Li-wafers tsa SOI (Silicon-On-Insulator).emela thepa e khethehileng ea semiconductor e nang le lera la silicon le tšesaane haholo le entsoeng ka holim'a lera la insulating oxide. Sebopeho sena se ikhethileng sa sandwich se fana ka lintlafatso tse kholo tsa ts'ebetso bakeng sa lisebelisoa tsa semiconductor.

Sebopeho sa Sebopeho:

Lera la Sesebelisoa (Silicon e ka Holimo):

Botenya ho tloha ho li-nanometers tse 'maloa ho isa ho li-micrometer, tse sebetsang e le lera le sebetsang la ho etsa transistor.

Lera le Epetsoeng la Oxide (BOX):

Lera le sireletsang silicon dioxide (botenya ba 0.05-15μm) le arolang lera la sesebelisoa ho tloha substrate ka motlakase.

Motheo oa Substrate:

Silicone e ngata (100-500μm thick) e fana ka tšehetso ea mochine.

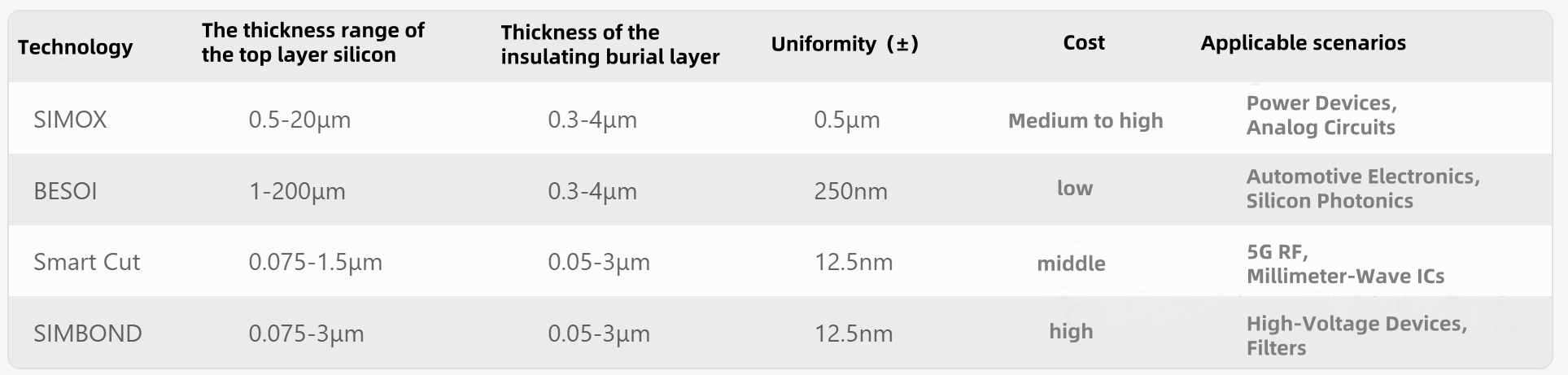

Ho ea ka thekenoloji ea mokhoa oa ho lokisa, litsela tse tloaelehileng tsa li-wafers tsa silicon tsa SOI li ka khetholloa e le: SIMOX (theknoloji ea ho itšehla ka oksijene ea ho itšehla thajana), BESOI (theknoloji ea ho fokotsa bonding), le Smart Cut (theknoloji e bohlale ea ho hlobolisa).

