tsepamisa maikutlo ho:

Sub-nanometer Particle Removal: Theknoloji e teng ea ho hloekisa e ka sebetsana le likaroloana tsa nanometer-scale, empa ka phokotso e eketsehileng ea boholo ba sesebelisoa, ho tlosa likaroloana tsa sub-nanometer e tla ba phephetso e ncha.

Tlhoekiso ea Botala le Eco-friendly: Ho fokotsa tšebeliso ea lik'hemik'hale tse kotsi tikolohong le ho theha mekhoa e mengata ea ho hloekisa eco-friendly, joalo ka ho hloekisa ozone le ho hloekisa megasonic, ho tla ba bohlokoa le ho feta.

Maemo a Phahameng a Boiketsetso le Bohlale: Litsamaiso tse bohlale li tla thusa ho lekola nako ea nnete le ho lokisoa ha mekhahlelo e fapaneng nakong ea ts'ebetso ea ho hloekisa, ho ntlafatsa ts'ebetso ea ho hloekisa le ho sebetsa hantle ha tlhahiso.

Theknoloji ea ho hloekisa li-wafer, e le mohato oa bohlokoa tlhahisong ea semiconductor, e bapala karolo ea bohlokoa ho netefatsa hore ho na le libaka tse hloekileng tsa wafer bakeng sa lits'ebetso tse latelang. Ho kopanya mekhoa e fapaneng ea ho hloekisa ka katleho ho tlosa litšila, ho fana ka sebaka se hloekileng sa substrate bakeng sa mehato e latelang. Ha theknoloji e ntse e hatela pele, lits'ebetso tsa ho hloekisa li tla tsoela pele ho ntlafatsoa ho fihlela litlhoko tsa ho nepahala ho holimo le litheko tse tlase tsa bofokoli tlhahisong ea li-semiconductor.

Nako ea poso: Oct-08-2024