SiC Ceramic Tray ea Wafer Carrier e nang le khanyetso e phahameng ea mocheso

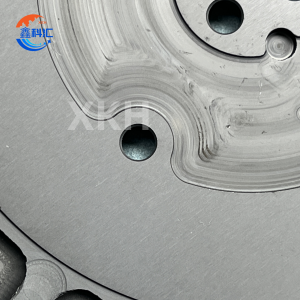

Terei ea Ceramic ea Silicon Carbide (SiC Tray).

Karolo e phahameng ea ts'ebetso ea ceramic e thehiloeng holim'a thepa ea silicon carbide (SiC), e entsoeng bakeng sa lisebelisoa tse tsoetseng pele tsa indasteri tse kang tlhahiso ea semiconductor le tlhahiso ea LED. Mesebetsi ea eona ea mantlha e kenyelletsa ho sebetsa e le sejari sa liphaephe, sethala sa ts'ebetso ea etching, kapa ts'ehetso ea ts'ebetso ea mocheso o phahameng, ho fana ka ts'ebetso e ikhethang ea mocheso, ho hanyetsa mocheso o phahameng, le botsitso ba lik'hemik'hale ho netefatsa ts'ebetso e ts'oanang le lihlahisoa tsa lihlahisoa.

Lintlha tsa bohlokoa

1. Thermal Performance

- High Thermal Conductivity: 140–300 W/m·K, e fetang haholo graphite e tlwaelehileng (85 W/m·K), e thusang ho qhalana ha mocheso ka potlako le ho fokotsa kgatello ya mocheso.

- Thermal Expansion Coefficient: 4.0×10⁻⁶/℃ (25–1000℃), e bapisang silicon e haufi (2.6×10⁻⁶/℃), e fokotsang likotsi tsa ho senyeha ha mocheso.

2. Thepa ea Mechanical

- Matla a Phahameng: Matla a Flexural ≥320 MPa (20 ℃), e hanyetsanang le khatello le tšusumetso.

- Matla a Phahameng: Mohs hardness 9.5, ea bobeli ho daemane, e fanang ka khanyetso e phahameng ea ho apara.

3. Ho tsitsa ha lik'hemik'hale

- Corrosion Resistance: E hanana le li-acid tse matla (mohlala, HF, H₂SO₄), e loketseng maemo a ts'ebetso ea etching.

- Non-Magnetic: Ts'oaetso ea makenete ea kahare <1×10⁻⁶ emu/g, ho qoba ho kena-kenana le lisebelisoa tse nepahetseng.

4. Mamello e Feteletseng ea Tikoloho

- Ho tšoarella ha Mocheso o Phahameng: Mocheso oa nako e telele oa ts'ebetso ho fihlela ho 1600-1900 ℃; khanyetso ea nako e khuts'oane ho fihla ho 2200 ℃ (tikoloho e se nang oksijene).

- Thermal Shock Resistance: E mamella liphetoho tsa tšohanyetso tsa mocheso (ΔT> 1000℃) ntle le ho phatloha.

Lisebelisoa

| Sebaka sa Likopo | Specific Scenarios | Boleng ba Tekheniki |

| Tlhahiso ea Semiconductor | Wafer etching (ICP), tšesaane-filimi deposition (MOCVD), CMP polishing | Boima bo phahameng ba mocheso bo tiisa hore ho na le libaka tse tšoanang tsa mocheso; katoloso e tlase ea mocheso e fokotsa leqephe la wafer. |

| Tlhahiso ea LED | Khōlo ea Epitaxial (mohlala, GaN), li-wafer dicing, ho paka | E hatella mefokolo ea mefuta e mengata, e ntlafatsa ts'ebetso e khanyang ea LED le nako ea bophelo. |

| Indasteri ea Photovoltaic | Lisebelisoa tsa silicon wafer sintering, lisebelisoa tsa PECVD li tšehetsa | Mocheso o phahameng le ho hanyetsa mocheso oa mocheso o eketsa nako ea bophelo ba lisebelisoa. |

| Laser & Optics | Li-substrates tse futhumatsang tsa laser tse matla, li tšehetsa sistimi ea optical | Mocheso o phahameng oa mocheso o nolofalletsa ho senya mocheso ka potlako, ho tsitsisa likarolo tsa optical. |

| Lisebelisoa tsa Analytical | TGA/DSC ba nang le sampole | Mocheso o tlase le karabo e potlakileng ea mocheso li ntlafatsa ho lekanya ho nepahala. |

Melemo ea Sehlahisoa

- Ts'ebetso e Felletseng: Ts'ebetso ea mocheso, matla, le ho hanyetsa kutu ho feta lirafshoa tsa alumina le silicon nitride, tse fihlelang litlhoko tse feteletseng tsa ts'ebetso.

