SiC ceramic plate/tray bakeng sa 4inch 6inch wafer holder bakeng sa ICP

SiC ceramic plate Abstract

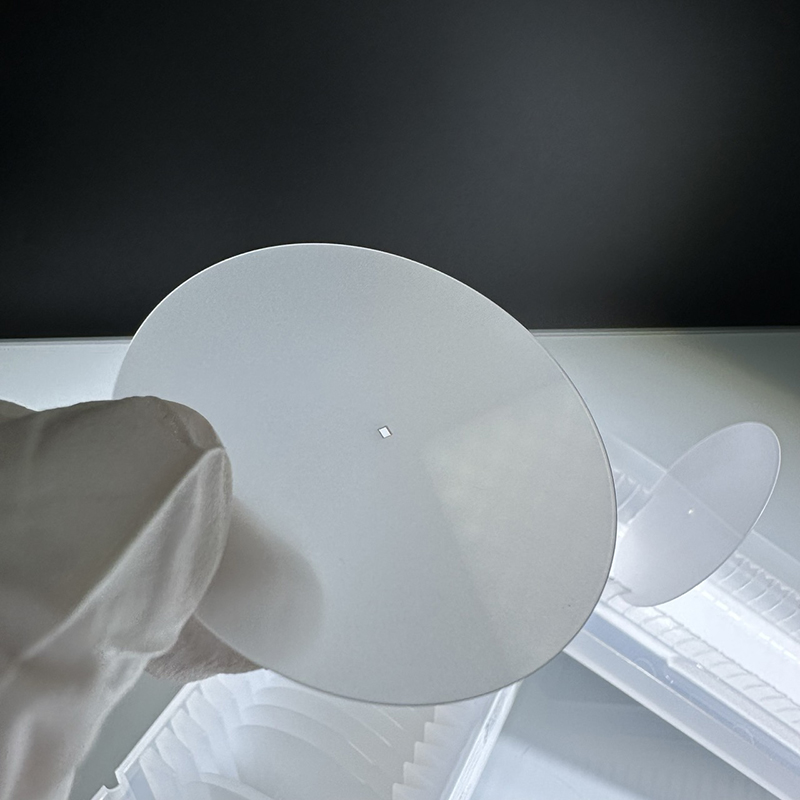

SiC ceramic plate ke karolo ea ts'ebetso e phahameng e entsoeng ka Silicon Carbide ea boleng bo holimo, e etselitsoeng ho sebelisoa libakeng tse futhumetseng haholo, tsa lik'hemik'hale le tsa mochini. E tsebahala ka ho thatafala ha eona ho ikhethang, ho tsamaisa mocheso, le ho hanyetsa kutu, poleiti ea SiC e sebelisoa haholo e le sejari sa liphaephe, susceptor, kapa karolo ea meralo indastering ea semiconductor, LED, photovoltaic le aerospace.

Ka botsitso bo ikhethang ba mocheso ho fihlela ho 1600 ° C le khanyetso e ntle ea likhase tse sebetsang le maemo a plasma, poleiti ea SiC e netefatsa ts'ebetso e ts'oanang nakong ea ts'ebetso e phahameng ea mocheso, ho beha le ho hasana. Microstructure ea eona e teteaneng, e se nang porous e fokotsa tlhahiso ea likaroloana, e etsa hore e be e loketseng bakeng sa lits'ebetso tse hloekileng haholo ka har'a vacuum kapa litlhophiso tsa kamore e hloekileng.

SiC ceramic plate Kopo

1. Semiconductor Manufacturing

Lipoleiti tsa ceramic tsa SiC hangata li sebelisoa e le li-wafer carriers, susceptors, le pedestal plates in the semiconductor fabrication equipments tse kang CVD (Chemical Vapor Deposition), PVD (Physical Vapor Deposition), le etching systems. Ts'ebetso ea bona e ntle ea mocheso le katoloso e tlase ea mocheso li li lumella ho boloka kabo e ts'oanang ea mocheso, e leng bohlokoa bakeng sa ts'ebetso e nepahetseng ea li-wafer. Ho hanyetsa ha SiC ho likhase tse senyang le plasmas ho tiisa ho tšoarella libakeng tse thata, ho thusa ho fokotsa tšilafalo ea likaroloana le tlhokomelo ea lisebelisoa.

