Precision Microjet Laser System bakeng sa Lisebelisoa tse Thata le tse Brittle

Likarolo tsa Bohlokoa

1. Dual-Wavelength Nd: YAG Laser Source

E sebelisa laser ea diode-pumped solid-state Nd:YAG, sistimi e ts'ehetsa bolelele ba maqhubu a botala (532nm) le infrared (1064nm). Bokhoni bona ba lihlopha tse peli bo etsa hore ho be le tšebelisano e phahameng le mefuta e mengata e fapaneng ea li-profiles tsa ho monya, ho ntlafatsa lebelo la ts'ebetso le boleng.

2. Phetiso ea Laser ea Microjet e ncha

Ka ho kopanya laser le microjet ea metsi a khatello e phahameng, sistimi ena e sebelisa ponahatso e felletseng ea kahare ho matla a laser hantle haufi le molapo oa metsi. Mokhoa ona o ikhethang oa ho fana ka thepa o netefatsa ho tsepamisa maikutlo ho hoholo ka ho hasanya ho fokolang le ho fana ka bophara ba mela e le 20μm, e fanang ka boleng bo sehiloeng bo sa bapisoang.

3. Taolo ea Mocheso ho Micro Scale

Mojule oa ho pholile oa metsi o kenyellelitsoeng hantle o laola mocheso sebakeng sa ts'ebetso, ho boloka sebaka se amehileng ke mocheso (HAZ) ka hare ho 5μm. Tšobotsi ena e bohlokoa haholo ha o sebetsa ka lisebelisoa tse thibelang mocheso le tse sa robeheng tse kang SiC kapa GaN.

4. Modular Matla a Configuration

Sethala se tšehetsa mekhoa e meraro ea matla a laser-50W, 100W, le 200W-e lumellang bareki ho khetha tlhophiso e lumellanang le litlhoko tsa bona tsa ho sebetsa le tharollo.

5. Precision Motion Control Platform

Sistimi e kenyelletsa sethala se nepahetseng haholo se nang le maemo a ± 5μm, se nang le motsamao oa li-axis tse 5 le li-motor tse ikhethileng kapa tse tsamaeang ka kotloloho. Sena se tiisa ho pheta-pheta le ho feto-fetoha ha maemo, esita le bakeng sa li-geometri tse rarahaneng kapa ts'ebetso ea batch.

Libaka tsa Kopo

Silicon Carbide Wafer Processing:

E nepahetse bakeng sa ho rema, ho seha le ho theola li-wafers tsa SiC ka lisebelisoa tsa elektroniki.

Mochine oa Mochine oa Gallium Nitride (GaN):

E ts'ehetsa ho ngola le ho itšeha ka mokhoa o nepahetseng haholo, o etselitsoeng RF le lits'ebetso tsa LED.

Sebopeho sa Wide Bandgap Semiconductor:

E lumellana le daemane, gallium oxide, le lisebelisoa tse ling tse hlahang bakeng sa lisebelisoa tse phahameng tsa maqhubu a phahameng.

Aerospace Composite Cutting:

Ho itšeha ho nepahetseng ha likarolo tsa matrix tsa ceramic le li-substrates tse tsoetseng pele tsa boemo ba moea.

LTCC & Lisebelisoa tsa Photovoltaic:

E sebelisoa bakeng sa micro ka ho cheka, trenching le scribing ho PCB e phahameng haholo le tlhahiso ea lisele tsa letsatsi.

Scintillator & Optical Crystal Shaping:

E nolofalletsa ho seha sekoli se tlase sa yttrium-aluminium garnet, LSO, BGO, le lisebelisoa tse ling tse nepahetseng.

Tlhaloso

| Tlhaloso | Boleng |

| Mofuta oa Laser | DPSS Nd:YAG |

| Li-wavelengths li tšehelitsoe | 532nm / 1064nm |

| Likhetho tsa Matla | 50W / 100W / 200W |

| Boemo bo Nepahetseng | ±5μm |

| Bonyane Bophara ba Mola | ≤20μm |

| Sebaka se Ametsoeng ke Mocheso | ≤5μm |

| Sistimi ea Motion | Linear/ Enjene e khannang ka kotloloho |

| Max Energy Density | Ho fihla ho 10⁷ W/cm² |

Qetello

Sistimi ena ea laser ea microjet e hlalosa bocha meeli ea machining ea laser bakeng sa lisebelisoa tse thata, tse brittle, le tse bonolo haholo tsa mocheso. Ka kopano ea eona e ikhethang ea laser-metsi, ho tsamaellana ha maqhubu a mabeli, le sistimi e feto-fetohang ea ho sisinyeha, e fana ka tharollo e lokiselitsoeng bakeng sa bafuputsi, bahlahisi le bahokahanyi ba sistimi ba sebetsang ka thepa ea morao-rao. Ebang e sebelisoa ka masela a semiconductor, li-labs tsa aerospace, kapa tlhahiso ea liphanele tsa letsatsi, sethala sena se fana ka ts'epo, ho pheta-pheta, le ho nepahala ho matlafatsang ts'ebetso ea thepa ea moloko o latelang.

