Tafole ea likateng

1. Lipheo tsa mantlha le Bohlokoa ba ho Hloekisa Wafer

2. Tekolo ea Tšoaetso le Mekhoa e Tsoetseng Pele ea Tlhahlobo

3. Mekhoa e tsoetseng pele ea ho Hloekisa le Melao-motheo ea Tekheniki

4. Lintho tsa Bohlokoa tsa Ts'ebetsong ea Technical le Taolo ea Ts'ebetso

5. Mekhoa ea Kamoso le Litsela tse ncha

6.XKH Qetello-to-Qetellong Tharollo le Tikoloho ea Litšebeletso

Ho hloekisoa ha Wafer ke ts'ebetso ea bohlokoa tlhahisong ea semiconductor, kaha le litšila tse maemong a atomic li ka theola ts'ebetso ea sesebelisoa kapa chai. Ts'ebetso ea ho hloekisa hangata e kenyelletsa mehato e mengata ea ho tlosa litšila tse fapaneng, joalo ka masalla a organic, litšila tsa tšepe, likaroloana le li-oxide tsa tlhaho.

1. Sepheo sa ho Hloekisa Wafer

- Tlosa litšila tse phelang (mohlala, masala a photoresist, menoana).

- Felisa litšila tsa tšepe (mohlala, Fe, Cu, Ni).

- Felisa tšilafalo ea likaroloana (mohlala, lerōle, likotoana tsa silicon).

- Tlosa li-oxide tsa tlhaho (mohlala, likarolo tsa SiO₂ tse entsoeng nakong ea ho pepeseha moeeng).

2. Bohlokoa ba Tlhoekiso e Matla ea Wafer

- E netefatsa tlhahiso e phahameng ea ts'ebetso le ts'ebetso ea sesebelisoa.

- E fokotsa liphoso le litheko tsa li-wafer scrap.

- E ntlafatsa boleng ba sefahleho le botsitso.

Pele ho hloekisa ka matla, ho bohlokoa ho hlahloba tšilafalo e teng. Ho utloisisa mofuta, kabo ea boholo, le tlhophiso ea sebaka sa lintho tse silafatsang holim'a wafer ho ntlafatsa k'hemistri ea ho hloekisa le ho kenya matla a mochini.

3. Mekhoa e tsoetseng pele ea Analytical bakeng sa Tlhahlobo ea Tšoaetso

3.1 Tlhahlobo ea likarolo tsa bokaholimo

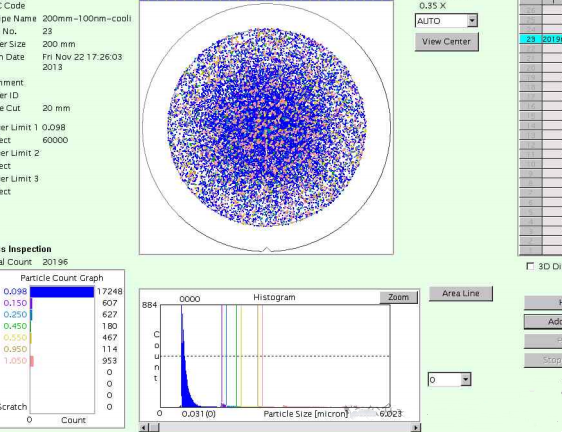

- Lisebelisoa tse ikhethileng tsa likaroloana li sebelisa ho hasanya ka laser kapa pono ea komporo ho bala, boholo le litšila tsa 'mapa.

- Matla a ho hasanya ha leseli a hokahana le boholo ba likaroloana tse nyane joalo ka mashome a li-nanometers le density e tlase joalo ka likaroloana tse 0.1/cm².

- Calibration ka litekanyetso e netefatsa ho tšepahala ha hardware. Lits'oants'o tsa pele le ka mor'a ho hloekisa li tiisa katleho ea ho tlosa, ho ntlafatsa ts'ebetso ea ho khanna.

3.2 Tlhahlobo ea Sebopeho sa Elemental

- Litheknoloji tse sebetsanang le maemo li khetholla sebopeho sa mantlha.

