Semiconductor Laser Lift-Off Equipment Revolutionize Ingot Thinning

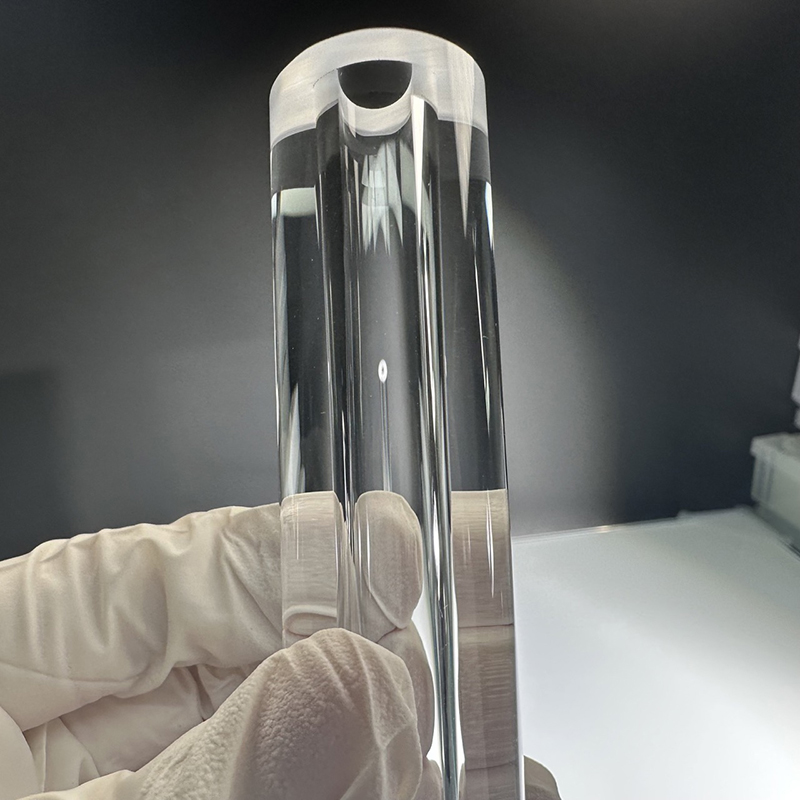

Setšoantšo se qaqileng

Kenyelletso ea Sehlahisoa ea Semiconductor Laser Lift-Off Equipment

Thepa ea Semiconductor Laser Lift-Off Equipment ke tharollo e ikhethang ea indasteri e etselitsoeng ho fokotsa li-ingots tsa semiconductor tse nepahetseng le tse sa amaneng le batho ka mekhoa ea ho phahamisa e hlahisoang ke laser. Sistimi ena e tsoetseng pele e bapala karolo ea bohlokoa mekhoeng ea sejoale-joale ea semiconductor wafering, haholo ha ho etsoa li-wafers tse tšesaane haholo bakeng sa lisebelisoa tsa motlakase tse sebetsang hantle, li-LED le lisebelisoa tsa RF. Ka ho nolofalletsa ho arola likarolo tse tšesaane ho tloha ho li-ingots tse ngata kapa li-substrates tsa bafani, Semiconductor Laser Lift-Off Equipment e fetola mokhoa oa ho sesa ha ingot ka ho felisa mehato ea mechine ea ho sakha, ho sila le ea lik'hemik'hale.

Ho fokotsa ka tloaelo li-ingots tsa semiconductor, joalo ka gallium nitride (GaN), silicon carbide (SiC), le safire, hangata ke mosebetsi o boima, o senya, 'me o atisa ho ba le li-microcracks kapa tšenyo e holim'a metsi. Ka lehlakoreng le leng, Semiconductor Laser Lift-Off Equipment e fana ka mokhoa o sa senyeheng, o nepahetseng o fokotsang tahlehelo ea thepa le khatello ea maikutlo ha o ntse o eketsa tlhahiso. E ts'ehetsa mefuta e mengata e fapaneng ea lisebelisoa tsa kristale le metsoako 'me e ka kopanngoa ka mokhoa o sa tsitsang ho mela ea tlhahiso ea semiconductor e ka pele kapa e bohareng.

