Ts'ebetsong ea nts'etsopele ea indasteri ea semiconductor, kristale e le 'ngoe e bentšitsoengliphaphatha tsa siliconphetha karolo ea bohlokoa. Li sebetsa e le lisebelisoa tsa mantlha bakeng sa tlhahiso ea lisebelisoa tse fapaneng tsa microelectronic. Ho tloha lipotolohong tse rarahaneng le tse nepahetseng tse kopaneng ho isa ho li-microprocessors tse lebelo le holimo le li-sensor tse sebetsang ka bongata, kristale e le 'ngoe e bentšitsoeng.liphaphatha tsa siliconli bohlokoa. Phapang ea ts'ebetso ea bona le litlhaloso ka kotloloho li ama boleng le ts'ebetso ea lihlahisoa tsa ho qetela. Ka tlase ke litlhaloso tse tloaelehileng le litekanyetso tsa liphaephe tsa silicon tse bentšitsoeng tse le 'ngoe:

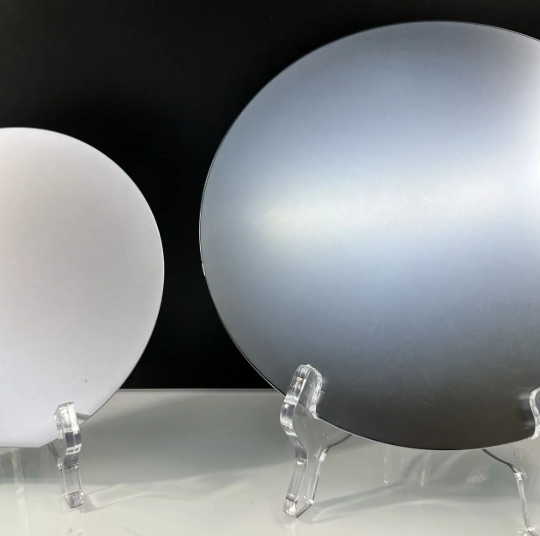

Diameter: Boholo ba semiconductor single crystal silicon wafers bo lekanngoa ka bophara ba bona, 'me ba tla ka mefuta e fapaneng ea litlhaloso. Li-diameter tse tloaelehileng li kenyelletsa 2 inches (50.8mm), 3 inches (76.2mm), 4 inches (100mm), 5 inches (125mm), 6 inches (150mm), 8 inches (200mm), 12 inches (300mm), le 18 inches (450mm). Li-diameter tse fapaneng li loketse litlhoko tse fapaneng tsa tlhahiso le litlhoko tsa ts'ebetso. Ka mohlala, li-wafers tse nyenyane tse bophara ba li-wafers li atisa ho sebelisoa bakeng sa lisebelisoa tse khethehileng tsa microelectronic tse nyenyane, ha li-wafers tse kholoanyane li bonts'a katleho e phahameng ea tlhahiso le melemo ea litšenyehelo tlhahisong e kholo ea potoloho e kopanetsoeng. Litlhoko tsa bokaholimo li arotsoe e le e bentšitsoeng ka lehlakore le le leng (SSP) le e bentšitsoeng ka mahlakoreng a mabeli (DSP). Li-wafers tse bentšitsoeng ka lehlakoreng le le leng li sebelisoa bakeng sa lisebelisoa tse hlokang ho bata haholo ka lehlakoreng le le leng, joalo ka li-sensor tse itseng. Li-wafer tse entsoeng ka mahlakoreng a mabeli li atisa ho sebelisoa bakeng sa lipotoloho tse kopantsoeng le lihlahisoa tse ling tse hlokang ho nepahala ho phahameng ka bobeli. Tlhokahalo ea Bokaholimo (Qetella): SSP e bentšitsoeng ka lehlakoreng le le leng / DSP e bentšitsoeng ka mahlakoreng a mabeli.