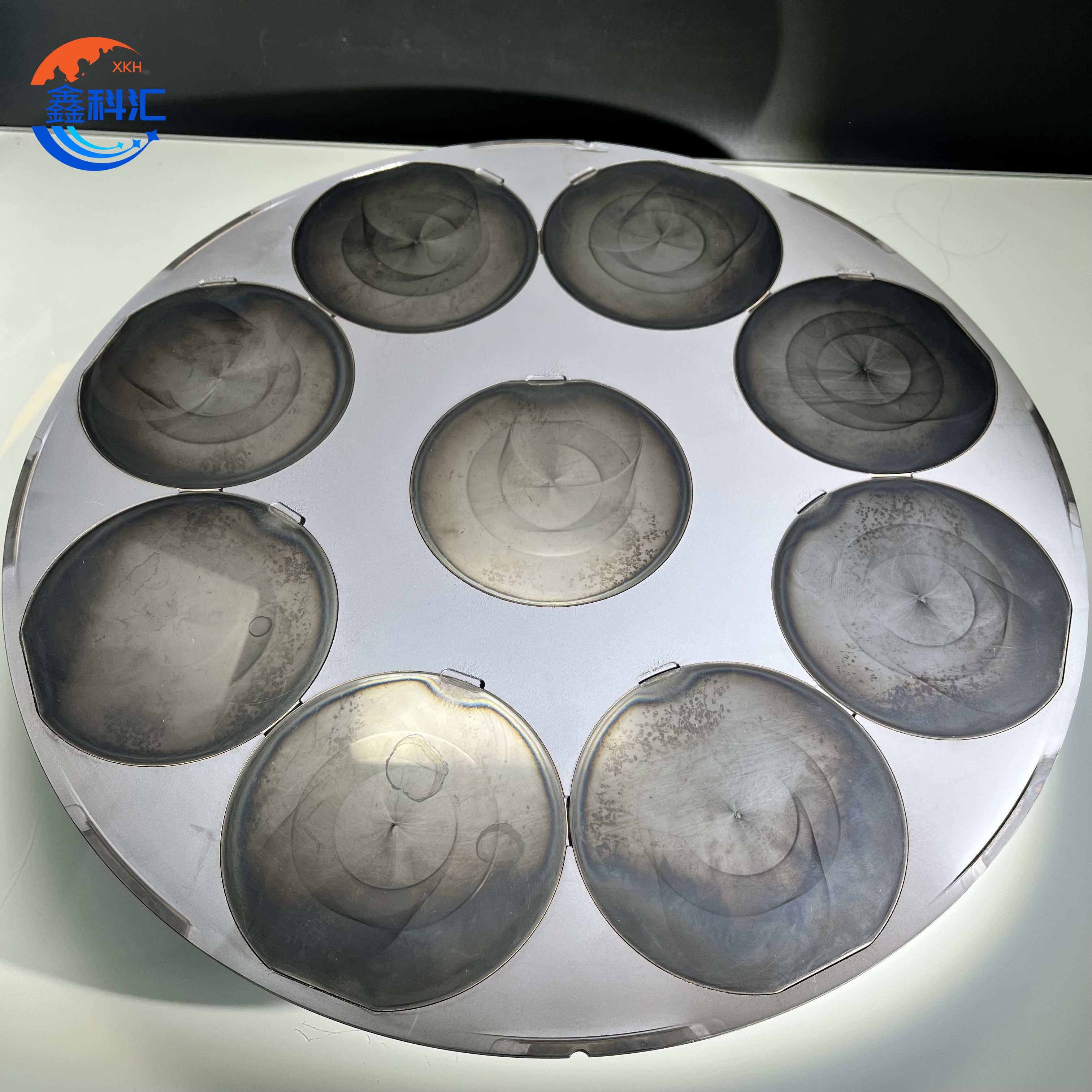

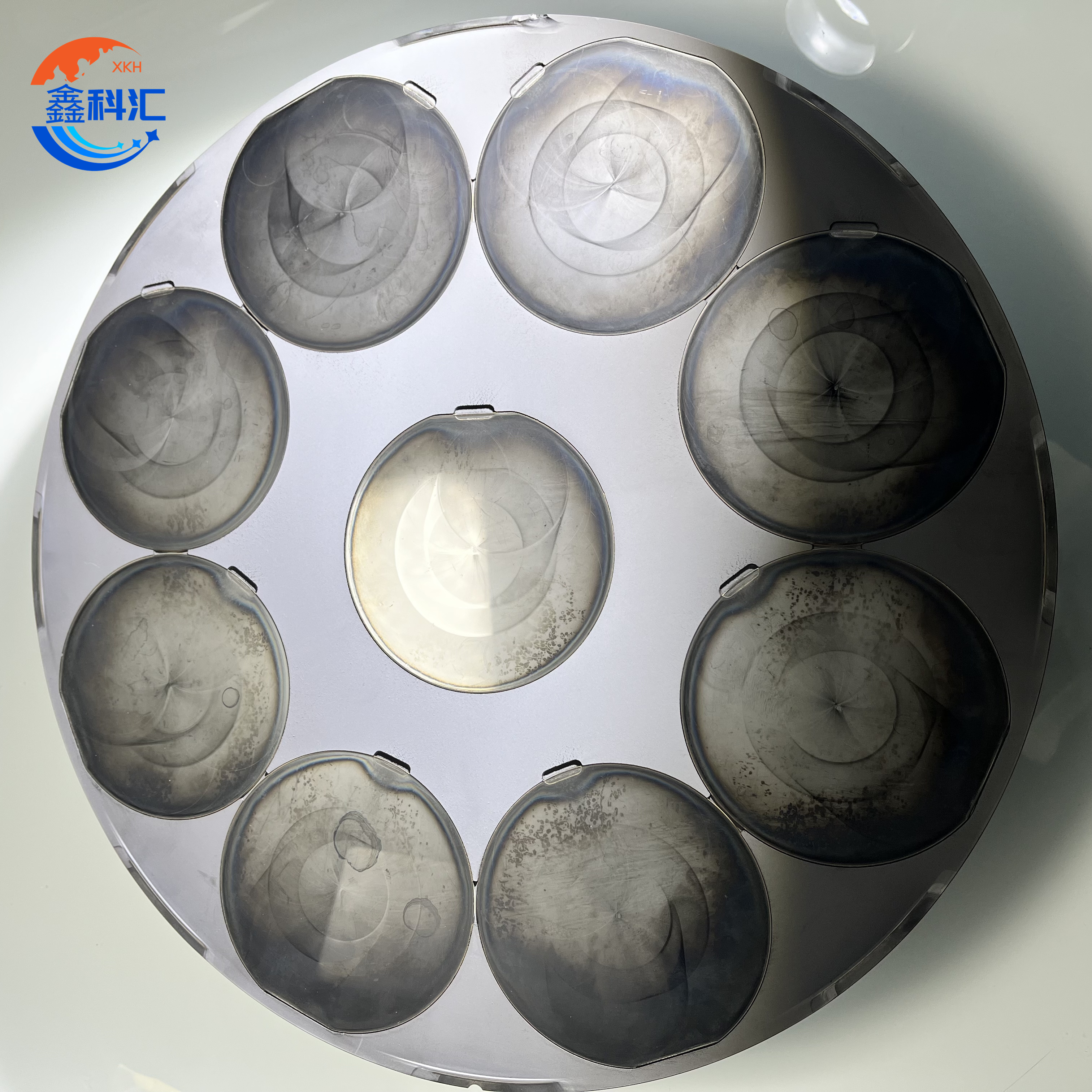

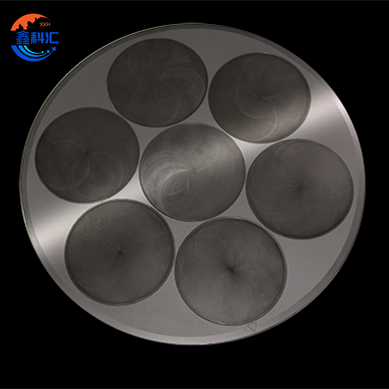

2. Indasteri ea LED - ICP Etching

Lefapheng la tlhahiso ea LED, lipoleiti tsa SiC ke likarolo tsa bohlokoa ho ICP (Inductively Coupled Plasma) etching system. E sebetsa e le li-wafer holders, li fana ka sethala se tsitsitseng le se matla sa mocheso ho tšehetsa li-sapphire kapa GaN wafers nakong ea ts'ebetso ea plasma. Ho hanyetsa ha bona ka plasma e ntle, ho bata ha bokaholimo, le botsitso ba sebopeho li thusa ho netefatsa ho nepahala le ho ts'oana ho hoholo, ho lebisang keketsehong ea chai le ts'ebetso ea lisebelisoa ho li-chips tsa LED.