- Moralo oa Boima bo Bobebe: Boima ba 3.1–3.2 g/cm³ (40% ea tšepe), e fokotsang boima ba 'mele le ho ntlafatsa ho nepahala ha motsamao.

- Nako e telele le ho ts'epahala: Bophelo ba ts'ebeletso bo feta lilemo tse 5 ho 1600 ℃, ho fokotsa nako ea ho theola le ho theola litšenyehelo tsa ts'ebetso ka 30%.

- Itokisetso: E ts'ehetsa li-geometri tse rarahaneng (mohlala, likomiki tse monyang tse nang le li-porous, li-tray tse nang le likarolo tse ngata) tse nang le phoso ea ho batalla <15 μm bakeng sa lits'ebetso tse nepahetseng.

Litlhaloso tsa Tekheniki

| Sehlopha sa Parameter | Letšoao |

| Thepa ea 'Mele | |

| Botenya | ≥3.10 g/cm³ |

| Flexural Strength (20℃) | 320–410 MPa |

| Thermal Conductivity (20 ℃) | 140–300 W/(m·K) |

| Mocheso oa Katoloso ea Mocheso (25–1000℃) | 4.0×10⁻⁶/℃ |

| Thepa ea lik'hemik'hale | |

| Ho hanyetsa Acid (HF/H₂SO₄) | Ha ho kutu ka mor'a ho qoelisoa ka lihora tse 24 |

| Machining Precision | |

| Bophatlalatsi | ≤15 μm (300×300 limilimithara) |

| Bokhopo ba Sefahleho (Ra) | ≤0.4 μm |

Litšebeletso tsa XKH

XKH e fana ka litharollo tse felletseng tsa indasteri tse mabapi le nts'etsopele ea moetlo, machining a nepahetseng, le taolo e matla ea boleng. Bakeng sa nts'etsopele ea moetlo, e fana ka tharollo ea lisebelisoa tsa bohloeki bo phahameng (> 99.999%) le porous (30-50% porosity), e kopantsoeng le mohlala oa 3D le papiso ho ntlafatsa li-geometri tse rarahaneng bakeng sa lits'ebetso tse kang li-semiconductors le sefofane. Ho sebetsa ka mokhoa o nepahetseng ho latela mokhoa o hlophisitsoeng: ho sebetsa ka phofo → ho hatella ka isostatic/dry → 2200°C sintering → CNC/diamond grinding → tlhahlobo, ho netefatsa hore nanometer-level polishing le ±0.01 mm dimensional mamello. Taolo ea boleng e kenyelletsa tlhahlobo ea ts'ebetso e felletseng (sebopeho sa XRD, sebopeho sa SEM, ho kobeha lintlha tse 3) le tšehetso ea tekheniki (ts'ebetso ea ts'ebetso, lipuisano tsa 24/7, tlhahiso ea sampole ea lihora tse 48), ho fana ka likarolo tse tšepahalang, tse sebetsang hantle bakeng sa litlhoko tse tsoetseng pele tsa indasteri.

Lipotso tse atisang ho botsoa (FAQ)

1. Q: Ke liindasteri life tse sebelisang literei tsa silicon carbide ceramic?

A: E sebelisoa haholo tlhahisong ea li-semiconductor (ho sebetsana le li-wafer), matla a letsatsi (mekhoa ea PECVD), lisebelisoa tsa bongaka (likarolo tsa MRI), le sebaka sa sefofane (likarolo tse phahameng tsa mocheso) ka lebaka la ho hanyetsa mocheso o feteletseng le botsitso ba lik'hemik'hale.

2. P: Ke joang silicon carbide e fetang quartz/glass trays?

A: Ho hanyetsa mocheso o phahameng oa mocheso (ho fihla ho 1800 ° C vs. quartz's 1100 ° C), tšitiso ea zero magnetic, le nako e telele ea bophelo (lilemo tse 5+ khahlanong le likhoeli tse 6-12 tsa quartz).

3. P: Na literei tsa silicon carbide li khona ho sebetsana le maemo a asiti?

A: Ho joalo. E hanyetsana le HF, H2SO4, le NaOH ka <0.01mm corrosion/selemo, e li etsang hore e be tse loketseng bakeng sa ho hloekisa lik'hemik'hale le ho hloekisa liphaphatha.

4. P: Na literei tsa silicon carbide lia lumellana le boiketsetso?

A: Ho joalo. E etselitsoe ho phunya le ho ts'oara liroboto, e nang le bokaholimo bo bataletseng <0.01mm ho thibela tšilafalo ea likaroloana maselang a ikemetseng.

5. P: Papiso ea litšenyehelo ke bokae ha e bapisoa le thepa ea setso?

A: Theko e phahameng ea pele (3-5x quartz) empa TCO e tlase ho 30-50% ka lebaka la nako e telele ea bophelo, nako e fokotsehileng, le ho baballa matla ho tsoa ho mocheso o phahameng oa mocheso.