- X-ray Photoelectron Spectroscopy (XPS/ESCA): E sekaseka maemo a lik'hemik'hale a holim'a metsi ka ho khantša sephaphatha ka mahlaseli a X le ho metha lielektrone tse ntšoang.

- Glow Discharge Optical Emission Spectroscopy (GD-OES): Melara ya bokahodimo e tshesane haholo ka tatellano ha e ntse e hlahloba ponahalo e ntshitsweng ho fumana sebopeho sa motheo se itshetlehileng ka botebo.

- Meeli ea ho sibolla e fihla likarolong tse milione (ppm), e tataisang khetho e nepahetseng ea ho hloekisa k'hemistri.

3.3 Tlhahlobo ea Tšilafalo ea Morphological

- Scanning Electron Microscopy (SEM)homo ho senola libopeho tse silafetseng le likarolo tse lekanang, ho bontša mekhoa ea ho khomarela (lik’hemik’hale vs. mechanical).

- Atomic Force Microscopy (AFM): Maps nanoscale topography ho lekanya bolelele ba likaroloana le thepa ea mochini.

- Focused Ion Beam (FIB) Milling + Transmission Electron Microscopy (TEM): E fana ka maikutlo a ka hare a litšila tse patiloeng.

4. Mekhoa e tsoetseng pele ea ho hloekisa

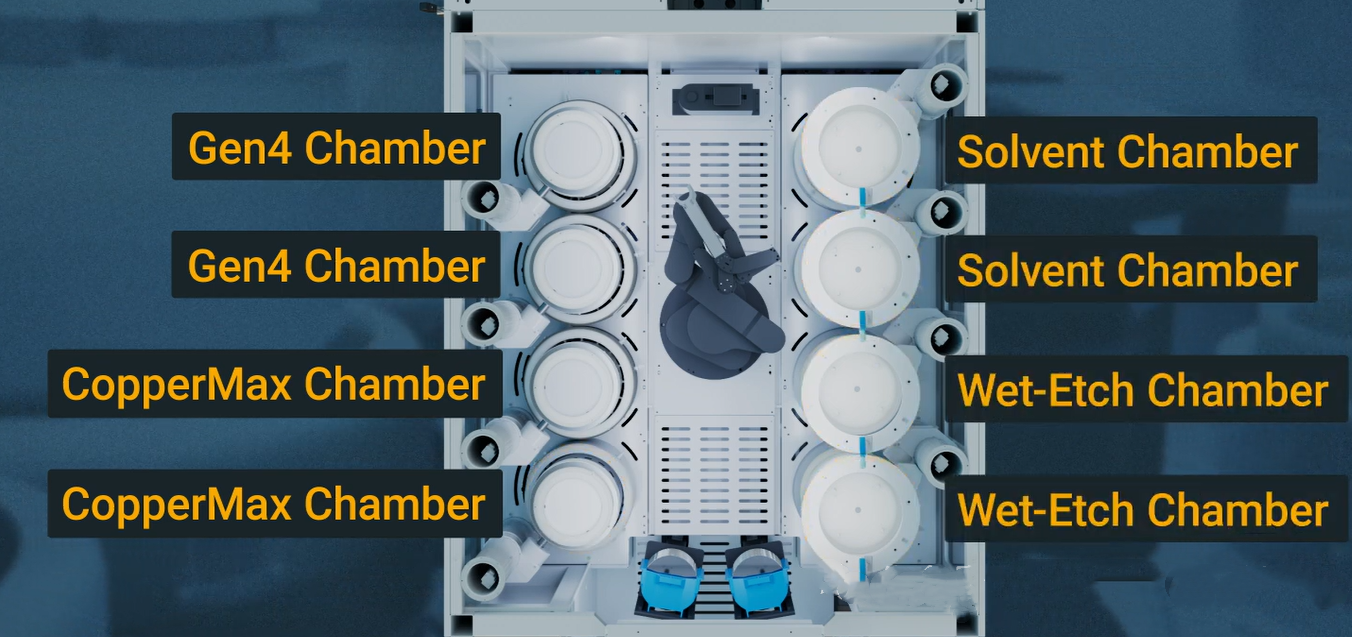

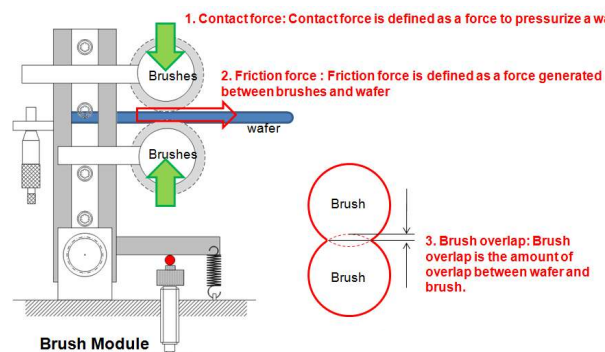

