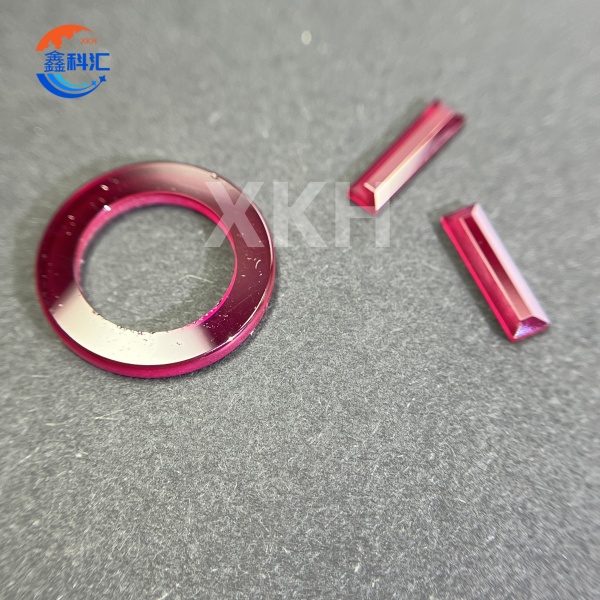

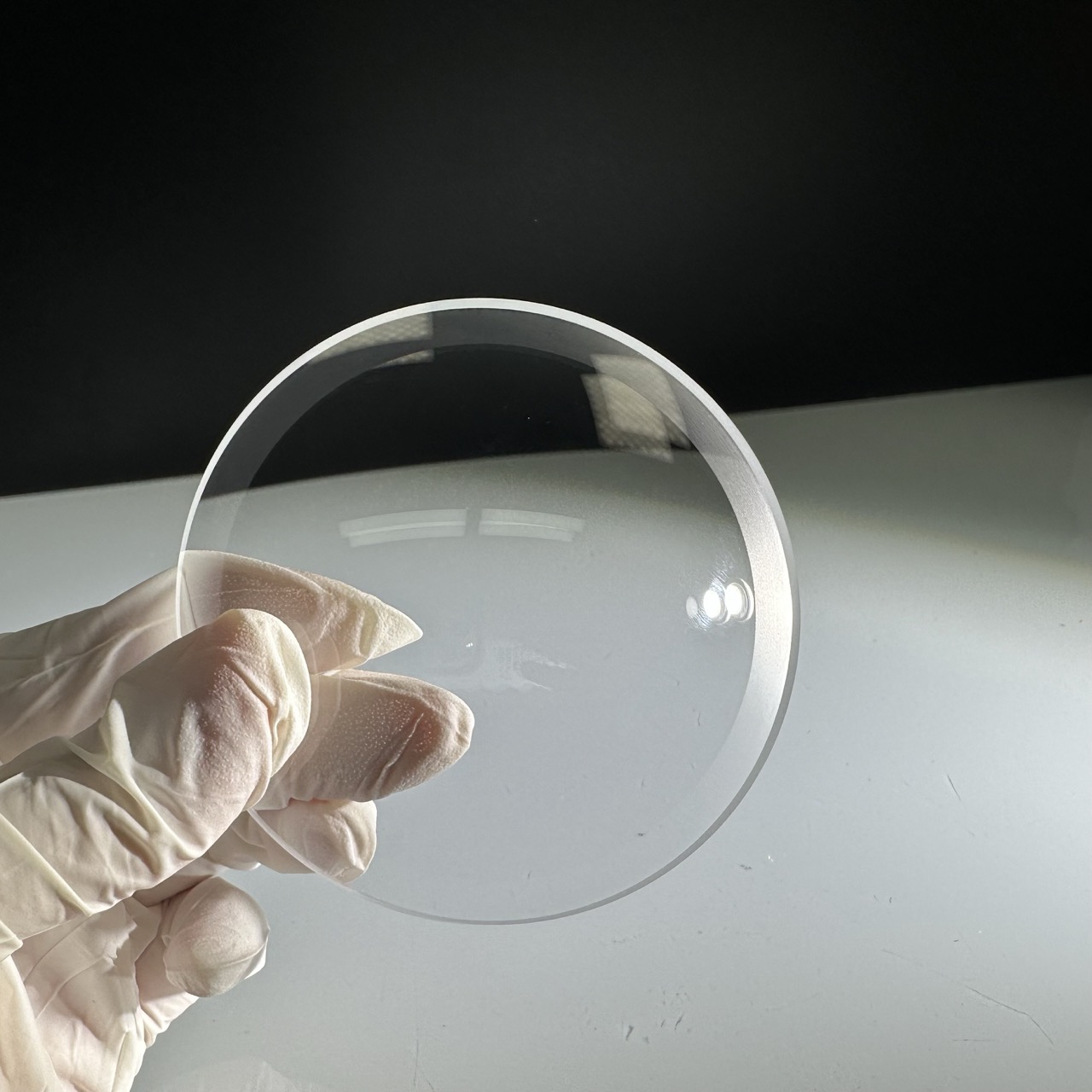

Ruby Optical Components Precision Windows Bearing Assemblies Ho hanyetsa Mocheso o Phahameng

