Semiconductor Laser Lift-Off Thepa

Setšoantšo se qaqileng

Tlhaloso ea lihlahisoa tsa lisebelisoa tsa Laser Lift-Off

Thepa ea Semiconductor Laser Lift-Off Equipment e emela tharollo ea moloko o latelang bakeng sa ts'ebetso e tsoetseng pele ea ingot ts'ebetsong ea thepa ea semiconductor. Ho fapana le mekhoa e tloaelehileng ea ho roala, e itšetlehileng ka ho sila ka mochine, ho sakha terata ea daemane, kapa ho etsa planarization ea lik'hemik'hale, sethala sena sa laser-based se fana ka mokhoa o mong o sa amaneng le o senyehileng bakeng sa ho tlosa likarolo tse tšesaane ho tloha ho li-ingots tse ngata tsa semiconductor.

E ntlafalitsoe bakeng sa lisebelisoa tse brittle le tsa boleng bo holimo tse kang gallium nitride (GaN), silicon carbide (SiC), sapphire, le gallium arsenide (GaAs), Semiconductor Laser Lift-Off Equipment e nolofalletsa ho seha ka mokhoa o nepahetseng lifilimi tsa sekala sa wafer ka kotloloho ho tsoa ho kristale engot. Theknoloji ena ea katleho e fokotsa litšila tsa thepa haholo, e ntlafatsa ts'ebetso, 'me e ntlafatsa botšepehi ba substrate - tseo kaofela li leng bohlokoa bakeng sa lisebelisoa tsa moloko o latelang oa motlakase oa motlakase, lisebelisoa tsa RF, photonics, le micro-displays.

Ka ho totobatsoa ho taolo e ikemetseng, sebopeho sa mabala, le lisebelisoa tsa laser-material interaction analytics, Semiconductor Laser Lift-Off Equipment e etselitsoe ho hokahana ka mokhoa o se nang seams ho li-workflows tsa semiconductor ha e ntse e ts'ehetsa phetoho ea R&D le sekhahla sa tlhahiso ea bongata.

Theknoloji le Molao-motheo oa Ts'ebetso oa Lisebelisoa tsa Laser Lift-Off

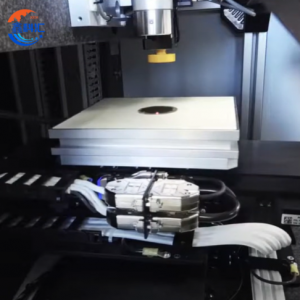

Ts'ebetso e entsoeng ke Semiconductor Laser Lift-Off Equipment e qala ka ho khantša ingot ea mofani ho tloha ka lehlakoreng le leng ho sebelisa lebone la laser la ultraviolet le matla a phahameng. Lebala lena le tsepamisitsoe botebong ba botebo bo itseng ba ka hare, hangata ho ipapisitse le sebopeho se entsoeng ka boenjiniere, moo ho monya matla ho matlafatsoang ka lebaka la phapang ea optical, thermal, kapa chemical.

Sebakeng sena sa ho monya matla, ho futhumatsa sebakeng se lebisang ho phatloha ho hoholo ka potlako, katoloso ea khase, kapa ho bola ha lesela le kopaneng (mohlala, filimi ea khatello kapa oxide ea sehlabelo). Tšitiso ena e laoloang ka nepo e etsa hore lesela le kaholimo la kristale - le botenya ba mashome a li-micrometer - le tlohe ho ingot ea motheo ka mokhoa o hloekileng.

The Semiconductor Laser Lift-Off Equipment e phahamisa lihlooho tsa ho skena tse tsamaisanang le motsamao, taolo e hlophisitsoeng ea z-axis, le reflectometry ea nako ea 'nete ho netefatsa hore molumo o mong le o mong o fana ka matla hantle sefofaneng se shebiloeng. Thepa e ka hlophisoa ka mokhoa oa ho phatloha kapa oa li-pulse tse ngata ho ntlafatsa boreleli le ho fokotsa khatello ea maikutlo. Habohlokoa, hobane lebone la laser ha le kopane le thepa ka 'mele, kotsi ea ho qhekella, ho inama kapa ho phunya holimo e fokotsehile haholo.

Sena se etsa hore mokhoa oa laser lift-off thinning e fetole papali, haholo-holo lits'ebetsong tseo ho tsona li-wafers tse bataletseng haholo, tse tšesaane haholo li hlokehang ka sub-micron TTV (Total Thickness Variation).