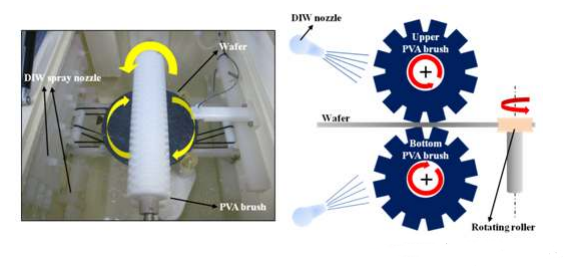

Le ha ho hloekisoa ha solvent ka katleho ho tlosa litšila tsa manyolo, mekhoa e meng e tsoetseng pele ea hlokahala bakeng sa likaroloana tsa inorganic, masala a tšepe le litšila tsa ionic:

.

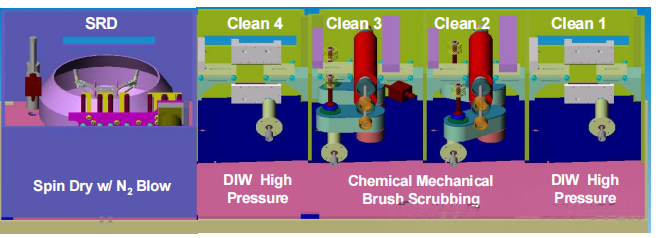

4.1 Ho hloekisa RCA

- E thehiloe ke RCA Laboratories, mokhoa ona o sebelisa mokhoa oa ho hlapa habeli ho tlosa litšila tsa polar.

- SC-1 (Standard Clean-1): E tlosa ditshila le dikarolwana tse sebedisang motswako wa NH₄OH, H₂O₂, le H₂O(mohlala, 1:1:5 karolelano ho ~20°C). E etsa lera le lesesaane la silicon dioxide.

- SC-2 (Standard Clean-2): E tlosa ditshila tsa metallic ka ho sebedisa HCl, H₂O₂, le H₂O (mohlala, 1:1:6 karolelano ho ~80°C). E siea sebaka se se nang letho.

- E leka-lekanya bohloeki le tšireletso ea bokaholimo.

.

4.2 Ho hloekisa Ozone

- E qoelisa liphaphatha ka metsing a nang le ozone-saturated deionized (O₃/H₂O) .

- E sebetsa hantle ka oxidizes le ho tlosa lintho tse phelang ntle le ho senya sephaphatha, e siea sebaka se nang le lik'hemik'hale.

.