Type/Dopant: (1) Semiconductor ea mofuta oa N: Ha liathomo tse itseng tse sa hloekang li kenngoa ka har'a semiconductor ea kahare, li fetola conductivity ea eona. Ka mohlala, ha likaroloana tsa pentavalent tse kang naetrojene (N), phosphorus (P), arsenic (As), kapa antimone (Sb) li eketsoa, li-electrone tsa bona tsa valence li theha maqhama a covalent le lielektrone tsa valence tsa liathomo tsa silicon tse potolohileng, tse siea elektronike e eketsehileng e sa tlangoa ke tlamo e kopanetsoeng. Sena se fella ka khokahanyo ea elektronike e kholo ho feta mahloriso a lesoba, ho etsa semiconductor ea mofuta oa N, e tsejoang hape e le semiconductor ea mofuta oa electron. Li-semiconductors tsa mofuta oa N li bohlokoa ho hlahiseng lisebelisoa tse hlokang lielektrone e le tsona tse tsamaisang tjhaja, joalo ka lisebelisoa tse itseng tsa motlakase. (2) P-mofuta oa Semiconductor: Ha likarolo tse tharo tsa litšila tse kang boron (B), gallium (Ga), kapa indium (In) li kenngoa ka har'a semiconductor ea silicon, li-electrone tsa valence tsa liathomo tse sa hloekang li theha maqhama a covalent le liathomo tsa silicon tse potolohileng, empa ha li na bonyane elektronike e le 'ngoe ea valence' me ha li khone ho theha selekane se feletseng. Sena se lebisa tlhokomelong ea lesoba e kholo ho feta mahloriso a electron, ho etsa semiconductor ea mofuta oa P, e tsejoang hape e le semiconductor ea mofuta oa lesoba. Li-semiconductors tsa mofuta oa P li phetha karolo ea bohlokoa ho hlahiseng lisebelisoa moo likoti li sebetsang e le li-carriers tse ka sehloohong, tse kang diode le li-transistors tse itseng.

Resistivity: Resistivity ke palo ea mantlha ea 'mele e lekanyang ts'ebetso ea motlakase ea liphaephe tse betliloeng tsa kristale tsa silicon. Boleng ba eona bo bonahatsa ts'ebetso ea conductive ea thepa. Ha re ntse re e-na le resistivity e tlaase, ho molemo hore ho be le conductivity ea sephaphatha sa silicon; ka lehlakoreng le leng, e phahameng ea resistivity, ho futsaneha conductivity. Restivity ea li-wafers tsa silicon e khethoa ke thepa ea bona ea tlhaho, 'me mocheso le ona o na le tšusumetso e kholo. Ka kakaretso, ho hanyetsa ha li-wafers tsa silicon ho eketseha ka mocheso. Lits'ebetsong tse sebetsang, lisebelisoa tse fapaneng tsa microelectronic li na le litlhoko tse fapaneng tsa resistivity bakeng sa li-wafers tsa silicon. Mohlala, li-wafers tse sebelisoang tlhahisong e kopaneng ea potoloho li hloka taolo e nepahetseng ea resistivity ho netefatsa ts'ebetso e tsitsitseng le e tšepahalang ea sesebelisoa.

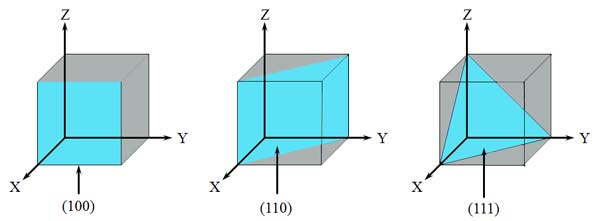

Mokhoa: Mokhoa oa kristale oa sephaphatha o emela tataiso ea crystallographic ea silicon lattice, eo ka tloaelo e hlalositsoeng ke li-indices tsa Miller tse kang (100), (110), (111), joalo-joalo. Mekhoa e fapaneng ea kristale e na le litšobotsi tse fapaneng tsa 'mele, tse kang boima ba mela, bo fapaneng ho latela mokhoa oa ho sheba. Phapang ena e ka ama ts'ebetso ea wafer mehatong e latelang ea ts'ebetso le ts'ebetso ea ho qetela ea lisebelisoa tsa microelectronic. Ts'ebetsong ea tlhahiso, ho khetha sephaphatha sa silicon se nang le sebopeho se nepahetseng bakeng sa litlhoko tse fapaneng tsa sesebelisoa ho ka ntlafatsa ts'ebetso ea sesebelisoa, ho ntlafatsa katleho ea tlhahiso, le ho ntlafatsa boleng ba sehlahisoa.