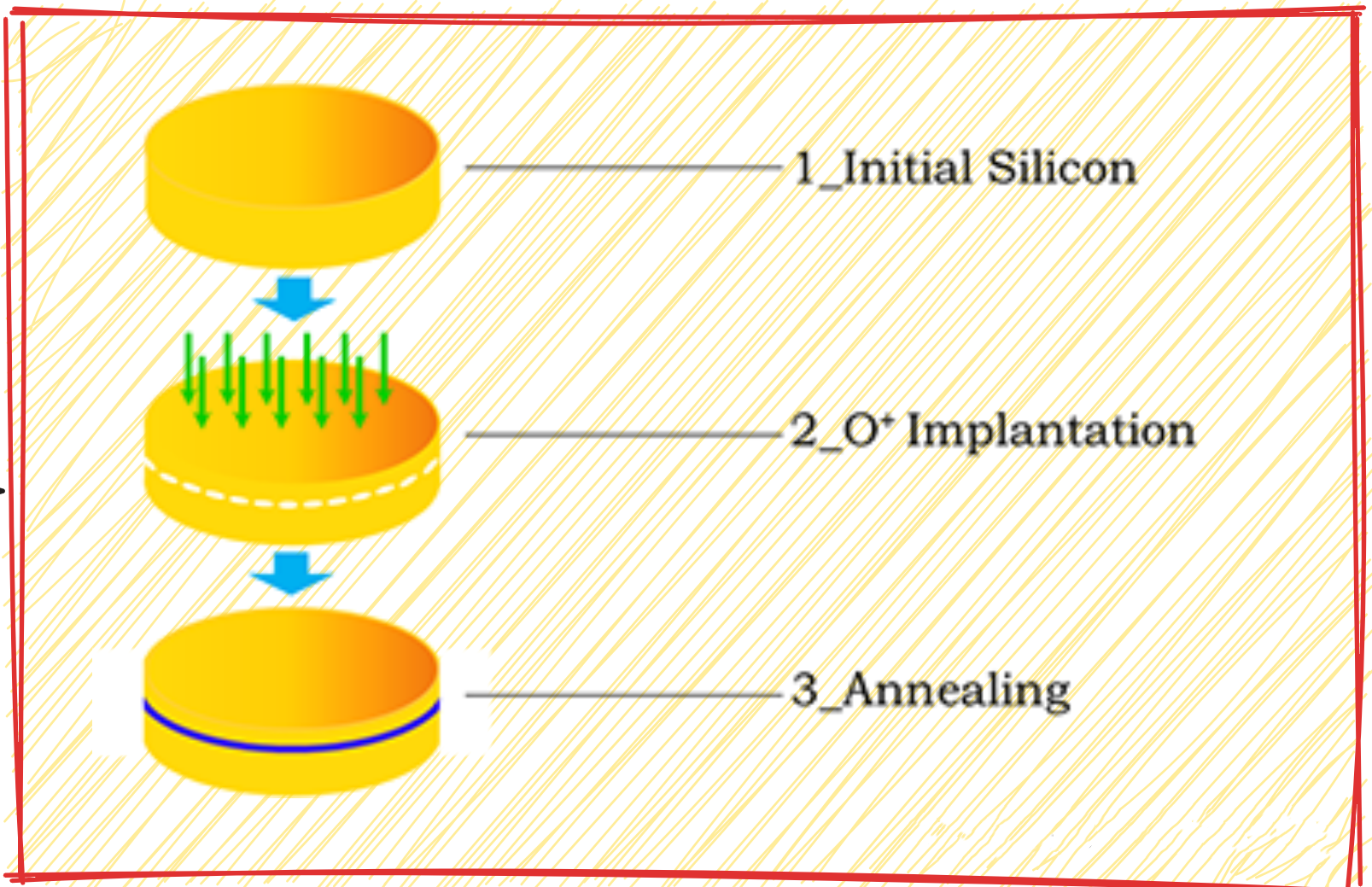

SIMOX (theknoloji ea ho itšehla thajana ea oksijene) ke mokhoa o kenyelletsang ho kenya li-ion tsa oksijene tse nang le matla a phahameng ka har'a li-wafers tsa silicon ho etsa lesela le kentsoeng la silicon dioxide, ebe le kenngoa ka har'a mocheso o phahameng oa mocheso ho lokisa liphoso tsa lattice. Moko-taba ke ente ea oksijene ea ion e tobileng ho theha oksijene e patiloeng.