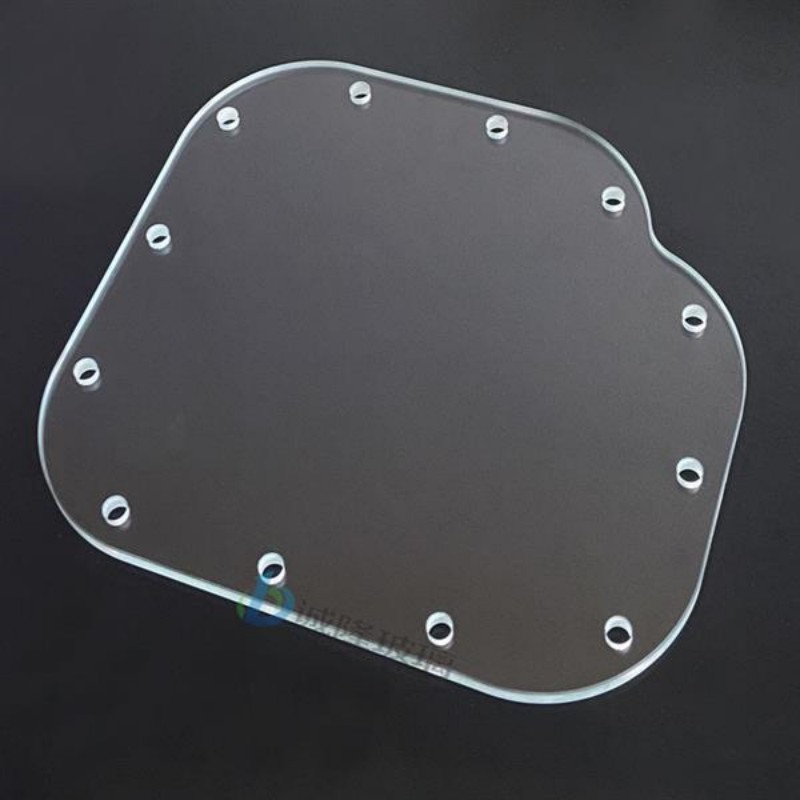

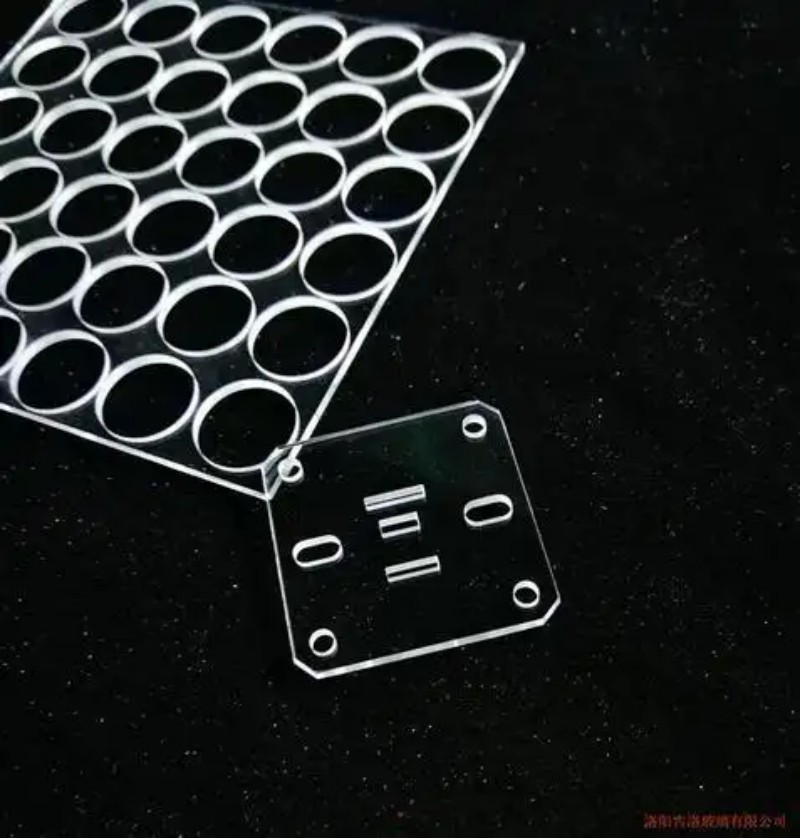

