Li-wafers tsa SiC ke li-semiconductors tse entsoeng ka silicon carbide. Boitsebiso bona bo entsoe ka 1893 'me bo loketse mefuta e fapaneng ea lisebelisoa. Haholo-holo e loketse li-diode tsa Schottky, li-junction barrier Schottky diode, li-switches le tšepe-oxide-semiconductor field-effect transistors. Ka lebaka la boima ba eona bo phahameng, ke khetho e babatsehang bakeng sa likarolo tsa motlakase tsa motlakase.

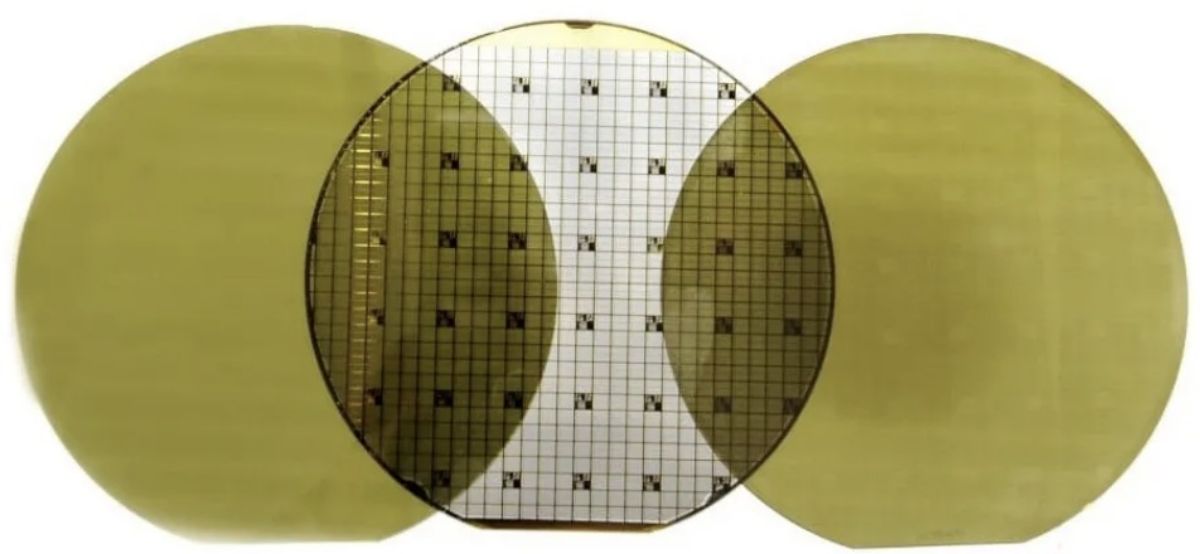

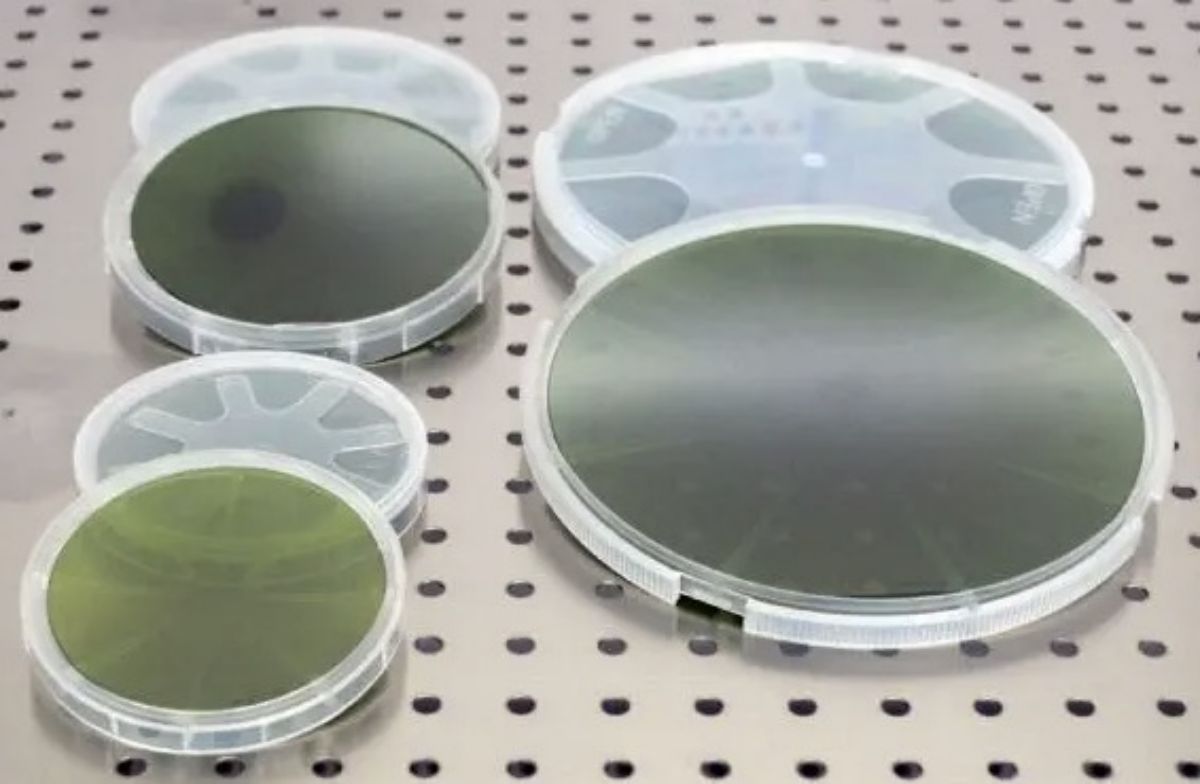

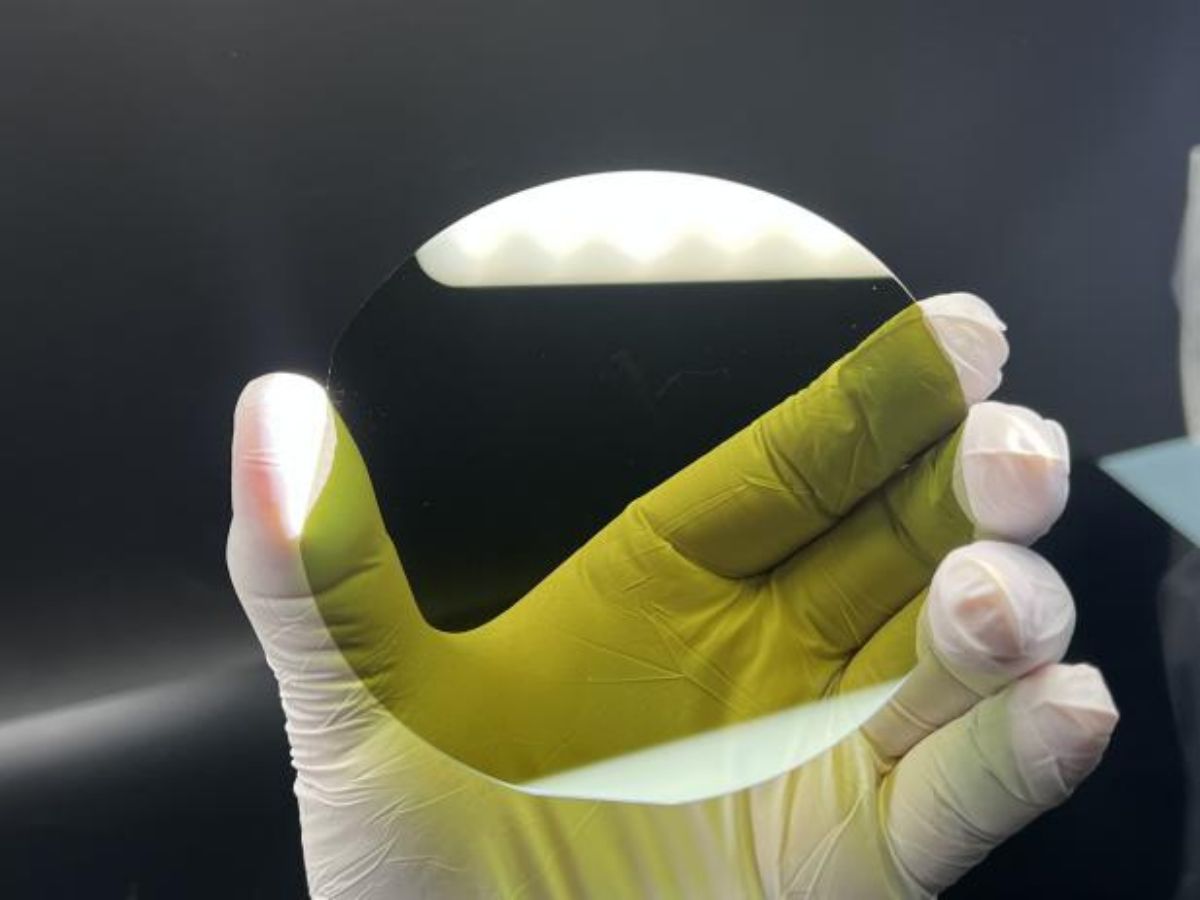

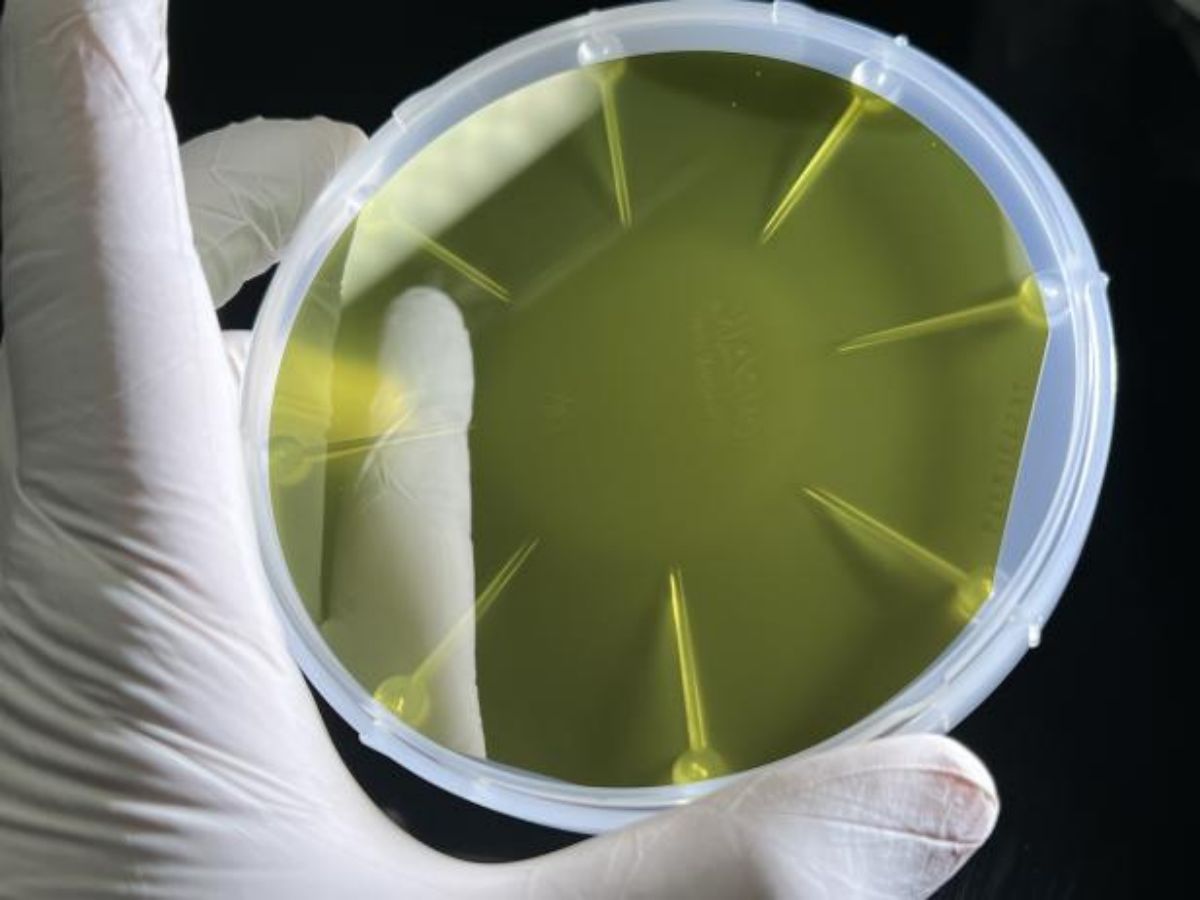

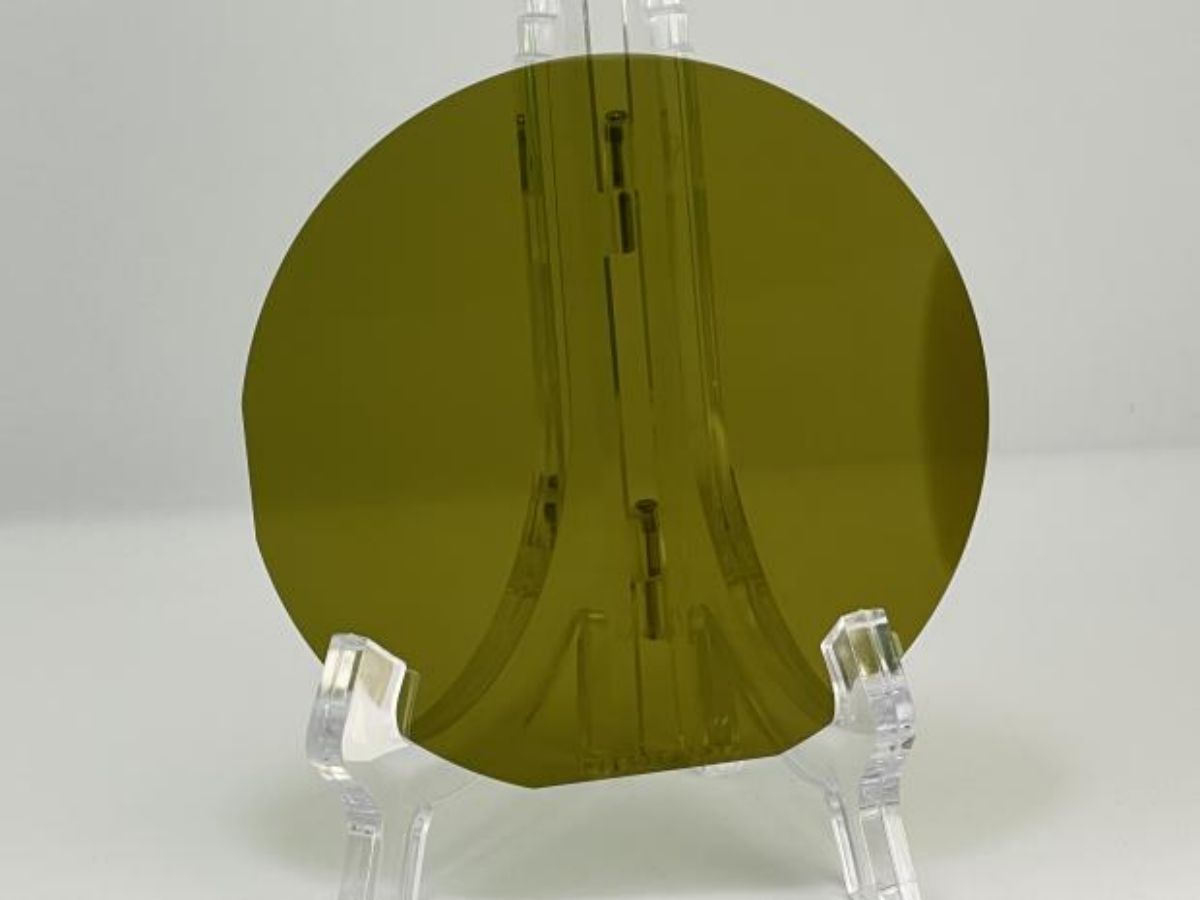

Hajoale, ho na le mefuta e 'meli ea mantlha ea li-wafers tsa SiC. Ea pele ke sephaphatha se bentšitsoeng, e leng sephaphatha se le seng sa silicon carbide. E entsoe ka likristale tse phahameng tsa SiC tse hloekileng 'me e ka ba 100mm kapa 150mm ka bophara. E sebelisoa lisebelisoa tsa elektronike tse matla haholo. Mofuta oa bobeli ke epitaxial crystal silicon carbide wafer. Mofuta ona oa sephaphatha o entsoe ka ho kenyelletsa lera le le leng la likristale tsa silicon carbide holimo. Mokhoa ona o hloka taolo e nepahetseng ea botenya ba thepa mme o tsejoa e le N-mofuta oa epitaxy.