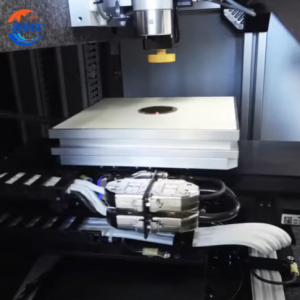

Ka laser wavelengths e lokisehang, litsamaiso tsa ho tsepamisa maikutlo tse feto-fetohang, le li-wafer chucks tse tsamaisanang le vacuum, sesebelisoa sena se loketse ka ho khetheha bakeng sa ho seha ka ingot, popo ea lamella, le pokello ea lifilimi tse tšesaane haholo bakeng sa meaho ea lisebelisoa tse otlolohileng kapa phetiso ea heteroepitaxial layer.

Parameter ea Semiconductor Laser Lift-Off Equipment

| Wavelength | IR/SHG/THG/FHG |

|---|---|

| Pulse Width | Nanosecond, Picosecond, Femtosecond |

| Sistimi ea Optical | Sistimi e tsitsitseng ea optical kapa sistimi ea Galvano-optical |

| Mothati oa XY | 500 limilimithara × 500 limilimithara |

| Tshebetso Range | 160 limilimithara |

| Lebelo la Motsamao | Boholo ba 1,000 mm/sec |

| Pheta-pheta | ±1 μm kapa ka tlase ho moo |

| Boemo bo Nepahetseng ka ho Fetisisa: | ± 5 μm kapa ka tlase |

| Boholo ba Wafer | 2-6 lisenthimithara kapa tse etselitsoeng motho |

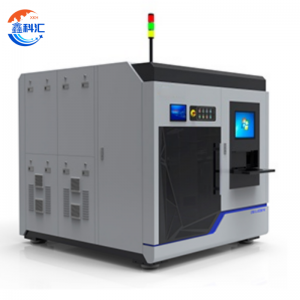

| Taolo | Windows 10, 11 le PLC |

| Matla a Phepelo ea Matla | AC 200 V ±20 V, Mokhahlelo o le mong, 50/60 kHz |

| Litekanyo tsa ka ntle | 2400 mm (W) × 1700 mm (D) × 2000 mm (H) |

| Boima ba 'mele | 1,000 lik'hilograma |

Molao-motheo oa ho sebetsa oa Semiconductor Laser Lift-Off Equipment

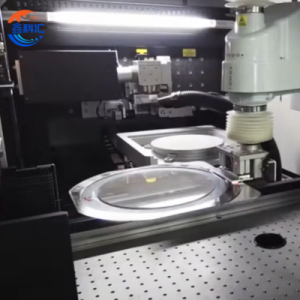

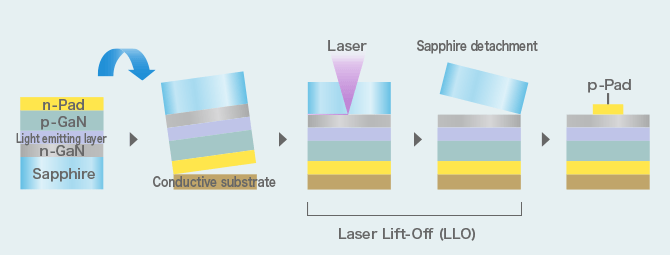

Mochine oa mantlha oa Semiconductor Laser Lift-Off Equipment e itšetlehile ka khetho e khethiloeng ea ho senyeha ha photothermal kapa ablation ho interface pakeng tsa ingot ea mofani le epitaxial kapa target layer. Laser ea matla a phahameng a UV (hangata KrF ho 248 nm kapa li-laser tsa boemo bo tiileng tsa UV ho pota 355 nm) e tsepamisitsoe ka lisebelisoa tsa mofani tse bonaletsang kapa tse bonaletsang, moo matla a monngoang ka boikhethelo ka botebo bo reriloeng esale pele.