Parameter ea Semiconductor Laser Lift-Off Equipment

| Wavelength | IR/SHG/THG/FHG |

|---|---|

| Pulse Width | Nanosecond, Picosecond, Femtosecond |

| Sistimi ea Optical | Sistimi e tsitsitseng ea optical kapa sistimi ea Galvano-optical |

| Mothati oa XY | 500 limilimithara × 500 limilimithara |

| Tshebetso Range | 160 limilimithara |

| Lebelo la Motsamao | Boholo ba 1,000 mm/sec |

| Pheta-pheta | ±1 μm kapa ka tlase ho moo |

| Boemo bo Nepahetseng ka ho Fetisisa: | ± 5 μm kapa ka tlase |

| Boholo ba Wafer | 2-6 lisenthimithara kapa tse etselitsoeng motho |

| Taolo | Windows 10, 11 le PLC |

| Matla a Phepelo ea Matla | AC 200 V ±20 V, Mokhahlelo o le mong, 50/60 kHz |

| Litekanyo tsa ka ntle | 2400 mm (W) × 1700 mm (D) × 2000 mm (H) |

| Boima ba 'mele | 1,000 lik'hilograma |

Lisebelisoa tsa indasteri ea lisebelisoa tsa Laser Lift-Off

Semiconductor Laser Lift-Off Equipment e fetola ka potlako hore na lisebelisoa li lokisoa joang libakeng tse ngata tsa semiconductor:

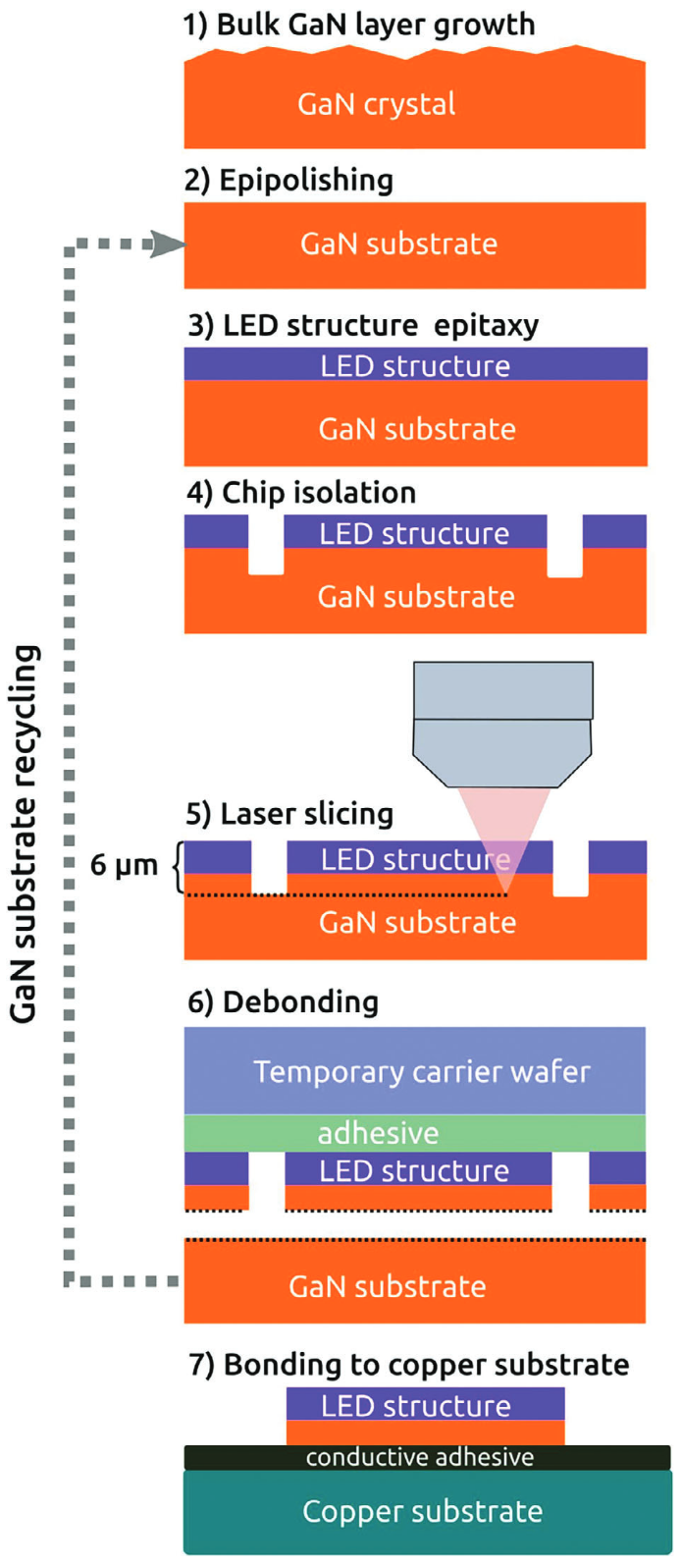

- Lisebelisoa tsa Matla a GaN tse otlolohileng tsa Laser Lift-Off Equipment

Ho phahamisoa ha lifilimi tsa GaN-on-GaN tse tšesaane haholo ho tsoa ho li-ingots tse ngata ho nolofalletsa meralo e emeng e otlolohileng le tšebeliso ea li-substrates tse turang.