Mofuta o latelang ke beta silicon carbide. Beta SiC e hlahisoa ka mocheso o ka holimo ho likhato tse 1700 tsa Celsius. Alpha carbides ke tsona tse atileng haholo 'me li na le sebopeho sa kristale sa hexagonal se ts'oanang le wurtzite. Foromo ea beta e tšoana le taemane 'me e sebelisoa lits'ebetsong tse ling. Haesale e le khetho ea pele bakeng sa lihlahisoa tse felisitsoeng ka matla a koloi ea motlakase. Barekisi ba 'maloa ba karolo ea boraro ea li-silicon carbide wafer hajoale ba ntse ba sebetsa thepa ena e ncha.

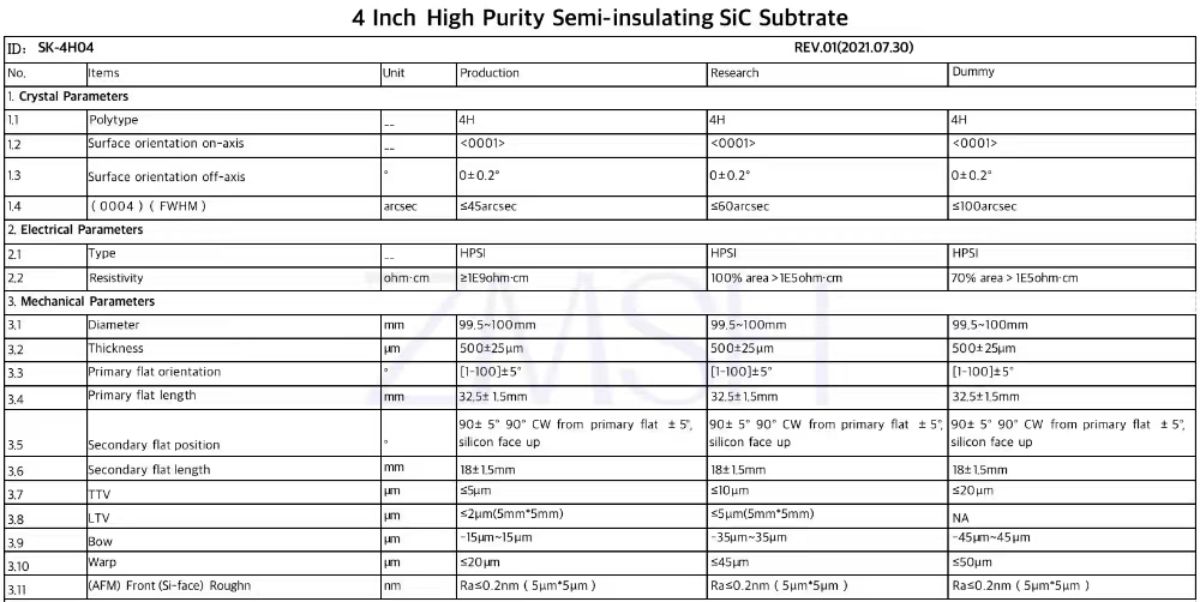

Li-wafer tsa ZMSH SiC ke lisebelisoa tse tsebahalang haholo tsa semiconductor. Ke thepa ea boleng bo holimo ea semiconductor e loketseng lits'ebetso tse ngata. ZMSH silicon carbide wafers ke lisebelisoa tse molemo haholo bakeng sa lisebelisoa tse fapaneng tsa elektroniki. ZMSH e fana ka mefuta e mengata e fapaneng ea liphaephe tsa boleng bo holimo tsa SiC le li-substrates. Li fumaneha ka liforomo tsa mofuta oa N le semi-insulated.

