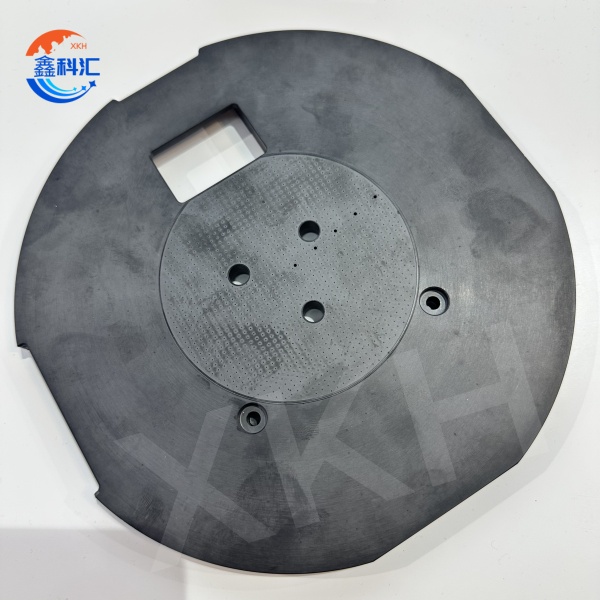

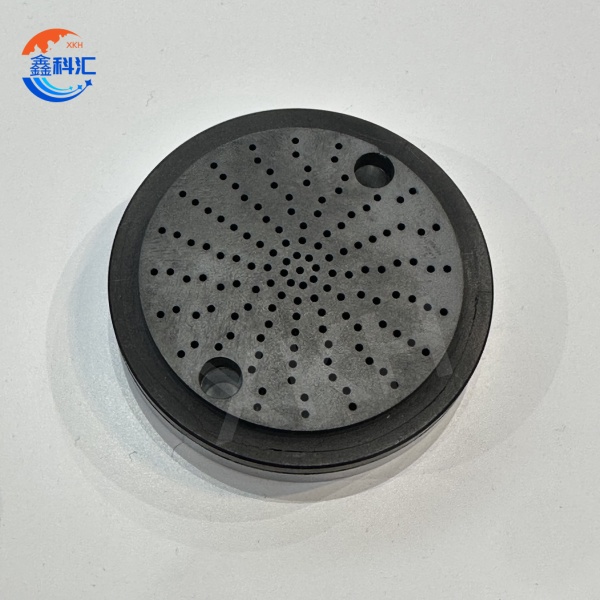

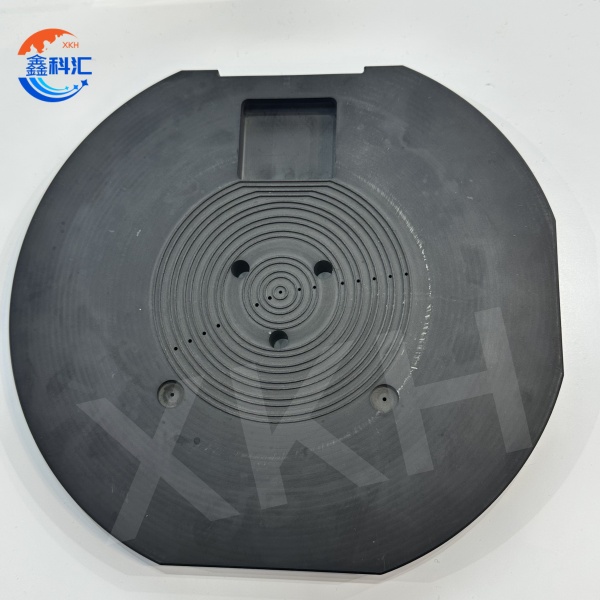

SiC ceramic chuck tray Ceramic suction cups ho sebetsa ka mokhoa o ikhethileng

Litšobotsi tsa lintho tse bonahalang:

1.Bothata bo phahameng: boima ba Mohs ba silicon carbide ke 9.2-9.5, ea bobeli ho ea ho daemane, e nang le khanyetso e matla ea ho apara.

2. Mocheso o phahameng oa mocheso: mocheso oa mocheso oa silicon carbide o ka holimo ho 120-200 W / m · K, o ka senyang mocheso ka potlako 'me o loketse tikoloho e phahameng ea mocheso.

3. Coefficient e tlaase ea ho atolosa mocheso: silicon carbide katoloso ea mocheso oa mocheso o tlaase (4.0-4.5 × 10⁻⁶/K), o ntse o ka boloka botsitso ba dimensional mocheso o phahameng.

4. Ho tsitsa ha lik'hemik'hale: silicon carbide acid le alkali corrosion resistance, e loketseng ho sebelisoa tikolohong ea lik'hemik'hale tse senyang.

5. Matla a phahameng a mochine: silicon carbide e na le matla a holimo a ho kobeha le matla a ho hatella, 'me e khona ho mamella khatello e kholo ea mochine.

Likaroloana:

1.Ka indastering ea semiconductor, li-wafers tse tšesaane haholo li hloka ho beoa holim'a mohope oa ho huloa ka vacuum, mochini oa vacuum suction o sebelisetsoa ho lokisa liphaephe, 'me mokhoa oa ho tlotsa, ho tšesa, ho oka, ho hloekisa le ho itšeha o etsoa holim'a li-wafers.

2.Silicon carbide sucker e na le conductivity e ntle ea mocheso, e ka khutsufatsa ka katleho nako ea waxing le waxing, ho ntlafatsa katleho ea tlhahiso.

3.Silicon carbide vacuum sucker e boetse e na le acid e ntle le khanyetso ea kutu ea alkali.

