SiC wafer's abstract

Li-wafers tsa silicon carbide (SiC).e fetohile sebaka sa khetho bakeng sa lisebelisoa tsa elektronike tse matla a holimo, tse lebelo le phahameng le mocheso o phahameng ho pholletsa le makoloi, matla a tsosolositsoeng le a sefofane. Potefolio ea rona e akaretsa li-polytypes tsa bohlokoa le merero ea doping-nitrogen-doped 4H (4H-N), high-purity semi-insulating (HPSI), nitrogen-doped 3C (3C-N), le mofuta oa p-4H / 6H (4H / 6H-P) - e fanoa ka lihlopha tse tharo tsa boleng: PRIME (e bentšitsoeng ka ho feletseng, lisebelisoa tse sa tsitsang tsa DUMMY) PATLISISO (mekhahlelo ea tloaelo ea epi le li-profaele tsa doping bakeng sa R&D). Bophahamo ba li-wafer bo bolelele ba 2 ″, 4 ″, 6 ″, 8 ″ le 12 ″ ho lumellana le lisebelisoa tsa khale le masela a tsoetseng pele. Re boetse re fana ka li-boules tsa monocrystalline le likristale tsa peo tse shebaneng hantle ho ts'ehetsa kholo ea kristale ka tlung.

Li-wafers tsa rona tsa 4H-N li na le li-carrier densities ho tloha ho 1×10¹⁶ ho isa ho 1×10¹⁹ cm⁻³ le tse hanyetsanang le 0.01–10 Ω·cm, li fana ka motsamao o motle oa elektronike le libaka tse senyehang ka holimo ho 2 MV/cm—li loketseng bakeng sa Schottky diode, le JMOSsFET diode. Li-substrates tsa HPSI li feta 1×10¹² Ω·cm tse hanyetsanang le li-micropipe tse ka tlase ho 0.1 cm⁻², tse netefatsang ho lutla ho fokolang bakeng sa lisebelisoa tsa RF le microwave. Cubic 3C-N, e fumanehang ka liforomo tsa 2 ″ le 4 ″, e nolofalletsa heteroepitaxy ho silicon mme e ts'ehetsa lits'ebetso tse ncha tsa photonic le MEMS. Li-wafers tsa mofuta oa P-4H/6H-P, tse entsoeng ka aluminium ho isa ho 1×10¹⁶–5×10¹⁸ cm⁻³, li thusa ka meralo ea lisebelisoa tse tlatselletsang.

SiC wafer, PRIME wafers e entsoe ka polishing ea lik'hemik'hale ho <0.2 nm RMS holim'a botenya, phapang e felletseng ea botenya tlasa 3 µm, le seqha <10 µm. Li-substrates tsa DUMMY li potlakisa liteko tsa ho kopanya le ho paka, ha li-wafers tsa RESEARCH li na le botenya ba epi-layer ea 2–30 µm le doping ea bespoke. Lihlahisoa tsohle li netefalitsoe ke X-ray diffraction (rocking curve <30 arcsec) le Raman spectroscopy, ka liteko tsa motlakase-Litekanyo tsa Hall, C-V profiling, le micropipe scanning-ho netefatsa hore JEDEC le SEMI lia lumellana.

Li-boules tse fihlang ho limilimithara tse 150 li lengoa ka PVT le CVD ka likhahla tse ka tlase ho 1×10³ cm⁻² le lipalo tse tlase tsa micropipe. Likristale tsa peo li khaoloa ka har'a 0.1 ° ea c-axis ho netefatsa kholo e ka ikatisang le chai e ngata ea ho seha.

Ka ho kopanya li-polytypes tse ngata, mefuta e fapaneng ea li-doping, limaraka tsa boleng, boholo ba liphaephe tsa SiC, le tlhahiso ea ka tlung le tlhahiso ea kristale ea peo, sethala sa rona sa SiC substrate se tsamaisa liketane tsa phepelo le ho potlakisa nts'etsopele ea lisebelisoa bakeng sa likoloi tsa motlakase, li-grids tse bohlale, le lits'ebetso tse thata tsa tikoloho.

