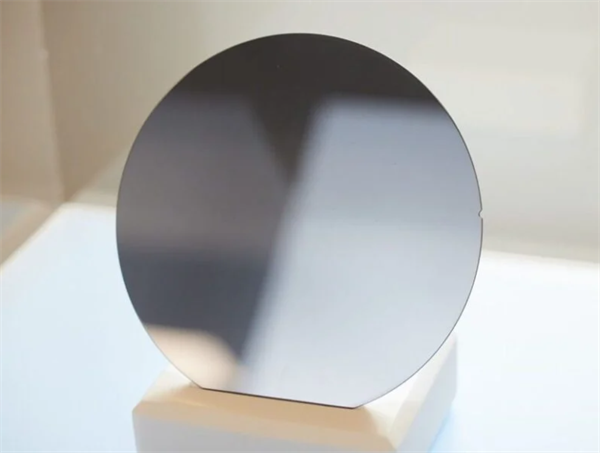

P-mofuta oa SiC oafer 4H/6H-P 3C-N 6inch thickeness 350 μm with Primary Flat Orientation

Specification4H/6H-P Mofuta oa SiC Composite Substrates Tafole e tloaelehileng ea parameter

6 inch bophara ba Silicon Carbide (SiC) Substrate Tlhaloso

| Kereiti | Zero MPD TlhahisoKereiti (Z Kereiti) | Tlhahiso e TloaelehilengKereiti (P Kereiti) | Sehlopha sa Dummy (D Kereiti) | ||

| Diameter | 145.5 limilimithara ~ 150.0 limilimithara | ||||

| Botenya | 350 μm ± 25 μm | ||||

| Wafer Orientation | -Offaxis: 2.0° -4.0° ho leba [1120] ± 0.5° bakeng sa 4H/6H-P, Ho axis:〈111〉± 0.5° bakeng sa 3C-N | ||||

| Boima ba Micropipe | 0cm-2 | ||||

| Ho hanyetsa | mofuta oa 4H/6H-P | ≤0.1 Ωꞏcm | ≤0.3 Ωꞏcm | ||

| n-mofuta 3C-N | ≤0.8 mΩꞏcm | ≤1 m Ωꞏcm | |||

| Maemo a Motheo a Flat | 4H/6H-P | -{1010} ± 5.0° | |||

| 3C-N | -{110} ± 5.0° | ||||

| Bolelele ba Phatlalatso ba Pele | 32.5 limilimithara ± 2.0 limilimithara | ||||

| Bolelele ba Bokhabane ba Bobeli | 18.0 limilimithara ± 2.0 limilimithara | ||||

| Boemo ba Bobeli ba Flat | Sefahleho sa silicon holimo: 90° CW. ho tloha ho Prime flat ± 5.0° | ||||

| Kenyelletso ea Edge | 3 limilimithara | 6 limilimithara | |||

| LTV/TTV/Bow /Warp | ≤2.5 μm/≤5 μm/≤15 μm/≤30 μm | ≤10 μm/≤15 μm/≤25 μm/≤40 μm | |||

| Boqhobane | Polish Ra≤1 nm | ||||

| CMP Ra≤0.2 nm | Ra≤0.5 nm | ||||

| Edge Cracks By High Intensity Leseli | Ha ho letho | Bolelele bo akaretsang ≤ 10 mm, bolelele bo le bong≤2 mm | |||

| Hex Plates By High Intensity Light | Kakaretso ≤0.05% | Kakaretso ≤0.1% | |||

| Libaka tsa Polytype Ka Leseli le Matla a Phahameng | Ha ho letho | Kakaretso≤3% | |||

| Likakaretso tsa Carbon tse bonoang | Kakaretso ≤0.05% | Kakaretso ≤3% | |||

| Silicon Surface Scratches By High Intensity Light | Ha ho letho | Bolelele ba kakaretso≤1× bophara ba wafer | |||

| Edge Chips Phahameng ka ho Matla Leseli | Ha ho e lumelletsoeng ≥0.2mm bophara le botebo | 5 e lumelletsoe, ≤1 mm ka 'ngoe | |||

| Tšilafalo ea Sefahleho sa Silicon Ka Matla a Phahameng | Ha ho letho | ||||

| Sephutheloana | Multi-wafer Cassette kapa Single Wafer Container | ||||

Lintlha:

