Sapphire Crystal Growth Furnace KY Kyropoulos Method for Sapphire Wafer and Optical Window Production

Molao-motheo oa ho Sebetsa

Molao-motheo oa mantlha oa mokhoa oa KY o kenyelletsa ho qhibilihisa lisebelisoa tse tala tsa Al₂O₃ ka tungsten / molybdenum crucible ka 2050 ° C. Kristale ea peo e theoleloa ka har'a ho qhibiliha, e lateloa ke ho tlosoa ho laoloang (0.5-10 mm / h) le ho potoloha (0.5-20 rpm) ho finyella kholo ea tataiso ea likristale tse le 'ngoe tsa α-Al₂O₃. Lintlha tsa bohlokoa li kenyelletsa:

• Likristale tsa boholo bo boholo (boholo. Φ400 mm × 500 mm)

• Sapphire ea boemo bo tlase ba khatello ea kelello (wavefront distortion <λ/8 @ 633 nm)

• Likristale tse nang le metsi (mohlala, Ti³⁰ doping bakeng sa star safire)

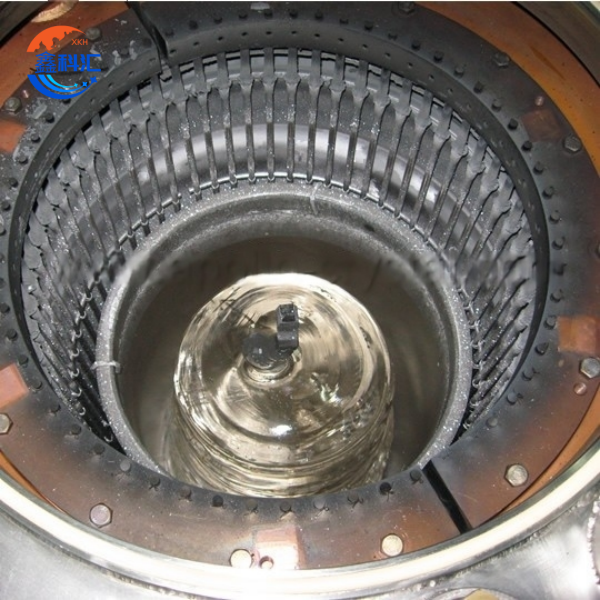

Likarolo tsa Core System

1. Sistimi ea ho qhibiliha ha mocheso o phahameng

• Tungsten-molybdenum crucible composite (max. temp. 2300°C)

• Sefuthumatsi sa graphite sa libaka tse ngata (± 0.5°C taolo ea mocheso)

2. Sistimi ea Kholiso ea Crystal

• Mochine o hulang o tsamaisoang ke servo (±0.01 mm ka nepo)

• Magnetic fluid rotary seal (0–30 rpm stepless speed regulation)

3. Taolo ea Tšimo ea Thermal

• Taolo ea mocheso e ikemetseng ea libaka tse 5 (1800–2200°C)

• Thebe e feto-fetohang ea mocheso (±2°C/cm gradient)

• Vacuum & Atmosphere System

• 10⁻⁴ Vacuum e phahameng haholo

• Taolo ea khase e tsoakiloeng ea Ar/N₂/H₂

4. Intelligent Monitoring

• Ts'ebetso ea ts'ebetso ea kristale ea nako ea sebele ea kristale

• Ho lemoha boemo ba ho qhibiliha ha multispectral

KY vs. CZ Method Papiso

| Parameter | Mokhoa oa KY | Mokhoa oa CZ |

| Max. Boholo ba Crystal | Φ400 limilimithara | Φ200 limilimithara |

| Sekhahla sa Khōlo | 5–15 mm/h | 20–50 mm/h |

| Defect Density | <100/cm² | 500-1000/cm² |

| Tšebeliso ea Matla | 80–120 kWh/kg | 50–80 kWh/kg |

| Lisebelisoa tse Tloaelehileng | Lifensetere tsa mahlo / liphaphatha tse kholo | LED substrates/mabenyane |

Lisebelisoa tsa Bohlokoa

1. Windows ea Optoelectronic

• Li-dome tsa sesole tsa IR (phetisetso >85%@3–5 μm)

• Lifensetere tsa laser tsa UV (mamella matla a 200 W/cm²)

2. Li-Semiconductor Substrates

• GaN epitaxial wafers (2–8 inch, TTV <10 μm)

• Li-substrates tsa SOI (bokhopo ba bokaholimo <0.2 nm)

3. Consumer Electronics

• Khalase e koahelang khamera ea Smartphone (Mohs hardness 9)

• Lipontšo tsa Smartwatch (kaonefatso ea 10× scratch resistance)

4. Lisebelisoa tse Khethehileng

• Disebediswa tsa IR tsa IR tse hlwekileng haholo (coefficient ya ho monya <10⁻³ cm⁻¹)

• Lifensetere tsa ho bona sebatli sa nyutlelie (ho mamella mahlaseli: 10¹⁶ n/cm²)