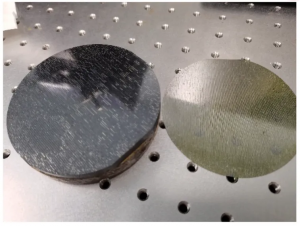

Ho monya matla hoa sebakeng sena ho etsa hore ho be le khatello e phahameng ea khase kapa sekhahla sa katoloso ea mocheso sehokelong, se qalang ho hloekisoa ho hloekileng ha sephaphatha kapa lera la sesebelisoa ho tloha setsing sa ingot. Ts'ebetso e hlophisitsoe hantle ka ho lokisa liparamente tse joalo ka bophara ba pulse, laser fluence, lebelo la ho hlahloba, le botebo ba z-axis. Sephetho ke selae se tšesaane haholo-hangata se fihlang ho 10 ho isa ho 50 µm-se arohaneng hantle ho tsoa ho engot ea motsoali ntle le ho khojoa ka mochini.

Mokhoa ona oa ho phahamisa laser bakeng sa ho fokotsa ingot o qoba tahlehelo ea kerf le tšenyo ea bokaholimo e amanang le sakha ea terata ea daemane kapa ho phuphusela ka mochini. E boetse e boloka botšepehi ba kristale le ho fokotsa litlhoko tsa ho pholisa ka tlaase, ho etsa Semiconductor Laser Lift-Off Equipment e le sesebelisoa sa ho fetola papali bakeng sa tlhahiso ea liphaphatha tsa moloko o latelang.

Lisebelisoa tsa Semiconductor Laser Lift-Off Equipment

Semiconductor Laser Lift-Off Equipment e fumana ts'ebeliso e pharalletseng ho ingot thinning ho pholletsa le mefuta e mengata ea lisebelisoa tse tsoetseng pele le mefuta ea lisebelisoa, ho kenyelletsa:

-

GaN le GaAs Ingot Thinning bakeng sa Lisebelisoa tsa Matla

E thusa ho etsa li-wafer tse tšesaane bakeng sa ts'ebetso e phahameng, li-transistors tsa matla a hanang hanyane le diode.

-

SiC Substrate Reclamation le Lamella Separation

E lumella ho phahamisoa hoa li-wafer-scale ho tloha ho li-substrate tsa SiC tse ngata bakeng sa meaho e emeng ea lisebelisoa le tšebeliso ea liphaphatha hape.

-

Sekhahla sa LED

E thusa ho phahamisa likarolo tsa GaN ho tloha ho li-ingots tse teteaneng tsa safire ho hlahisa li-substrates tsa LED tse tšesaane haholo.

-

RF le Microwave Device Fabrication

E ts'ehetsa li-ultra-thin high-electron-mobility transistor (HEMT) tse hlokahalang ho 5G le litsamaiso tsa radar.

-

Epitaxial Layer Transfer

E qolla ka nepo likarolo tsa epitaxial ho li-ingots tsa crystalline bakeng sa ho sebelisoa hape kapa ho kopanngoa ho li-heterostructures.

-

Lisele tsa letsatsi tse Thin-Film le li-Photovoltaics

E sebelisoa ho arola likarolo tse tšesaane tsa li-absorber bakeng sa lisele tsa letsatsi tse tenyetsehang kapa tse sebetsang hantle haholo.

Sebakeng se seng le se seng sa libaka tsena, Semiconductor Laser Lift-Off Equipment e fana ka taolo e ke keng ea lekanngoa holim'a ho lekana ha botenya, boleng ba bokaholimo le botšepehi ba lera.

Melemo ea Laser-Thehiloeng Ingot Thinning

-

Tahlehelo ea Lintho tsa Zero-Kerf

Ha ho bapisoa le mekhoa ea setso ea ho seha liphaephe, mokhoa oa laser o fella ka tšebeliso ea thepa e ka bang 100%.