2 --- Silicon Carbide: Ho ea nakong e ncha ea li-wafers

Lintho tsa 'mele le litšobotsi tsa silicon carbide

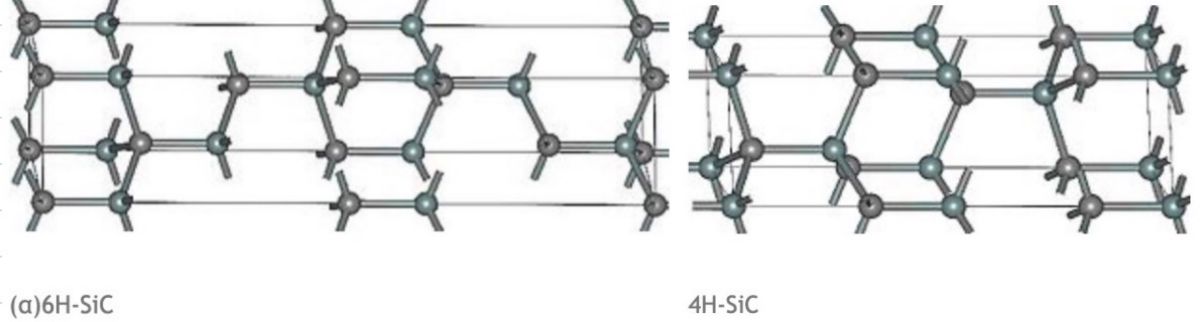

Silicon carbide e na le mohaho o khethehileng oa kristale, o sebelisa mohaho o haufi-ufi oa hexagonal o tšoanang le daemane. Sebopeho sena se nolofalletsa silicon carbide ho ba le conductivity e ntle ea mocheso le ho hanyetsa mocheso o phahameng. Ha ho bapisoa le lisebelisoa tsa silicon tsa setso, silicon carbide e na le lekhalo le leholo la lekhalo la sehlopha, le fanang ka sebaka se phahameng sa li-electron band, se hlahisang motsamao o phahameng oa elektronike le ho theoha ho fokolang hona joale. Ntle le moo, silicon carbide e boetse e na le lebelo le phahameng la ho hoholeha ha elektronike le ho hanyetsa ka tlase ha thepa ka boeona, e fana ka ts'ebetso e ntle bakeng sa lisebelisoa tse phahameng tsa matla.

Linyeoe tsa kopo le litebello tsa li-wafers tsa silicon carbide

Lisebelisoa tsa motlakase oa motlakase

Silicon carbide wafer e na le tebello e pharalletseng ea ts'ebeliso tšimong ea matla a elektroniki. Ka lebaka la ho tsamaea ha lielektrone tse phahameng le ho tsamaisa mocheso o motle, li-wafers tsa SIC li ka sebelisoa ho etsa lisebelisoa tsa ho fetola matla a matla, tse kang li-module tsa motlakase bakeng sa likoloi tsa motlakase le li-inverters tsa letsatsi. Ho tsitsisa ha mocheso o phahameng oa li-wafers tsa silicon carbide ho nolofalletsa lisebelisoa tsena ho sebetsa libakeng tse phahameng tsa mocheso, ho fana ka katleho e kholo le ho tšepahala.

Lisebelisoa tsa Optoelectronic

Lefapheng la lisebelisoa tsa optoelectronic, li-wafers tsa silicon carbide li bontša melemo ea tsona e ikhethang. Lisebelisoa tsa Silicon carbide li na le litšobotsi tse pharalletseng tsa lekhalo, tse e nolofalletsang ho fumana matla a phahameng a photonon le tahlehelo e tlase ea leseli ho lisebelisoa tsa optoelectronic. Li-wafers tsa silicon carbide li ka sebelisoa ho lokisa lisebelisoa tsa puisano tse potlakileng, li-photodetectors le lasers. Ts'ebetso ea eona e ntle ea mocheso le sekoli se tlase sa kristale se etsa hore e be se loketseng bakeng sa ho lokisoa ha lisebelisoa tsa boleng bo holimo tsa optoelectronic.