4.Ha ho bapisoa le sejana sa setso sa corundum carrier, khutsufatsa ho futhumatsa le ho theola mocheso le nako ea ho pholile, ho ntlafatsa katleho ea mosebetsi; Ka nako e ts'oanang, e ka fokotsa ho apara pakeng tsa lipoleiti tse ka holimo le tse tlaase, ho boloka ho nepahala ha sefofane se setle, le ho lelefatsa bophelo ba tšebeletso ka hoo e ka bang 40%.

5.Tekanyo ea thepa e nyenyane, boima bo bobebe. Ho bonolo hore basebetsi ba nke liphalete, ho fokotsa kotsi ea ho thulana ho bakoang ke mathata a lipalangoang ka hoo e ka bang 20%.

6.Size: bophara bo boholo ba 640mm; Flatness: 3um kapa ka tlase

Sebaka sa kopo:

1. Ho etsa semiconductor

● Ho sebetsa ka Wafer:

Bakeng sa ho lokisoa ha wafer ho photolithography, etching, deposition e tšesaane ea filimi le lits'ebetso tse ling, ho netefatsa ho nepahala ho phahameng le ts'ebetso e tsitsitseng. Mocheso oa eona o phahameng le khanyetso ea kutu e loketse maemo a thata a tlhahiso ea semiconductor.

● Epitaxial growth:

Ka SiC kapa GaN epitaxial kgolo, e le sejari sa mocheso le ho lokisa li-wafers, ho netefatsa ho tšoana ha mocheso le boleng ba kristale ka mocheso o phahameng, ho ntlafatsa tshebetso ea lisebelisoa.

2. Thepa ea motlakase ea lifoto

●Manufacturing LED:

E sebelisetsoa ho lokisa sapphire kapa SiC substrate, 'me e le mochine o futhumatsang ka mokhoa oa MOCVD, ho netefatsa hore ho tšoana ha kholo ea epitaxial, ho ntlafatsa katleho e khanyang ea LED le boleng.

●Laser diode:

Joalo ka mokhoa o phahameng oa ho nepahala, ho lokisa le ho futhumatsa substrate ho netefatsa botsitso ba mocheso oa ts'ebetso, ho ntlafatsa matla a tlhahiso le ho ts'epahala ha laser diode.

3. Ho sebetsa ka mokhoa o nepahetseng

● Optical component process:

E sebelisetsoa ho lokisa likarolo tse nepahetseng tse kang lilense tsa optical le li-filters ho netefatsa ho nepahala ho phahameng le tšilafalo e tlaase nakong ea ts'ebetso, 'me e loketse bakeng sa machining a phahameng haholo.

● Ho sebetsa ka Ceramic:

Joalo ka sebopeho se phahameng sa botsitso, se loketse bakeng sa machining a nepahetseng a lisebelisoa tsa ceramic ho netefatsa ho nepahala ha machining le ho tsitsa tlas'a mocheso o phahameng le tikoloho e senyang.

4. Liteko tsa mahlale

●Teko ea mocheso o phahameng:

Joalo ka sesebelisoa sa ho lokisa sampole maemong a mocheso o phahameng, se ts'ehetsa liteko tse feteletseng tsa mocheso ho feta 1600 ° C ho netefatsa ho ts'oana ha mocheso le botsitso ba sampole.

●Teko ea Vacuum:

E le mohlala oa ho lokisa le ho futhumatsa sejari sebakeng sa vacuum, ho etsa bonnete ba ho nepahala le ho pheta-pheta ha teko, e loketseng ho koahela le ho phekola mocheso.

Lintlha tsa tekheniki:

| (Thepa) | (Yuniti) | (sic) | |

| (Litaba tsa SiC) |

| (Wt)% | >99 |

| (Karolelano ea boholo ba lijo-thollo) |

| micron | 4-10 |

| (Density) |

| kg/dm3 | >3.14 |

| (Ho bonahala porosity) |

| Vo1% | <0.5 |

| (Vickers hardness) | HV 0.5 | GPA | 28 |

| *(Matla a flexural) | 20ºC | MPa | 450 |

| (Matla a hatellang) | 20ºC | MPa | 3900 |

| (Modulus ea Elastic) | 20ºC | GPA | 420 |

| (Bothata ba ho robeha) |

| MPa/m'% | 3.5 |

| (Thermal conductivity) | 20°C | W/(m*K) | 160 |

| (Ho hanyetsa) | 20°C | Ohm.cm | 106-108 |

|

| a(RT**...80ºC) | K-1*10-6 | 4.3 |

|

|

| oºC | 1700 |

Ka lilemo tsa ho bokella tekheniki le boiphihlelo ba indasteri, XKH e khona ho hlophisa likarolo tsa bohlokoa joalo ka boholo, mokhoa oa ho futhumatsa le moralo oa vacuum adsorption ea chuck ho latela litlhoko tse ikhethang tsa moreki, ho etsa bonnete ba hore sehlahisoa se ikamahanya hantle le ts'ebetso ea moreki. Li-chucks tsa ceramic tsa SiC silicon carbide li fetohile likarolo tsa bohlokoa haholo ts'ebetsong ea li-wafer, kholo ea epitaxial le mekhoa e meng ea bohlokoa ka lebaka la conductivity ea tsona e ntle ea mocheso, botsitso bo phahameng ba mocheso le botsitso ba lik'hemik'hale. Haholo-holo ha ho etsoa thepa ea semiconductor ea moloko oa boraro joalo ka SiC le GaN, tlhoko ea li-chucks tsa silicon carbide ceramic e ntse e hola. Nakong e tlang, ka tsoelo-pele e potlakileng ea 5G, likoloi tsa motlakase, bohlale ba maiketsetso le mahlale a mang, litebello tsa ts'ebeliso ea silicon carbide ceramic chucks indastering ea semiconductor e tla ba kholo.

Setšoantšo se qaqileng