SiC wafer's abstract

Li-wafers tsa silicon carbide (SiC).e fetohile sebaka sa khetho sa SiC bakeng sa matla a phahameng, maqhubu a phahameng, le lisebelisoa tsa elektronike tse nang le mocheso o phahameng ho pholletsa le likoloi, matla a tsosolositsoeng le a sefofane. Potefolio ea rona e akaretsa li-polytypes tsa bohlokoa le li-doping schemes-nitrogen-doped 4H (4H-N), high-purity semi-insulating (HPSI), nitrogen-doped 3C (3C-N), le p-type 4H / 6H (4H / 6H-P) -e fanoa ka lihlopha tse tharo tsa boleng: SiC waferPRIME (e bentšitsoeng ka botlalo, li-substrates tsa boemo ba lisebelisoa), DUMMY (e lapiloe kapa e sa belisoa bakeng sa liteko tsa ts'ebetso), le RESEARCH (mekhahlelo ea tloaelo ea epi le liprofaele tsa doping bakeng sa R&D). SiC Wafer diameters span 2″, 4″, 6″, 8″, le 12″ ho lumellana le lisebelisoa tsa lefa le masela a tsoetseng pele. Re boetse re fana ka li-boules tsa monocrystalline le likristale tsa peo tse shebaneng hantle ho ts'ehetsa kholo ea kristale ka tlung.

Li-wafers tsa rona tsa 4H-N SiC li na le li-carrier densities ho tloha 1 × 10¹⁶ ho 1 × 10¹⁹ cm⁻³ le resistivities ea 0.01–10 Ω·cm, e fana ka motsamao o motle oa elektronike le libaka tse senyehang ka holimo ho 2 MV/cm - tse loketseng Schottky diode, MOSFET diode, le JFETS. Li-substrates tsa HPSI li feta 1×10¹² Ω·cm tse hanyetsanang le li-micropipe tse ka tlase ho 0.1 cm⁻², tse netefatsang ho lutla ho fokolang bakeng sa lisebelisoa tsa RF le microwave. Cubic 3C-N, e fumanehang ka liforomo tsa 2 ″ le 4 ″, e nolofalletsa heteroepitaxy ho silicon mme e ts'ehetsa lits'ebetso tse ncha tsa photonic le MEMS. SiC wafer P-type 4H/6H-P wafers, e entsoeng ka aluminium ho isa ho 1×10¹⁶–5×10¹⁸ cm⁻³, e thusa meralo ea lisebelisoa tse tlatselletsang.

Li-wafer tsa SiC PRIME li na le polishing ea lik'hemik'hale ho ea ho <0.2 nm RMS holim'a bokaholimo, phapang e felletseng ea botenya tlasa 3 µm, le bow <10 µm. Li-substrates tsa DUMMY li potlakisa liteko tsa ho kopanya le ho paka, ha li-wafers tsa RESEARCH li na le botenya ba epi-layer ea 2–30 µm le doping ea bespoke. Lihlahisoa tsohle li netefalitsoe ke X-ray diffraction (rocking curve <30 arcsec) le Raman spectroscopy, ka liteko tsa motlakase-Litekanyo tsa Hall, C-V profiling, le micropipe scanning-ho netefatsa hore JEDEC le SEMI lia lumellana.

Li-boules tse fihlang ho limilimithara tse 150 li lengoa ka PVT le CVD ka likhahla tse ka tlase ho 1×10³ cm⁻² le lipalo tse tlase tsa micropipe. Likristale tsa peo li khaoloa ka har'a 0.1 ° ea c-axis ho netefatsa kholo e ka ikatisang le chai e ngata ea ho seha.

Ka ho kopanya li-polytypes tse ngata, mefuta e fapaneng ea li-doping, limaraka tsa boleng, boholo ba liphaephe tsa SiC, le tlhahiso ea ka tlung le tlhahiso ea kristale ea peo, sethala sa rona sa SiC substrate se tsamaisa liketane tsa phepelo le ho potlakisa nts'etsopele ea lisebelisoa bakeng sa likoloi tsa motlakase, li-grids tse bohlale, le lits'ebetso tse thata tsa tikoloho.