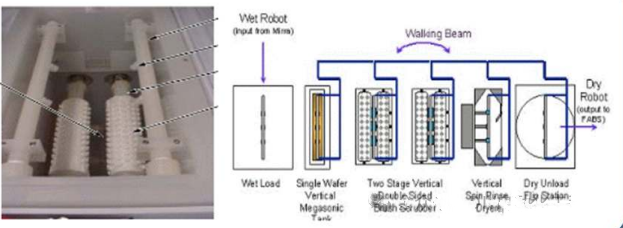

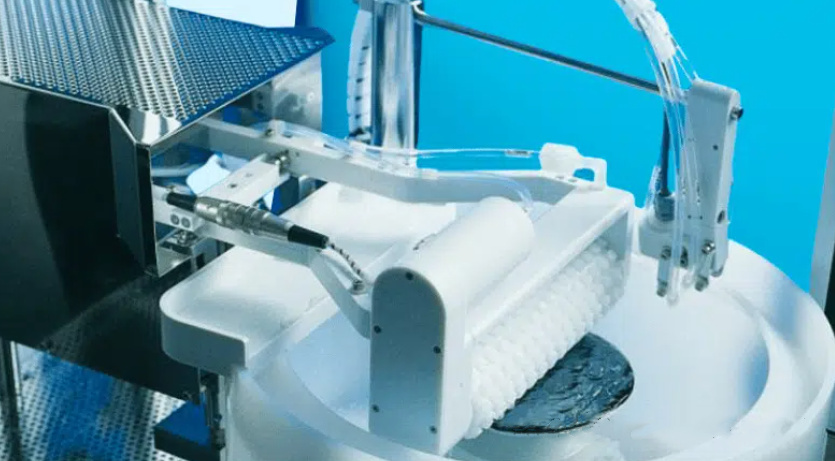

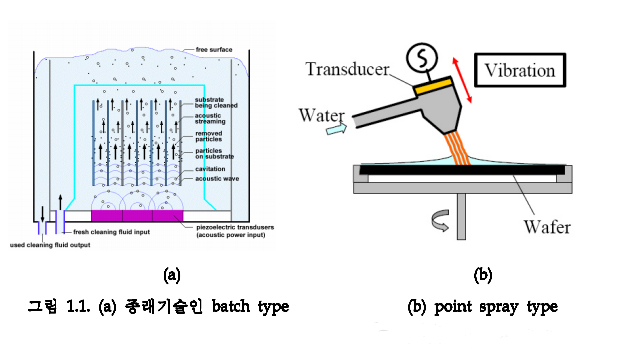

4.3 Ho Hloekisa Megasonic.

- E sebelisa matla a phahameng a maqhubu a ultrasonic (hangata 750–900 kHz) hammoho le litharollo tsa ho hloekisa.

- E hlahisa li-bubble tsa cavitation tse lahlang litšila. E kenella ka har'a li-geometri tse rarahaneng ha e ntse e fokotsa tšenyo ea meaho e boreleli.

4.4 Ho hloekisa Cryogenic

- Ka potlako e pholisa li-wafers ho mocheso oa cryogenic, litšila tse senyang.

- Ho hlatsoa ka mor'a moo kapa ho hlatsoa ha bonolo ho tlosa likaroloana tse lokolohileng. E thibela tšilafalo le ho hasana holimo.

- Mokhoa o potlakileng, o omileng o nang le tšebeliso e fokolang ea lik'hemik'hale.

Qetello:

Joaloka mofani ea ka sehloohong oa litharollo tsa semiconductor tse felletseng, XKH e khannoa ke boqapi ba mahlale 'me bareki ba hloka ho fana ka lits'ebeletso tsa ho qetela ho isa qetellong, tse kenyelletsang phepelo ea lisebelisoa tsa boleng bo holimo, masela a liphaephe, le ho hloekisa ka nepo. Ha re fane feela ka lisebelisoa tse tsebahalang lefatšeng ka bophara tsa semiconductor (mohlala, mechini ea lithography, etching system) tse nang le litharollo tse lokiselitsoeng empa hape le theknoloji ea pele-ho kenyelletsa ho hloekisa RCA, tlhoekiso ea ozone le tlhoekiso e matla - ho netefatsa bohloeki ba boemo ba athomo bakeng sa tlhahiso ea liphaphatha, ho ntlafatsa haholo tlhahiso ea bareki. Ho sebelisa lihlopha tse arabelang ka potlako le marang-rang a lits'ebeletso tse bohlale, re fana ka ts'ehetso e felletseng ho tloha ho ho kenya lisebelisoa le ts'ebetso ea ts'ebetso ho isa tlhokomelong e boletsoeng esale pele, ho matlafatsa bareki ho hlola liphephetso tsa tekheniki le ho hatela pele ka nepo le nts'etsopele e tsitsitseng ea semiconductor. Re khethe bakeng sa synergy ea katleho e habeli ea boiphihlelo ba tekheniki le boleng ba khoebo.

Nako ea poso: Sep-02-2025