※ Meeli ea bofokoli e sebetsa sebakeng sohle sa wafer ntle le sebaka se ka thoko. # Mengoako e lokela ho hlahlojoa ho Si face o

Sephaphatha sa SiC sa mofuta oa P, 4H/6H-P 3C-N, se nang le boholo ba 6-inch le botenya ba 350 μm, se bapala karolo ea bohlokoa tlhahisong ea indasteri ea lisebelisoa tsa elektroniki tse sebetsang hantle. Ts'ebetso ea eona e ntle ea mocheso le matla a phahameng a ho senyeha ho etsa hore e be e loketseng bakeng sa lisebelisoa tsa tlhahiso tse kang li-switches tsa motlakase, li-diode le li-transistors tse sebelisoang libakeng tse nang le mocheso o phahameng joalo ka likoloi tsa motlakase, marang-rang a motlakase le lisebelisoa tse nchafalitsoeng tsa matla. Bokhoni ba wafer ea ho sebetsa hantle maemong a thata bo netefatsa ts'ebetso e tšepahalang lits'ebetsong tsa indasteri tse hlokang matla a phahameng a matla le matla a matla. Ntle le moo, sebopeho sa eona sa mantlha se sephara se thusa ho hokahana hantle nakong ea ho etsoa ha sesebelisoa, ho ntlafatsa ts'ebetso ea tlhahiso le botsitso ba sehlahisoa.

Melemo ea N-mofuta oa SiC composite substrates e kenyelletsa

- High Thermal Conductivity: Li-wafers tsa SiC tsa mofuta oa P li tlosa mocheso ka katleho, li etsa hore e be tse loketseng bakeng sa lisebelisoa tse phahameng tsa mocheso.

- Motlakase o phahameng oa ho senya: E khona ho mamella li-voltage tse phahameng, e netefatsa ho ts'epahala ho lisebelisoa tsa elektronike tse matla le lisebelisoa tse phahameng haholo.

- Ho hanyetsana le Tikoloho e thata: Ho tšoarella ka mokhoa o babatsehang maemong a feteletseng, joalo ka mocheso o phahameng le libaka tse senyang.

- Phetoho e Matla ea Matla: Doping ea mofuta oa P e thusa ho sebetsana hantle le matla, ho etsa hore sephaphatha se lokele lits'ebetso tsa phetolo ea matla.

- Maemo a Motheo a Flat: E netefatsa ho lumellana ho nepahetseng nakong ea tlhahiso, ho ntlafatsa ho nepahala le ho tsitsa ha lisebelisoa.

- Sebopeho se Lesesaane (350 μm): Botenya bo nepahetseng ba wafer bo tšehetsa ho hokahana le lisebelisoa tsa elektroniki tse hahelletsoeng sebakeng.

Ka kakaretso, sephaphatha sa SiC sa mofuta oa P, 4H/6H-P 3C-N, se fana ka melemo e mengata e etsang hore se tšoanelehe haholo bakeng sa lits'ebetso tsa indasteri le tsa elektroniki. Mocheso oa eona o phahameng oa mocheso le motlakase oa ho senya o nolofalletsa ts'ebetso e ka tšeptjoang libakeng tse phahameng tsa mocheso le mocheso o phahameng, ha ho hanyetsa maemo a thata ho tiisa ho tšoarella. Doping ea mofuta oa P e lumella phetoho e nepahetseng ea matla, e etsa hore e be e loketseng bakeng sa lisebelisoa tsa motlakase le lisebelisoa tsa matla. Ho feta moo, sebaka sa mantlha sa sephara sa wafer se netefatsa teka-tekano e nepahetseng nakong ea ts'ebetso ea tlhahiso, e matlafatsa ts'ebetso ea tlhahiso. Ka botenya ba 350 μm, e loketse hantle bakeng sa ho kopanngoa le lisebelisoa tse tsoetseng pele, tse kopanetsoeng.

Setšoantšo se qaqileng