Leqephe la data la 6inch 4H-N mofuta oa SiC wafer

| Letlapa la data la 6inch SiC wafers | ||||

| Paramethara | Sub-Parameter | Z Kereiti | P Kereiti | D Kereiti |

| Diameter | 149.5–150.0 limilimithara | 149.5–150.0 limilimithara | 149.5–150.0 limilimithara | |

| Botenya | 4H‑N | 350 µm ± 15 µm | 350 µm ± 25 µm | 350 µm ± 25 µm |

| Botenya | 4H‑SI | 500 µm ± 15 µm | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Wafer Orientation | Off axis: 4.0 ° ho ea ho <11-20> ± 0.5 ° (4H-N); Ka lehlakoreng le leng: <0001> ±0.5° (4H-SI) | Off axis: 4.0 ° ho ea ho <11-20> ± 0.5 ° (4H-N); Ka lehlakoreng le leng: <0001> ±0.5° (4H-SI) | Off axis: 4.0 ° ho ea ho <11-20> ± 0.5 ° (4H-N); Ka lehlakoreng le leng: <0001> ±0.5° (4H-SI) | |

| Boima ba Micropipe | 4H‑N | ≤ 0.2 cm⁻² | ≤ 2 cm⁻² | ≤ 15 cm⁻² |

| Boima ba Micropipe | 4H‑SI | ≤ 1 cm⁻² | ≤ 5cm⁻² | ≤ 15 cm⁻² |

| Ho hanyetsa | 4H‑N | 0.015–0.024 Ω·cm | 0.015–0.028 Ω·cm | 0.015–0.028 Ω·cm |

| Ho hanyetsa | 4H‑SI | ≥ 1×10¹⁰ Ω·cm | ≥ 1×10⁵ Ω·cm | |

| Maemo a Motheo a Flat | [10-10] ± 5.0° | [10-10] ± 5.0° | [10-10] ± 5.0° | |

| Bolelele ba Phatlalatso ba Pele | 4H‑N | 47.5 limilimithara ± 2.0 limilimithara | ||

| Bolelele ba Phatlalatso ba Pele | 4H‑SI | Notch | ||

| Kenyelletso ea Edge | 3 limilimithara | |||

| Warp/LTV/TTV/Bow | ≤2.5 µm / ≤6 µm / ≤25 µm / ≤35 µm | ≤5 µm / ≤15 µm / ≤40 µm / ≤60 µm | ||

| Boqhobane | Sepolishe | Ra ≤ 1 nm | ||

| Boqhobane | CMP | Ra ≤ 0.2 nm | Ra ≤ 0.5 nm | |

| Mapheo a Edge | Ha ho letho | Bolelele bo akaretsang ≤ 20 mm, e le 'ngoe ≤ 2 mm | ||

| Lipoleiti tsa Hex | Sebaka sa pokello ≤ 0.05% | Sebaka sa pokello ≤ 0.1% | Kakaretso ≤ 1% | |

| Libaka tsa Polytype | Ha ho letho | Kakaretso ≤ 3% | Kakaretso ≤ 3% | |

| Li-Carbon Inclusions | Sebaka sa pokello ≤ 0.05% | Kakaretso ≤ 3% | ||

| Mekhoro ea Bokaholimo | Ha ho letho | Bolelele bo kopantseng ≤ 1 × bophara ba wafer | ||

| Li-Chips tsa Edge | Ha e lumelloe ≥ 0.2 mm bophara & botebo | Ho fihla ho li-chips tse 7, ≤ 1 mm ka 'ngoe | ||

| TSD (Threading Screw Dislocation) | ≤ 500 cm⁻² | N/A | ||

| BPD (Base Plane Dislocation) | ≤ 1000 cm⁻² | N/A | ||

| Tšilafalo ea Bokaholimo | Ha ho letho | |||

| Sephutheloana | Multi-wafer cassette kapa single wafer setshelo | Multi-wafer cassette kapa single wafer setshelo | Multi-wafer cassette kapa single wafer setshelo | |