Maikutlo

Ka tlhokahalo e ntseng e hola ea lisebelisoa tsa elektroniki tse sebetsang hantle haholo, li-wafers tsa silicon carbide li na le bokamoso bo ts'episang e le thepa e nang le thepa e ntle haholo le bokhoni bo pharaletseng ba ts'ebeliso. Ka ntlafatso e tsoelang pele ea theknoloji ea ho lokisa le ho fokotsa litšenyehelo, ts'ebeliso ea khoebo ea li-wafers tsa silicon carbide e tla khothaletsoa. Ho lebeletsoe hore lilemong tse 'maloa tse tlang, li-wafers tsa silicon carbide li tla kena' marakeng butle-butle 'me e be khetho e tloaelehileng bakeng sa lisebelisoa tse phahameng tsa matla, maqhubu a phahameng le mocheso o phahameng.

3--- Tlhahlobo e tebileng ea 'maraka oa SiC oafer le mekhoa ea theknoloji

Tlhahlobo e tebileng ea bakhanni ba 'maraka oa silicon carbide (SiC).

Kholo ea 'maraka oa silicon carbide (SiC) e susumetsoa ke lintlha tse' maloa tsa bohlokoa, 'me tlhahlobo e tebileng ea phello ea lintlha tsena' marakeng e bohlokoa. Mona ke tse ling tsa mabaka a ka sehloohong a limmaraka:

Ho boloka matla le ts'ireletso ea tikoloho: Litšobotsi tse phahameng tsa ts'ebetso le ts'ebeliso e tlase ea matla a thepa ea silicon carbide e etsa hore e tumme tšimong ea ho boloka matla le ts'ireletso ea tikoloho. Tlhokahalo ea likoloi tsa motlakase, li-inverter tsa letsatsi le lisebelisoa tse ling tsa phetolo ea matla e tsamaisa kholo ea 'maraka ea li-wafers tsa silicon carbide kaha li thusa ho fokotsa litšila tsa matla.

Lisebelisoa tsa Power Electronics: Silicon carbide e ipabola lits'ebetsong tsa elektronike tsa matla 'me e ka sebelisoa ka matla a motlakase tlas'a khatello e phahameng le maemo a mocheso o phahameng. Ka ho ata ha matla a tsosolositsoeng le ho khothaletsa phetoho ea matla a motlakase, tlhoko ea li-wafers tsa silicon carbide 'marakeng oa lisebelisoa tsa elektroniki e ntse e eketseha.

Li-wafers tsa SiC tsa nakong e tlang tsa nts'etsopele ea theknoloji ea tlhahiso ea tlhahlobo e qaqileng

Tlhahiso e ngata le phokotso ea litšenyehelo: Tlhahiso ea nakong e tlang ea SiC e tla shebana haholo le tlhahiso ea bongata le phokotso ea litšenyehelo. Sena se kenyeletsa mekhoa e ntlafetseng ea ho hōla e kang chemical vapor deposition (CVD) le physical vapor deposition (PVD) ho eketsa tlhahiso le ho fokotsa litšenyehelo tsa tlhahiso. Ho feta moo, ho lebeletsoe ho amoheloa ha mekhoa ea tlhahiso e bohlale le e ikemetseng e tla ntlafatsa ts'ebetso.

Boholo le sebopeho se secha sa wafer: Boholo le sebopeho sa li-wafers tsa SiC li ka fetoha nakong e tlang ho fihlela litlhoko tsa lits'ebetso tse fapaneng. Sena se ka kenyelletsa liphaephe tse kholoanyane tsa bophara, libopeho tse fapaneng, kapa liphaephe tse ngata ho fana ka maemo a bonolo a moralo le likhetho tsa ts'ebetso.

Matla a Matla le Tlhahiso e Tala: Ho etsoa ha li-wafers tsa SiC nakong e tlang ho tla totobatsa matla a matla le tlhahiso e tala. Lifeme tse tsamaisoang ke matla a ka nchafatsoang, lisebelisoa tse tala, ho sebelisoa ha litšila le mekhoa ea tlhahiso ea khabone e tlase e tla fetoha mekhoa ea tlhahiso.

Nako ea poso: Jan-19-2024