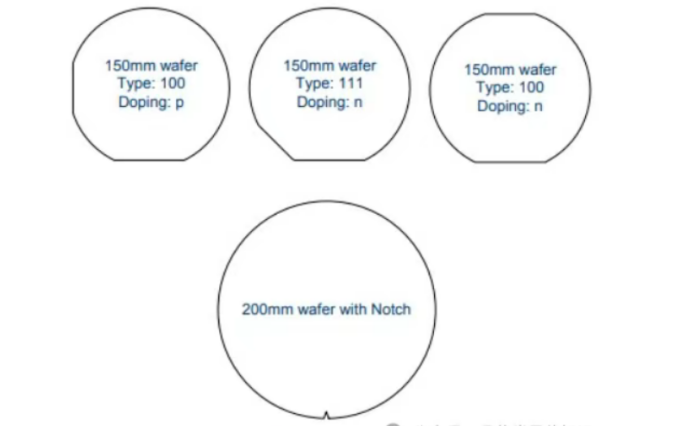

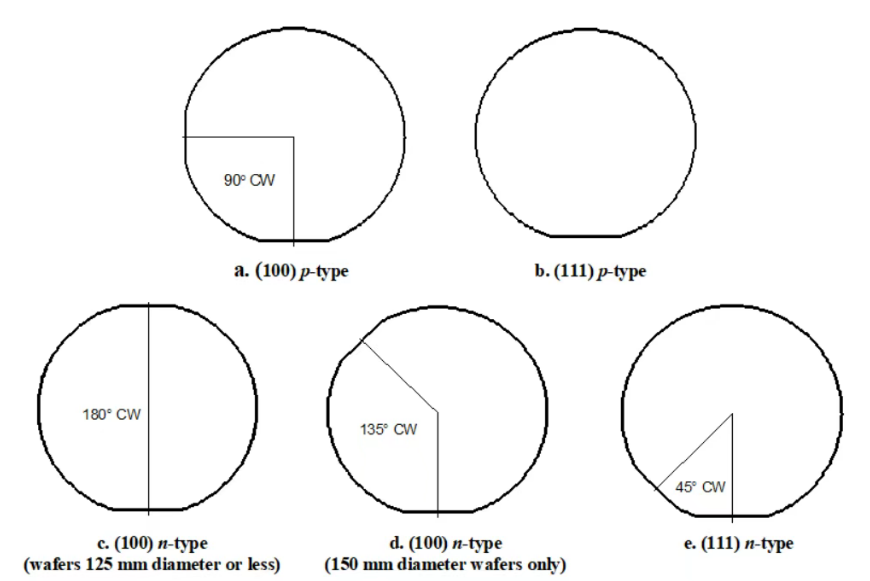

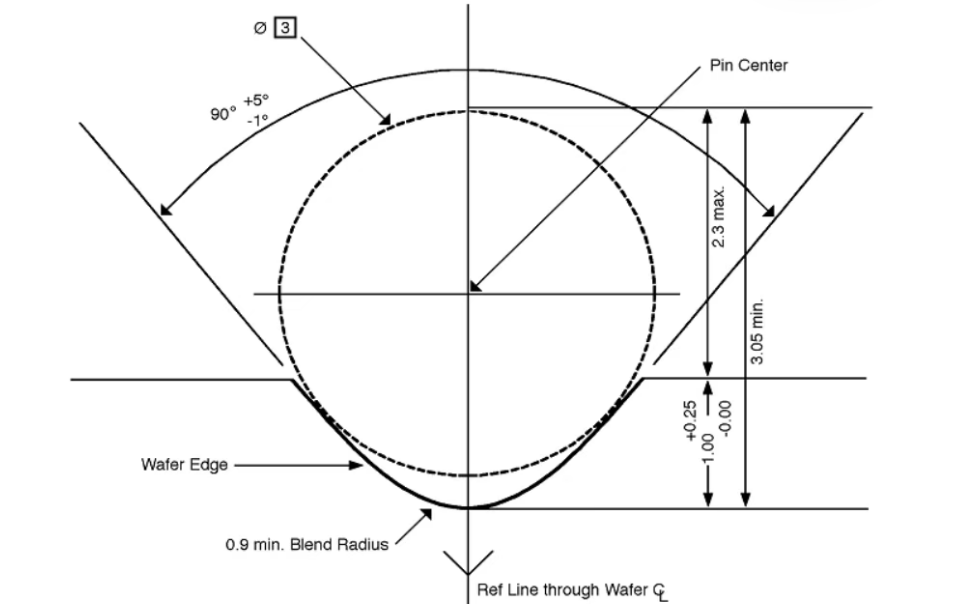

Flat/Notch: Moeli o bataletseng (Flat) kapa V-notch (Notch) selikalikoe sa sephaphatha sa silicon se bapala karolo ea bohlokoa ho tolamisong ea kristale 'me ke sesupo sa bohlokoa tlhahisong le ts'ebetsong ea sephaphatha. Li-wafers tsa li-diameter tse fapaneng li lumellana le litekanyetso tse fapaneng bakeng sa bolelele ba Flat kapa Notch. Likarolo tsa tlhophiso li arotsoe ka folete ea mantlha le ea bobeli. Folete ea mantlha e sebelisoa haholo ho tseba hore na kristale e mabapi le ts'ebeliso ea mantlha ea kristale le ts'ebeliso ea ts'ebetso ea sephaphatha, athe folete ea bobeli e thusa ho hokahanngoa le ho sebetsa hantle, ho netefatsa ts'ebetso e nepahetseng le ho ts'oana ha sephaphatha moleng oa tlhahiso.

Botenya: Botenya ba sephaphatha hangata bo hlalosoa ka li-micrometer (μm), ka bophara bo tloaelehileng pakeng tsa 100μm le 1000μm. Li-wafers tsa botenya bo fapaneng li loketse mefuta e fapaneng ea lisebelisoa tsa microelectronic. Li-wafers tse tšesaane (mohlala, 100μm - 300μm) li sebelisoa hangata bakeng sa tlhahiso ea li-chip