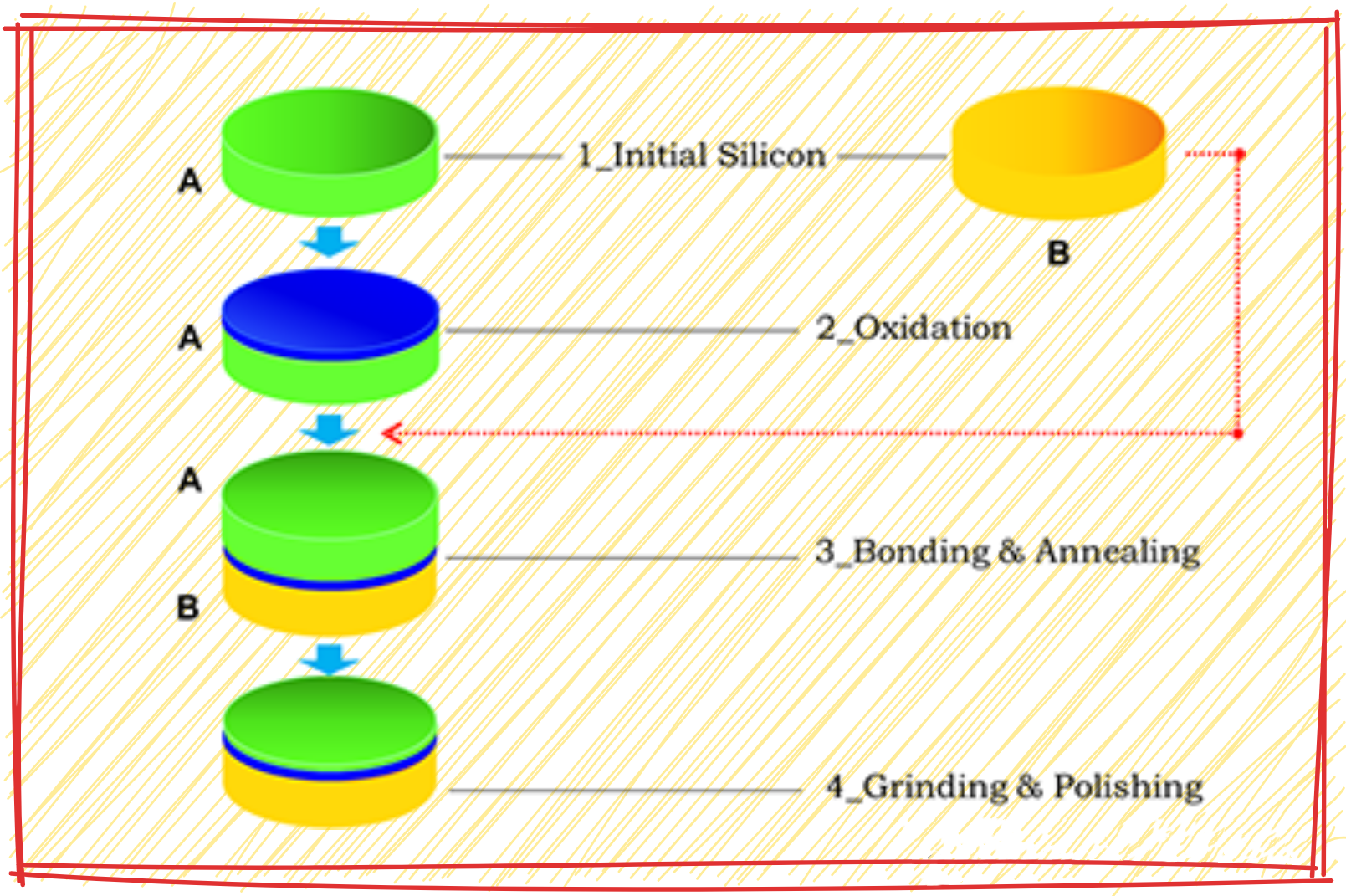

BESOI (Theknoloji ea Bonding Thinning) e kenyelletsa ho tlama li-wafer tse peli tsa silicon ebe o tšesa e 'ngoe ea tsona ka ho sila ka mochini le ho kenya lik'hemik'hale ho theha sebopeho sa SOI. Taba ea mantlha ke ho kopanya le ho ota.