- SiC Wafer Thinning bakeng sa Lisebelisoa tsa Schottky le MOSFET

E fokotsa botenya ba lisebelisoa ha e ntse e boloka polanete ea substrate - e loketse lisebelisoa tsa elektroniki tse fetohang ka potlako.

- Lisebelisoa tsa LED tse thehiloeng ho Sapphire le Lisebelisoa tsa Laser Lift-Off Equipment

E thusa karohano e sebetsang hantle ea lilae tsa lisebelisoa ho tloha libouleng tsa safire ho ts'ehetsa tlhahiso e tšesaane, e ntlafalitsoeng ka mocheso oa micro-LED.

- III-V Material Engineering ea Laser Lift-Off Equipment

E thusa ho aroloa ha likarolo tsa GaAs, InP, le AlGaN bakeng sa kopanyo e tsoetseng pele ea optoelectronic.

- Thin-Wafer IC le Sensor Fabrication

E hlahisa likarolo tse tšesaane tse sebetsang bakeng sa li-sensor tsa khatello, li-accelerometer, kapa li-photodiode, moo bongata e leng bothata ba ts'ebetso.

- Motlakase oa Flexible le Transparent Electronics

E lokisa li-substrates tse tšesaane haholo tse loketseng likhalase tse tenyetsehang, li-circuits tse ka roaloang, le lifensetere tse bohlale tse bonaletsang.

Sebakeng se seng le se seng sa libaka tsena, Semiconductor Laser Lift-Off Equipment e bapala karolo ea bohlokoa ho nolofatseng ts'ebetso ea miniaturization, tšebeliso ea thepa hape le ho nolofatsa ts'ebetso.

Lipotso Tse Botsoang Khafetsa (FAQ) ea Lisebelisoa tsa Laser Lift-Off

Q1: Ke botenya bo bokae boo nka bo fihlelang ha ke sebelisa Semiconductor Laser Lift-Off Equipment?

A1:Ka tloaelo pakeng tsa 10-30 microns ho itšetlehile ka thepa. Ts'ebetso e khona ho hlahisa liphetho tse nyane ka li-setups tse fetotsoeng.

Q2: Na see se ka sebelisoa ho arola li-wafers tse ngata ho ingot e le 'ngoe?

A2:Ee. Bareki ba bangata ba sebelisa mokhoa oa ho phahamisa laser ho etsa lits'oants'o tse ngata tse tšesaane tse tsoang ho ingot e le 'ngoe e ngata.

Q3: Ke likarolo life tsa polokeho tse kenyellelitsoeng bakeng sa ts'ebetso ea laser e matla?

A3:Likamore tsa sehlopha sa 1, li-interlock system, tšireletso ea maballo, le li-shutoff tse ikemetseng kaofela ke maemo.

Q4: Sistimi ee e bapisoa joang le lisaha tsa terata ea daemane ho latela litšenyehelo?

A4:Le hoja capex ea pele e ka 'na ea e-ba holimo, laser lift-off haholo e fokotsa litšenyehelo tse ka sebelisoang, tšenyo ea substrate, le mehato ea ka mor'a ho sebetsa - ho theola kakaretso ea litšenyehelo tsa botho (TCO) nako e telele.

Q5: Na ts'ebetso e ka senyeha ho 6-inch kapa 8-inch ingots?

A5:Ruri. Sethala se ts'ehetsa li-substrates tse ka bang 12-inch tse nang le kabo e tšoanang ea maballo le mekhahlelo e meholo ea metsamao.

Mabapi le rona

XKH e sebetsa ka ho khetheha ho nts'etsopele ea theknoloji e phahameng, tlhahiso, le thekiso ea likhalase tse khethehileng tsa optical le lisebelisoa tse ncha tsa kristale. Lihlahisoa tsa rona li fana ka lisebelisoa tsa elektroniki tsa optical, lisebelisoa tsa elektroniki tsa bareki le sesole. Re fana ka lisebelisoa tsa mahlo tsa Sapphire, likoahelo tsa lense tsa mohala oa thekeng, Ceramics, LT, Silicon Carbide SIC, Quartz, le liphaphatha tsa kristale tsa semiconductor. Ka boitseanape bo nang le boiphihlelo le lisebelisoa tse tsoetseng pele, re ipabola ts'ebetsong ea lihlahisoa tse sa tloaelehang, ka sepheo sa ho ba khoebo e etelletseng pele ea theknoloji e phahameng ea optoelectronic.