-

Khatello e Nyenyane le Warping

Phahamiso e sa amaneng le motho e felisa ho thothomela ha mochini, ho fokotsa seqha sa liphaephe le sebopeho sa microcrack.

-

Paballo ea Boleng ba Bokaholimo

Ha ho hlokahale ho roala ka morao kapa ho bentša maemong a mangata, kaha laser lift-off e boloka botšepehi bo holimo.

-

Phahamiso e Phahameng le Boikemisetso ba Boiketsetso

E khona ho sebetsana le li-substrates tse makholo nako le nako ka ho kenya / ho laolla ka boiketsetso.

-

E Ikamahanya le Lintho Tse Ngata

E lumellana le GaN, SiC, safire, GaAs, le lisebelisoa tse hlahang tsa III-V.

-

E Sireletsehileng Tikolohong

E fokotsa ts'ebeliso ea li-abrasives le lik'hemik'hale tse bohale tse tloaelehileng lits'ebetsong tsa thinning tse thehiloeng ho slurry.

-

Tšebeliso ea Substrate hape

Li-ingots tsa bafani li ka sebelisoa hape bakeng sa li-cycles tse ngata tsa ho phahamisa, ho fokotsa litšenyehelo tsa thepa haholo.

Lipotso Tse Botsoang Khafetsa (FAQ) ea Semiconductor Laser Lift-Off Equipment

-

Q1: Ke mofuta ofe oa botenya oo Semiconductor Laser Lift-Off Equipment e ka o fihlelang bakeng sa lilae tsa wafer?

A1:Botenya bo tloaelehileng ba selae bo tloha ho 10 µm ho isa ho 100 µm ho ipapisitsoe le thepa le tlhophiso.Q2: Na lisebelisoa tsee li ka sebelisoa ho etsa li-ingots tse tšesaane tse entsoeng ka lisebelisoa tse opaque joalo ka SiC?

A2:Ee. Ka ho lokisa laser wavelength le ho ntlafatsa boenjineri ba sehokelo (mohlala, li-interlayers tsa sehlabelo), esita le lisebelisoa tse sa boneng hantle li ka sebetsoa.Q3: Karolo ea bafani e hokahana joang pele ho phahamisoa ha laser?

A3:Sistimi e sebelisa li-module tsa alignment tse thehiloeng ponong ea sub-micron tse nang le maikutlo a tsoang ho matšoao a fiducial le liskena tsa ho bonahatsa bokaholimo.Q4: Nako e lebelletsoeng ea potoloho bakeng sa ts'ebetso e le 'ngoe ea laser lift-off ke efe?

A4:Ho ipapisitse le boholo ba liphaephe le botenya, lipotoloho tse tloaelehileng li nka metsotso e 2 ho isa ho e 10.Q5: Na ts'ebetso e hloka tikoloho e hloekileng ea kamore?

A5:Le hoja e sa tlamehe, ho kopanngoa ha kamore e hloekileng ho khothalletsoa ho boloka bohloeki ba substrate le lihlahisoa tsa lisebelisoa nakong ea ts'ebetso e nepahetseng haholo.

Mabapi le rona

XKH e sebetsa ka ho khetheha ho nts'etsopele ea theknoloji e phahameng, tlhahiso, le thekiso ea likhalase tse khethehileng tsa optical le lisebelisoa tse ncha tsa kristale. Lihlahisoa tsa rona li fana ka lisebelisoa tsa elektroniki tsa optical, lisebelisoa tsa elektroniki tsa bareki le sesole. Re fana ka lisebelisoa tsa mahlo tsa Sapphire, likoahelo tsa lense tsa mohala oa thekeng, Ceramics, LT, Silicon Carbide SIC, Quartz, le liphaphatha tsa kristale tsa semiconductor. Ka boitseanape bo nang le boiphihlelo le lisebelisoa tse tsoetseng pele, re ipabola ts'ebetsong ea lihlahisoa tse sa tloaelehang, ka sepheo sa ho ba khoebo e etelletseng pele ea theknoloji e phahameng ea optoelectronic.