Leqephe la data la 4inch 4H-N mofuta oa SiC wafer

| Letlapa la data la 4inch SiC wafer | |||

| Paramethara | Zero MPD Tlhahiso | Mophato o Tlwaelehileng wa Tlhahiso (P Grade) | Kereiti ya Dummy (D Grade) |

| Diameter | 99.5 mm–100.0 limilimithara | ||

| Botenya (4H-N) | 350µm±15µm | 350µm±25µm | |

| Botenya (4H-Si) | 500µm±15µm | 500µm±25µm | |

| Wafer Orientation | Off axis: 4.0 ° ho ea <1120> ± 0.5 ° bakeng sa 4H-N; Ka lehlakoreng le leng: <0001> ± 0.5 ° bakeng sa 4H-Si | ||

| Boima ba Micropipe (4H-N) | ≤0.2 cm⁻² | ≤2 cm⁻² | ≤15 cm⁻² |

| Boima ba Micropipe (4H-Si) | ≤1 cm⁻² | ≤5 cm⁻² | ≤15 cm⁻² |

| Resistivity (4H-N) | 0.015–0.024 Ω·cm | 0.015–0.028 Ω·cm | |

| Resistivity (4H-Si) | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |

| Maemo a Motheo a Flat | [10-10] ±5.0° | ||

| Bolelele ba Phatlalatso ba Pele | 32.5 limilimithara ±2.0 limilimithara | ||

| Bolelele ba Bokhabane ba Bobeli | 18.0 limilimithara ±2.0 limilimithara | ||

| Boemo ba Bobeli ba Flat | Sefahleho sa silicon: 90 ° CW ho tloha sephara se seholo ± 5.0 ° | ||

| Kenyelletso ea Edge | 3 limilimithara | ||

| LTV/TTV/Bow Warp | ≤2.5 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| Boqhobane | Polish Ra ≤1 nm; CMP Ra ≤0.2 nm | Ra ≤0.5 nm | |

| Edge Cracks By High Intensity Leseli | Ha ho letho | Ha ho letho | Bolelele ba kakaretso ≤10 mm; bolelele bo le bong ≤2 mm |

| Hex Plates By High Intensity Light | Kakaretso ≤0.05% | Kakaretso ≤0.05% | Kakaretso ≤0.1% |

| Libaka tsa Polytype Ka Leseli le Matla a Phahameng | Ha ho letho | Kakaretso ≤3% | |

| Likakaretso tsa Carbon tse bonoang | Kakaretso ≤0.05% | Kakaretso ≤3% | |

| Silicon Surface Scratches Ka Leseli le Matla a Phahameng | Ha ho letho | Bolelele bo kopantseng ≤1 bophara ba wafer | |

| Edge Chips Ka Leseli le Matla a Phahameng | Ha ho e lumelletsoeng ≥0.2 mm bophara le botebo | 5 e lumelletsoe, ≤1 mm ka 'ngoe | |

| Tšilafalo ea Sefahleho sa Silicon Ka Leseli le Matla a Phahameng | Ha ho letho | ||

| Ho thijoa ha screw screw | ≤500 cm⁻² | N/A | |

| Sephutheloana | Multi-wafer cassette kapa single wafer setshelo | Multi-wafer cassette kapa single wafer setshelo | Multi-wafer cassette kapa single wafer setshelo |

Leqephe la data la 4inch HPSI mofuta oa SiC wafer

| Leqephe la data la 4inch HPSI mofuta oa SiC wafer | |||

| Paramethara | Kereiti ea Tlhahiso ea Zero MPD (Mophato oa Z) | Mophato o Tlwaelehileng wa Tlhahiso (P Grade) | Kereiti ya Dummy (D Grade) |

| Diameter | 99.5–100.0 limilimithara | ||

| Botenya (4H-Si) | 500 µm ±20 µm | 500 µm ±25 µm | |

| Wafer Orientation | Off axis: 4.0 ° ho ea ho <11-20> ± 0.5 ° bakeng sa 4H-N; Ka lehlakoreng le leng: <0001> ± 0.5 ° bakeng sa 4H-Si | ||

| Boima ba Micropipe (4H-Si) | ≤1 cm⁻² | ≤5 cm⁻² | ≤15 cm⁻² |

| Resistivity (4H-Si) | ≥1E9 Ω·cm | ≥1E5 Ω·cm | |

| Maemo a Motheo a Flat | (10-10) ± 5.0 ° | ||

| Bolelele ba Phatlalatso ba Pele | 32.5 limilimithara ±2.0 limilimithara | ||

| Bolelele ba Bokhabane ba Bobeli | 18.0 limilimithara ±2.0 limilimithara | ||

| Boemo ba Bobeli ba Flat | Sefahleho sa silicon: 90 ° CW ho tloha sephara se seholo ± 5.0 ° | ||