3. Photovoltaics (PV) le Matla a Letsatsi

Lipoleiti tsa ceramic tsa SiC li boetse li sebelisoa tlhahisong ea lisele tsa letsatsi, haholo-holo nakong ea mocheso o phahameng oa mocheso le mehato ea ho koala. Ho se sebetse ha bona mochesong o phahameng le bokhoni ba ho hanela warping ho netefatsa ts'ebetso e tsitsitseng ea li-wafers tsa silicon. Ho feta moo, kotsi ea bona e tlase ea tšoaetso ke ea bohlokoa bakeng sa ho boloka bokhoni ba lisele tsa photovoltaic.

SiC ceramic plate Properties

1. Matla a Ikhethang a Mechini le ho Thatafala

Lipoleiti tsa ceramic tsa SiC li bonts'a matla a holimo haholo a mochini, a nang le matla a tloaelehileng a ho feto-fetoha a fetang 400 MPa le Vickers boima bo fihlang> 2000 HV. Sena se ba etsa hore ba se ke ba hlola ba apara ka mokhoa o ts'oanelang, ho senyeha le ho senyeha, ho netefatsa bophelo bo bolelele ba tšebeletso leha ba le tlas'a moroalo o mongata kapa baesekele e futhumatsang khafetsa.

2. High Thermal Conductivity

SiC e na le conductivity e ntle ea mocheso (hangata 120–200 W/m·K), e e lumellang hore e arole mocheso ka ho lekana hohle holim'a eona. Thepa ena e bohlokoa lits'ebetsong tse kang li-wafer etching, deposition, kapa sintering, moo ho lumellana ha mocheso ho amang tlhahiso le boleng ba sehlahisoa ka kotloloho.

3. Phahameng ka ho Fetisisa Thermal Stability

Ka ntlha e phahameng ea ho qhibiliha (2700 ° C) le coefficient e tlaase ea ho atolosa mocheso (4.0 × 10⁻⁶/K), lipoleiti tsa SiC ceramic li boloka ho nepahala ha dimensional le botšepehi ba sebopeho tlas'a mocheso o potlakileng le oa ho pholisa. Sena se etsa hore e be tse loketseng bakeng sa lits'ebetso tsa libopi tsa mocheso o phahameng, likamore tsa vacuum le tikoloho ea plasma.

| Theknoloji Thepa | ||||

| Index | Yuniti | Boleng | ||

| Lebitso la Boitsebiso | Reaction Sintered Silicon Carbide | Pressureless Sintered Silicon Carbide | Recrystallized Silicon Carbide | |

| Sebopeho | RBSiC | SSiC | R-SiC | |

| Boima ba Bongata | g/cm3 | 3 | 3.15 ± 0.03 | 2.60-2,70 |

| Flexural Matla | MPa (kpsi) | 338(49) | 380(55) | 80-90 (20°C) 90-100(1400°C) |

| Matla a Khatellang | MPa (kpsi) | 1120(158) | 3970(560) | > 600 |

| Ho thatafala | Knoop | 2700 | 2800 | / |

| Qetello e Fetang | MPa m1/2 | 4.5 | 4 | / |

| Thermal Conductivity | W/mk | 95 | 120 | 23 |

| Coefficient ea Katoloso ea Thermal | 10-6.1/°C | 5 | 4 | 4.7 |

| Mocheso o khethehileng | Joule/g 0k | 0.8 | 0.67 | / |

| Mocheso o moholo moeeng | ℃ | 1200 | 1500 | 1600 |

| Elastic modulus | GPA | 360 | 410 | 240 |

SiC ceramic plate Q&A

Q: Ke thepa efe ea silicon carbide plate?

A: Lipoleiti tsa Silicon carbide (SiC) li tsejoa ka matla a tsona a phahameng, boima le botsitso ba mocheso. Ba fana ka conductivity e babatsehang ea mocheso le katoloso e tlaase ea mocheso, ho netefatsa ts'ebetso e ka tšeptjoang tlas'a mocheso o feteletseng. SiC e boetse e na le lik'hemik'hale, e hanyetsanang le li-acids, alkalis, le tikoloho ea plasma, e etsang hore e be e loketseng bakeng sa semiconductor le ts'ebetso ea LED. Sebaka sa eona se teteaneng, se boreleli se fokotsa ho hlahisa likaroloana, ho boloka ho lumellana ha kamore e hloekileng. Lipoleiti tsa SiC li sebelisoa haholo e le bajari ba li-wafer, li-susceptors, le likarolo tsa ts'ehetso libakeng tse phahameng tsa mocheso le tse senyang ho pholletsa le indasteri ea semiconductor, photovoltaic le aerospace.