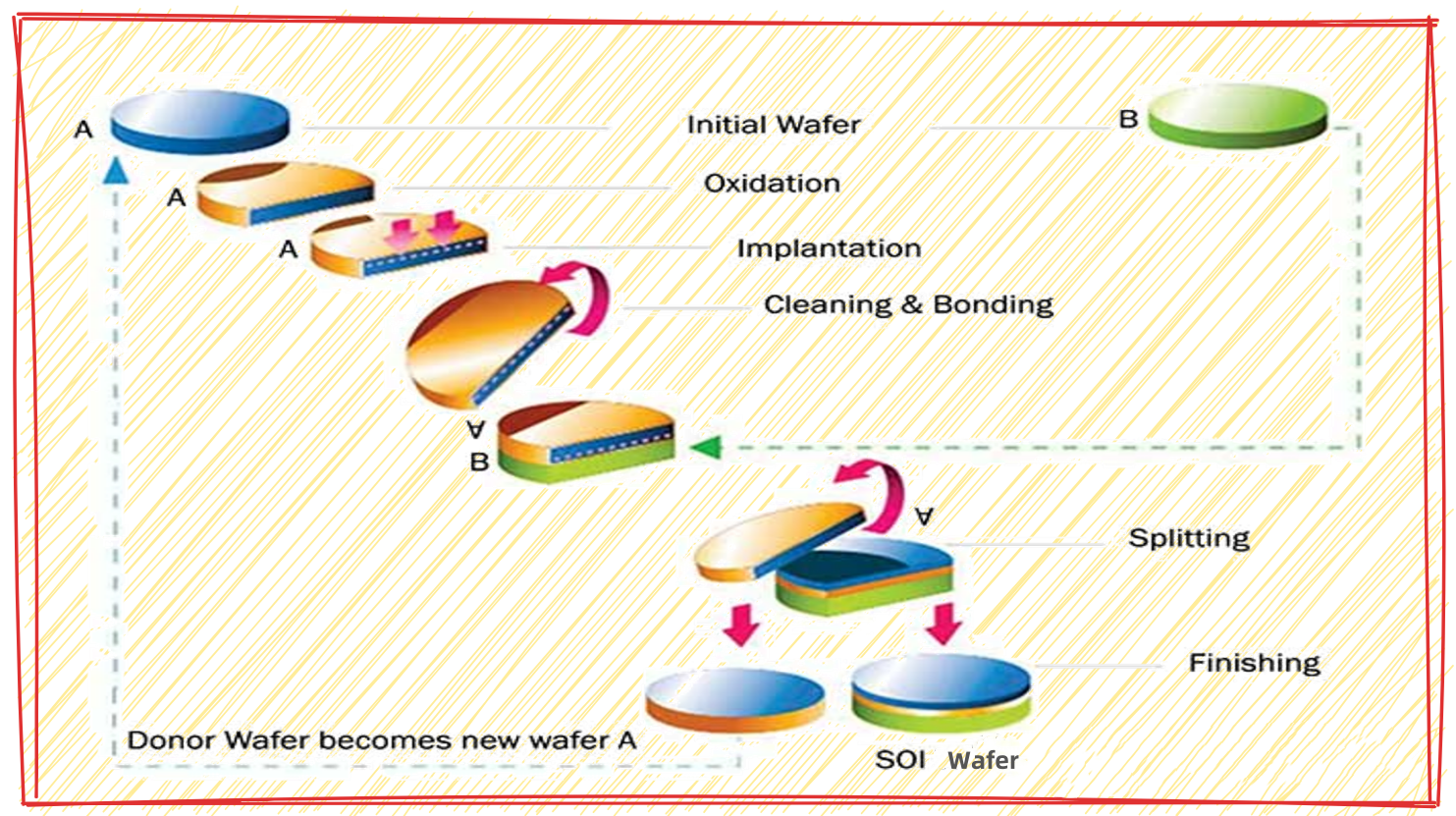

Smart Cut (Theknoloji ea Intelligent Exfoliation) e etsa lesela la exfoliation ka ente ea ion ea hydrogen. Ka mor'a ho tlamahanngoa, phekolo ea mocheso e etsoa ho exfoliate sephaphatha sa silicon haufi le lera la hydrogen ion, ho etsa lera le lesesaane la silicon. Ntho ea mantlha ke ho hlobola ente ea haedrojene.