Melemo ea Sesebelisoa sa Khōlo sa Sapphire Crystals (KY)

Thepa ea Kyropoulos (KY) e thehiloeng ke mokhoa oa ho holisa kristale ea safire e fana ka melemo e ke keng ea lekanngoa ea tekheniki, e e beha e le tharollo e tsoetseng pele bakeng sa tlhahiso ea maemo a indasteri. Melemo ea bohlokoa e kenyelletsa:

1. Bokhoni ba Bophara ba Khōlo: E khona ho holisa likristale tsa safire ho fihla ho lisenthimithara tse 12 (300 mm) ka bophara, e nolofalletsang tlhahiso e phahameng ea lihlahisoa tsa liphaephe le lisebelisoa tsa optical bakeng sa lisebelisoa tse tsoetseng pele tse kang GaN epitaxy le lifensetere tsa boemo ba sesole.

2. Ultra-Low Defect Density: E fihlella ho teteana ha sebaka <100/cm² ka moralo o ntlafalitsoeng oa sebaka sa mocheso le taolo e nepahetseng ea boemo ba mocheso, e netefatsang hore kristale e nepahetse bakeng sa lisebelisoa tsa optoelectronic.

3. High-Quality Optical Performance: E fana ka transmittance>85% ho phatlalla le ponahalo ya infrared spectra (400–5500 nm), e leng bohlokwa bakeng sa lifensetere tsa leseare tsa UV le infrared optics.

4. Advanced Automation: E na le mekhoa ea ho hula e tsamaisoang ke servo (± 0.01 mm ka nepo) le litiiso tsa rotary fluid (0–30 rpm stepless control), ho fokotsa ho kenella ha batho le ho matlafatsa botsitso.

5. Flexible Doping Options: E ts'ehetsa ho itloaetsa ka li-dopants tse kang Cr³⁰ (bakeng sa ruby) le Ti³⁰ (bakeng sa star safire), e sebetsana le 'maraka oa niche oa optoelectronics le mabenyane.

6. Effective Energy: Optimized thermal insulation (tungsten-molybdenum crucible) e fokotsa tshebediso ya matla ho fihla ho 80–120 kWh/kg, ka tlhodisano le mekgwa e meng ya kgolo.

7. Tlhahiso e Scalable: E fihlella tlhahiso ea khoeli le khoeli ea li-wafers tse 5,000+ ka linako tse potlakileng tsa potoloho (matsatsi a 8-10 bakeng sa likristale tsa 30-40 kg), tse netefalitsoeng ke lisebelisoa tse fetang 200 tsa lefats'e.

.

8. Boitšoaro ba Boemo ba Sesole: E kenyelletsa meralo e hananang le mahlaseli le lisebelisoa tse mamellang mocheso (ho mamella 10¹⁶ n/cm²), tse hlokahalang bakeng sa lisebelisoa tsa sefofane le nyutlelie.

Litlhahiso tsena li tiisa mokhoa oa KY e le tekanyetso ea khauta bakeng sa ho hlahisa likristale tsa safire tse sebetsang hantle, ho khanna tsoelo-pele ho likhokahano tsa 5G, computing ea quantum, le theknoloji ea ts'ireletso.

Litšebeletso tsa XKH

XKH e fana ka litharollo tse felletseng tsa li-turnkey bakeng sa lits'ebetso tsa kholo ea kristale ea safire, tse kenyelletsang ho kenya, ho ntlafatsa ts'ebetso, le koetliso ea basebetsi ho netefatsa ts'ebetso e se nang moeli. Re fana ka litlolo tsa kholo tse netefalitsoeng esale pele (50+) tse etselitsoeng litlhoko tse fapaneng tsa indasteri, ho fokotsa haholo nako ea R&D bakeng sa bareki. Bakeng sa lits'ebetso tse ikhethileng, lits'ebeletso tsa nts'etsopele ea moetlo li thusa ho etsa tlhophiso ea "cavity" (Φ200-400 mm) le sistimi e tsoetseng pele ea doping (Cr/Ti/Ni), e ts'ehetsang lisebelisoa tsa optical tse sebetsang hantle le lisebelisoa tse hananang le radiation.

Litšebeletso tsa tlatsetso ea boleng li kenyelletsa ts'ebetso ea kamora kholo joalo ka ho seha, ho sila le ho bentša, tse tlatselletsoang ke mefuta e mengata ea lihlahisoa tsa safire joalo ka li-wafers, li-tubes le likheo tsa majoe a bohlokoa. Litlhahiso tsena li fana ka likarolo ho tloha ho lisebelisoa tsa elektroniki tsa bareki ho isa sebakeng sa sefofane. Tšehetso ea rona ea tekheniki e fana ka tiisetso ea likhoeli tse 24 le tlhahlobo ea nako ea sebele ea nako ea sebele, e netefatsang nako e fokolang le katleho e tsitsitseng ea tlhahiso.