tse hlokang taolo e tiileng ea botenya, ho fokotsa boholo le boima ba chip le ho eketsa boima ba ho kopanya. Li-wafers tse teteaneng (mohlala, 500μm - 1000μm) li sebelisoa haholo lisebelisoa tse hlokang matla a phahameng a mochine, joalo ka lisebelisoa tsa semiconductor tsa matla, ho netefatsa botsitso nakong ea ts'ebetso.

Bokhopo ba Bokaholimo: Bokhopo ba bokaholimo ke e 'ngoe ea lintlha tsa bohlokoa tsa ho lekola boleng ba liphaephe, kaha bo ama ka kotloloho ho khomarela pakeng tsa sephaphatha le thepa ea filimi e tšesaane e behiloeng kamora moo, hammoho le ts'ebetso ea motlakase ea sesebelisoa. Hangata e hlalosoa e le motso mean square (RMS) roughness (ka nm). Bokaholimo bo tlase bo bolela hore bokaholimo bo boreleli, bo thusang ho fokotsa liketsahalo tse kang ho hasanya ha elektronike le ho ntlafatsa ts'ebetso ea sesebelisoa le ho ts'epahala. Ts'ebetsong e tsoetseng pele ea tlhahiso ea li-semiconductor, litlhoko tsa ho ba boima ba holim'a metsi li ntse li eketseha, haholo-holo bakeng sa tlhahiso ea potoloho e kopantsoeng ea maemo a holimo, moo ho thatafala ha holim'a metsi ho tlamehang ho laoloa ho ea ho li-nanometer tse seng kae kapa ho feta.