Sapphire (α-Al₂O₃) e hlahile e le sesebelisoa sa bohlokoa se sebetsang indastering ea sejoale-joale, se bonts'ang boleng bo ke keng ba khutlisoa lits'ebetsong tse ngata tsa theknoloji e phahameng ka lebaka la thepa ea eona e ikhethang ea physicochemical. Joaloka mofani ea ka sehloohong oa litharollo tsa thepa ea safire, XKH e na le bokhoni bo feletseng ba ketane ea indasteri-ho tloha khōlong ea kristale ho ea ho machining e nepahetseng-e re thusang ho fana ka lisebelisoa tsa safire tse hlophisitsoeng ho kenyeletsa lifensetere tsa optical, li-mechanical bearings le laser elements. Ka ho sebelisa mahlale a tsoetseng pele a tlhahiso le lits'ebetso tse matla tsa taolo ea boleng, re ikemiselitse ho fa bareki ba indasteri litharollo tsa sehlahisoa sa safire se sebetsang hantle, se tšepahalang.

Tlhaloso ea tekheniki:

| Sehlopha sa Parameter | Tlhaloso |

| Thepa ea Motheo | |

| Sebopeho sa Crystal | Hexagonal (α-Al₂O₃) |

| Mohs Hardness | 9 |

| Botenya | 3.98g/cm³ |

| Melting Point | 2050°C |

| Thepa ea Optical | |

| Sebaka sa phetiso | 0.15-5.5 μm |

| Refractive Index | 1.76 @ 589nm |

| Birefringence | 0.008 |

| Thepa ea Mechini | |

| Flexural Matla | 400-700 MPa |

| Elastic modulus | 345 GPA |

| Thermal Keketso Coeff. | 7.5×10⁻⁶/K (25-1000°C) |

| Phekolo ea Bokaholimo | |

| Qetello e Tloaelehileng | Ra ≤ 0,05 μm |

| Qetello e Phahameng ka ho Fetisisa | Ra ≤ 0.01 μm |

| Likhetho tsa ho roala | Liaparo tsa AR/HR/Metallic |

Likarolo tsa Bohlokoa:

- Ho Ikamahanya le Boemo ba Tikoloho bo Ikhethileng

Likarolo tsa safire li bonts'a ts'ebetso e ikhethang maemong a feteletseng, li boloka ts'ebetso e tsitsitseng ho pholletsa le mocheso o pharalletseng oa -200°C ho ea +1000°C. Sebopeho sa bona se ikhethang sa kristale se fana ka khanyetso e phahameng ea mocheso oa mocheso, ho thibela ho phunyeha kapa ho senyeha esita le tlas'a ho fetoha ha mocheso ka potlako. Maemong a vacuum, likarolo tsa safire li sebetsa ka mokhoa o ts'epahalang maemong a phahameng haholo a vacuum (10⁻⁶ Pa) ntle le tšilafalo e tsoang. Ho feta moo, safire e bonts'a khanyetso e ntle ea mahlaseli, e boloka sebopeho le ts'ebetso ho litekanyetso tsa radiation ho fihla ho 10⁶ Gy.

- Ho tšoarella ho sa feleng

Ka boima ba Mohs ba 9 (ea bobeli ho daemane), likarolo tsa safire li fana ka khanyetso e ikhethang ea ho apara. Teko ea ho bapisa e bonts'a likarolo tsa safire li bonts'a litekanyetso tsa ho apara feela 1/10th ea lisebelisoa tsa tšepe tsa setso. Ho latela lik'hemik'hale, safire e hanyetsana le hoo e batlang e le liesiti tsohle tse matla (ntle le HF), alkalis, le metsoako ea tlhaho. Lintho tsena li nolofalletsa likarolo tsa safire ho finyella bophelo ba tšebeletso ka makhetlo a 5-8 ho feta lisebelisoa tse tloaelehileng, ho fokotsa haholo litšenyehelo tsa tlhokomelo le nako ea ho theoha.