| Kenyelletso ea Edge | 3 limilimithara | ||

| LTV/TTV/Bow Warp | ≤3 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| Ho thatafala (C sefahleho) | Sepolishe | Ra ≤1 nm | |

| Bokhopo (Si face) | CMP | Ra ≤0.2 nm | Ra ≤0.5 nm |

| Edge Cracks By High Intensity Leseli | Ha ho letho | Bolelele ba kakaretso ≤10 mm; bolelele bo le bong ≤2 mm | |

| Hex Plates By High Intensity Light | Kakaretso ≤0.05% | Kakaretso ≤0.05% | Kakaretso ≤0.1% |

| Libaka tsa Polytype Ka Leseli le Matla a Phahameng | Ha ho letho | Kakaretso ≤3% | |

| Likakaretso tsa Carbon tse bonoang | Kakaretso ≤0.05% | Kakaretso ≤3% | |

| Silicon Surface Scratches Ka Leseli le Matla a Phahameng | Ha ho letho | Bolelele bo kopantseng ≤1 bophara ba wafer | |

| Edge Chips Ka Leseli le Matla a Phahameng | Ha ho e lumelletsoeng ≥0.2 mm bophara le botebo | 5 e lumelletsoe, ≤1 mm ka 'ngoe | |

| Tšilafalo ea Sefahleho sa Silicon Ka Leseli le Matla a Phahameng | Ha ho letho | Ha ho letho | |

| Ho kheloha ha Screw Dislocation | ≤500 cm⁻² | N/A | |

| Sephutheloana | Multi-wafer cassette kapa single wafer setshelo | ||

Sesebelisoa sa SiC wafer

-

SiC Wafer Power Modules bakeng sa EV Inverters

Li-MOSFET tse thehiloeng ho SiC le li-diode tse hahiloeng holim'a li-wafer substrates tsa SiC tsa boleng bo holimo li fana ka tahlehelo e phahameng haholo. Ka ho sebelisa theknoloji ea SiC wafer, li-module tsena tsa matla li sebetsa maemong a phahameng le mocheso, li nolofalletsa li-inverters tse sebetsang hantle haholoanyane. Ho kopanya SiC wafer e shoa ka mekhahlelo ea matla ho fokotsa litlhoko tsa ho pholisa le mehato ea maoto, ho bonts'a bokhoni bo feletseng ba SiC wafer innovation. -

Lisebelisoa tsa High-Frequency RF & 5G ho SiC Wafer

Li-amplifiers tsa RF le li-switches tse entsoeng sethaleng sa SiC safer sa semi-insulating li bonts'a conductivity e phahameng ea mocheso le motlakase oa ho senyeha. SiC wafer substrate e fokotsa tahlehelo ea dielectric maqhubu a GHz, ha matla a SiC wafer a lumella ts'ebetso e tsitsitseng tlas'a maemo a matla a phahameng, a mocheso o phahameng-ho etsa hore SiC wafer e be karolo ea khetho bakeng sa liteishene tse latelang tsa gen 5G le lisebelisoa tsa radar. -

Lisebelisoa tsa Optoelectronic & LED tse tsoang ho SiC Wafer

Li-LED tse putsoa le tsa UV tse holisitsoeng ho li-wafer substrates tsa SiC li rua molemo ka ho tsamaisana hantle le li-lattice le ho qhala mocheso. Ho sebelisa sephaphatha sa SiC se bentšitsoeng sa C-face se netefatsa likarolo tse tšoanang tsa epitaxial, athe boima ba tlhaho ba SiC wafer bo nolofalletsa sephaphatha se setle se tšesaane le ho paka lisebelisoa tse tšepahalang. Sena se etsa hore SiC wafer e be sethala sa lisebelisoa tsa matla a phahameng, tsa nako e telele tsa bophelo ba LED.