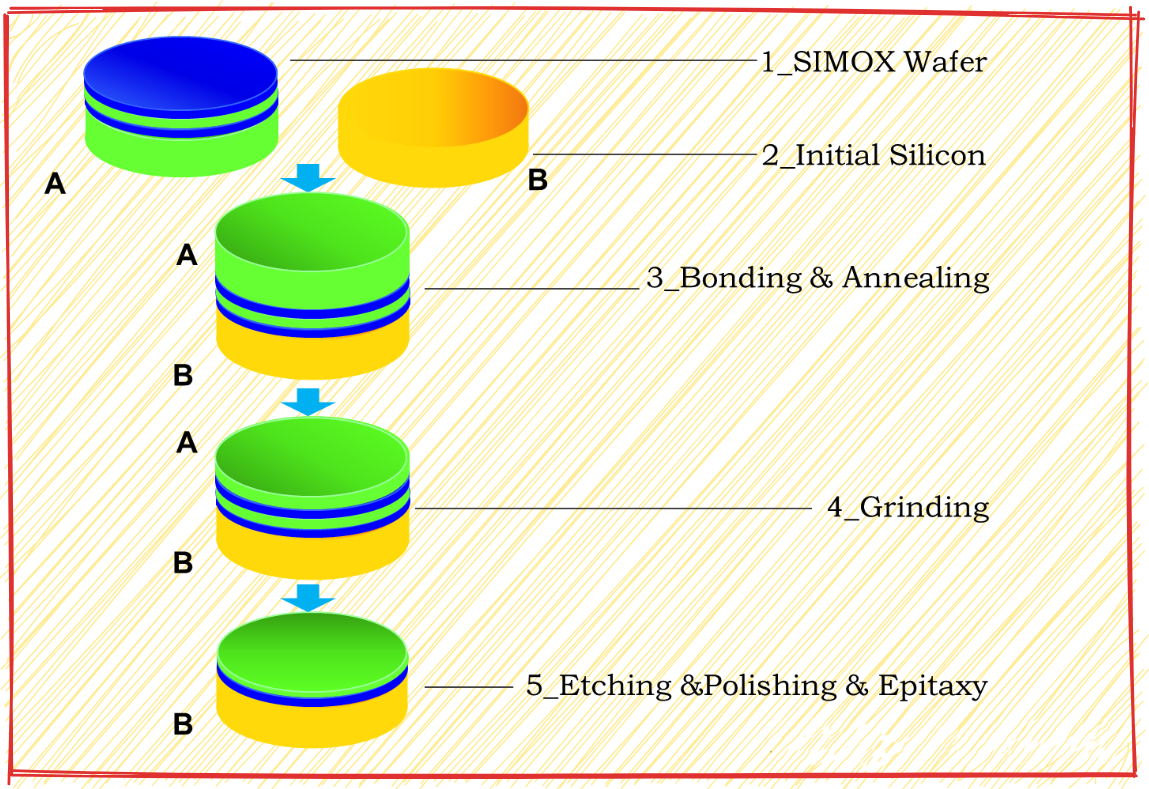

Hajoale, ho na le thekenoloji e 'ngoe e tsejoang e le SIMBOND (theknoloji ea ente ea oksijene), e hlahisitsoeng ke Xinao. Ha e le hantle, ke tsela e kopanyang mekhoa ea ho itšehla thajana ea oksijene le theknoloji ea ho kopanya. Tseleng ena ea tekheniki, oksijene e kentsoeng e sebelisoa e le lera le tšesaane la thibelo, 'me karolo ea 'nete e patiloeng ea oksijene ke lera la oxidation ea mocheso. Ka hona, ka nako e le 'ngoe e ntlafatsa litekanyetso tse kang ho tšoana ha silicon e ka holimo le boleng ba lera la oksijene le patiloeng.

Li-wafer tsa silicon tsa SOI tse entsoeng ka litsela tse fapaneng tsa tekheniki li na le mekhahlelo e fapaneng ea ts'ebetso 'me li loketse maemo a fapaneng a ts'ebeliso.

E latelang ke tafole ea kakaretso ea melemo ea mantlha ea ts'ebetso ea li-wafers tsa silicon tsa SOI, tse kopantsoeng le likarolo tsa bona tsa tekheniki le maemo a nnete a ts'ebeliso. Ha ho bapisoa le silicon e ngata ea setso, SOI e na le melemo e mengata ho leka-lekanya lebelo le tšebeliso ea matla. (PS: Ts'ebetso ea 22nm FD-SOI e haufi le ea FinFET, 'me litšenyehelo li fokotsehile ka 30%.)

| Molemo oa ts'ebetso | Theknoloji Molao-motheo | Ponahatso e Itseng | Maemo a Tloaelehileng a Kopo |

| Matla a tlase a Parasitic | Insulating layer (BOX) e thibela khokahanyo ea litefiso lipakeng tsa sesebelisoa le substrate | Lebelo la ho fetola le eketsehile ka 15% -30%, tšebeliso ea matla e fokotsehile ka 20% -50% | 5G RF, li-chips tsa puisano tse phahameng-frequency |

| Fokotse Leakage Current | Insulating layer e hatella litsela tsa hona joale tse lutlang | Nako ea ho lutla e fokotsehile ka >90%, bophelo bo atolositsoeng ba betri | Lisebelisoa tsa IoT, lisebelisoa tsa elektroniki tse Wearable |