- Tshebetso e Phahameng ka ho Fetisisa

Sapphire components provide unique advantages in precision manufacturing. Their ultra-low thermal expansion coefficient (7.5×10⁻⁶/K) ensures dimensional stability, typically achieving ±0.1μm/100mm variation. Through precision machining, we achieve surface flatness of λ/10@632.8nm and angular tolerances of ±15 arc-seconds, meeting the most stringent optical system requirements. These characteristics make sapphire ideal for high-precision measurement and optical applications.

Melemo ea Bohlokoa:

- Karolelano ea Ts'ebetso ho Litšenyehelo

Likarolo tsa rona tsa safire li boloka ho feta 85% ea lintlha tsa bohlokoa tsa ts'ebetso ha re ntse re fana ka ho boloka litšenyehelo tse fetang 30% ha ho bapisoa le lihlahisoa tsa khale tsa safire. Ka kholo e ntlafalitsoeng ea kristale le lits'ebetso tsa machining, re fihlela tekanyo e nepahetseng lipakeng tsa ts'ebetso le litšenyehelo. Taolo e matla ea boleng e netefatsa hore batch-to-batch e lumellana le ≤3% e kheloha paramethareng.

- Bokhoni bo Felletseng ba Tšebeletso

Re boloka mokhoa o potlakileng oa ho arabela, o fana ka tharollo ea tekheniki nakong ea lihora tse 48. Mofuta oa rona oa tlhahiso o feto-fetohang o amohela liodara ho tloha ho 1 ho isa ho li-unit tsa 10,000. Protocol ea tlhahlobo ea mehato e 36 e akaretsa ho nepahala ha boholo, boleng ba bokaholimo, le thepa ea mochini ho netefatsa litekanyetso tsa boleng bo holimo.

Lisebelisoa tsa mantlha:

Lisebelisoa tsa Indasteri tsa Boemo bo Phahameng

Tlhahiso ea Semiconductor: Liporo tse tataisang bakeng sa liroboto tse tšoarang liphaephe

Precision Metrology: Probes for CMMs (Coordinate Measuring Machines)

Fiber Optics: Ho hula li-nozzles tse nang le botsitso bo phahameng ba mocheso

2. Advanced Optical Systems

Theknoloji ea Laser: High-LIDT (Tšenyo e Bakiloeng ke Laser) lifensetere le Q-switches

Lisebelisoa tsa Ts'ireletso: Li-missile domes tsa infrared

Spectroscopy: Prisms le lifensetere bakeng sa lisebelisoa tsa tlhahlobo

3. Likopo tse Feteletseng tsa Tikoloho

Aerospace: Li-bearings tsa taolo ea maikutlo bakeng sa sefofa-sebakeng

Patlisiso e tebileng ea Leoatle: Boema-kepe bo hananang le khatello

Indasteri ea Nyutlelie: Lifensetere tsa ho shebella tse sirelelitsoeng ke mahlaseli

XKH'sLitšebeletso:

XKH e fana ka litharollo tsa likarolo tsa safire:

· Sehlahisoa sa Portfolio: 200+ mehlala e tloaelehileng e fumanehang; boholo ba tloaelo ho tloha 0.5-300mm

· Litšebeletso tsa Tekheniki: Boenjiniere ba kopo, ketsiso ea FEA, tlhahlobo ea ho hloleha

· Litlhare ka holim'a metsi: Liaparo tsa DLC, liphahlo tsa AR (Anti-Reflective).

· Tiisetso ea Boleng: Litlaleho tsa tlhahlobo tse netefalitsoeng ke motho oa boraro

· Logistics: Litlhahiso tsa tekheniki tsa lihora tse 48; 2-4 libeke tsa tlhahiso ea mohlala

Qetello

Likarolo tsa Sapphire li fana ka boleng bo ikhethang lits'ebetsong tse phahameng tsa indasteri ka thepa ea tsona e sa bapisoang ea physicochemical. Tlaleho ena e hlalositse ka botlalo litšobotsi tsa bona tsa bohlokoa, melemo, le ts'ebeliso ea li-multidisciplinary. Ka ho kopanya lits'ebeletso tse matla le taolo e thata ea boleng, XKH e fana ka litharollo tsa safire tse tšepahalang, tse theko e tlaase. Ha re hatela pele, re tla tsoelapele ho ntšetsa pele ts'ebetso ea lisebelisoa le mahlale a ts'ebetso ho holisa ts'ebeliso ea safire ho li-semiconductors, optics, aerospace, le ho feta. Re amohela litšebelisano-'moho le balekane ba indasteri ho kopanya mekhoa e mecha ea theknoloji ea thepa ea safire.