Lipotso le likarabo tsa SiC wafer

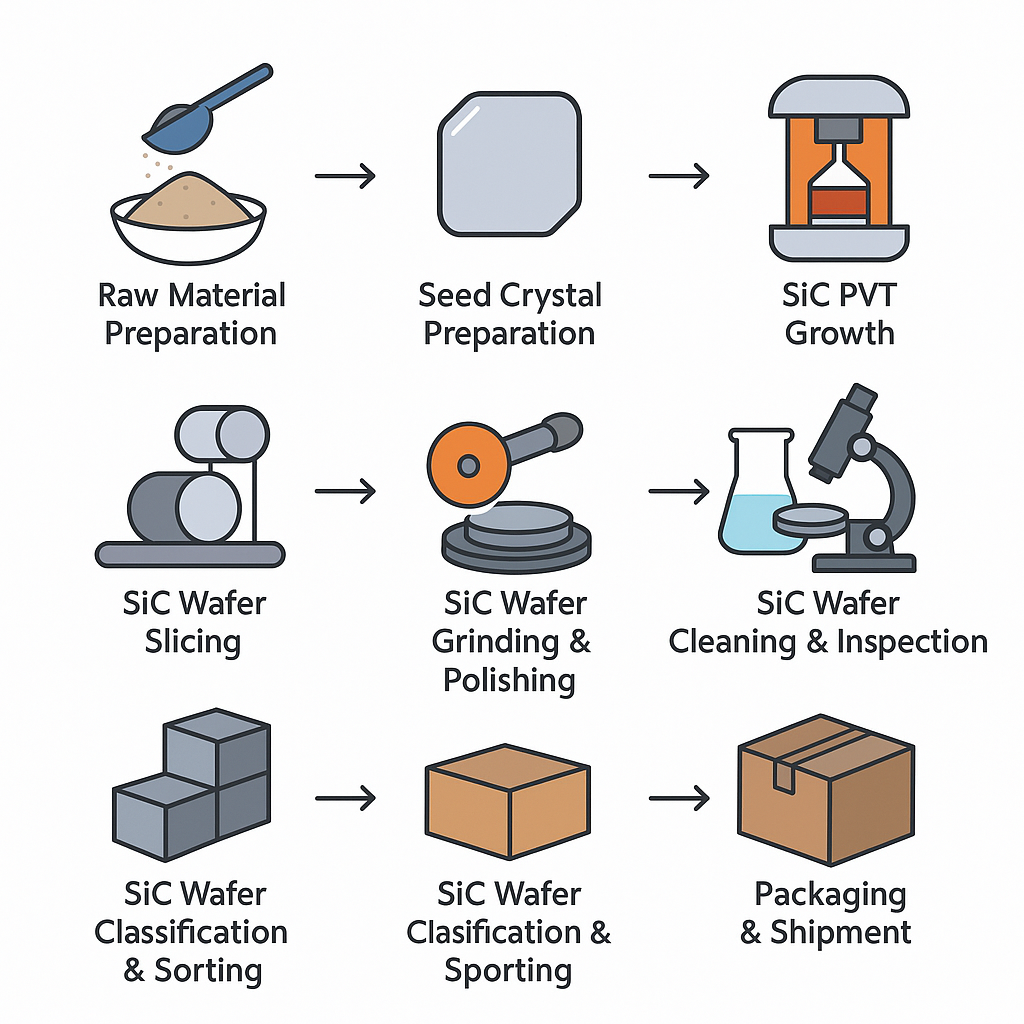

1. P: Li-wafers tsa SiC li etsoa joang?

A:

Li-wafers tsa SiC li entsoeMehato e qaqileng

-

Li-wafers tsa SiCTokisetso ea Lintho tse tala

- Sebelisa ≥5N-grade SiC phofo (litšila ≤1 ppm).

- Sefa le ho baka esale pele ho tlosa mesaletsa ea khabone kapa metsoako ea naetrojene.

-

SiCTokisetso ea Crystal ea Peo

-

Nka sengoathoana sa kristale e le 'ngoe ea 4H-SiC, sela haufi le 〈0001〉 ho ea ho ~ 10 × 10 mm².

-

Poleshe e nepahetseng ho ea ho Ra ≤0.1 nm 'me u tšoaee mokhoa oa kristale.