| Matla a Mahlaseli a Matlafalitsoeng | Insulating layer e thibela ho bokellana ha litefiso ho bakoang ke radiation | Mamello ea mahlaseli a ntlafetseng a 3-5x, a fokotsa ho ferekana ha ketsahalo e le 'ngoe | Sepakapaka, lisebelisoa tsa indasteri ea Nyutlelie |

| Taolo ea Phello ea Mokhoa o Mokhutšoane | Lera le lesesaane la silicon le fokotsa tšitiso ea tšimo ea motlakase lipakeng tsa drain le mohloli | Ho ntlafala ha threshold voltage stability, optimized subthreshold slope | Li-chips tse tsoetseng pele tsa node (<14nm) |

| Taolo e Ntlafetseng ea Thermal | Insulating layer e fokotsa mocheso oa conduction coupling | Ho bokella mocheso ka 30%, mocheso o tlase oa 15-25 ° C o tlase | 3D ICs, Elektronike ea likoloi |

| Ntlafatso ea Maqhubu a Phahameng | E fokotsehile matla a likokoana-hloko le motsamao o matlafalitsoeng oa mopalami | Ho lieha ho tlase ho 20%, ho tšehetsa> 30GHz ts'ebetso ea lets'oao | mmWave puisano, Satellite comm chips |

| E Eketsehile Moqapi oa Fetola | Ha ho na doping e hlokahalang, e tšehetsa leeme la morao | 13% -20% mehato e fokolang ea ts'ebetso, 40% e phahameng ea ho kopanya matla | Li-ICs tse tsoakiloeng, li-Sensors |

| Latch-up Immunity | Insulating layer e arola likaroloana tsa parasitic PN | Boemo ba hona joale ba latch-up bo nyolohetse ho> 100mA | Lisebelisoa tsa matla a phahameng a matla |

Ho akaretsa, melemo ea mantlha ea SOI ke: e sebetsa ka potlako ebile e sebetsa hantle haholo.

Ka lebaka la litšobotsi tsena tsa ts'ebetso ea SOI, e na le lits'ebetso tse pharalletseng masimong a hlokang ts'ebetso e ntle ea khafetsa le ts'ebetso ea ts'ebeliso ea matla.

Joalo ka ha ho bonts'itsoe ka tlase, ho ipapisitsoe le karolo ea masimo a kopo e tsamaellanang le SOI, ho ka bonoa hore RF le lisebelisoa tsa motlakase li ikarabella bakeng sa boholo ba mmaraka oa SOI.

| Sebaka sa Kopo | Karolo ea mmaraka |

| RF-SOI (Radio Frequency) | 45% |

| Matla SOI | 30% |

| FD-SOI (E Felletse ka ho Feletseng) | 15% |

| SOI ea mahlo | 8% |

| Mohloli oa SOI | 2% |

Ka kholo ea limmaraka tse kang puisano ea mehala le ho khanna ka mokhoa o ikemetseng, li-wafers tsa silicon tsa SOI le tsona li lebelletsoe ho boloka sekhahla se itseng sa kholo.

XKH, e le moqapi ea ka sehloohong oa theknoloji ea Silicon-On-Insulator (SOI), e fana ka litharollo tse felletseng tsa SOI ho tloha ho R&D ho isa tlhahiso ea bongata e sebelisang lits'ebetso tse etelletseng pele indastering. Potefolio ea rona e felletseng e kenyelletsa liphaephe tsa SOI tse 200mm/300mm tse tsamaisang mefuta e fapaneng ea RF-SOI, Power-SOI le FD-SOI, tse nang le taolo e thata ea boleng e netefatsang ts'ebetso e ikhethang (ho tšoana ha botenya ka har'a ± 1.5%). Re fana ka litharollo tse ikhethileng tse nang le botenya ba oxide e patiloeng (BOX) ho tloha ho 50nm ho isa ho 1.5μm le litlhaloso tse fapaneng tsa resistivity ho fihlela litlhoko tse ikhethileng. Ka lilemo tse 15 tsa boiphihlelo ba tekheniki le phepelo e matla ea lefats'e, re fana ka lisebelisoa tsa boleng bo holimo tsa SOI ho baetsi ba semiconductor ba maemo a holimo lefats'eng ka bophara, e leng se nolofalletsang mahlale a morao-rao a likhokahano tsa 5G, lisebelisoa tsa elektroniki tsa likoloi le lits'ebetso tsa mahlale a maiketsetso.

Nako ea poso: Apr-24-2025