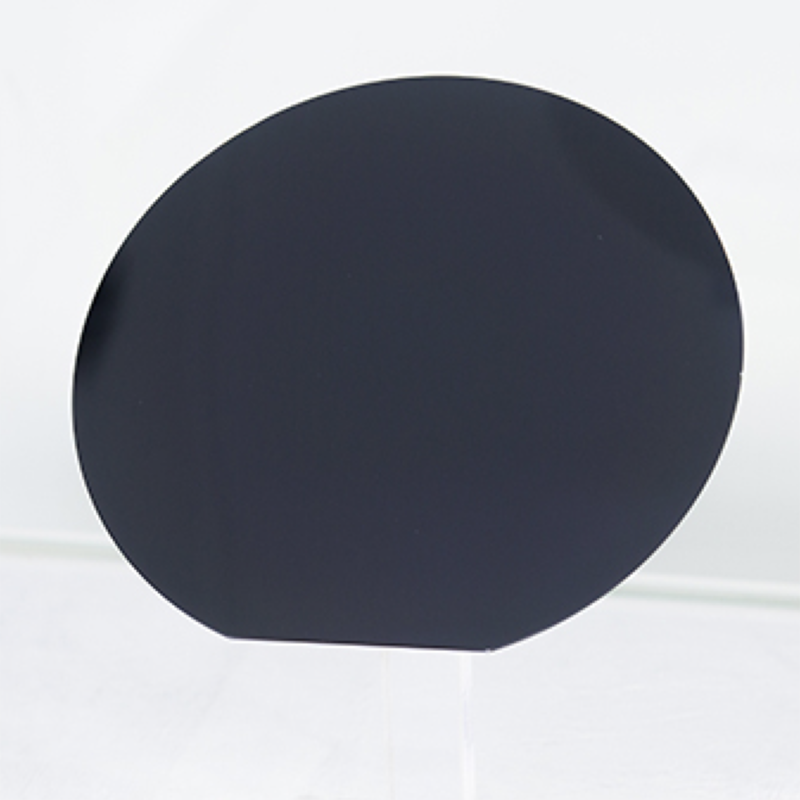

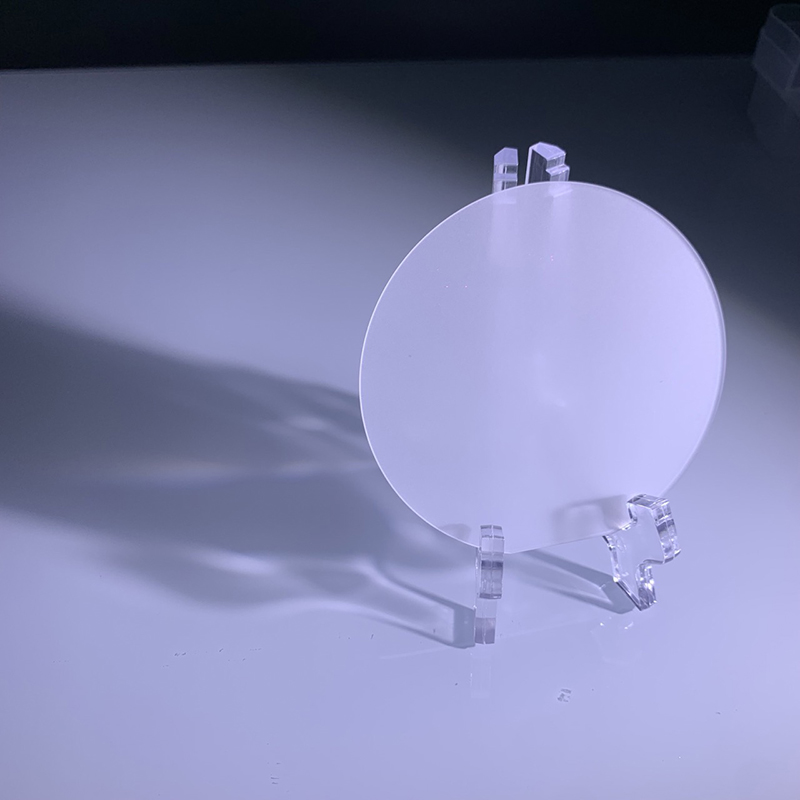

Setšoantšo se qaqileng