-

-

SiCKhōlo ea PVT (Sepalangoang sa Mouoane oa 'Meleng)

-

Laela graphite crucible: tlase ka phofo ea SiC, holimo ka kristale ea peo.

-

Tloha ho 10⁻³–10⁻⁵ Torr kapa tlatsa ka morao ka helium e hloekileng ka 1 atm.

-

Sebaka sa mohloli oa mocheso ho isa ho 2100-2300 ℃, boloka sebaka sa peo se pholile ho 100–150 ℃.

-

Laola sekhahla sa kholo ho 1–5 mm/h ho leka-lekanya boleng le tšebetso.

-

-

SiCIngot Annealing

-

Anneal SiC ingot e ntseng e holile ho 1600-1800 ℃ bakeng sa lihora tse 4-8.

-

Morero: imolla khatello ea maikutlo ea mocheso le ho fokotsa letsoalo la dislocation.

-

-

SiCWafer Slicing

-

Sebelisa sakha ea terata ea daemane ho arola engot hore e be liphaephe tse botenya ba 0.5-1 mm.

-

Fokotsa ho thothomela le matla a ka morao ho qoba mapetsong a manyane.

-

-

SiCSephaphathaHo sila & Ho pola

-

Ho sila ka mahoasheho tlosa tšenyo ea ho sakha (bokhopo ~ 10–30 µm).

-

Ho sila hantleho fihlela flatness ≤5 µm.

-

Ho hloekisoa ha lik'hemik'hale (CMP)ho fihlela qetellong ea seipone-joaloka (Ra ≤0.2 nm).

-

-

SiCSephaphathaHo Hloekisa le ho Hlahloba

-

Ho hloekisa ka mokhoa oa Ultrasonicka tharollo ea Piranha (H₂SO₄:H₂O₂), metsi a DI, ebe IPA.

-

XRD/Raman spectroscopyho netefatsa polytype (4H, 6H, 3C).

-

Interferometryho metha ho batalla (<5 µm) le ho phethoha (<20 µm).

-

Tlhahlobo ea lintlha tse 'neho leka ho hanyetsa (mohlala HPSI ≥10⁹ Ω·cm).

-

Tlhahlobo ea liphosotlas'a polarized light microscope le scratch tester.

-

-

SiCSephaphathaTlhophiso le Tlhophiso

-

Hlophisa li-wafers ka polytype le mofuta oa motlakase:

-

4H-SiC N-mofuta (4H-N): carrier concentration 10¹⁶–10¹⁸ cm⁻³

-

4H-SiC High Purity Semi-Insulating (4H-HPSI): resistivity ≥10⁹ Ω·cm

-

6H-SiC N-mofuta (6H-N)

-

Tse ling: 3C-SiC, P-mofuta, joalo-joalo.

-

-

-

SiCSephaphathaHo paka le ho Romela

2. P: Melemo ea bohlokoa ea li-wafers tsa SiC holim'a liphaphatha tsa silicon ke life?

A: Ha li bapisoa le li-wafers tsa silicon, li-wafers tsa SiC li thusa:

-

Ts'ebetso e phahameng ea motlakase(> 1,200 V) e nang le khanyetso e tlase.

-

Botsitso bo phahameng ba mocheso(> 300 °C) le taolo e ntlafalitsoeng ea mocheso.

-

Lebelo la ho chencha kapeleka tahlehelo e tlase ea ho switjha, ho fokotsa pholiso ea boemo ba sistimi le boholo ba li-converter tsa matla.

4. P: Ke liphoso life tse tloaelehileng tse amang tlhahiso le ts'ebetso ea SiC wafer?

A: Litšitiso tse ka sehloohong ho li-wafers tsa SiC li kenyelletsa li-micropipes, li-basal plane dislocations (BPDs), le li-scratches. Li-micropipe li ka baka ho hloleha ha sesebelisoa ho kotsi; BPD e eketsa ho hanyetsa ha nako; 'me mekhoro e ka holimo e lebisa ho robeheng ha liphaphatha kapa kholo e mpe ea epitaxial. Ka hona, tlhahlobo e matla le phokotso ea bofokoli li bohlokoa ho eketsa chai ea SiC.

Nako ea poso: Jun-30-2025