Kakaretso ea Botenya (TTV): Phapang e felletseng ea botenya e bolela phapang lipakeng tsa botenya bo boholo le bo tlase bo lekantsoeng lintlheng tse ngata holim'a sephaphatha, seo hangata se hlahisoang ka μm. TTV e phahameng e ka lebisa ho kheloha lits'ebetsong tse kang photolithography le etching, tse amang ts'ebetso ea lisebelisoa le lihlahisoa. Ka hona, ho laola TTV nakong ea tlhahiso ea li-wafer ke mohato oa bohlokoa ho netefatsa boleng ba sehlahisoa. Bakeng sa tlhahiso ea lisebelisoa tsa microelectronic tse nepahetseng haholo, hangata TTV e hlokoa hore e be ka har'a li-micrometer tse seng kae.

Bow: Bow e bolela ho kheloha lipakeng tsa bokaholimo ba sephaphatha le sefofane se loketseng se bataletseng, seo hangata se lekantsoeng ka μm. Li-wafers tse inamang ho feta tekano li ka robeha kapa tsa ba le khatello ea maikutlo e sa lekanang nakong ea ts'ebetso e latelang, tse amang katleho ea tlhahiso le boleng ba sehlahisoa. Haholo-holo lits'ebetsong tse hlokang flatness e phahameng, tse kang photolithography, ho khumama ho tlameha ho laoloa ka har'a mefuta e itseng ho netefatsa ho nepahala le ho lumellana ha mokhoa oa photolithographic.

Warp: Warp e bonts'a ho kheloha lipakeng tsa bokaholimo ba sekhuts'oane le sebopeho se setle sa spherical, hape se lekantsoeng ka μm. Joalo ka seqha, warp ke sesupo sa bohlokoa sa ho bata ha sephaphatha. Warp e feteletseng ha e ame feela ho nepahala ha ho beoa ha sephaphatha lisebelisoa tsa ho sebetsa empa hape e ka baka mathata nakong ea ts'ebetso ea ho paka chip, joalo ka tlamahano e mpe lipakeng tsa chip le thepa ea ho paka, e leng eona e amang ho ts'epahala ha sesebelisoa. Tlhahisong ea boemo bo holimo ea semiconductor, litlhoko tsa warp li ntse li thatafala ho fihlela litlhoko tsa ts'ebetso e tsoetseng pele ea tlhahiso ea li-chip le ho paka.

Boemo ba Edge: Boemo bo ka holimo ba sephaphatha bo bohlokoa bakeng sa ts'ebetso ea eona e latelang le ho e sebetsana. Ka tloaelo e hlalosoa ke Edge Exclusion Zone (EEZ), e hlalosang sebaka sa ho tloha moeling oa wafer moo ho sa lumelloeng ho sebetsa. Profaele e hlophisitsoeng hantle le taolo e nepahetseng ea EEZ e thusa ho qoba bofokoli, khatello ea maikutlo le litaba tse ling nakong ea ts'ebetso, ho ntlafatsa boleng ba lihlahisoa le chai. Lits'ebetsong tse ling tse tsoetseng pele tsa tlhahiso, ho nepahala ha profil e hlokahalang ho ba maemong a sub-micron.

Palo ea Particle: Palo le boholo ba kabo ea likaroloana tse holim'a sekoti li ama haholo ts'ebetso ea lisebelisoa tsa microelectronic. Likarolo tse ngata haholo kapa tse kholo li ka lebisa ho hloleheng ha sesebelisoa, joalo ka li-circuits tse khutšoane kapa ho lutla, ho fokotsa chai ea sehlahisoa. Ka hona, palo ea likaroloana hangata e lekanyetsoa ka ho bala likaroloana sebakeng sa yuniti, joalo ka palo ea likaroloana tse kholo ho feta 0.3μm. Taolo e matla ea palo ea likaroloana nakong ea tlhahiso ea li-wafer ke mohato oa bohlokoa ho netefatsa boleng ba sehlahisoa. Litheknoloji tse tsoetseng pele tsa ho hloekisa le tikoloho e hloekileng ea tlhahiso li sebelisoa ho fokotsa tšilafalo ea likaroloana holim'a bokaholimo.

![]()

![]()

![]()

![]()

![]()

Tlhahiso e amanang

Mofuta o le Mong oa Crystal Silicon Wafer Si Substrate Type N/P Optional Silicon Carbide Wafer

FZ CZ Si sephaephe se setokong sa 12inch Silicon wafer Prime kapa Test

Nako ea poso: Apr-18-2025